Patents

Literature

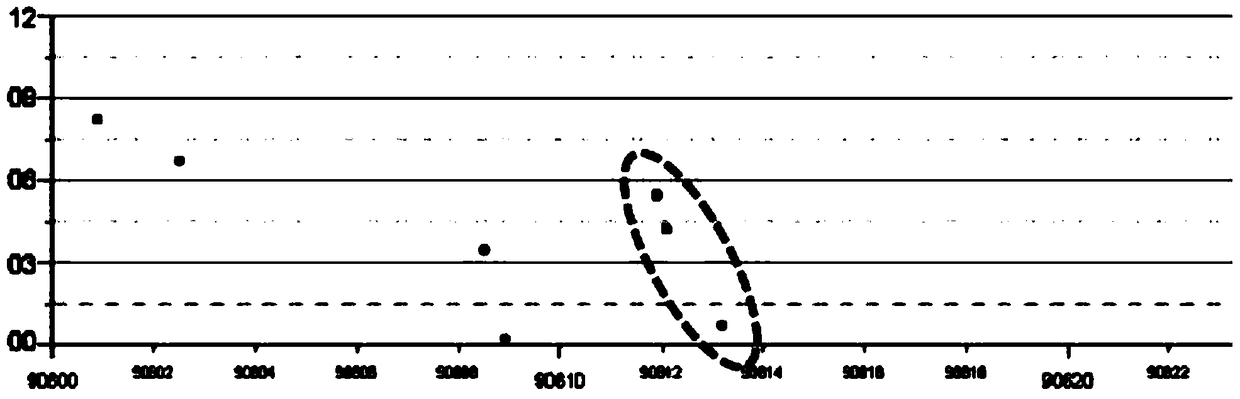

31results about How to "Accurate defect location" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

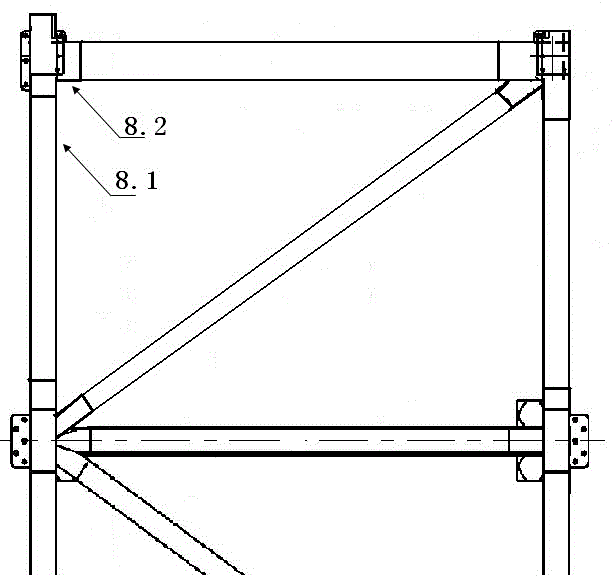

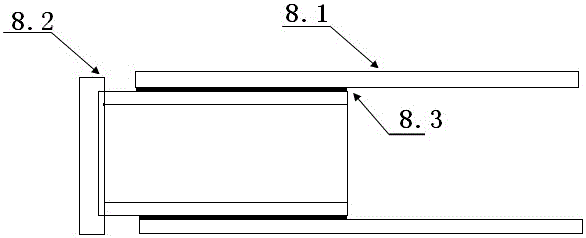

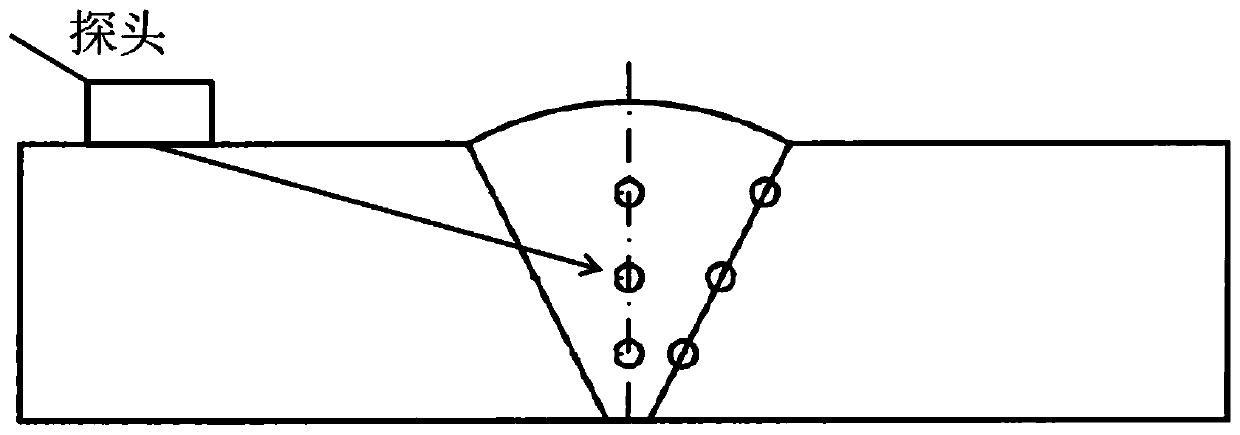

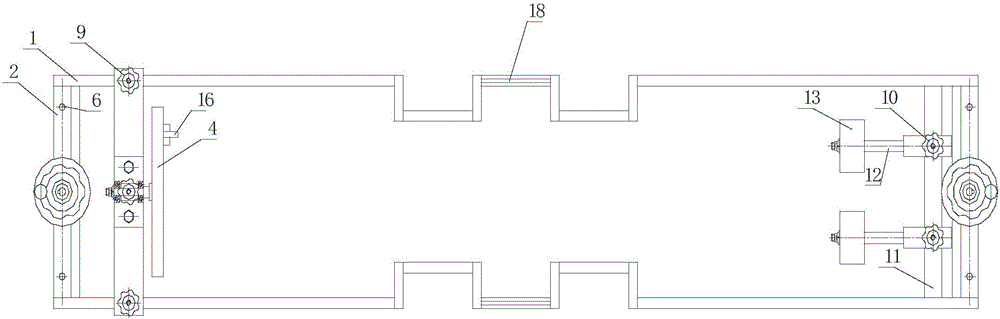

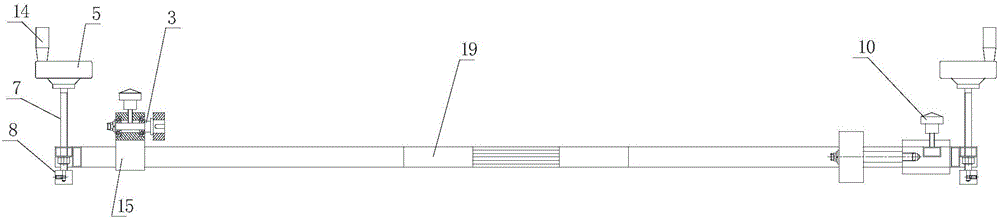

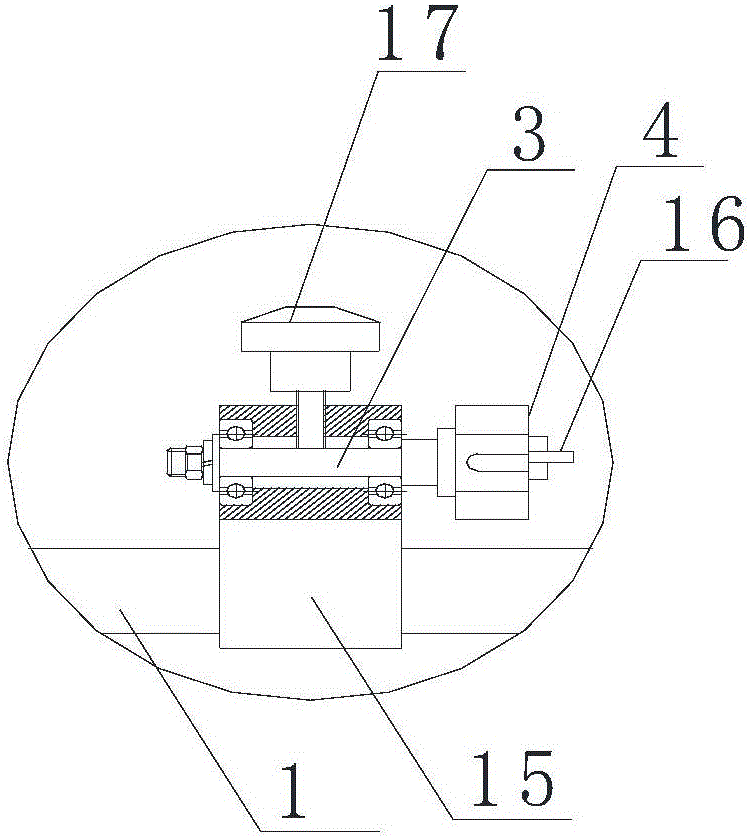

Device and method for detecting carbon fiber composite material truss bonding defects by ultrasonic phased array

InactiveCN105911144ASingle scan area increasedIncreased scanning areaAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringMechanical engineering

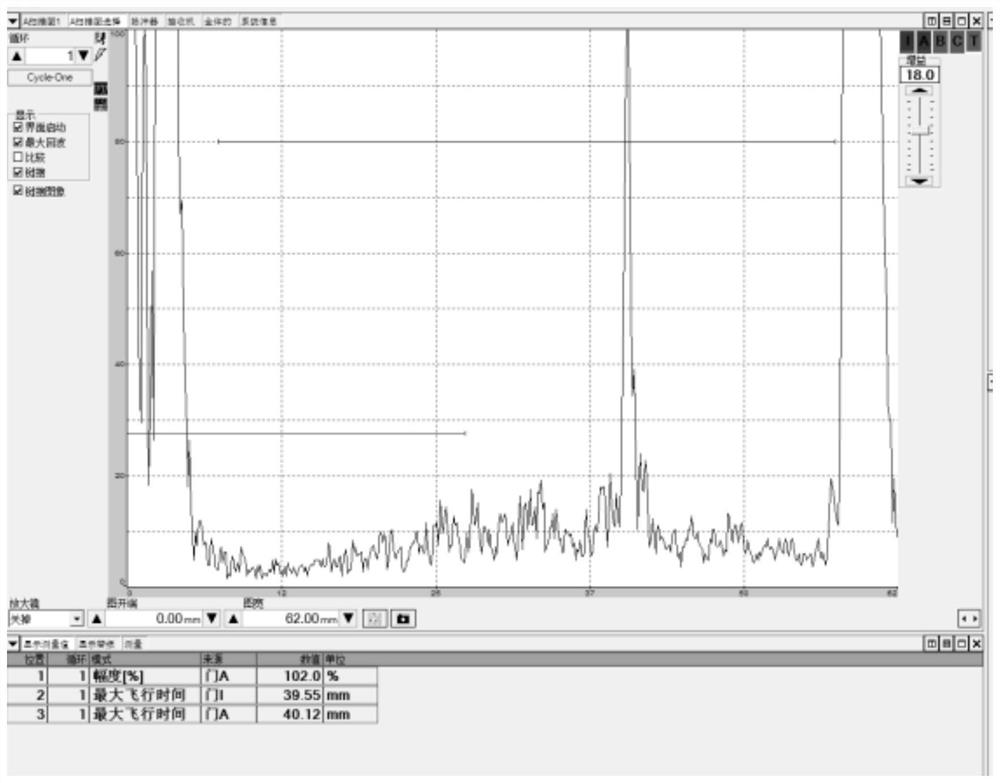

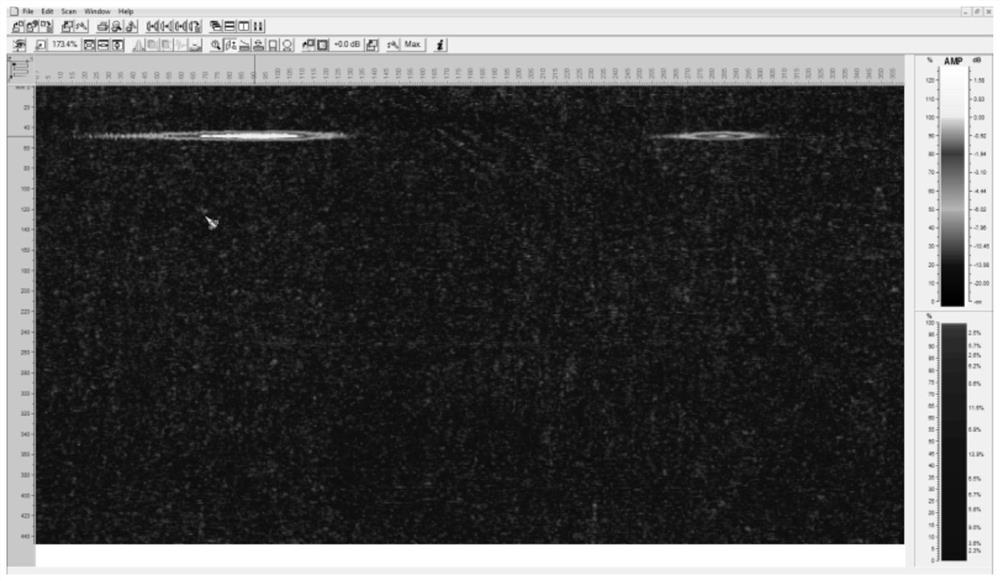

The invention relates to a device and a method for detecting carbon fiber composite material truss bonding defects by an ultrasonic phased array. The device comprises an ultrasonic phased array detector, a control computer, an ultrasonic phased array probe, a coupling wedge block, a displacement encoder, a coupling agent and a comparison specimen, wherein the ultrasonic phased array detector is connected with the control computer; the ultrasonic phased array probe is connected with the ultrasonic phased array detector; the probe end of the ultrasonic phased array probe is fixedly arranged on the coupling wedge block; the displacement encoder is connected with the ultrasonic phased array detector; the displacement encoder is fixedly connected with the coupling wedge block. The detection method comprises the following steps of connecting the detection device; setting the detection parameters; calibrating the ultrasonic phased array detector; adjusting scanning sensitivity; implementing detection; obtaining and recording the detection data. The device and the method have the advantages that the carbon fiber composite material truss bonding part with complicated space structure is detected, the better flexibility in use is realized, and the detection efficiency and the visual degree of detection results are improved.

Owner:SHANGHAI INST OF SATELLITE EQUIP

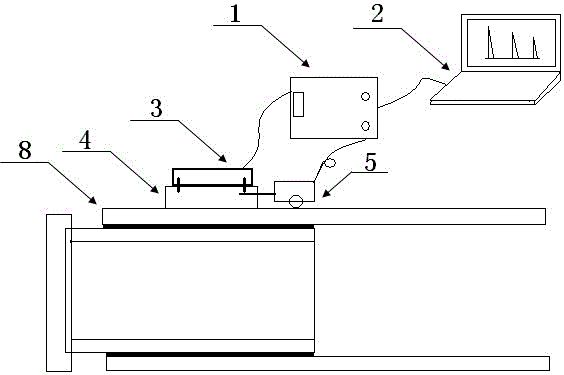

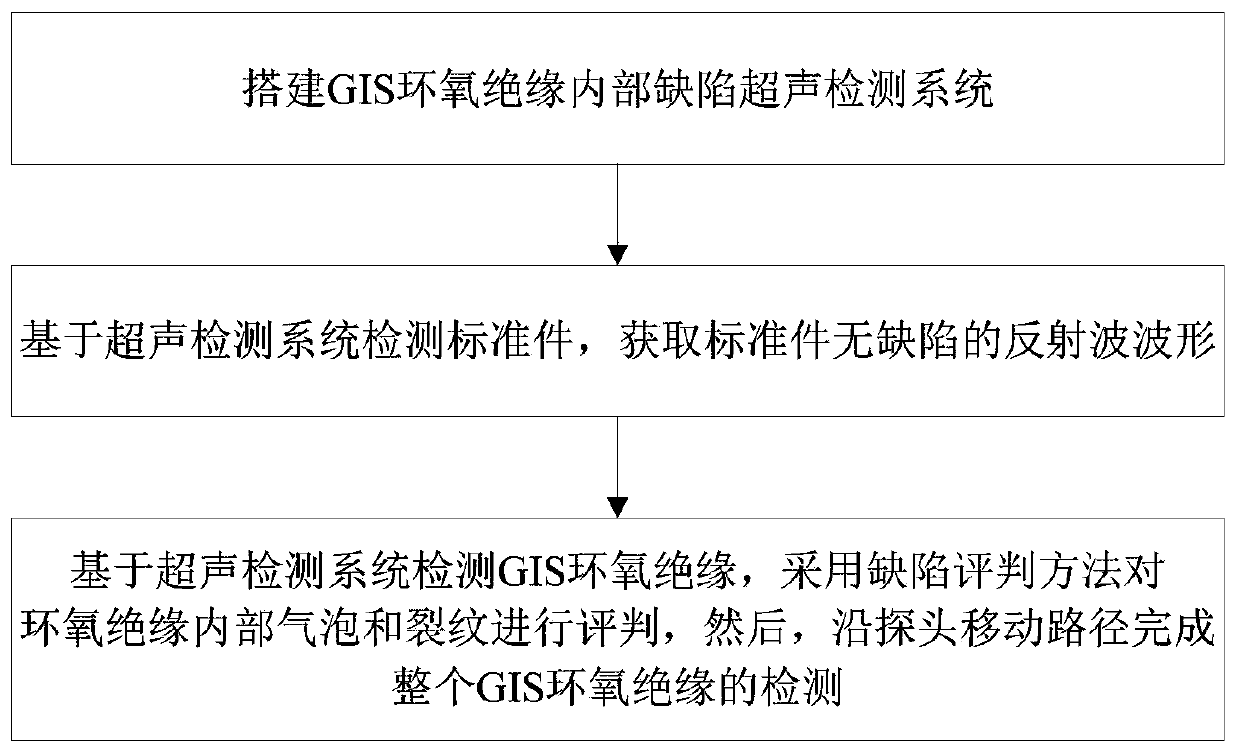

Ultrasonic testing method and ultrasonic testing system for internal defects of GIS epoxy insulator

InactiveCN110243935AImprove detection accuracyImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesLongitudinal waveUltrasonic attenuation

The invention belongs to the technical field of power transmission and transformation insulation equipment, and relates to an ultrasonic testing method and an ultrasonic testing system for internal defects of a GIS epoxy insulator. The ultrasonic testing method for internal defects of the GIS epoxy insulator comprises the following steps: constructing the ultrasonic testing system for internal defects of the GIS epoxy insulator; testing a testing standard component based on the ultrasonic testing system, and obtaining a non-defective reflected wave waveform of the standard component; testing the GIS epoxy insulator based on the ultrasonic testing system, judging interior bubbles and cracks of the epoxy insulator by using a defect judgment method, and then continuously testing the GIS epoxy insulator along the moving path of a probe. The method is high in testing precision and efficiency and accurate in defect positioning, small-sized bubbles and cracks can be tested, and the method can be used for pre-delivery inspection of insulators and also can be used for assembling field test of insulators. The ultrasonic testing system for internal defects of the GIS epoxy insulator comprises an ultrasonic instrument, an oscilloscope, an ultrasonic longitudinal wave normal probe, a computer and the GIS epoxy insulator. The system is low in cost, small in equipment volume, high in testing precision and efficiency and accurate in defect positioning.

