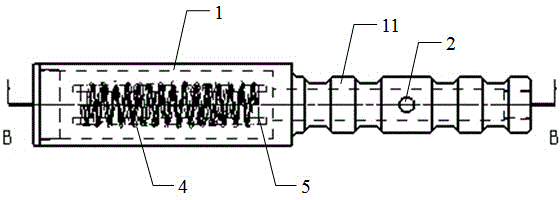

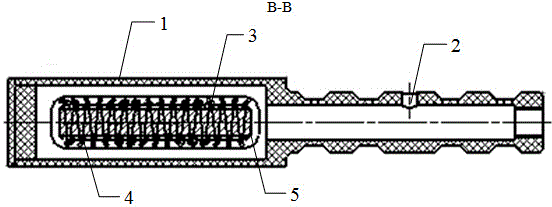

Sensing type grenade probe for blind hole magnetic powder flaw detection

A magnetic particle flaw detection and inductive technology, which is applied in the direction of material magnetic variables, can solve the problems of inability to detect magnetic particles, and achieve the effect of convenient defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

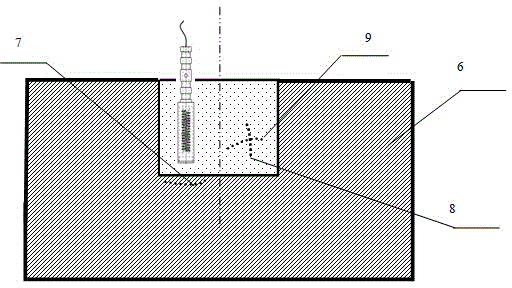

[0025] see image 3 As shown, the blind-hole magnetic particle flaw detection induction grenade probe of the present invention is connected to the magnetic particle flaw detector to obtain a low-voltage and high-current input power supply. The parameters of the magnetic particle flaw detector used are:

[0026] Output voltage: 10V; power supply: 380V 50HZ; circumferential magnetizing current: AC: 0-500A effective value, digital display, continuously adjustable, with power-off phase control; longitudinal magnetizing current: AC: 0-500A effective value, digital display , Continuously adjustable, with power-off phase control.

[0027] After connecting the magnetic particle flaw detector, the circumferential magnetizing current and the longitudinal magnetizing current are respectively selected as input. Put the magnetic particle flaw detection test piece on the surface of the workpiece, place the probes at 50mm, 100mm, and 200mm on the surface of the workpiece respectively, pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com