Aviation metal small diameter tube defect internal inspection probe and detection method

A technology for small-diameter pipes and metal pipe fittings, which is applied in the field of defect internal inspection probes and detection of aviation metal small-diameter pipes. The effect of the detection signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

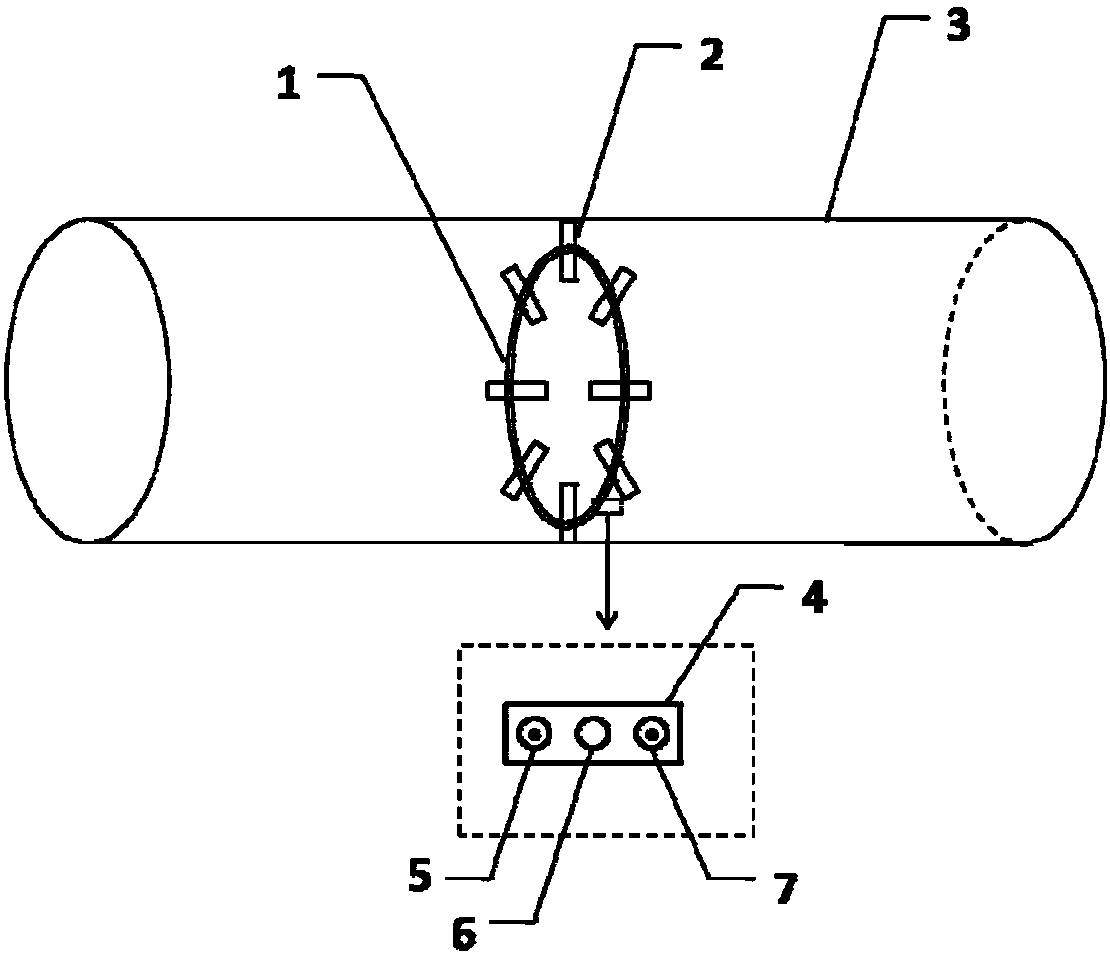

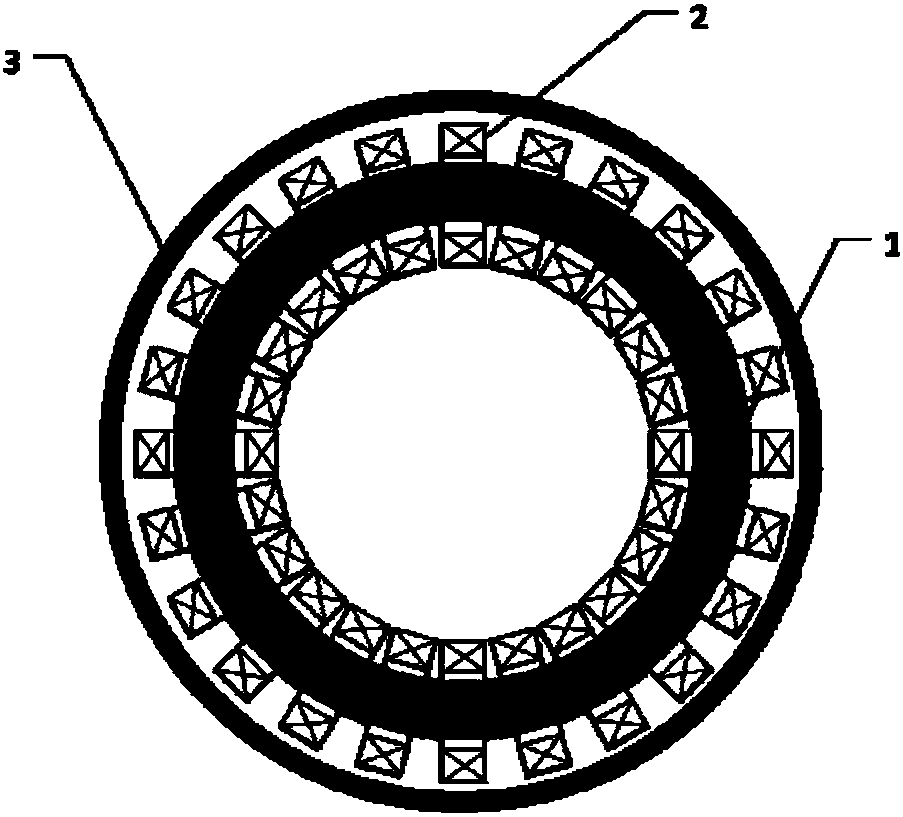

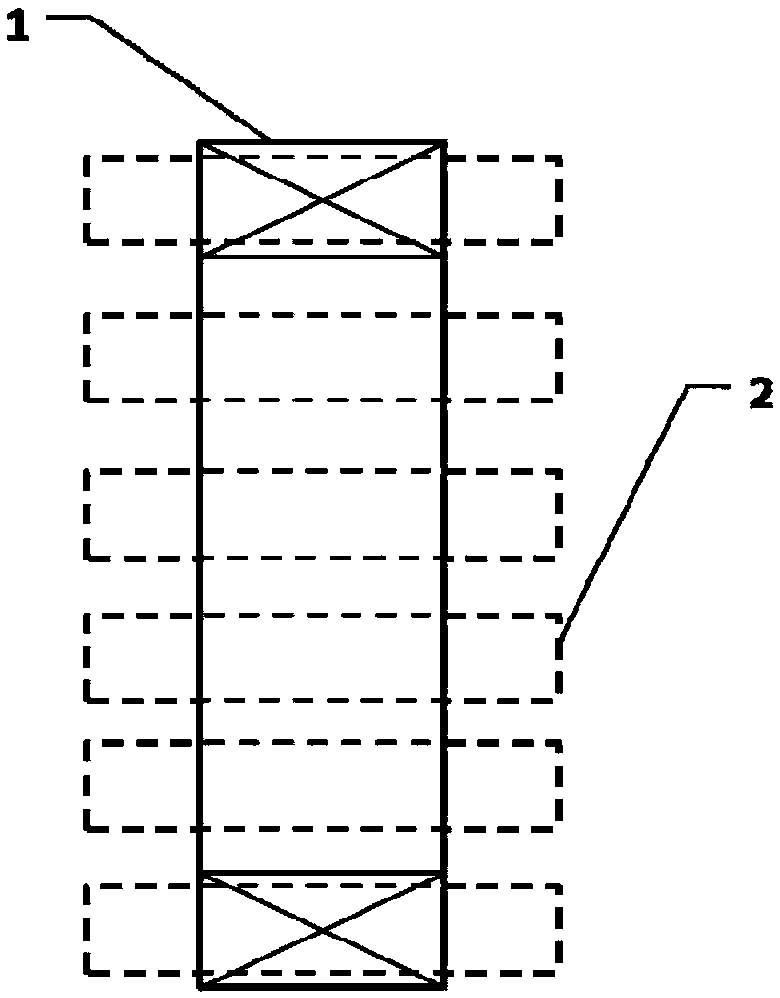

[0025] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is an aviation metal small-diameter pipe defect internal detection probe, including fixed on the photosensitive resin coil frame 3, a disk coil 1 and a circumferential rectangular coil group array 2 fixed on the photosensitive resin coil frame 3, the disk The central symmetry axis of the coil 1 coincides with the symmetry axis of the photosensitive resin coil skeleton 3, the rectangular coils in the circumferential rectangular coil group array 2 are evenly arranged, the adjacent rectangular coils are in contact with each other, and the disc coil 1 vertically passes through each The air domain surrounded by a rectangular coil.

[0026]The disc coil 1 and the three-core wire group 4 in the circumferential rectangular coil group array 2 are exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com