Owner:SOUTH CHINA UNIV OF TECH

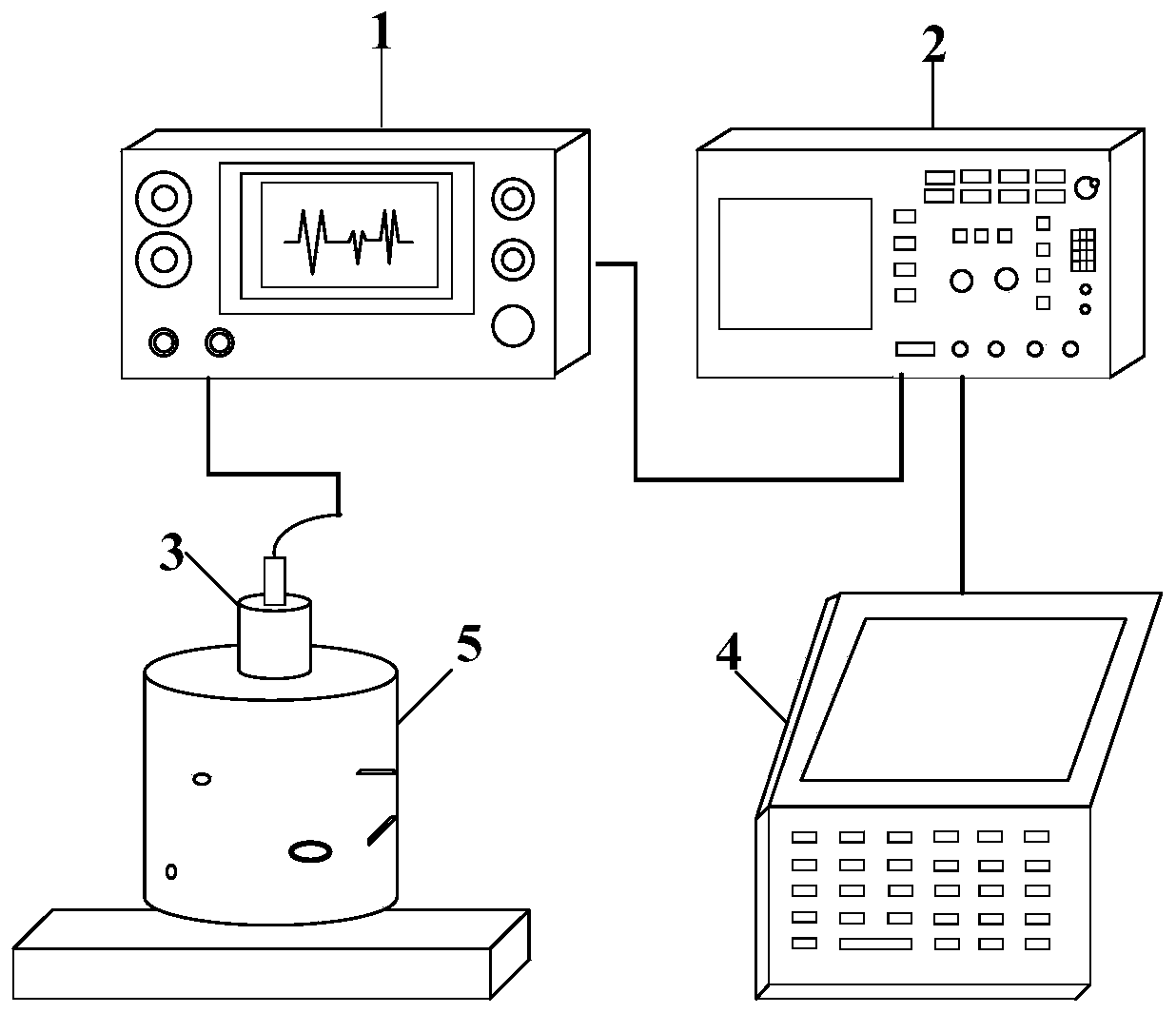

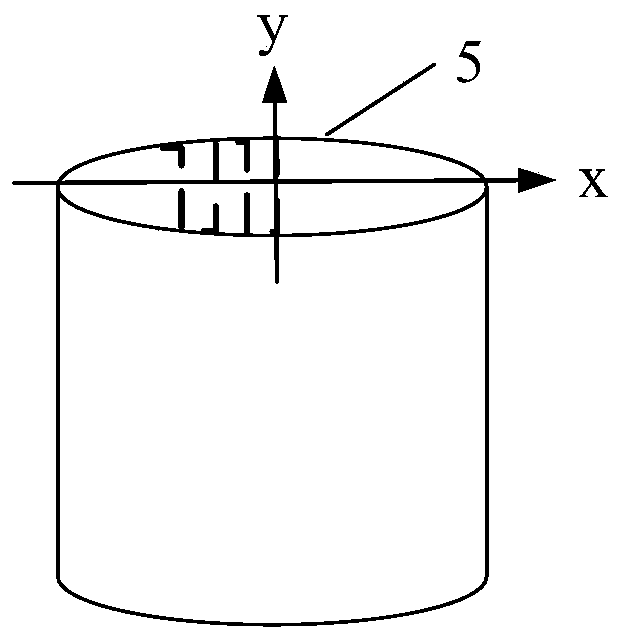

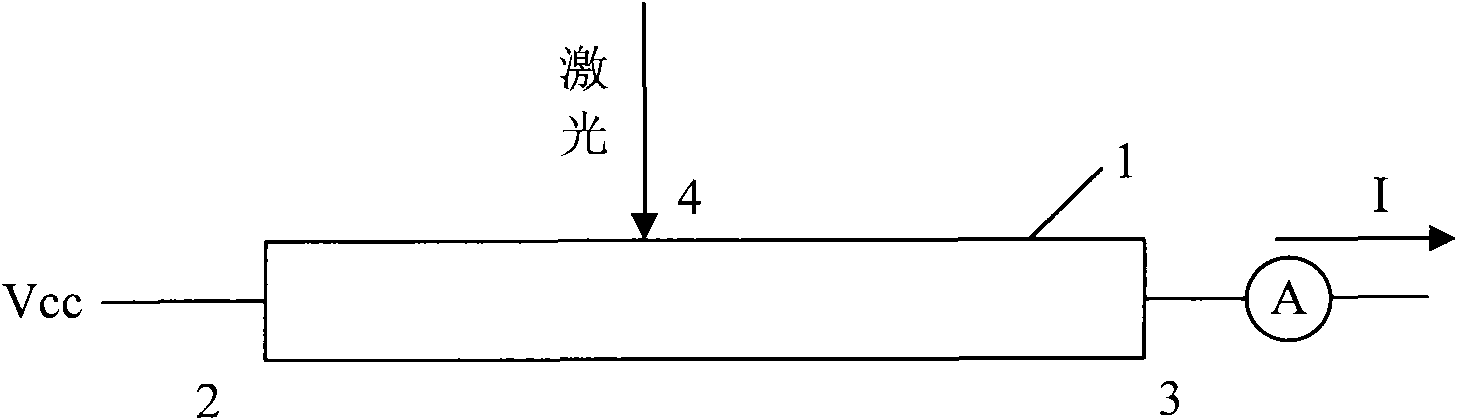

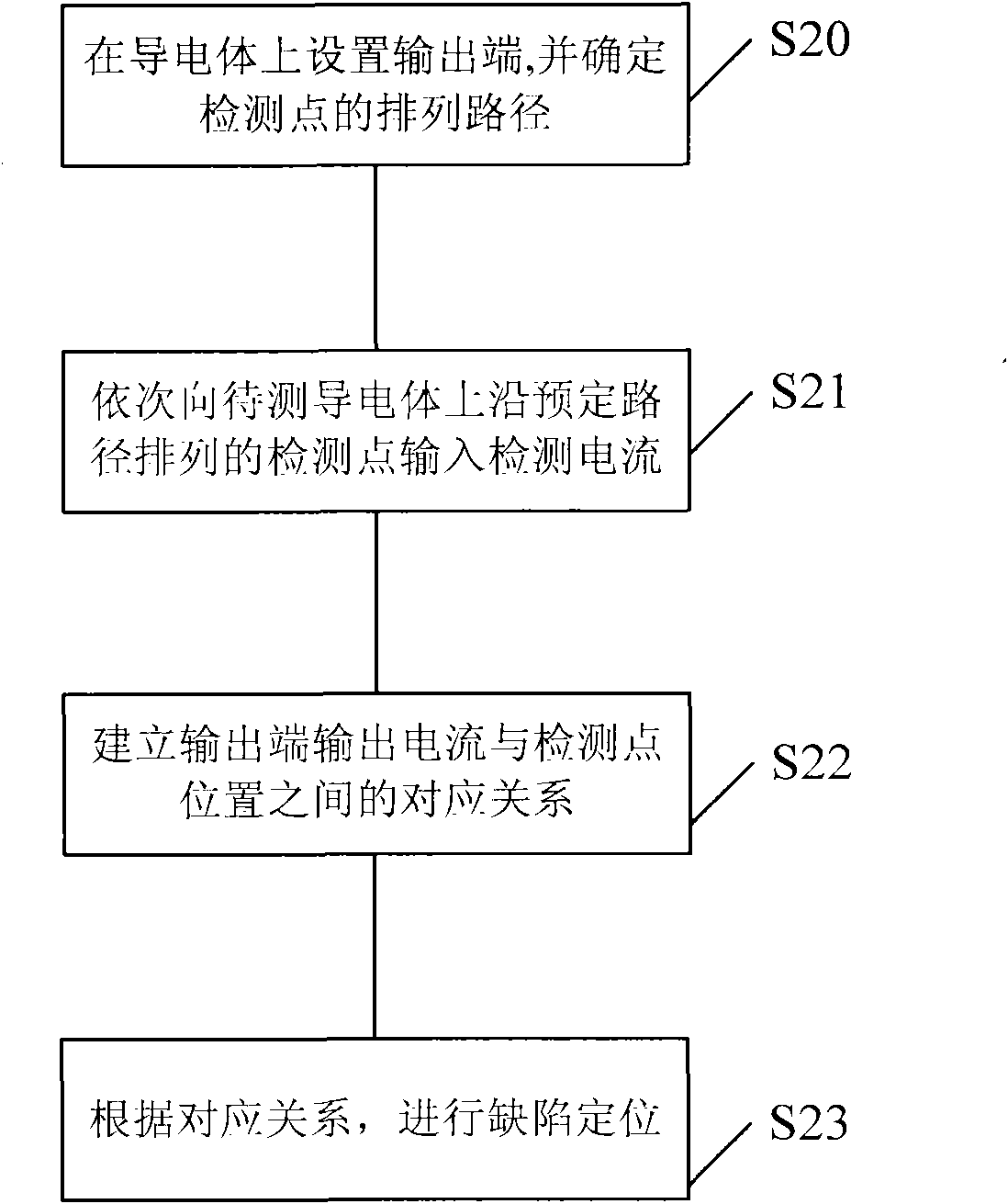

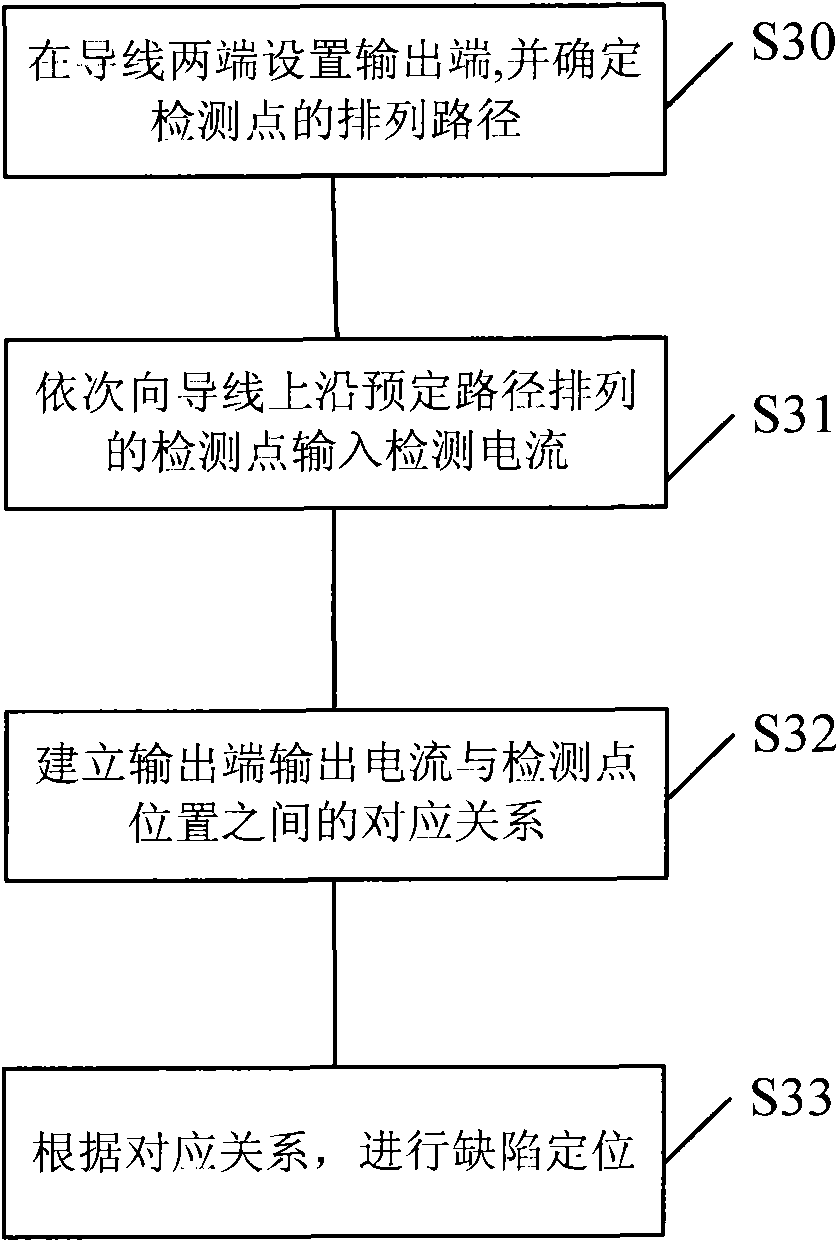

Failure detection method and device

InactiveCN101958262AAvoid sizeAvoid thermal effectsSemiconductor/solid-state device testing/measurementCurrent/voltage measurementEngineeringFailure analysis

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

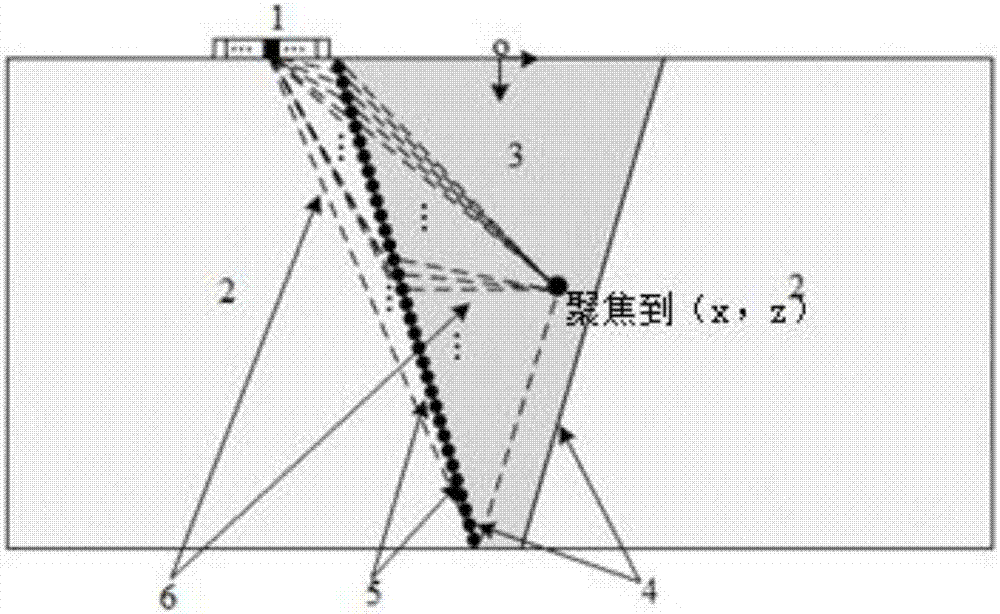

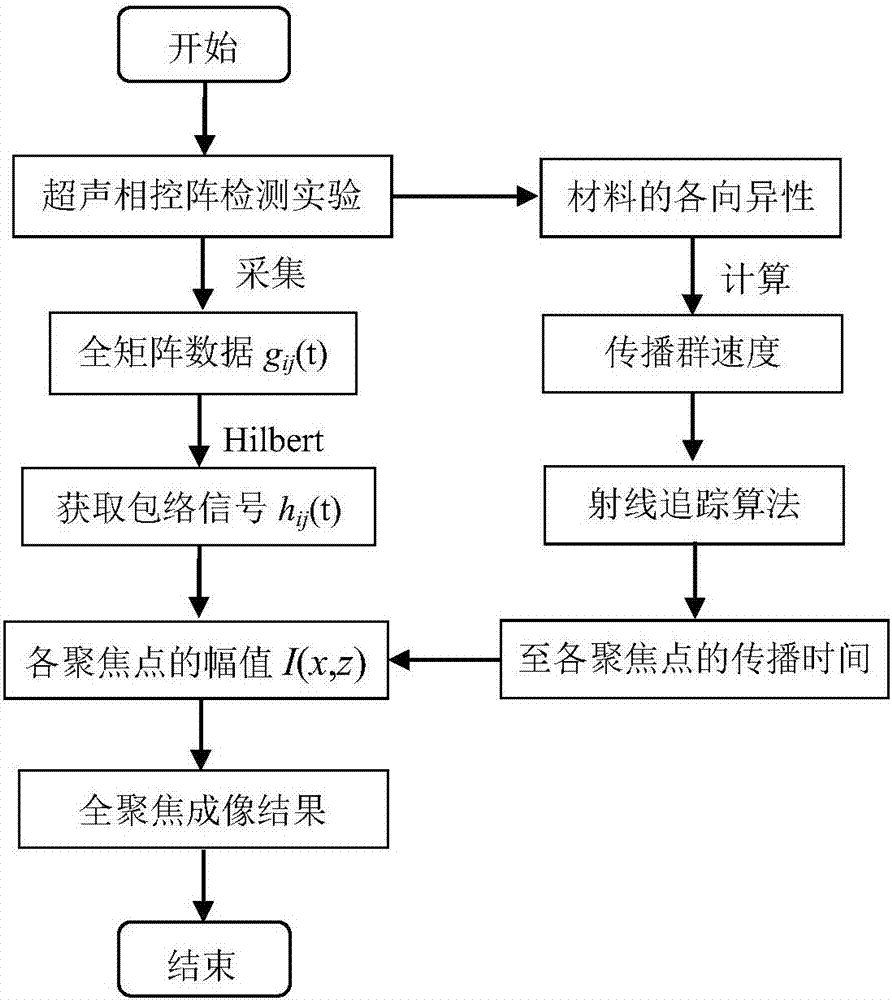

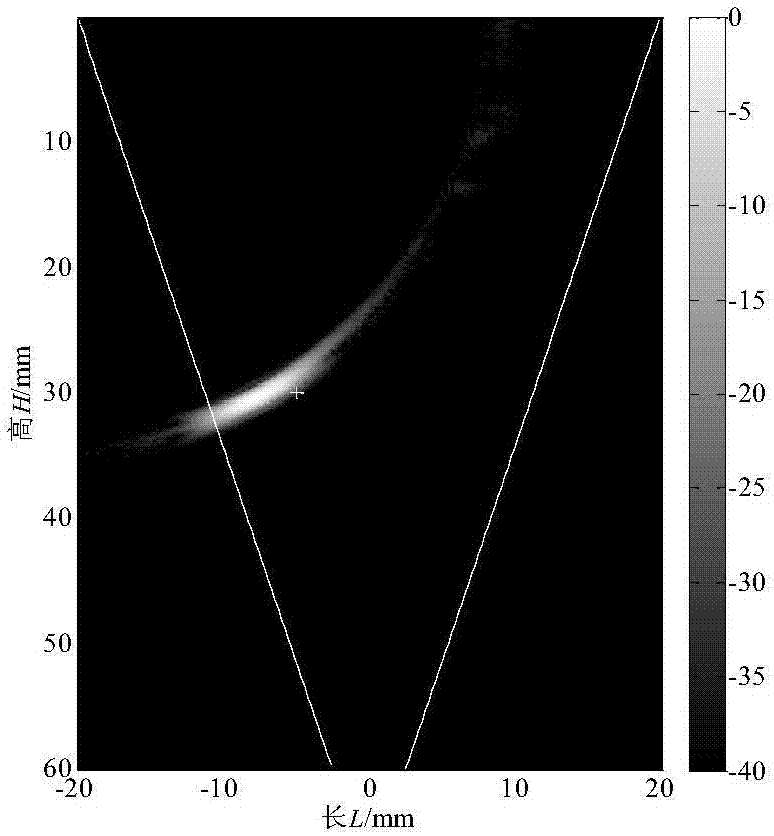

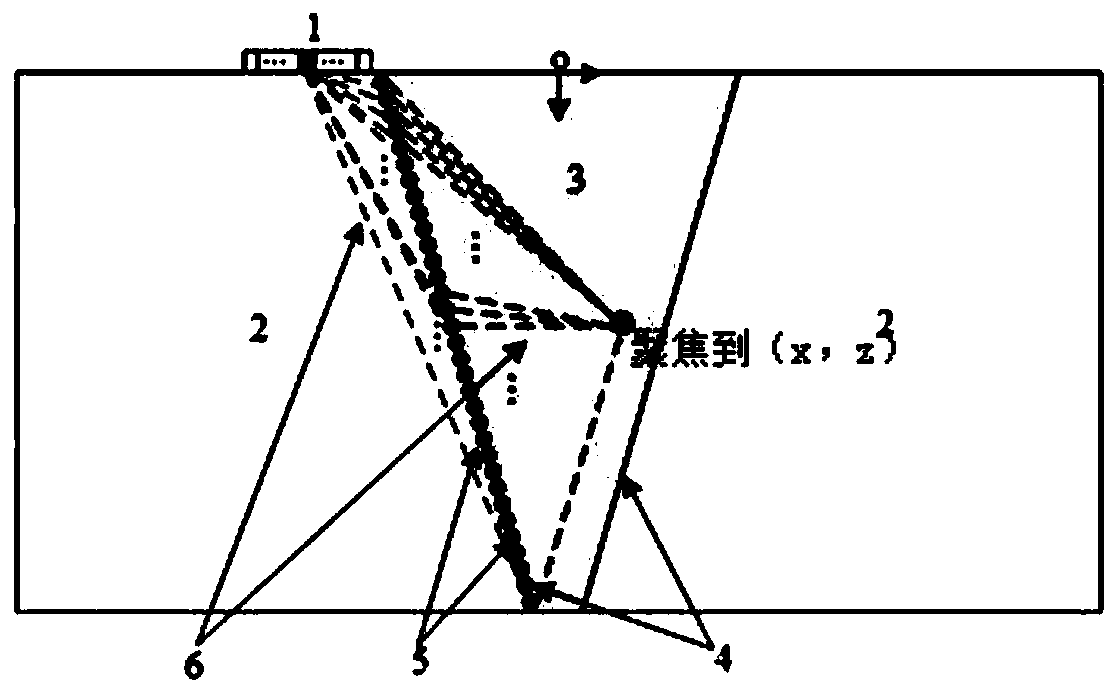

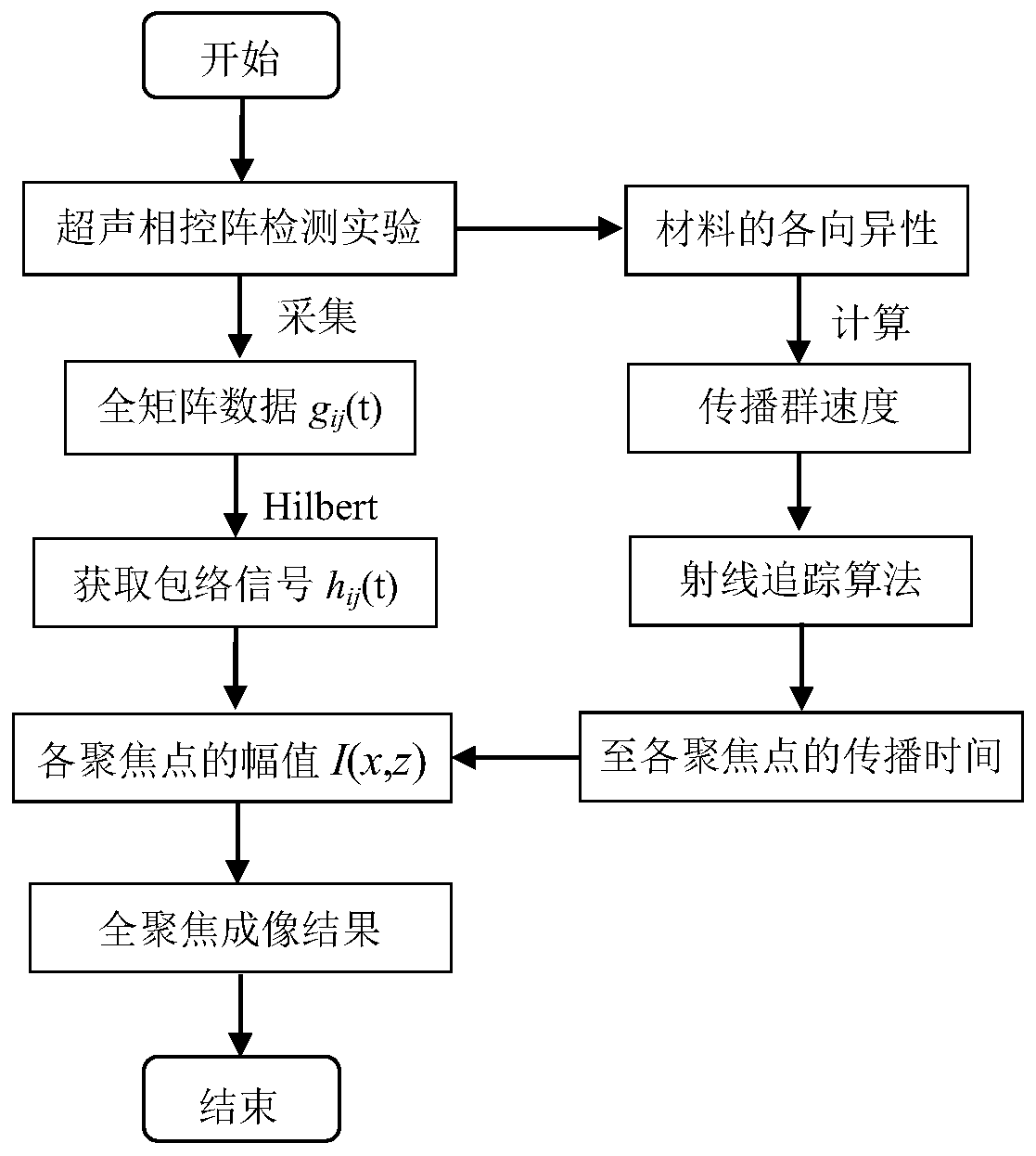

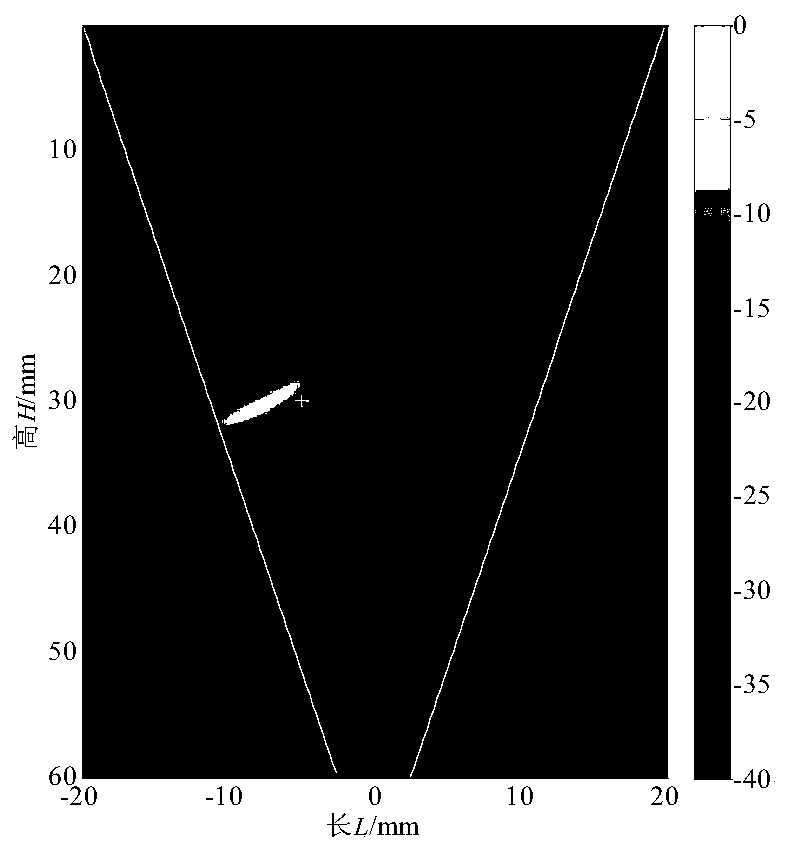

Corrected full-focus imaging method for anisotropy weld seam defect array detection

ActiveCN107085038AAccurate defect locationSolve the inaccurate defect positioningAnalysing solids using sonic/ultrasonic/infrasonic wavesWeld seamNondestructive testing

The invention discloses a corrected full-focus imaging method for anisotropy weld seam defect array detection and belongs to the field of nondestructive testing. The method comprises the steps of processing full-matrix data received by a one-dimensional linear array sensor of a phased array, taking material anisotropy into consideration, calculating out group velocity of ultrasonic waves in an anisotropy medium, then utilizing a ray tracing algorithm based on a Fermat principle to calculate out propagation time of the ultrasonic waves in the anisotropy medium and finally achieving full-focus imaging of anisotropy weld seams. The method has the advantages that weld seam anisotropy is taken into consideration, the high-operation-efficiency ray tracing method based on the Fermat principle and the full-focus imaging method are combined, the problem that general full-focus imaging has inaccuracy in locating defects in the anisotropy medium is solved, and meanwhile, detection precision of the phased array in the anisotropy medium is improved.

