Ultrasonic flaw detection device for slewing ring bearings in wind power generation

A technology of slewing bearing and flaw detection device, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc., which can solve the problems of insufficient detection technology, low efficiency, poor reliability, etc. , to achieve the effect of enhancing reliability, improving efficiency, accuracy and defect detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

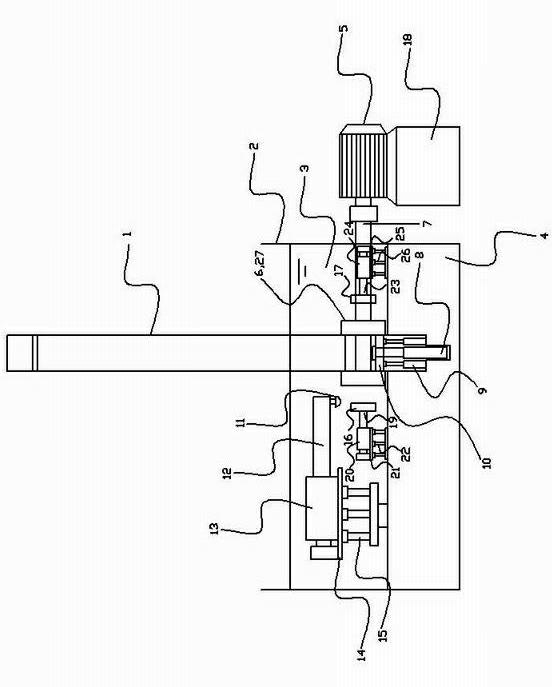

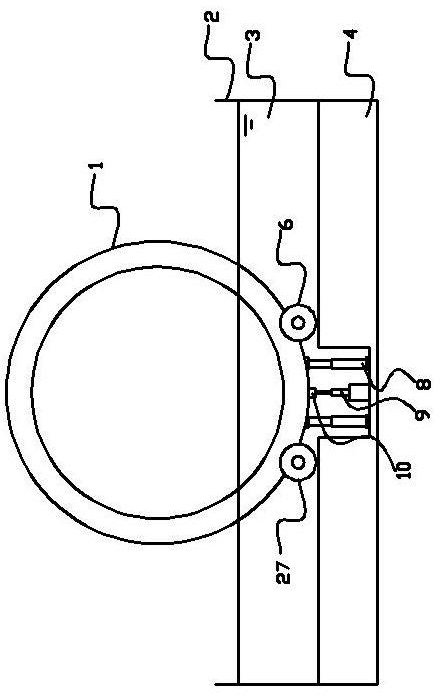

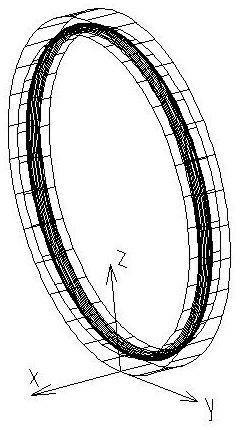

[0019] The device of the invention is composed of a base system, a power system, a buffer system, a raceway detection system, a tread detection system, a left side detection system and a right side detection system.

[0020] The base system consists of a bath 2 , an ultrasonic transmission medium 3 , a system base 4 , and an external base 18 . Power system is made of motor 5, driving wheel 6, driven wheel 27, connecting rod 7. The buffer system consists of a buffer cylinder 8. The raceway part detection system consists of a phased array probe 11 for raceway part detection, a piston rod 12 for raceway part detection, a lateral feed cylinder 13 for raceway part detection, a support plate 14 for raceway part detection, and a raceway part detection Constitute with longitudinal feed oil cylinder 15. The tread detection system consists of a tread detection cylinder 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com