Owner:BEIJING UNIV OF TECH

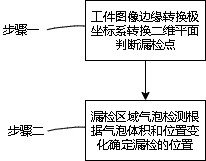

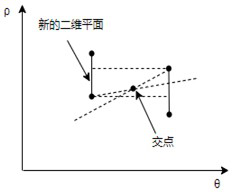

Irregular workpiece detection method based on machine vision

ActiveCN113706537AAvoid missing detectionImprove detection accuracyImage enhancementDetection of fluid at leakage pointMachine visionComputer graphics (images)

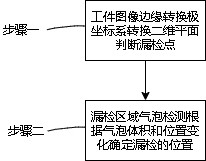

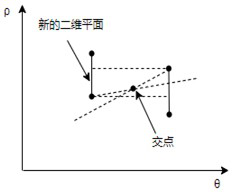

The invention relates to an irregular workpiece detection method based on machine vision, and the method comprises the steps: obtaining an irregular workpiece image, carrying out the edge detection, converting the edge of the workpiece image into a polar coordinate system, employing the intersection of the polar coordinate system in the horizontal direction of different theta connecting lines as a new two-dimensional plane through Hough transformation, according to the information gain of all connecting line intersection points in the two-dimensional plane, judging the intersection points to obtain missing detection points, obtaining a missing detection area according to the missing detection points, performing bubble detection on the workpiece, if the missing detection area does not have bubbles, determining that the workpiece does not have defects, and if the missing detection area has bubbles, obtaining an edge area of the bubbles in the missing detection area; and according to the volume and position changes of all bubbles in the adjacent frames and the single-frame image are analyzed according to the marginal areas of the bubbles, determining the accurate position of the missing detection defect, so the defect position of the irregular detection workpiece is more accurately positioned based on machine vision and comprehensive analysis, the detection precision is high, and the practicability is high.

Owner:NANTONG LANGGAO PETROCHEM EQUIP

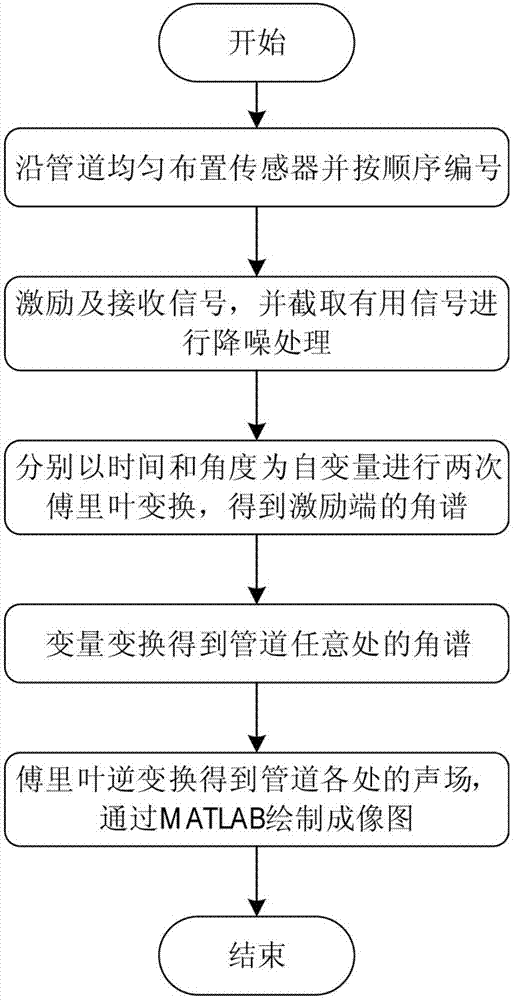

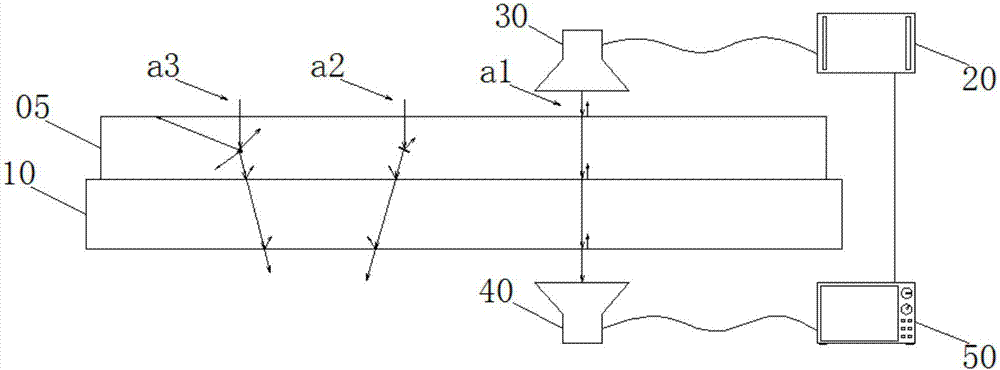

Ultrasonic guided wave-based pipeline flaw imaging method

InactiveCN107014905AEasy to understand and masterEliminate the effects ofAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationWave detection

The invention discloses an ultrasonic guided wave-based pipeline flaw imaging method, which is used for imaging flaws in a pipeline by using guided wave detection technology. The ultrasonic guided wave-based pipeline flaw imaging method comprises the following steps: under optimal excitation frequency, acquiring detection signals of all receiving sensors, denoising a waveform by using a wavelet filtering technology, and analyzing and calculating detection data by using a Fourier transformation and variable transformation method, so as to obtain data of sound fields at all positions of the pipeline. The invention provides a new research method for detecting pipeline flaws through guided waves with high efficiency; the imaging method does not need a focusing system, so that the influence of circumferential guided waves and other modal guided waves can be eliminated, and the long guided wave wavelength and low focused imaging efficiency can be overcome. The specific information of the flaws can be directly obtained from imaging results, no recalculation is needed. The ultrasonic guided wave-based pipeline flaw imaging method is strong in practicability, high in detection sensitivity, and precise for flaw positioning, and has wide application prospects in the field of nondestructive testing of pipelines.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE +1

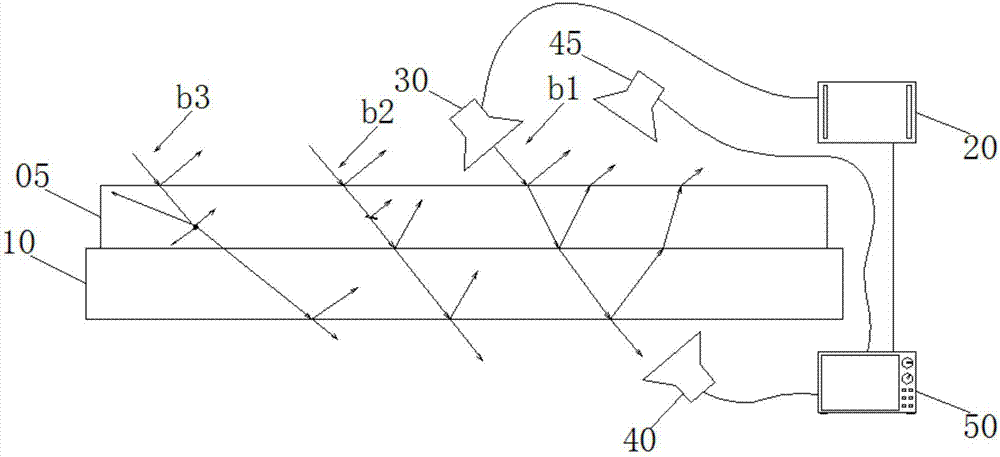

Glass detection device and method

ActiveCN107421967AThe detection process is fastAccurate defect locationFlaw detection using microwavesMicrowave emissionMicrowave beam

An embodiment of the invention provides a glass detection device used for solving the technical problem of absence of an effective detection method for inside of an original glass substrate. The glass detection device comprises a microwave-transparent carrier, a microwave transmitting antenna and a microwave receiving antenna, wherein the microwave transmitting antenna and the microwave receiving antenna are located on two sides of the microwave-transparent carrier respectively, and opening surfaces of the microwave transmitting antenna and the microwave receiving antenna are opposite. A detection structure for glass inside is formed by the glass detection device, and a defect position of the original glass substrate can be detected accurately through combination with a scanning position of microwave beams. The glass detection device provided by the embodiment of the invention is high in detection speed and has certain detect type distinguishing performance, and a defect in the glass is positioned accurately. The embodiment of the invention further provides a glass detection method.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

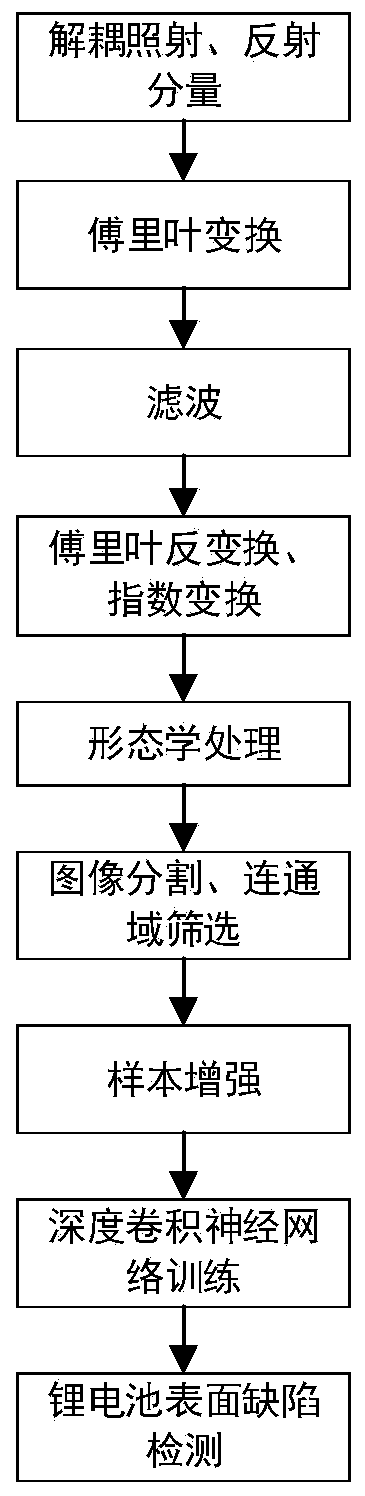

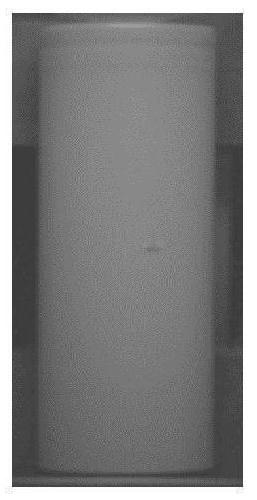

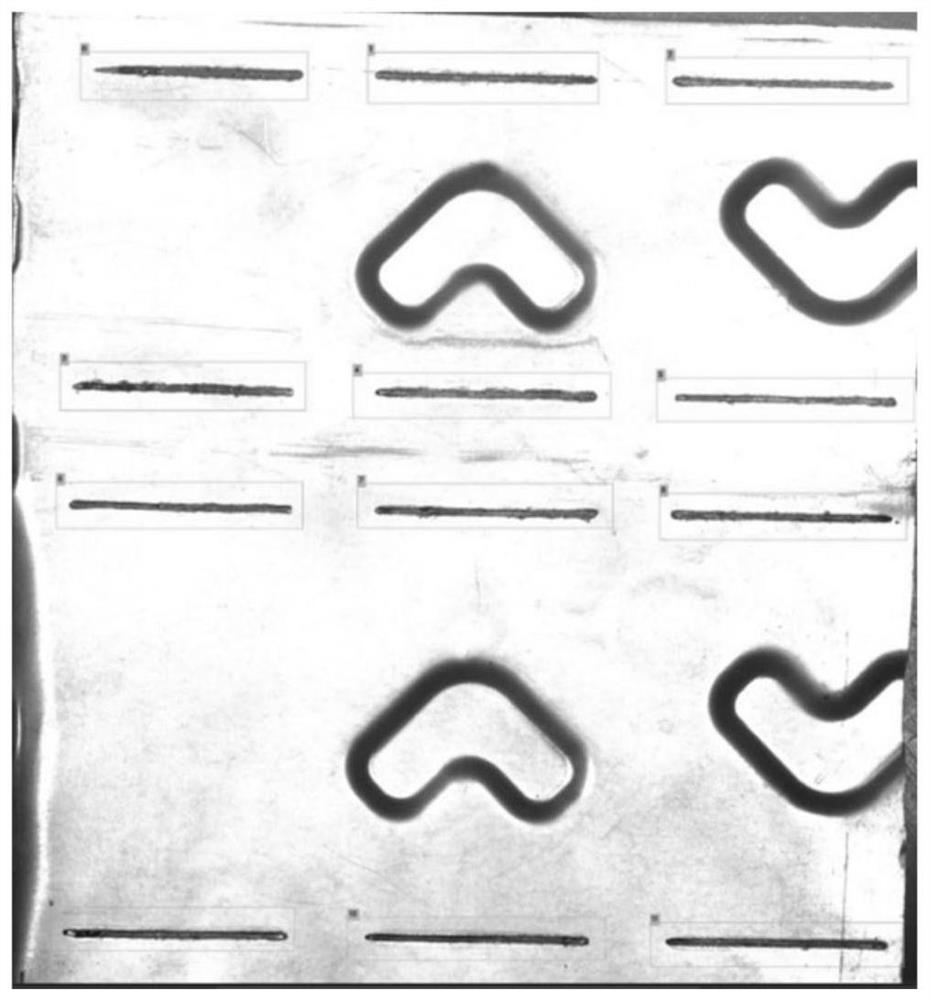

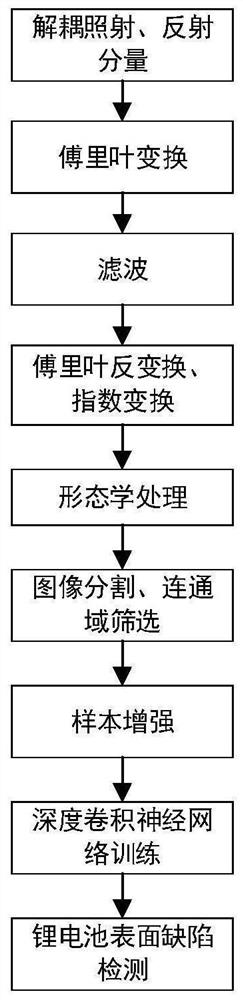

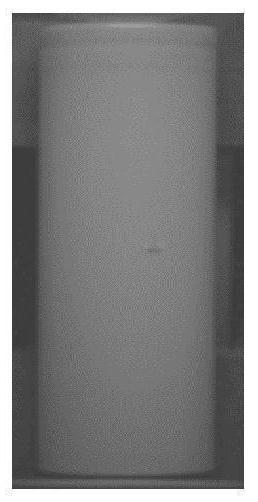

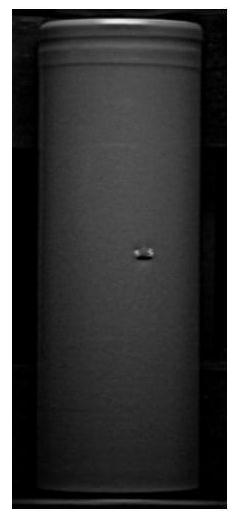

New energy lithium battery surface defect detection method based on adaptive deep learning

ActiveCN111105405AAccurate defect locationNo need for manual labelingImage enhancementImage analysisImage segmentationSample image

The invention discloses a new energy lithium battery surface defect detection method based on adaptive deep learning. The method comprises the following steps: carrying out nonlinear mapping on a lithium battery surface grayscale image; transforming the decoupled irradiation component and reflection component to a frequency domain; performing filtering, inverse Fourier transform and exponential transform on the frequency domain data to obtain a reconstructed lithium battery image; based on morphological processing and background differencing, enhancing gray scale response at the defect; carrying out image segmentation and connected domain analysis and screening processing, and taking a result as a labeled image; designing an operator to simulate illumination details, and carrying out sample enhancement operation on the surface grayscale image of the lithium battery; training a deep convolutional neural network based on the enhanced sample image set and the labeled image; and achievinglithium battery surface defect detection based on the trained network. By utilizing the method, the detection efficiency can be improved and the false detection rate can be reduced in a lithium battery surface defect detection scene.

Owner:芜湖楚睿智能科技有限公司

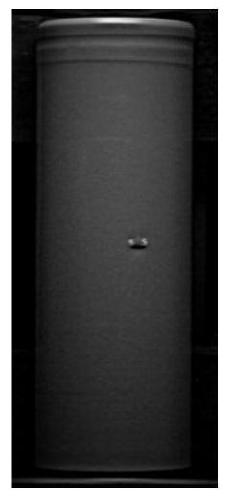

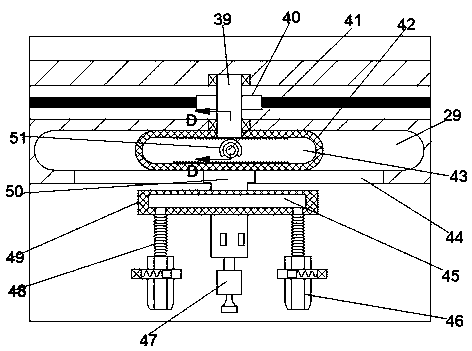

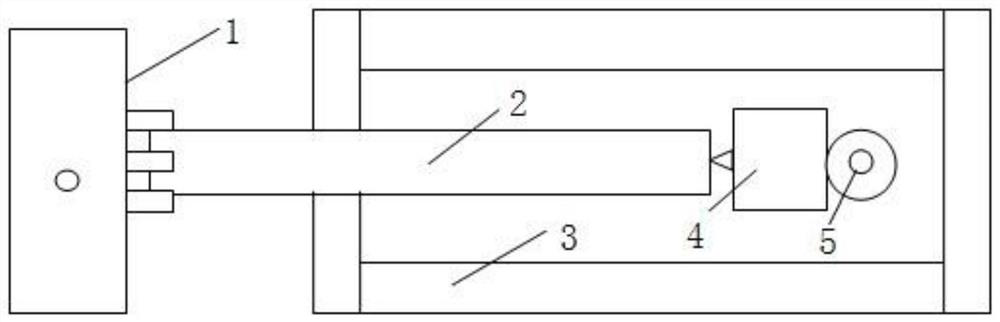

Ultrasonic detection device

InactiveCN111289617AStrong penetrating powerAccurate defect locationAnalysing solids using sonic/ultrasonic/infrasonic wavesElectric machineryEngineering

The invention discloses an ultrasonic detection device for a steel plate. The device comprises a shell and a detection cavity located in the shell; a power device is arranged in the detection cavity;the power device comprises a power cavity positioned on the lower side of the detection cavity; a motor is fixedly arranged on the upper end wall of the power cavity; the lower side of the motor is inpower connection with a power shaft; a first rotating shaft which extends downwards and is rotationally connected with the shell is arranged on the lower side of the power shaft; a moving device is arranged on the upper side of the power device; the moving device comprises a belt cavity. According to the invention, the device is suitable for nondestructive testing of various workpieces such as metal, nonmetal and composite materials; the device is simple in structure, high in penetrability, accurate in defect positioning, high in area defect detection rate, high in sensitivity, low in detection cost, high in speed, light in equipment, harmless to human bodies and the environment and convenient to use on site, and internal defects of a test piece within a large thickness range can be detected.

Owner:象山冰川智能装备有限公司

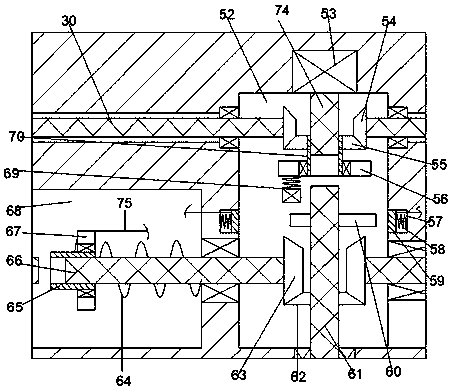

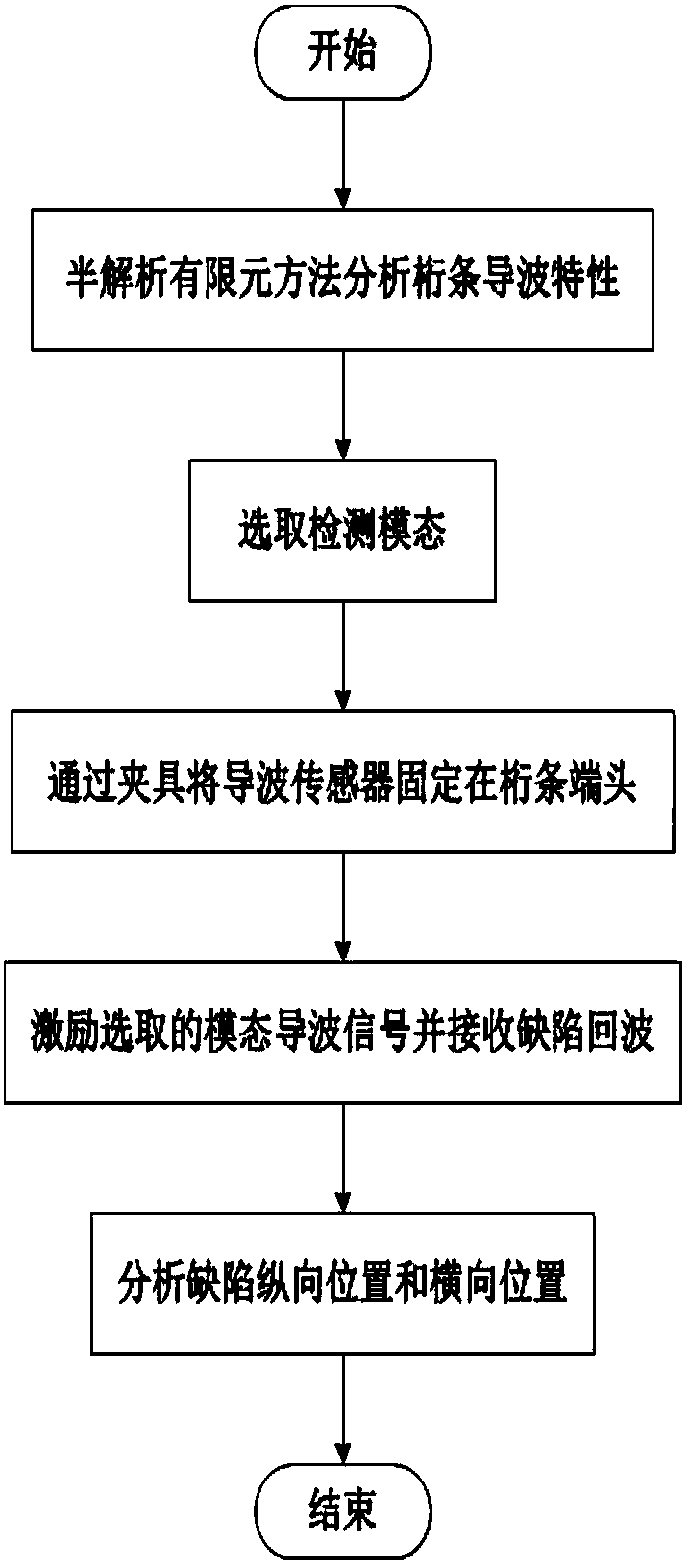

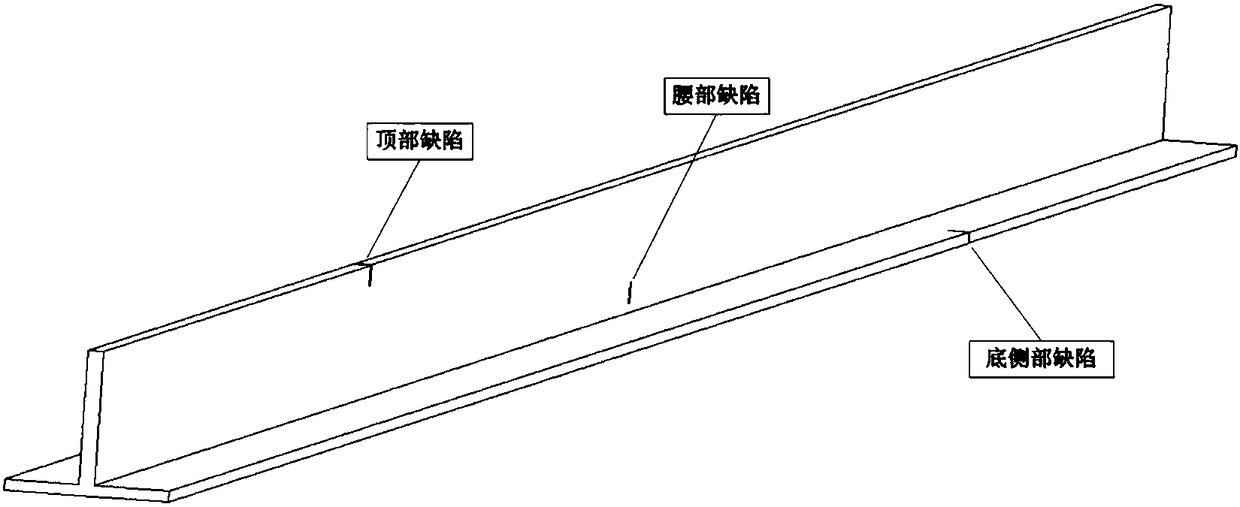

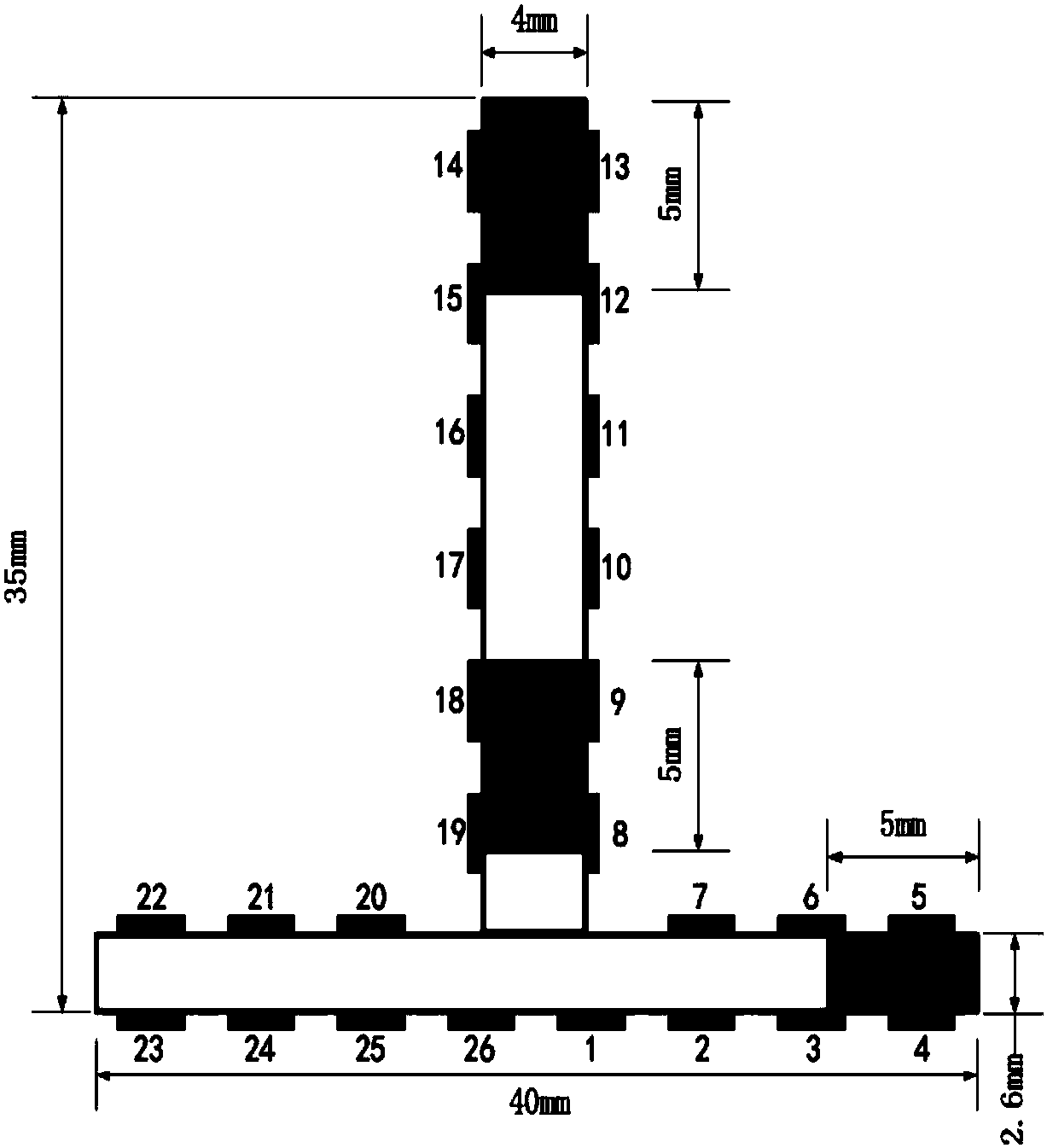

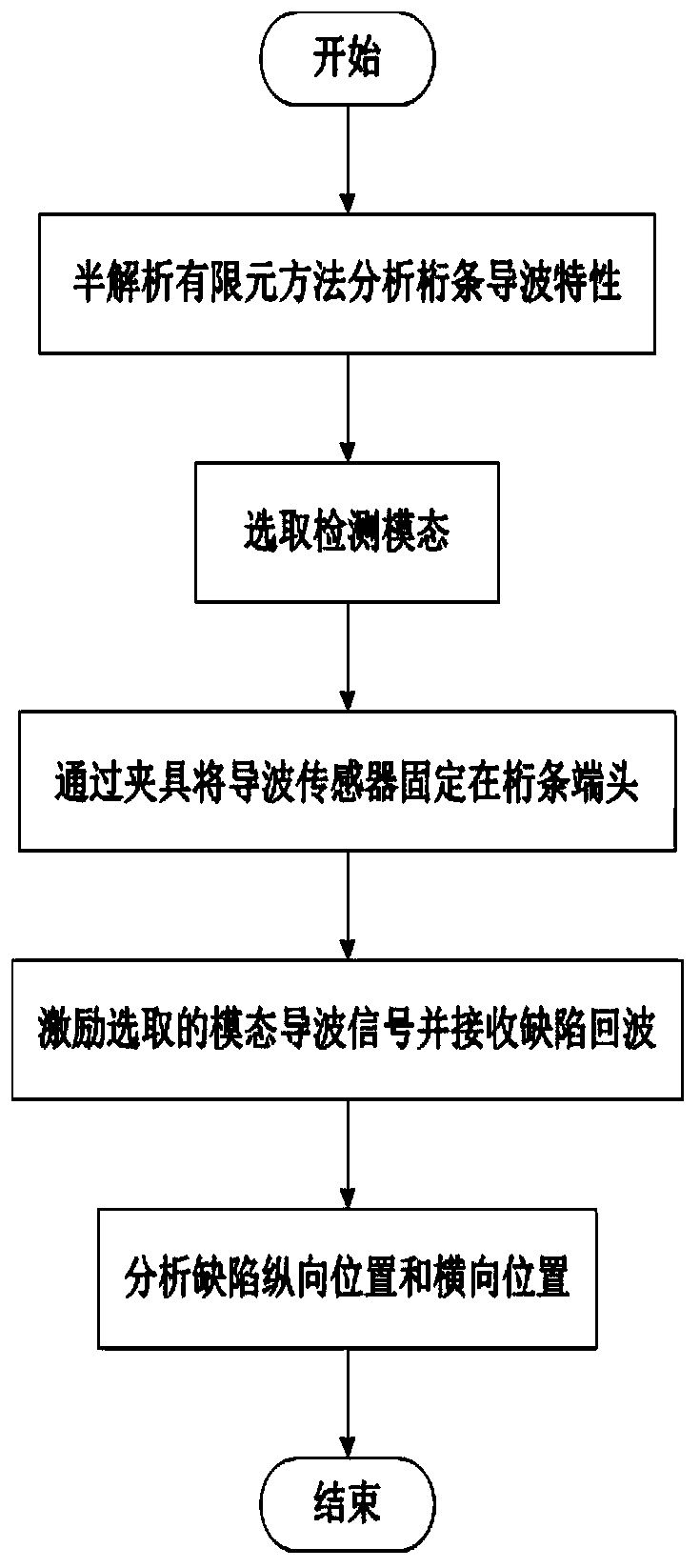

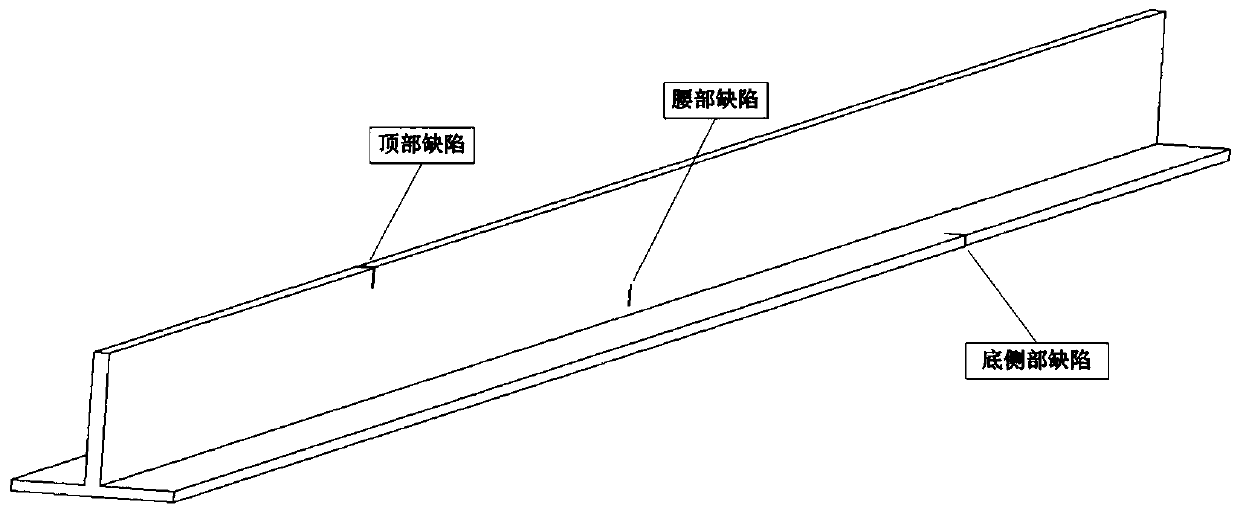

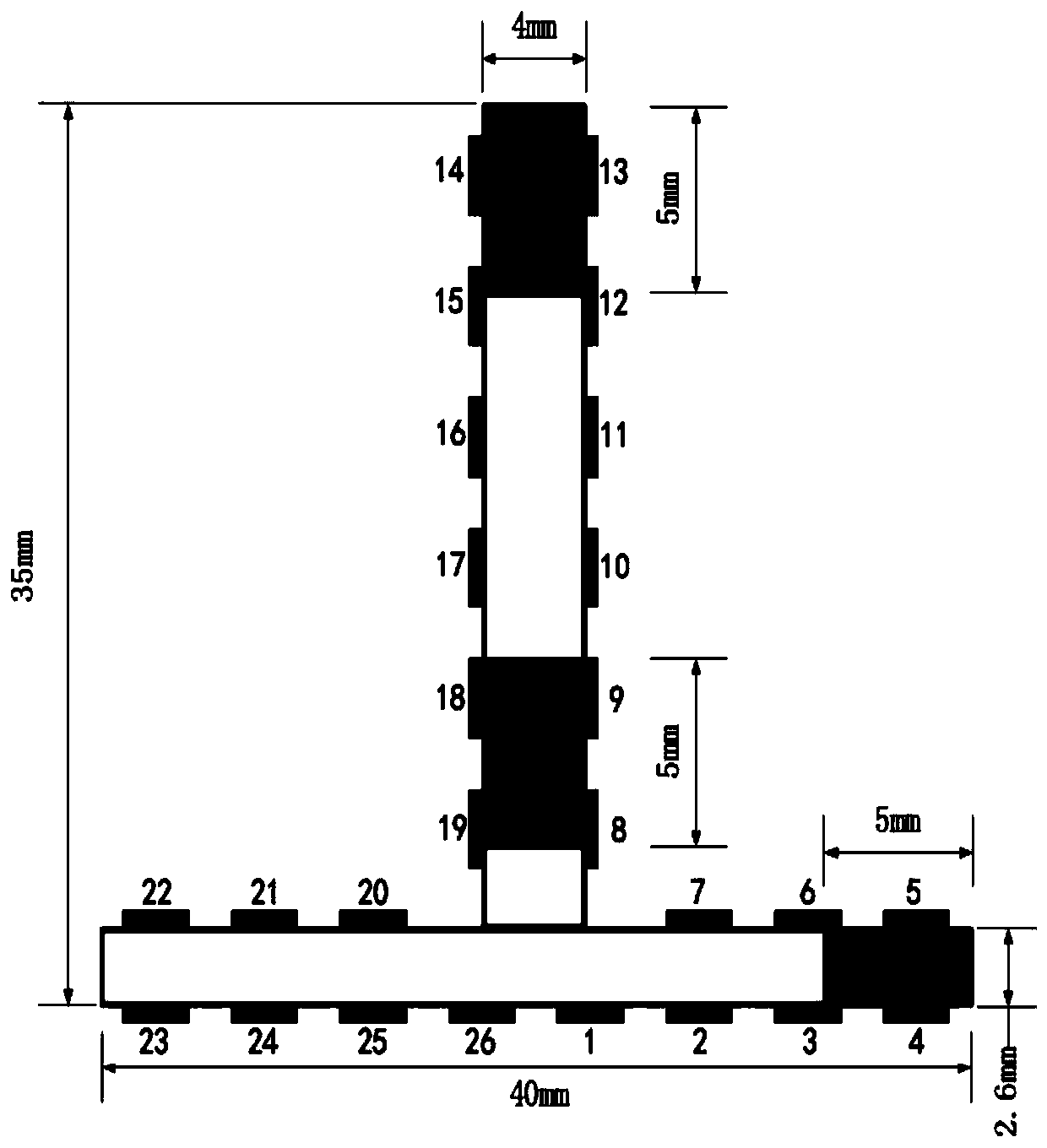

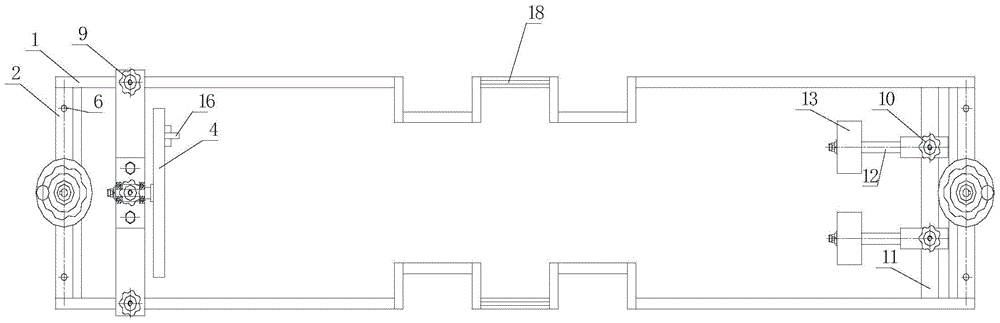

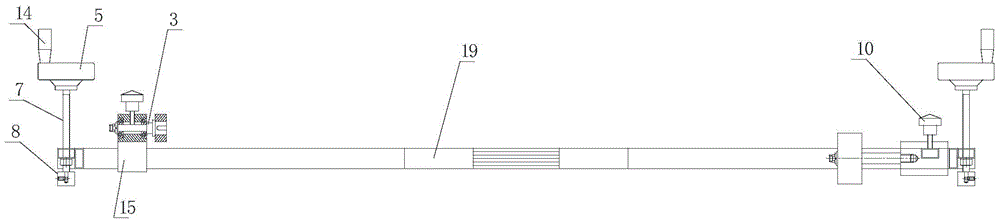

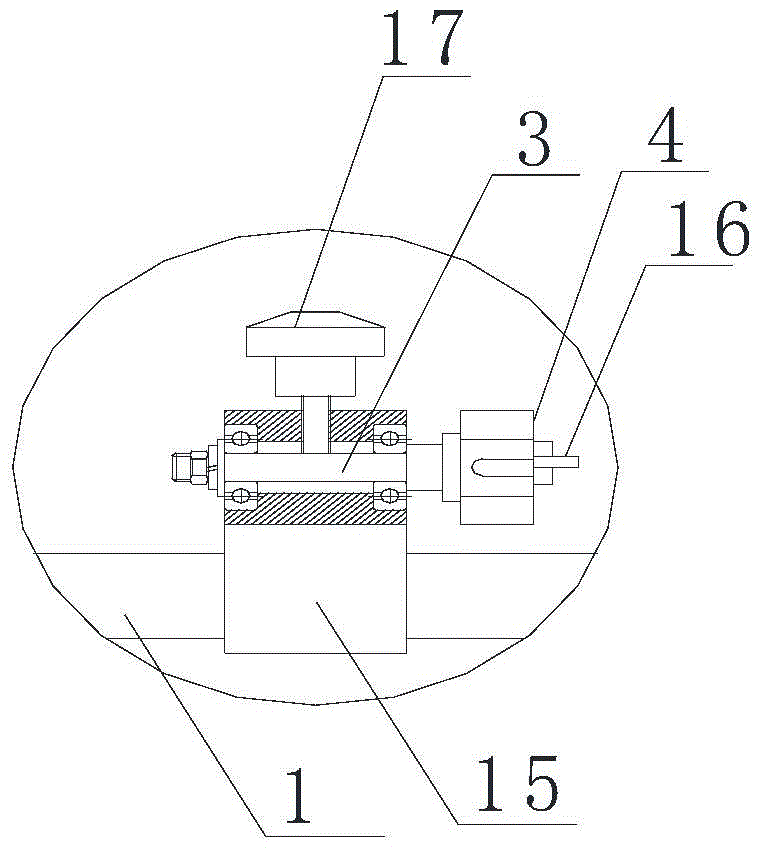

Method for positioning defects of T-type stringer on basis of ultrasonic guided waves

ActiveCN108152375AAccurate defect locationFast defect locationAnalysing solids using sonic/ultrasonic/infrasonic wavesWave structureSonification

The invention discloses a method for positioning defects of a T-type stringer on the basis of ultrasonic guided waves. The method comprises the following specific steps of: (S1) analyzing by the semi-analytical finite element method theory to obtain a guided-wave characteristic propagating on the T-type stringer; (S2) selecting all frequencies and modes for detection by frequency dispersion curvesand wave structures; (S3) carrying out excitation and reception of guided waves on the ends of the T-type stringer along guided-wave sensors arranged along the circumferential direction, wherein thesensors are fixed by clamps and are coupled with the surface of the stringer; (S4) using signal excitation equipment to generate guided-wave signals with the selected frequencies; (S5) determining longitudinal positions of the damages by time difference between peak values of echo signals and excitation signals according to the excitation frequency and the mode wave velocity selected every time, and determining positions of horizontal defects according to detection results of all frequencies and modes with different horizontal-defect sensitivity.

Owner:DALIAN UNIV OF TECH

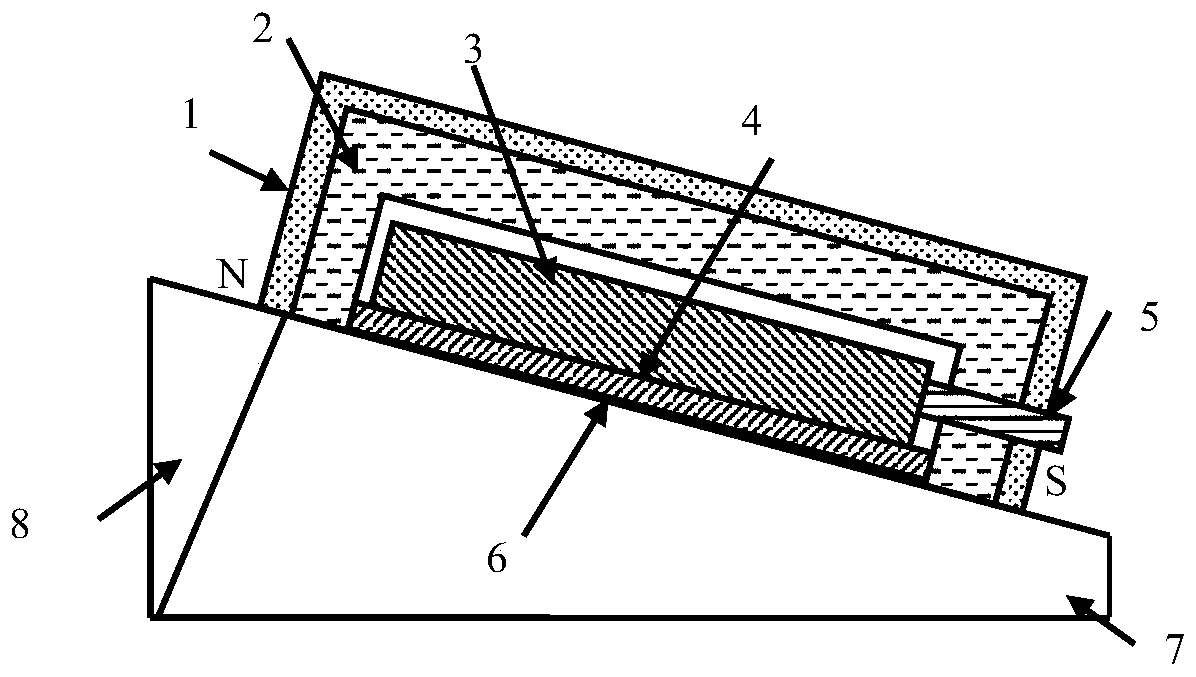

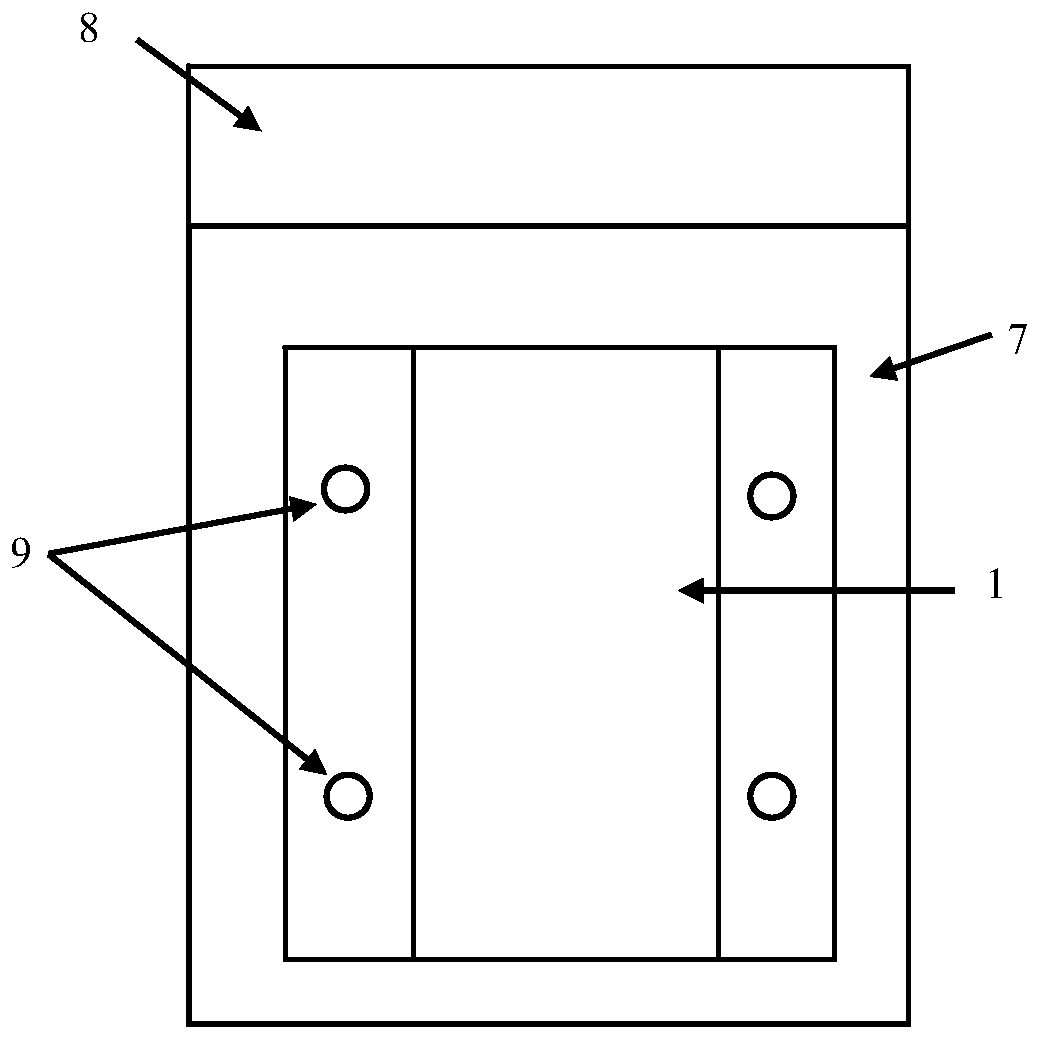

Horizontal shear wave energy converter used for coarse grain material welding line detection

PendingCN110057913AImprove detection accuracyThe result is accurateAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic waveEngineering

The invention relates to a horizontal shear wave energy converter used for coarse grain material welding line detection. The energy converter comprises an energy converter, a shell used for packagingthe energy converter body, a wedge block used for bearing the energy converter body, and a sound adsorption layer used for connecting to the end part of the wedge block, wherein the wedge block is adopted to spread the horizontal shear wave into the welding line at a certain angle, and the sound adsorption layer is adopted to eliminate residual sound waves in the wedge block. Compared with the prior art, the horizontal shear wave energy converter has the advantages of simple structure, accurate detection result, convenience in use and installation and the like.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

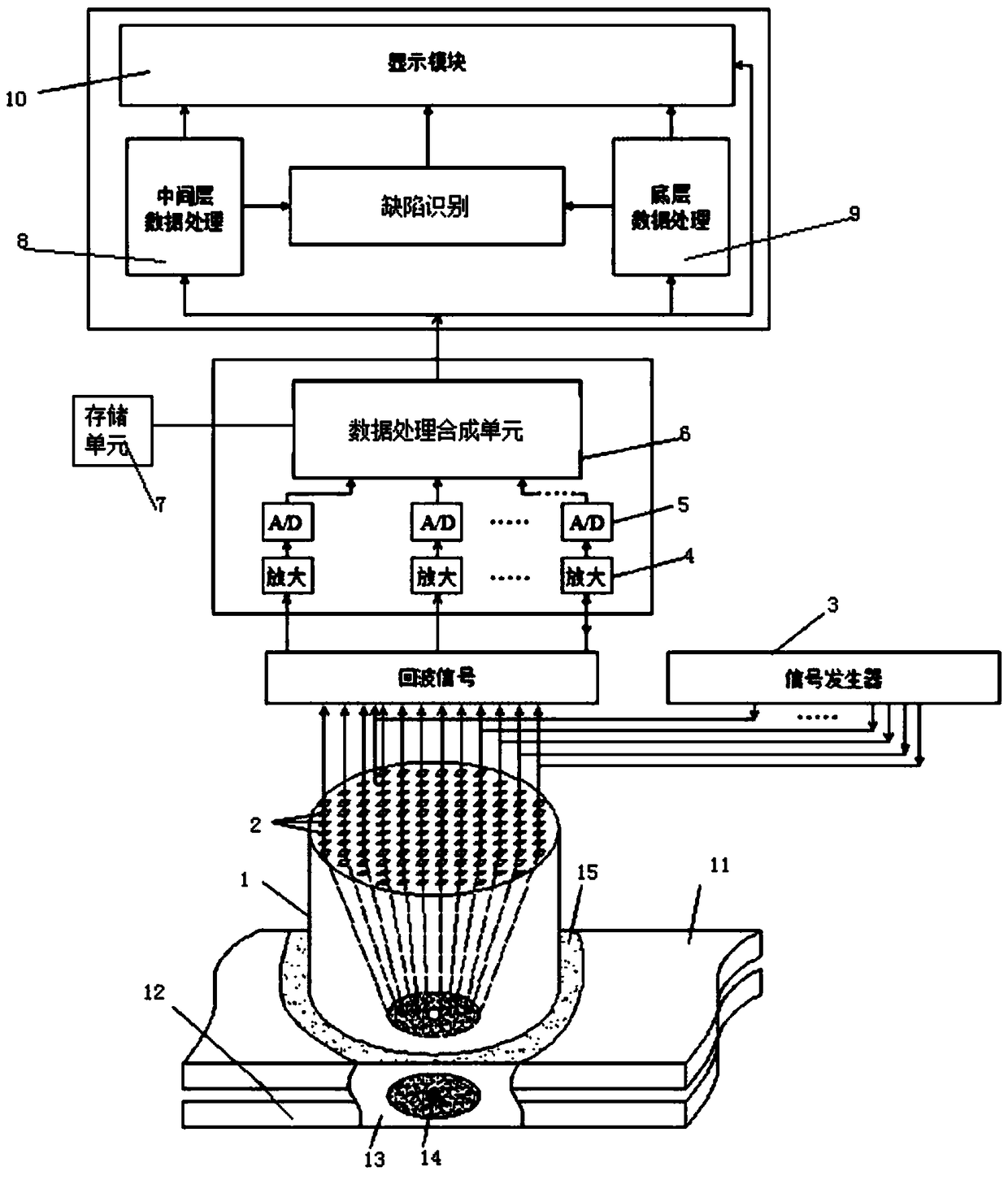

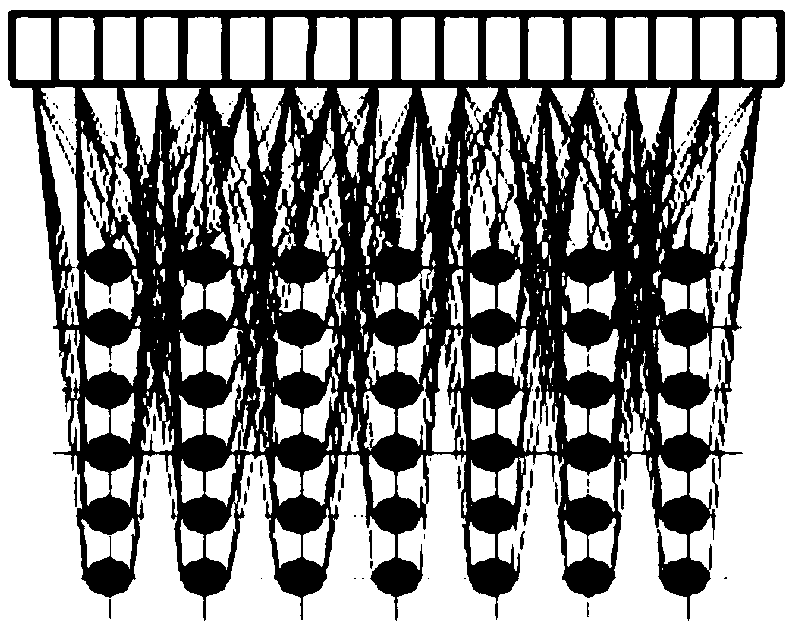

Solder joint inspection method for electric resistance welding based on full focusing synthetic aperture technology

InactiveCN108956779AIntuitive and clear displayLow technical requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectric resistance weldingPhased array

The invention discloses a solder joint inspection method for electric resistance welding based on a full focusing synthetic aperture technology. The method comprises the following steps: placing a phased array probe in a to-be-tested area, transmitting a pulsed electrical signal to each composite material wafer of the phased array probe by a pulse emission receiver, generating ultrasonic waves bya composite material wafer transducer, enabling the ultrasonic waves to generate reflected echo signals on a to-be-tested workpiece surface, a first metal layer bottom surface, a fusion zone bottom surface and the like, receiving the echo signals by the composite wafer transducer, feeding the signals into an amplifying circuit and an AD (Analog-Digital) conversion circuit in groups for performingsignal processing, feeding into a data processing composite unit, performing stack imaging on the echo signals by utilizing a full focusing synthetic aperture algorithm, performing three-dimensional imaging, displaying the image by a display module, obtaining the fusion zone size, and obtaining the nugget size by virtue of database comparison; and in addition, performing pseudo-color processing onthe obtained three-dimensional images, separating the solder side bottom layer from the fusion zone, recognizing the defect parts, and finally performing defect part display by the display module.

Owner:NANCHANG HANGKONG UNIVERSITY

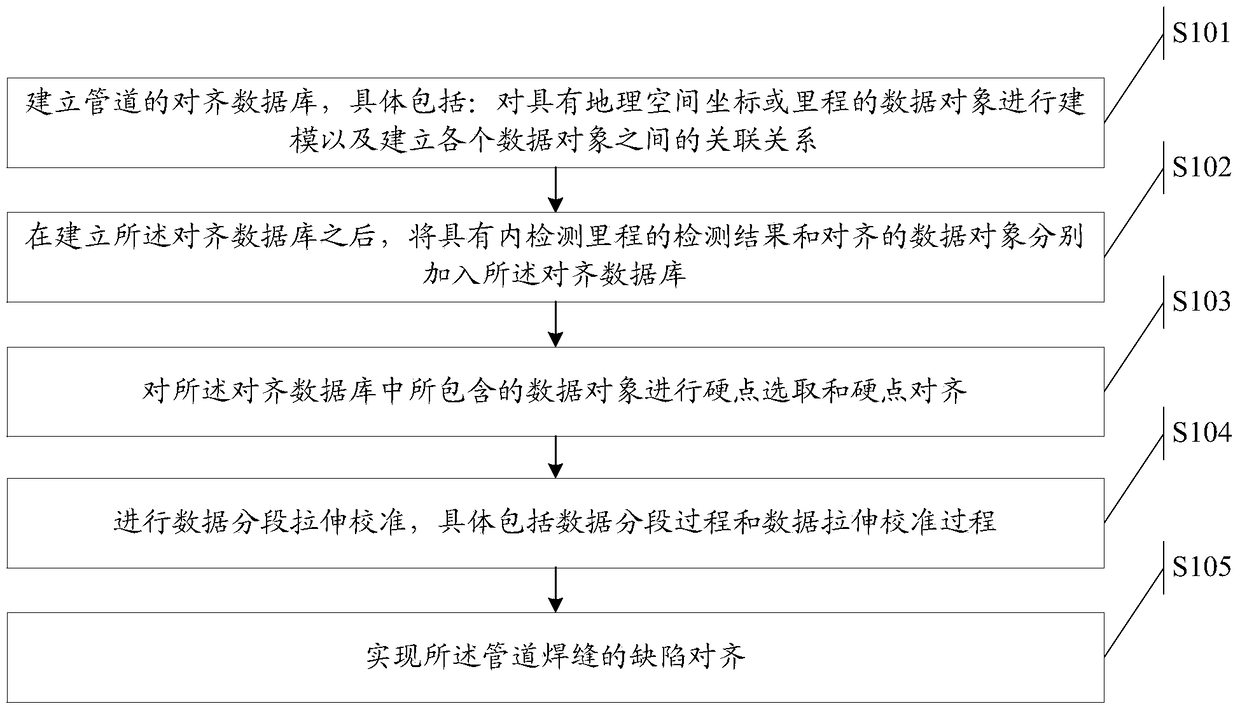

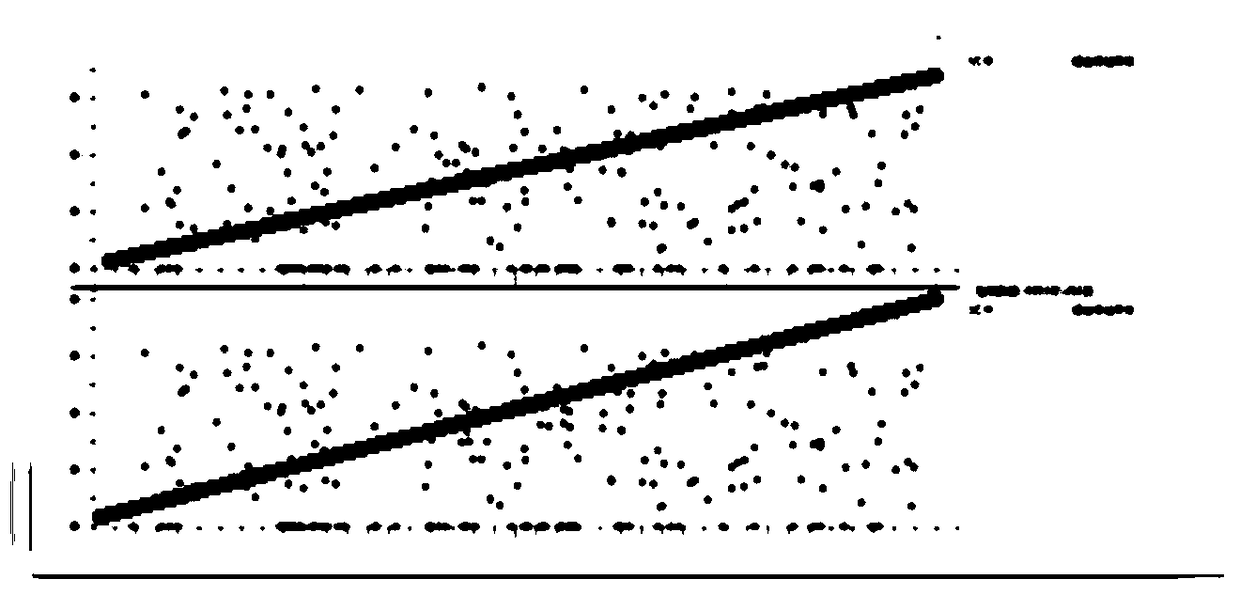

A Fitting Method of Mileage and Geospatial Coordinates of Pipeline Ontology Data

ActiveCN105354257BAccurate CalibrationAccurate defect locationGeographical information databasesSpecial data processing applicationsComputer scienceData objects

Owner:PIPECHINA SOUTH CHINA CO

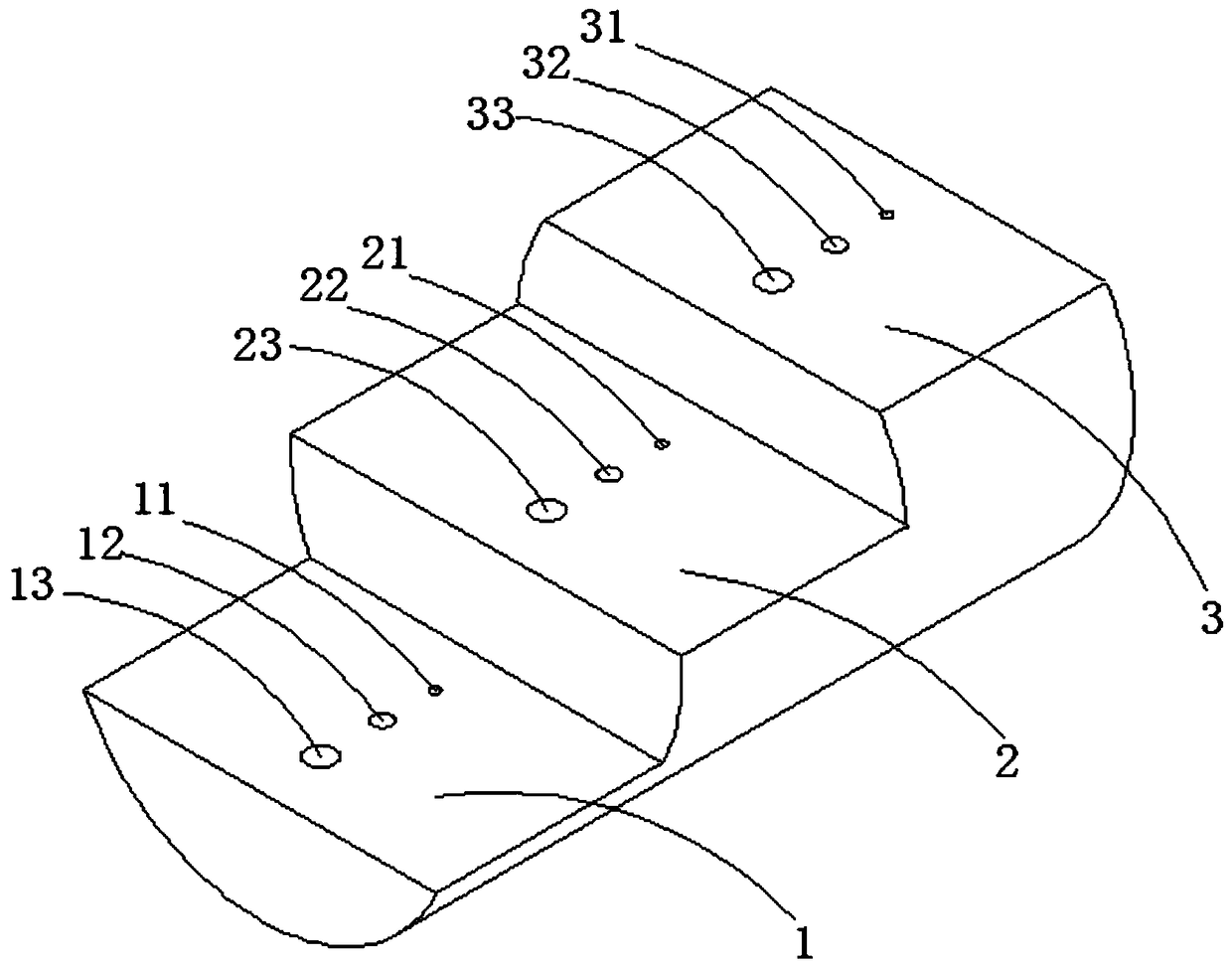

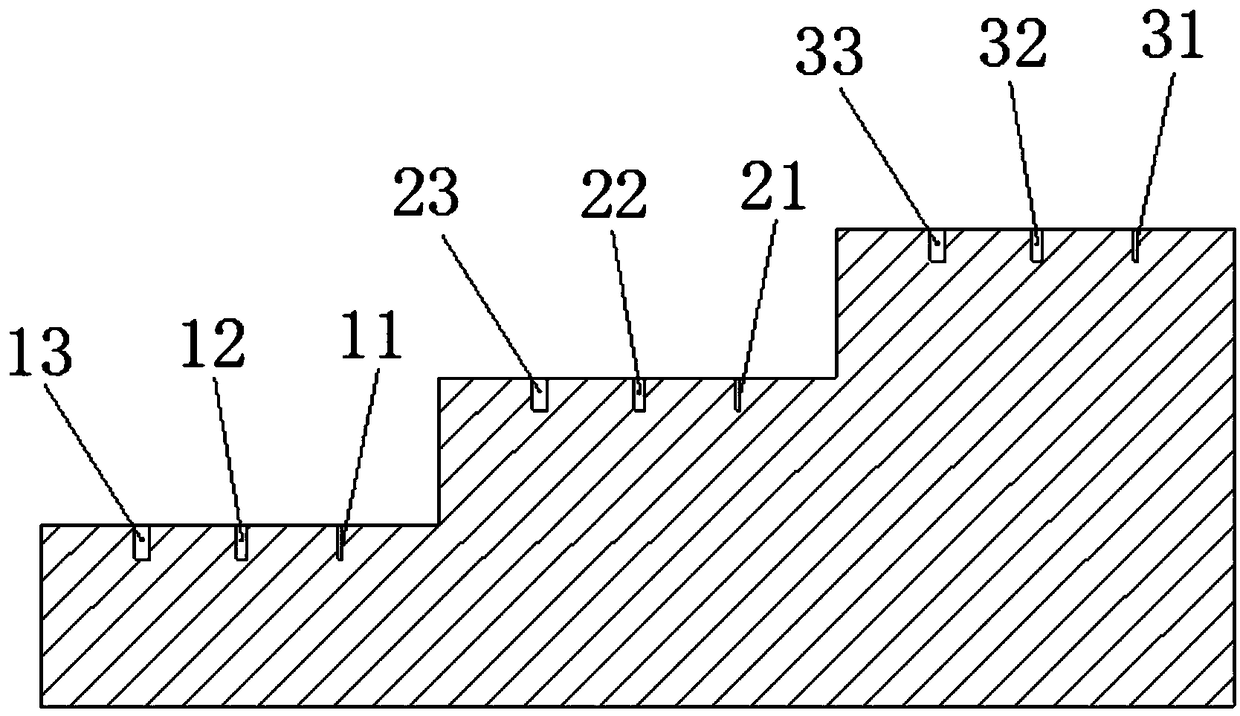

Reference block for alloy steel bar ultrasonic flaw detection and using method of reference block

PendingCN109358116AGood effectImprove yieldAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterials scienceAlloy steel

The invention provides a reference block for alloy steel bar ultrasonic flaw detection and a using method of the reference block. The reference block is a cylindrical matrix and comprises three comparison sections with the same diameter in the axial direction of the cylindrical matrix; a straight part is arranged on the circumferential wall of each comparison section; the circumferential wall of each comparison section is composed of the corresponding straight part and an arc part which are connected head to end in the circumferential direction of the circumferential wall; each straight part is a plane axially parallel to the cylindrical matrix; each arc part is a part of the circumferential surface sharing the axis with the matrix; flat bottom holes are formed in the planes of the straight parts; and the axes of the flat bottom holes are perpendicular to the planes of the straight parts, and intersect with the axis of the matrix. The reference block and a to-be-detected bar are similar in material and similar or the same in size, the structure is simple, the preparation cost is low, and flaw detection results are more accurate; and by arranging the three comparison sections for defect positioning, defect positioning is more accurate, the yield of steel is greatly increased, the detection cost is saved, and important significance for defect detection of the bar is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

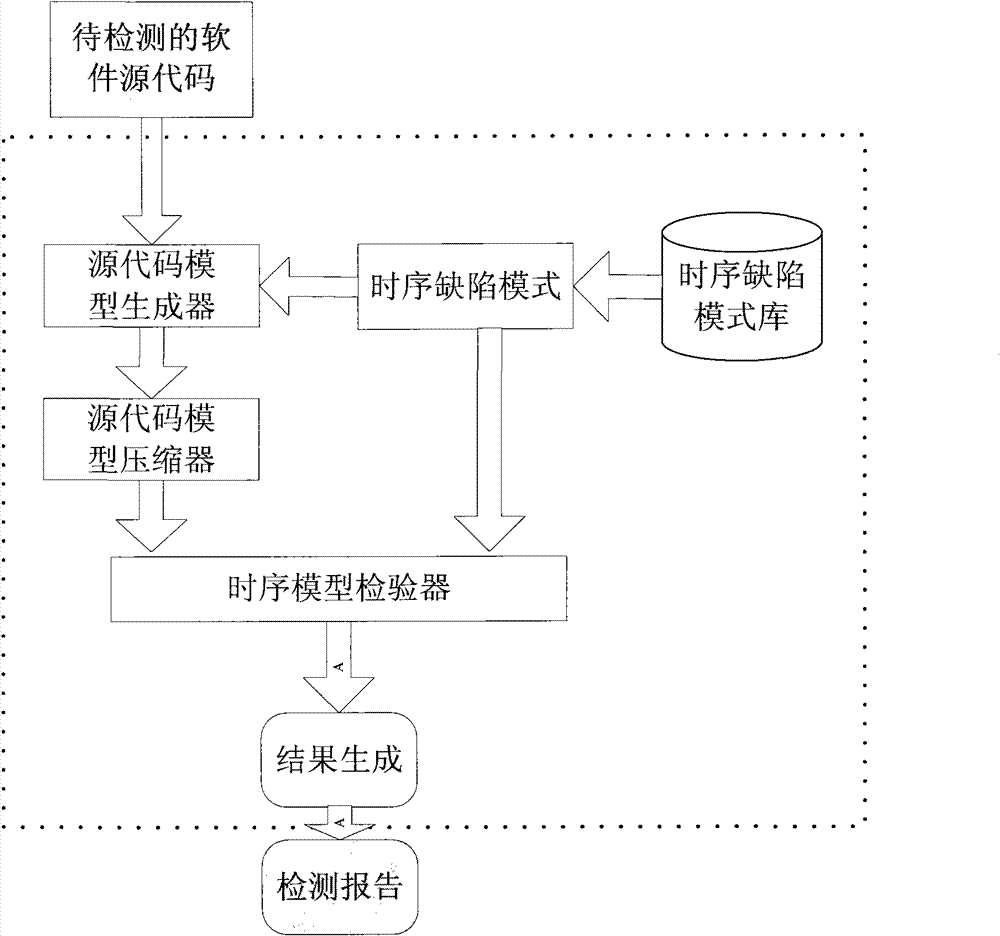

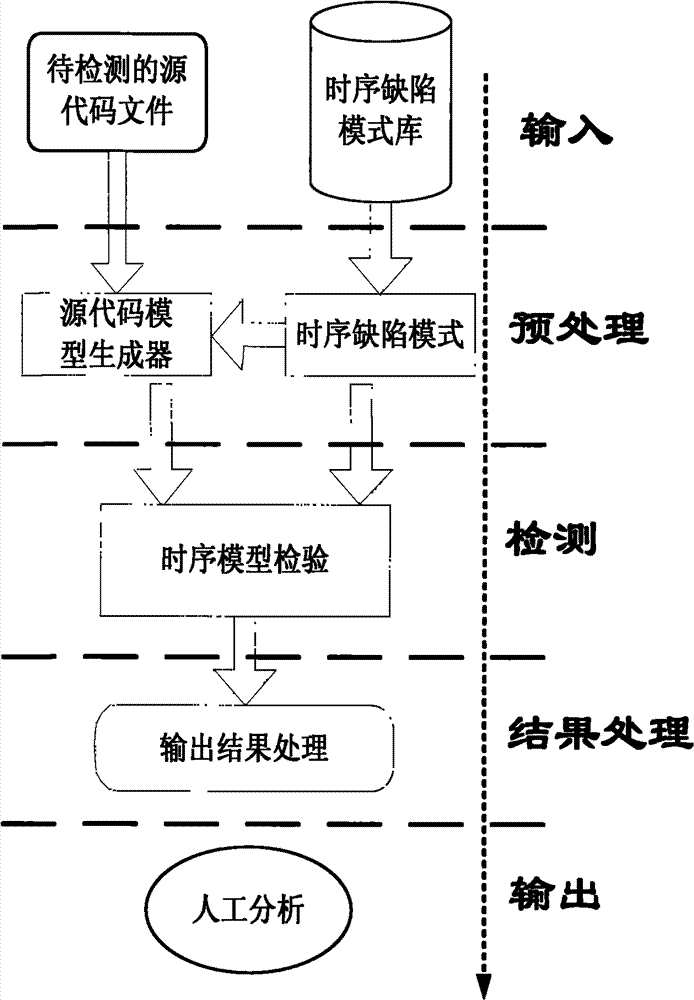

Timing sequence software quality defect detection method and system based on model detection

InactiveCN101833504BQuality improvementImprove quality inspection efficiencySoftware testing/debuggingTest efficiencySoftware engineering

The invention relates to software quality defect detection method and system based on static analysis, belonging to the technical field of computer information safety. The detection method comprises the concrete steps as follows: firstly, inputting detected source codes, and selecting a defect mode according to the detected source codes; secondly, pre-processing the detected source codes; thirdly, carrying out control flow graph compression on merged source codes; fourthly, determining whether defects exist in the mode of an original detected program; fifthly, treating results, i.e., converting the position information of a termination status of detected source program codes to the position information of the original source codes; and sixthly, outputting, i.e., showing final determined result to users. The detection method and system can find software defects in advance, shorten software development cycle, save development cost and improve software quality, directly positions the detected program source codes, accurately positions the defects, and can improve the test efficiency and reduce false alarm rate.

Owner:WUHAN HUAYA XINGTONG INFORMATION TECH CO LTD

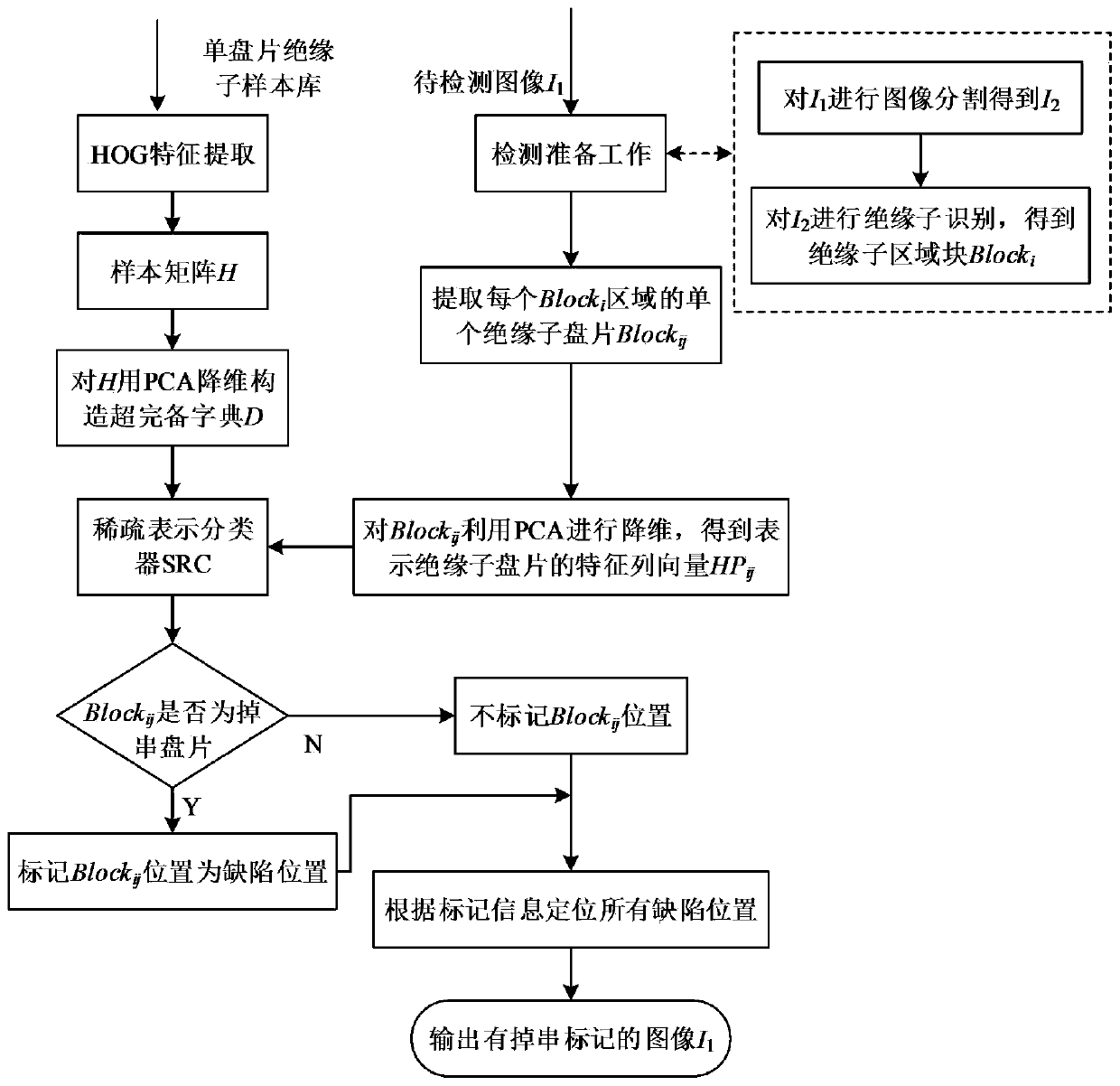

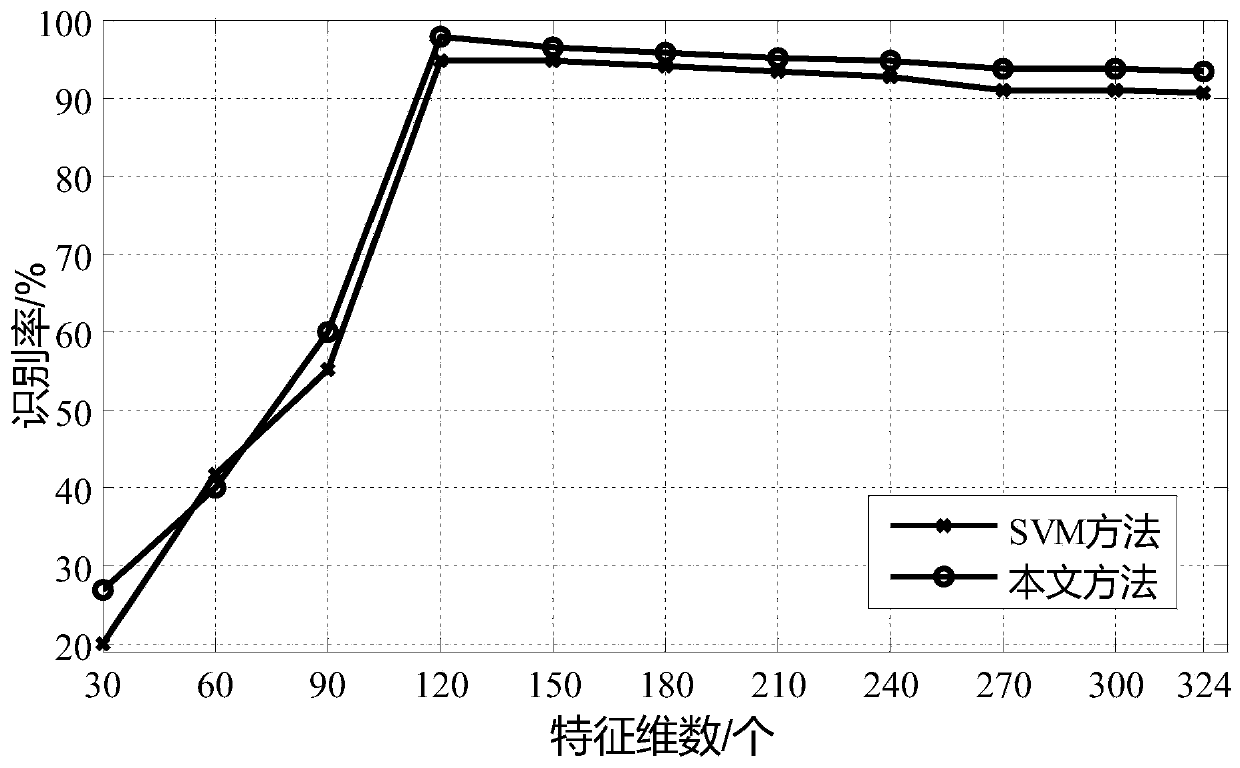

A Sparse Representation-Based Detection Method for Insulator Missing Series Defects

ActiveCN106778734BImplement string drop detectionImprove robustnessCharacter and pattern recognitionAlgorithmImage segmentation algorithm

The present invention is a detection method for insulator string drop defects based on sparse representation. Firstly, the image segmentation algorithm is used to segment the captured original image containing insulator strings, and background interference such as snow accumulation and power lines is eliminated, and the image is segmented into multiple Then, perform ASIFT matching between these disconnected areas and the insulators in the insulator string library, and the insulator string area is the number of matching points higher than the set threshold; then, the identified insulators Segment the insulator single disk in the string area to obtain multiple insulator small disks; finally, use the sparse representation classifier to classify and mark each insulator small disk, identify whether a single small disk has a string drop defect, and display it in the original image in the location identification. Compared with other methods, it has higher recognition accuracy and accurate defect location.

Owner:保定市斯德尔电气设备制造有限公司

A Method for Monitoring Defects of High Temperature Steam Injection Pipeline

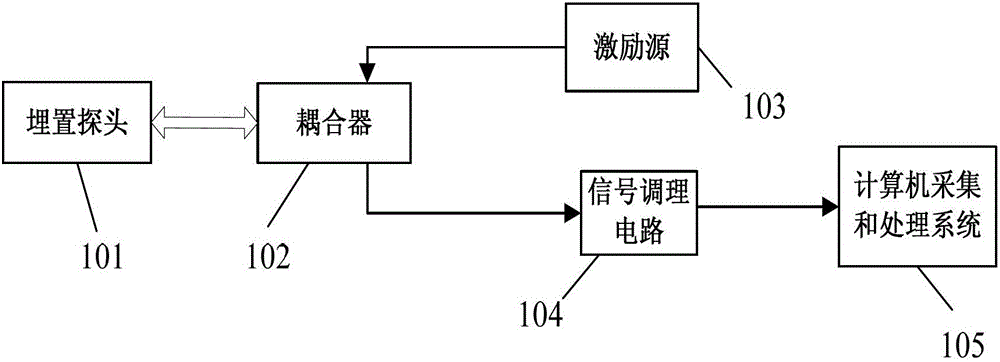

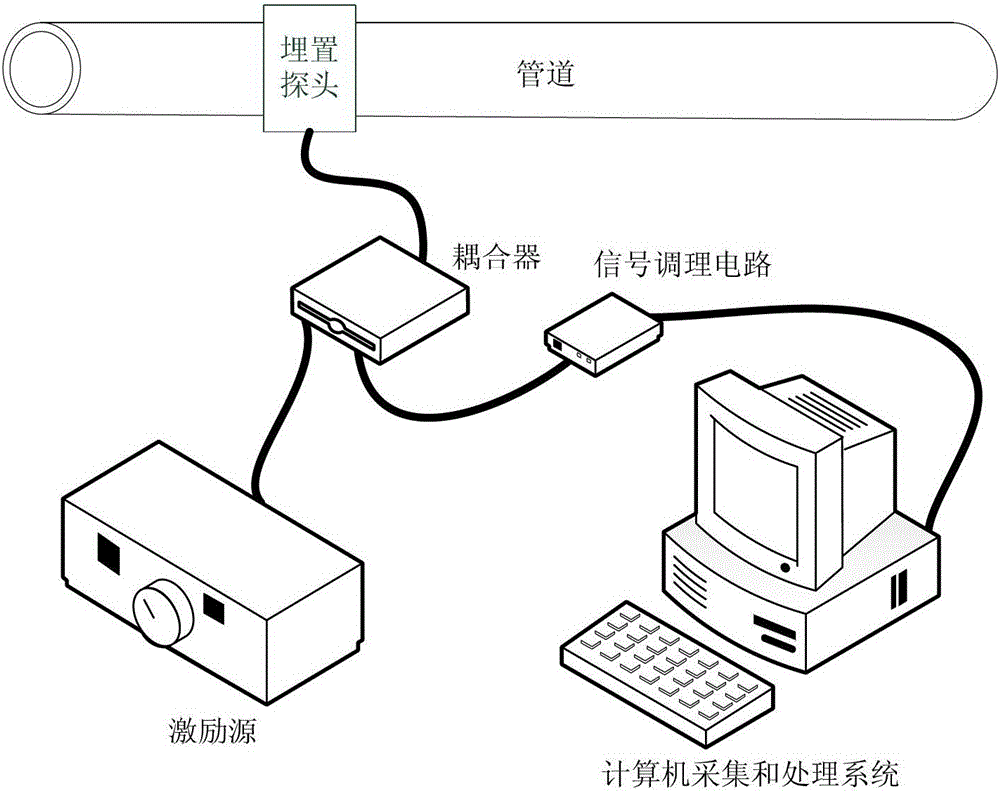

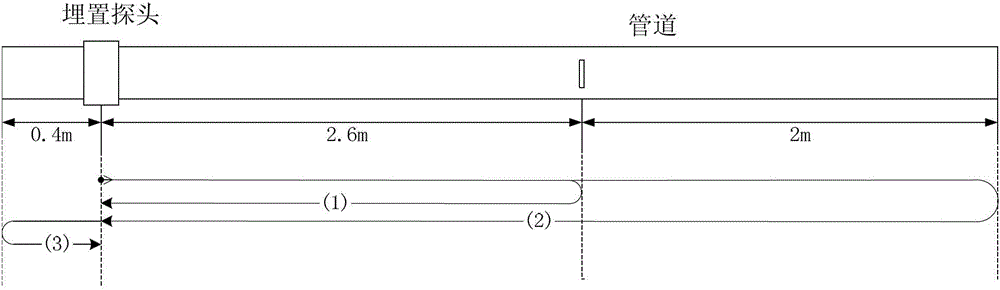

ActiveCN103412049BWith detection abilityReduced finish requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationData acquisition

The invention discloses a method for monitoring defects of a high-temperature steam injection pipeline. An embedded probe is connected with a probe interface of a coupler; an exciting circuit is connected with an excitation source interface of the coupler; an input end of a signal conditioning circuit is connected with a signal conditioning interface of the coupler, and an output end of the signal conditioning circuit is connected with a data acquisition card interface of a computer acquisition and processing system; the excitation source inputs a pulsed excitation signal to the embedded probe through the coupler, excites ultrasonic guided-waves in the pipeline, and generates ultrasonic echoes when encountering the defects, the ultrasonic echoes are transmitted to the embedded probe and are converted into voltage signals through the embedded probe; the voltage signals are transmitted to the signal conditioning circuit to be processed through the coupler and are output to the computer acquisition and processing system which acquires, processes and displays the ultrasonic echo signals containing defect information. The embedded probe can be embedded in an insulating layer of the pipeline, and the insulating layer of the high-temperature steam injection pipeline does not need to be damaged basically, but online detection and long-term monitoring for the defects of the pipeline can be realized, and the defects of the pipeline can be simply and accurately positioned.

Owner:TSINGHUA UNIV

A method for detecting welds and weld defects based on deep learning

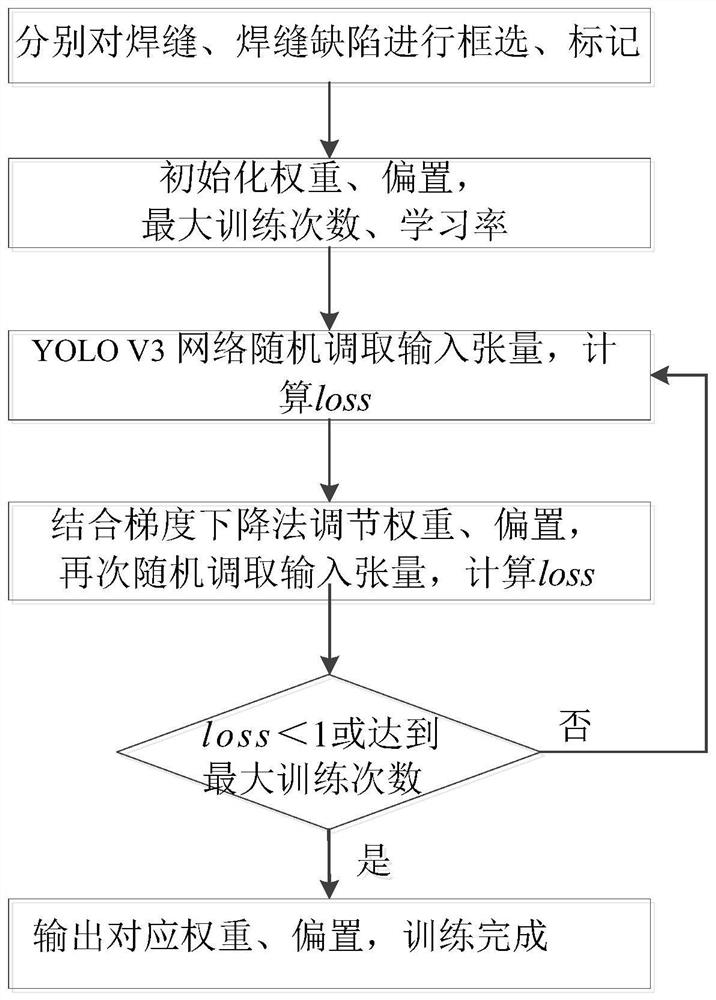

ActiveCN109900706BExact categoryHigh coincidenceOptically investigating flaws/contaminationPattern recognitionData set

The invention discloses a method for detecting weld seams and weld seam defects based on deep learning. The YOLOV3 network is used to realize the detection of weld seams and / or weld seam defects; the training steps of the network: the workpiece image is frame-selected by the positioning frame for the weld seam , marking, as a training data set; use the positioning frame to frame the weld defect and mark the defect type as the training data set I; obtain the coordinate x of the positioning frame p 、y p , and the width and height dimensions w p 、h p ; Initialize the network; randomly call the input tensor a j Carry out training calculations and output the detection results; use the detection results to calculate the error function loss of the prediction results; combine the gradient descent method to adjust the weight W and the bias value b, and cycle like this to obtain a trained network; this method, for multiple welds, Simultaneous detection of various defect types, one-time measurement can realize welding seam identification and positioning and defect detection, effectively improving measurement efficiency and accuracy.

Owner:易思维(杭州)科技股份有限公司

New energy lithium battery surface defect detection method based on adaptive deep learning

ActiveCN111105405BAccurate defect locationNo need for manual labelingImage enhancementImage analysisImage segmentationSample image

The invention discloses a new energy lithium battery surface defect detection method based on adaptive deep learning. Including: nonlinear mapping of the lithium battery surface grayscale image; transforming the decoupled illumination component and reflection component into the frequency domain; filtering, inverse Fourier transform, and exponential transformation of the frequency domain data to obtain the reconstructed lithium battery image ; Based on morphological processing and background difference, enhance the grayscale response at the defect; perform image segmentation, connected domain analysis and screening processing, and use the results as annotated images; design operators to simulate illumination details and perform sample enhancement on lithium battery surface grayscale images Operation; train a deep convolutional neural network based on the enhanced sample image set and annotated images; implement lithium battery surface defect detection based on the trained network. The present invention can improve the detection efficiency and reduce the false detection rate in the lithium battery surface defect detection scenario.

Owner:芜湖楚睿智能科技有限公司

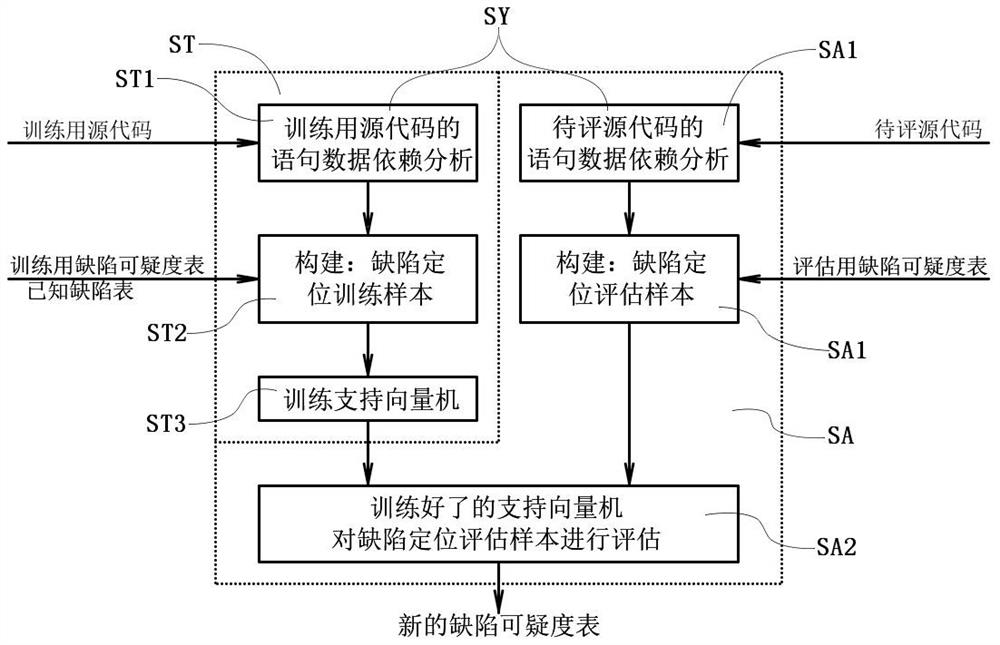

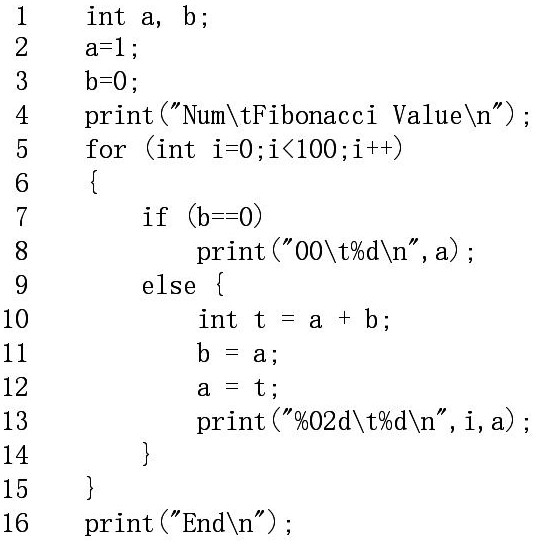

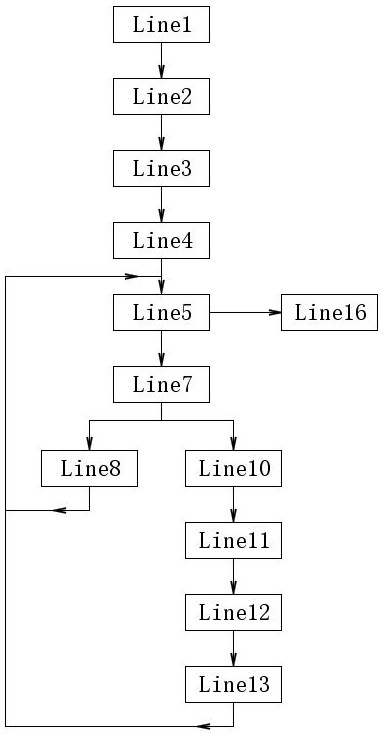

Method and device for enhancing defect positioning based on program dependence

ActiveCN113791976AEnhancement of defect localization resultsAccurate defect locationSoftware testing/debuggingManufacturing computing systemsAlgorithmTheoretical computer science

The invention discloses a method and a device for enhancing defect positioning based on program dependence. According to the method, statement data dependency relationships of a source code are analyzed, a statement defect suspicious degree table obtained by analyzing the source code through an existing software tool is combined with the statement data dependency relationships to form an eigenvalue vector composed of N + 1 suspicious degree values, and the eigenvalue vector serves as a sample of each statement of the source code and is input into a support vector machine for machine analysis, so that an optimized defect suspicious degree list is obtained. Therefore, a positioning result is enhanced, and defect positioning is more accurate.

Owner:NANJING UNIV

A method for dual-frequency ultrasonic detection of inclusions in bearing steel

ActiveCN110018234BEnhanced couplingNo pollution in the processAnalysing solids using sonic/ultrasonic/infrasonic wavesProcess efficiency improvementDouble frequencyMaterials science

The invention relates to a method for detecting inclusions in bearing steel by dual-frequency ultrasonic waves. A cylindrical bearing steel sample that has undergone quenching, tempering heat treatment and gold processing is installed on a water immersion high-frequency ultrasonic flaw detector, and a 10 MHz flat probe and The 25MHz focusing probe jointly detects the sample, and analyzes the A and C scanning images formed synchronously to determine the size, quantity and distribution of inclusions in the medium carbon bearing steel. In meeting the international high standard bearing steel testing requirements Based on this, a unique standard for judging the purity level of steel has been formed. In addition, this experimental method can accurately locate the detected inclusions, and can accurately locate the location of the inclusions, which is convenient for further research and analysis of the characteristics of the inclusions, and guides metallurgical production.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

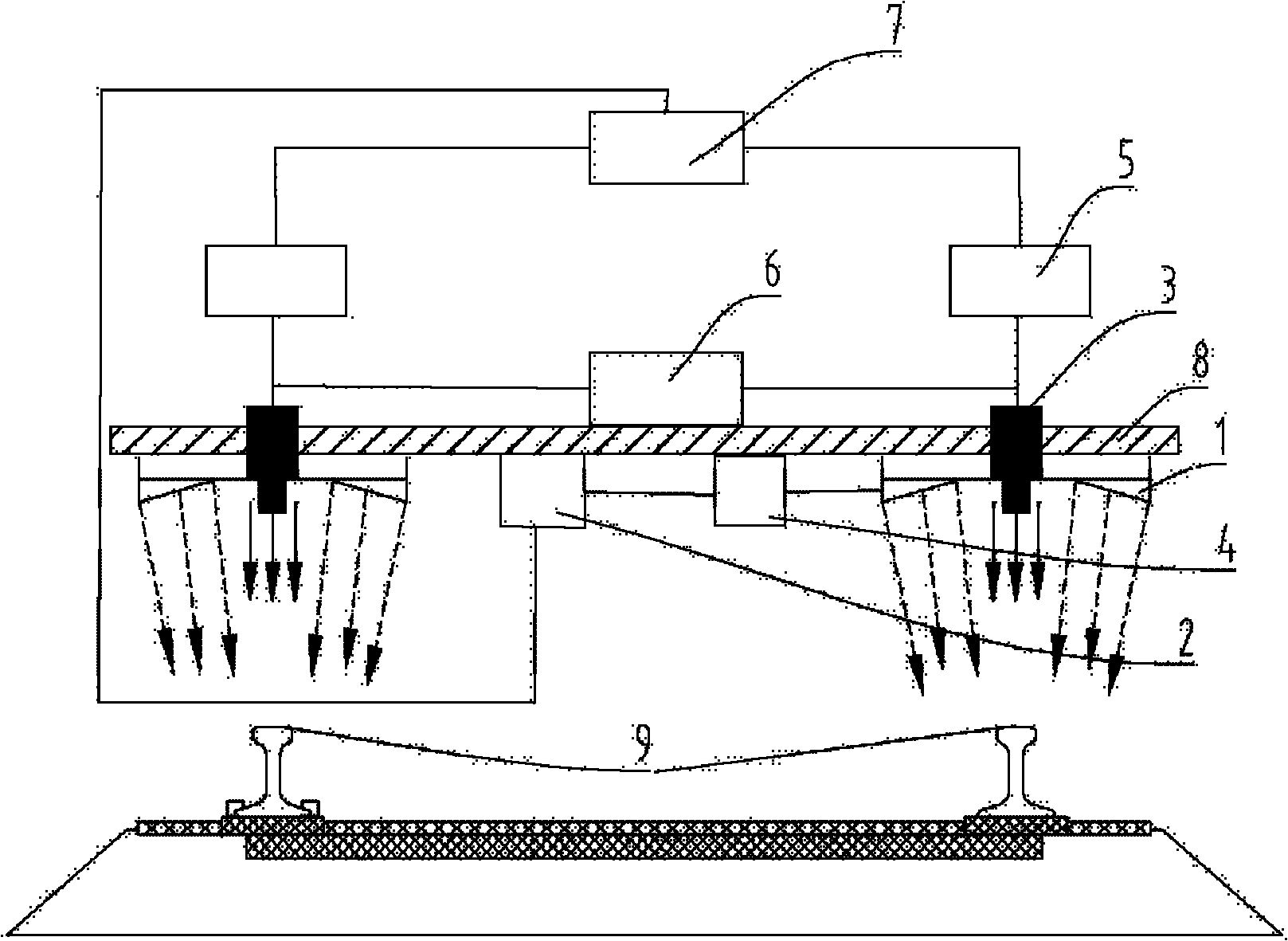

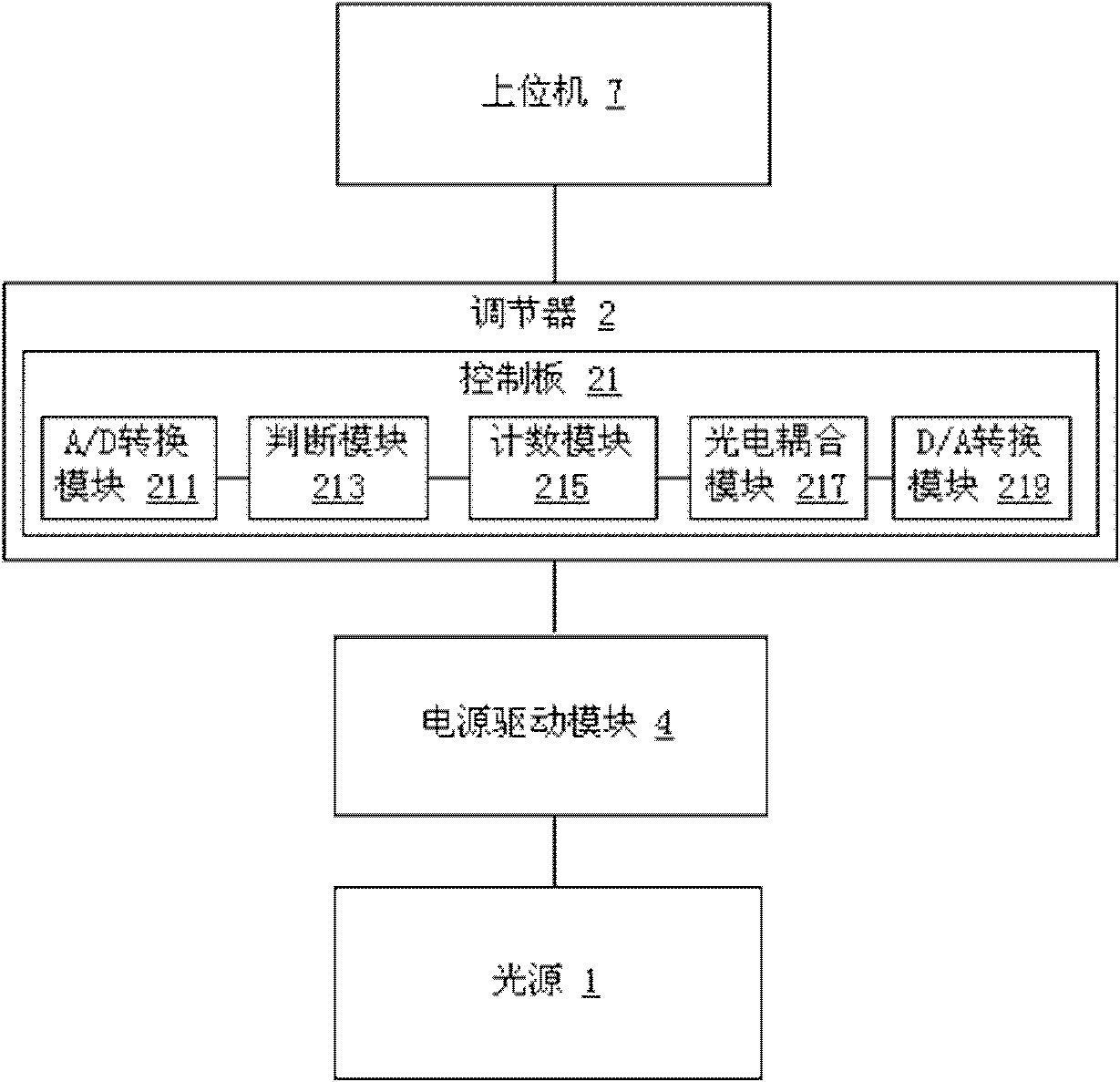

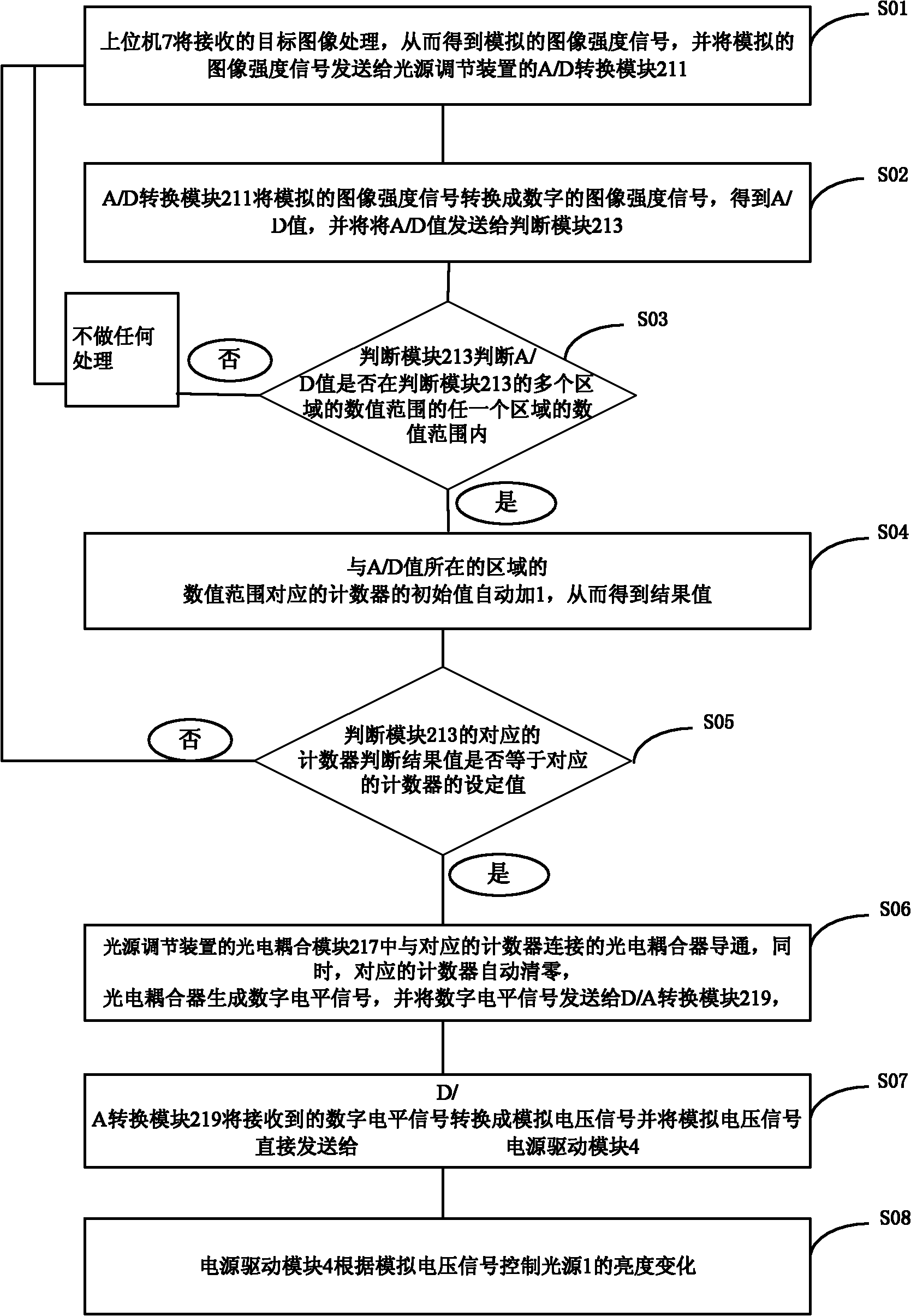

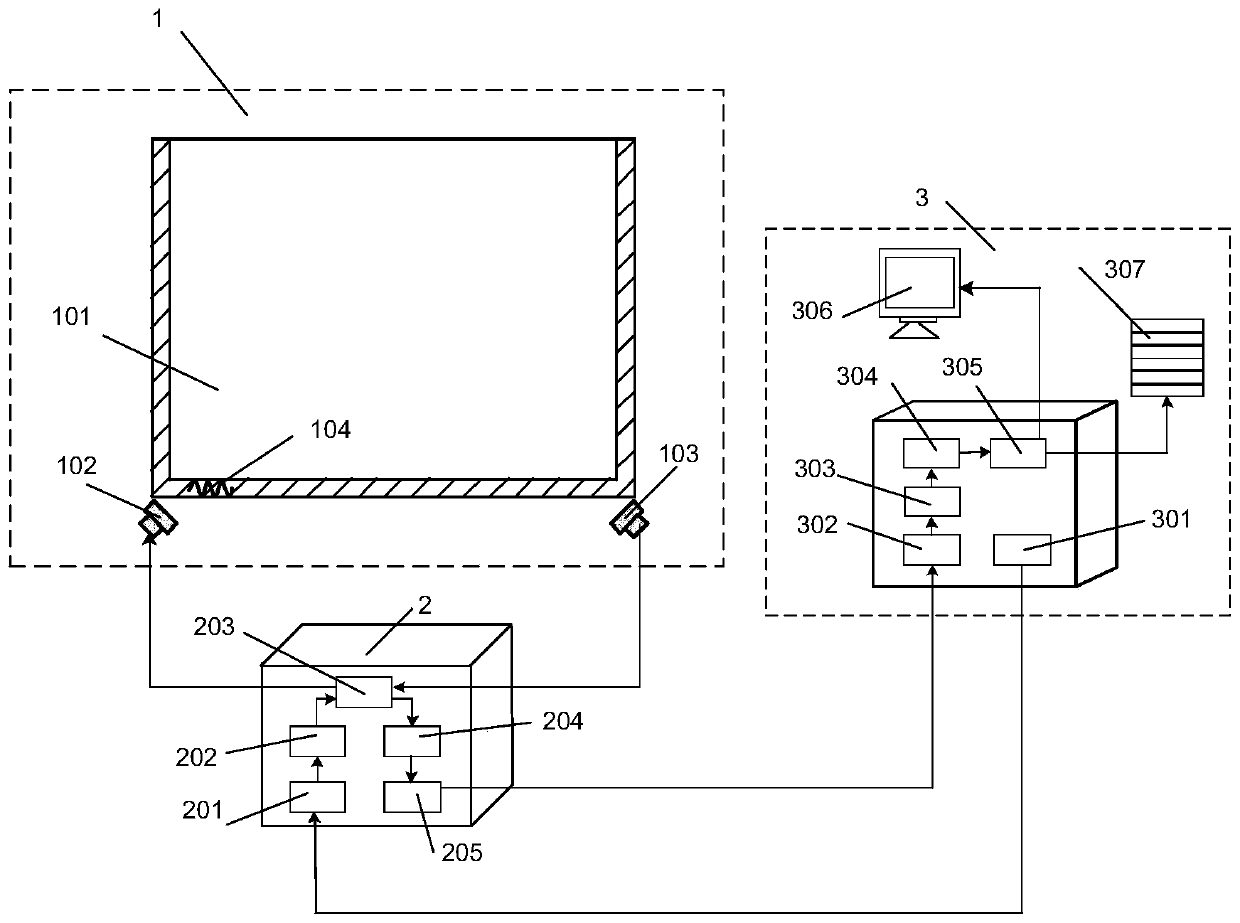

Perambulated inspection system and method

ActiveCN102507587BHigh inspection efficiencyHigh defect size detection accuracyOptically investigating flaws/contaminationUsing optical meansDefect sizeComputer graphics (images)

The invention provides a perambulated inspection system and method, wherein the perambulated inspection system comprises an installation frame, an upper computer, a plurality of cameras and a plurality of light sources; the cameras and the light sources are arranged on the installation frame; the installation frame is arranged above a target object and can move relative to the target object; the light sources are used for irradiating the target object; the cameras are used for shooting target object images so as to obtain target images; the cameras are used for sending the target images to the upper computer; and the upper computer is used for analyzing and processing the target images. According to the perambulated inspection system and method, disclosed by the invention, the effects of high efficiency on track perambulated inspection, accurate track defect positioning and high accuracy on defect size inspection can be achieved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

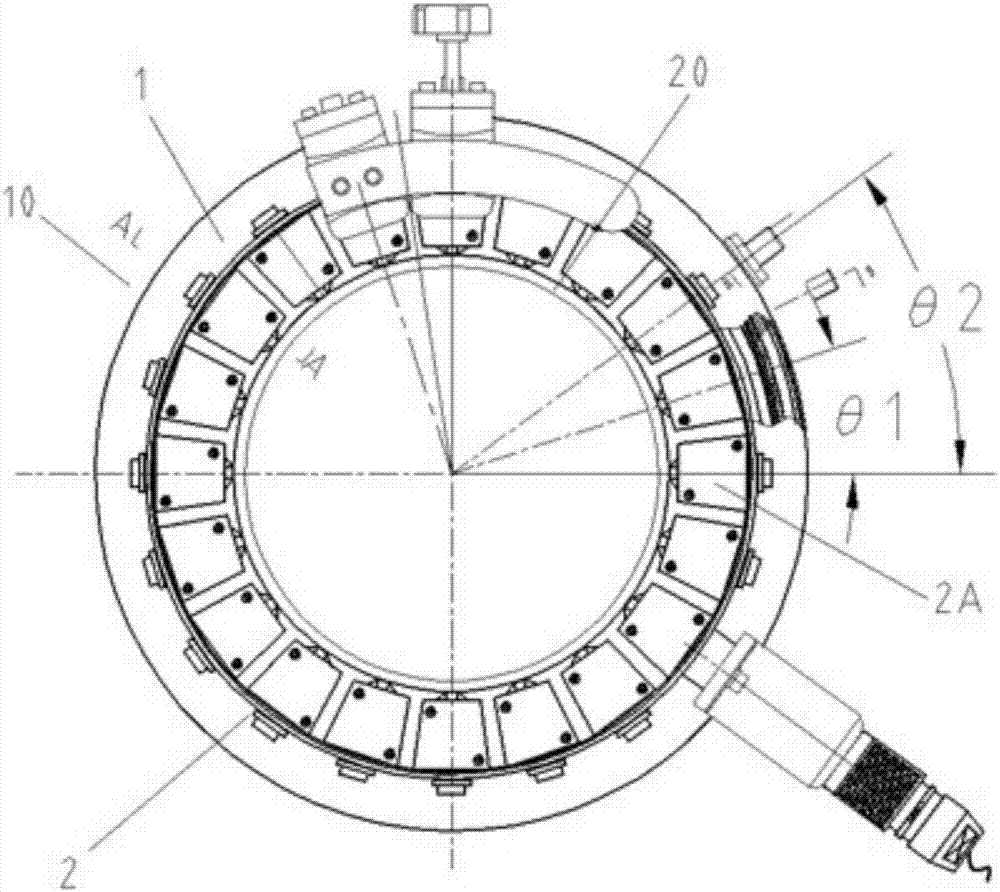

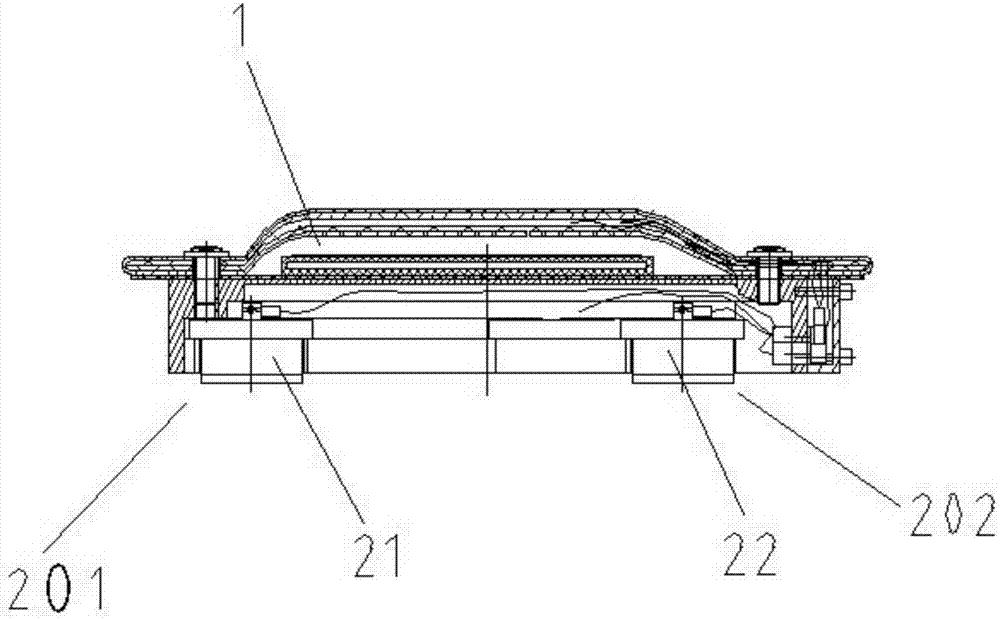

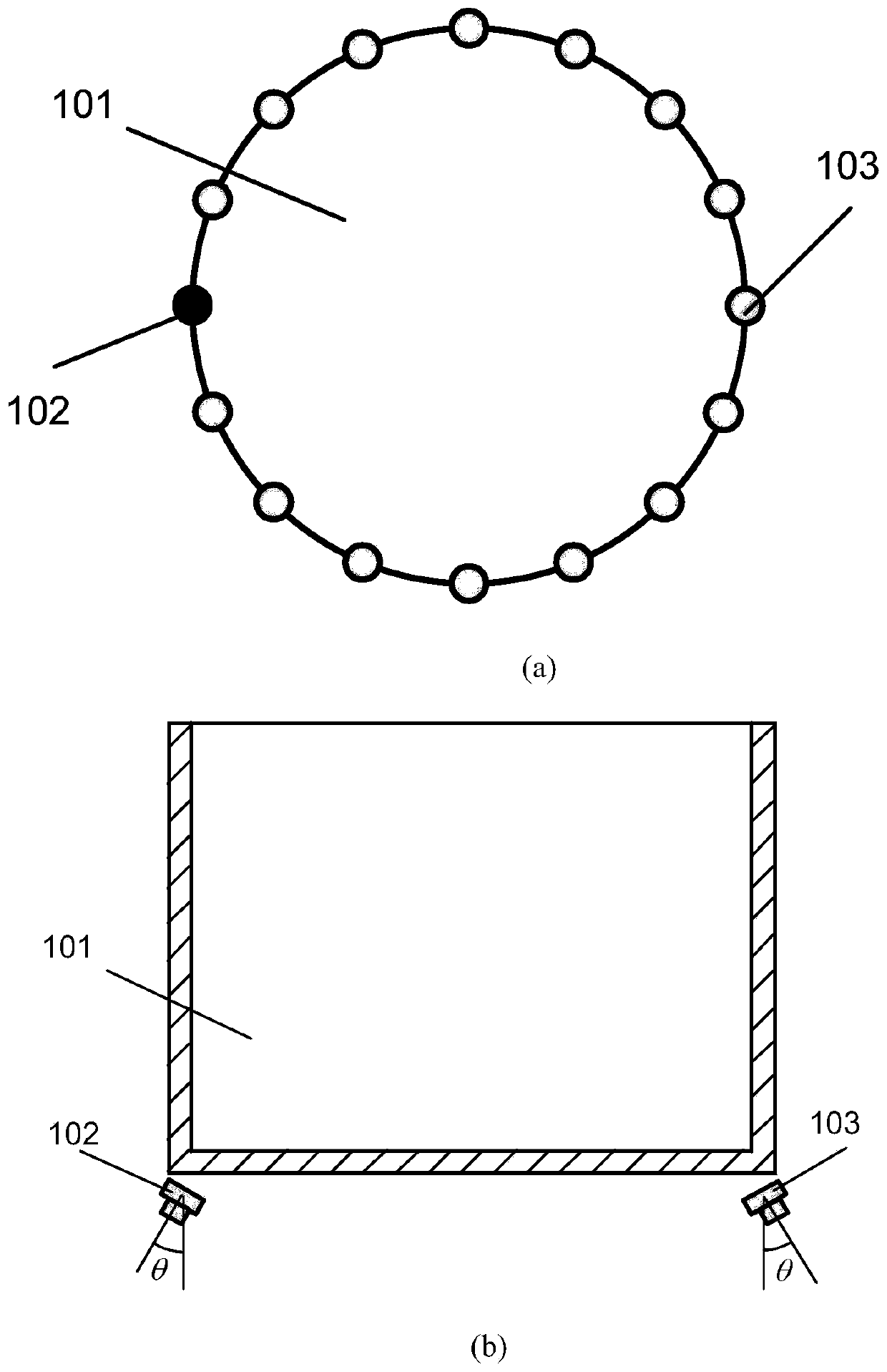

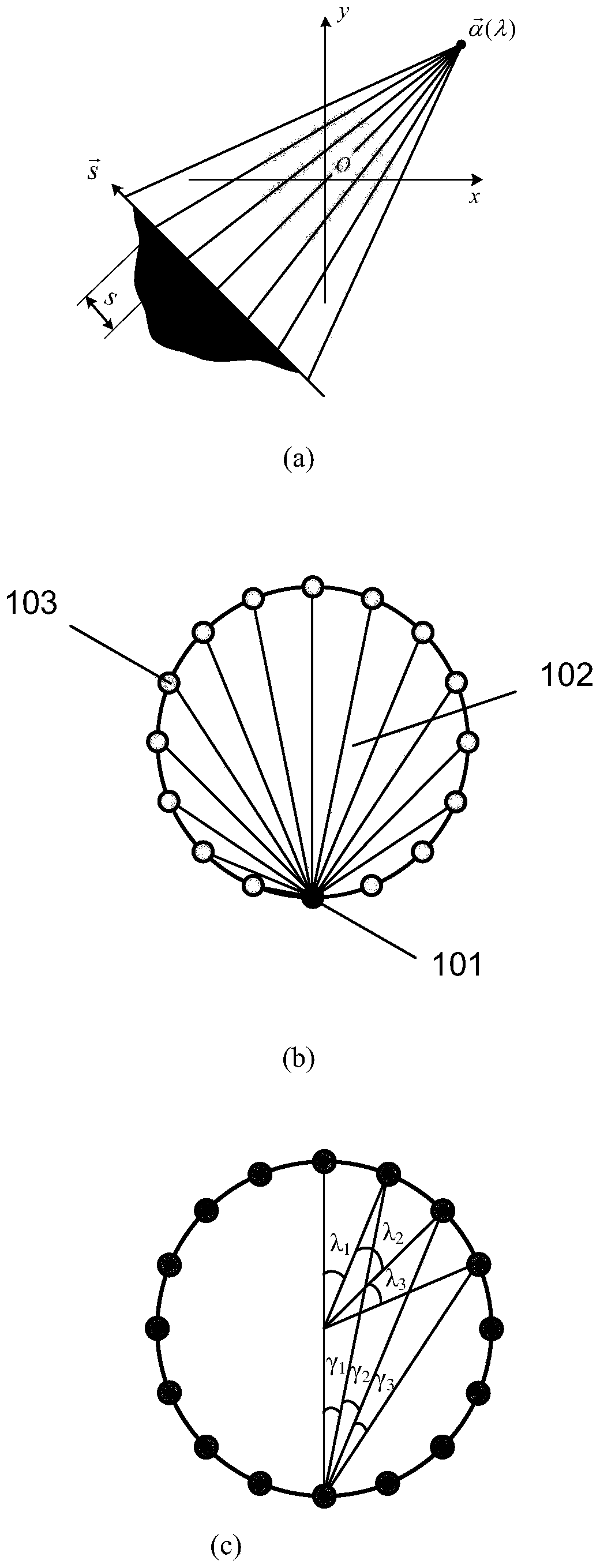

Lamb wave tomography method for defects of large storage tank bottom plate

InactiveCN110967400AAvoid difficultyEasy to useAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionEngineeringTomographic image

The invention discloses a tomography method for a circular bottom plate structure of a large storage tank, which is characterized in that air coupling transducers which are arranged along the circumference of a bottom plate of a storage tank at equal angular distances are used for collecting lamb wave signals, so that the defects of corrosion, rusting, pressure sensitivity and the like possibly existing in a contact type transducer due to the use of a coupling agent are avoided; by setting the included angle between the surface of the air coupling transducer and the surface of a detection workpiece, travel time information of a lamb wave single mode is obtained, and the difficulty of single mode signal extraction caused by frequency dispersion characteristics of the lamb wave is avoided; and an equal-angular-distance differential filtering back projection algorithm suitable for the circular bottom plate is derived, and the Lamb wave travel time information is subjected to differential,filtering and back projection operations in sequence to obtain the tomographic image of the circular storage tank bottom plate structure. The method has the advantages of the wide detection object range, the high reconstruction speed, convenience in use, the accurate defect positioning and the like, and a method support is provided for detecting defects, particularly corrosion defects, of the circular storage tank bottom plate structure.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

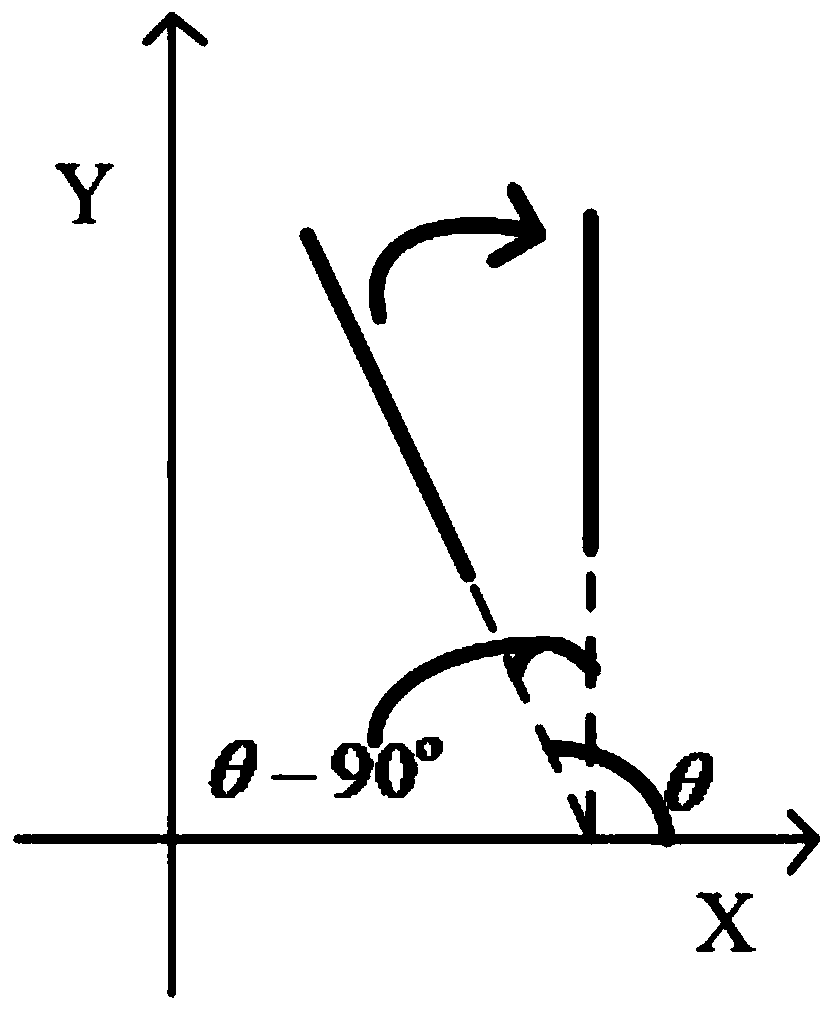

A Method of Irregular Workpiece Detection Based on Machine Vision

InactiveCN113706537BAvoid missing detectionImprove detection accuracyDetection of fluid at leakage pointImage enhancementMachine visionClassical mechanics

The invention relates to a method for detecting irregular workpieces based on machine vision. By acquiring images of irregular workpieces and performing edge detection, the edges of the workpiece images are converted into polar coordinates, and the polar coordinates are set in different positions by Hough transform. θ The intersection of the connecting lines in the horizontal direction is used as a new two-dimensional plane, and the missing points are obtained by judging the intersection points according to the information gain of all connecting points in the two-dimensional plane. If there are no bubbles in the inspected area, there is no defect in the workpiece. If there are bubbles in the missed inspection area, the edge area of the bubbles in the missed inspection area is obtained, and the volume and sum of all bubbles in adjacent frames and single-frame images are analyzed according to the edge area of the bubbles. Position change, determine the exact position of the missed detection defect, based on machine vision, comprehensive analysis, more accurate positioning of the defect position of the irregular detection workpiece, high detection accuracy and strong practicability.

Owner:NANTONG LANGGAO PETROCHEM EQUIP

Modified Omnifocus Imaging Method for Array Detection of Anisotropic Weld Defects

ActiveCN107085038BAccurate defect locationSolve the problem of inaccurate defect locationAnalysing solids using sonic/ultrasonic/infrasonic wavesPropagation timeClassical mechanics

The invention discloses a corrected full-focus imaging method for anisotropy weld seam defect array detection and belongs to the field of nondestructive testing. The method comprises the steps of processing full-matrix data received by a one-dimensional linear array sensor of a phased array, taking material anisotropy into consideration, calculating out group velocity of ultrasonic waves in an anisotropy medium, then utilizing a ray tracing algorithm based on a Fermat principle to calculate out propagation time of the ultrasonic waves in the anisotropy medium and finally achieving full-focus imaging of anisotropy weld seams. The method has the advantages that weld seam anisotropy is taken into consideration, the high-operation-efficiency ray tracing method based on the Fermat principle and the full-focus imaging method are combined, the problem that general full-focus imaging has inaccuracy in locating defects in the anisotropy medium is solved, and meanwhile, detection precision of the phased array in the anisotropy medium is improved.

Owner:BEIJING UNIV OF TECH

Post insulator flaw inspection device and usage method thereof

ActiveCN105116058AFree from damageNot hurtMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringChassis

Owner:STATE GRID CORP OF CHINA +1

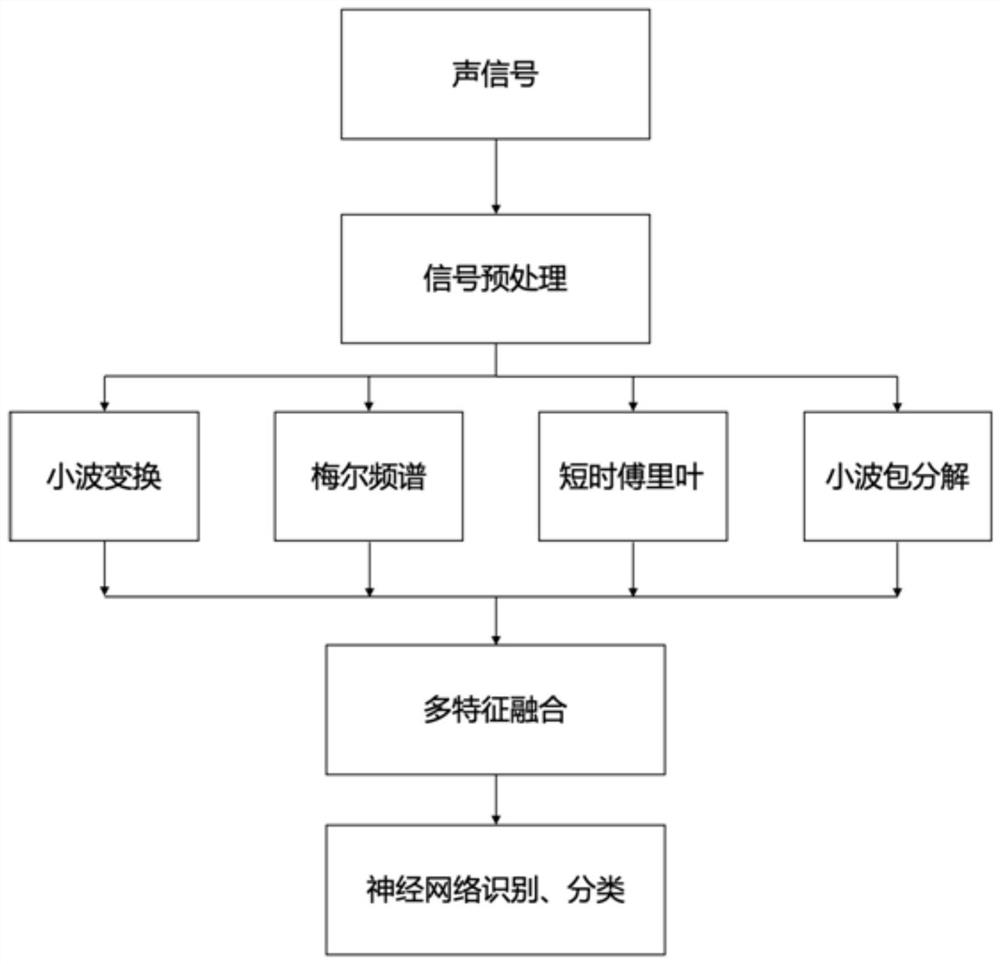

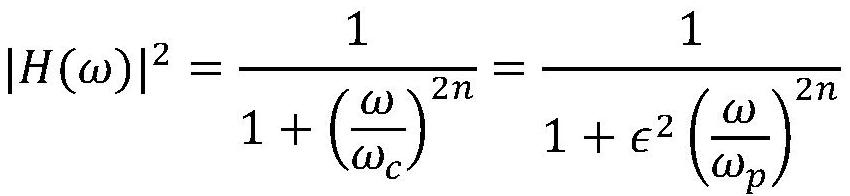

CMT welding defect identification method based on acoustic signal multi-feature fusion

PendingCN113537069AImprove accuracyAccurate defect locationWelding/cutting auxillary devicesProcessing detected response signalWavelet packet decompositionFeature fusion

The invention relates to the field of transportation equipment manufacturing, and particularly discloses a CMT welding defect identification method based on sound signal multi-feature fusion, and the method comprises the steps: taking a CMT welding defect as an analysis target in the analysis of a welding process signal, combining the existing data, and considering various conditions of faults and defects; adopting a plurality of mainstream signal analysis methods to carry out feature extraction such as wavelet transform, wavelet packet decomposition, Mel spectrum and short-time Fourier transform on sound signals; after feature extraction, fusing a plurality of signal features, and adopting a plurality of neural networks to carry out identification analysis on defect parts. Effective technical support is provided for analyzing welding acoustic signals so as to position defects, and the purpose of accurately positioning defect positions and defect types is achieved.

Owner:DALIAN JIAOTONG UNIVERSITY

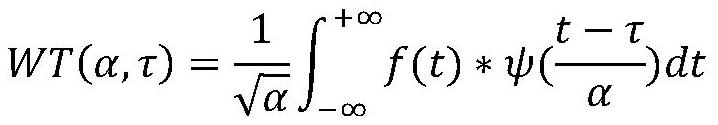

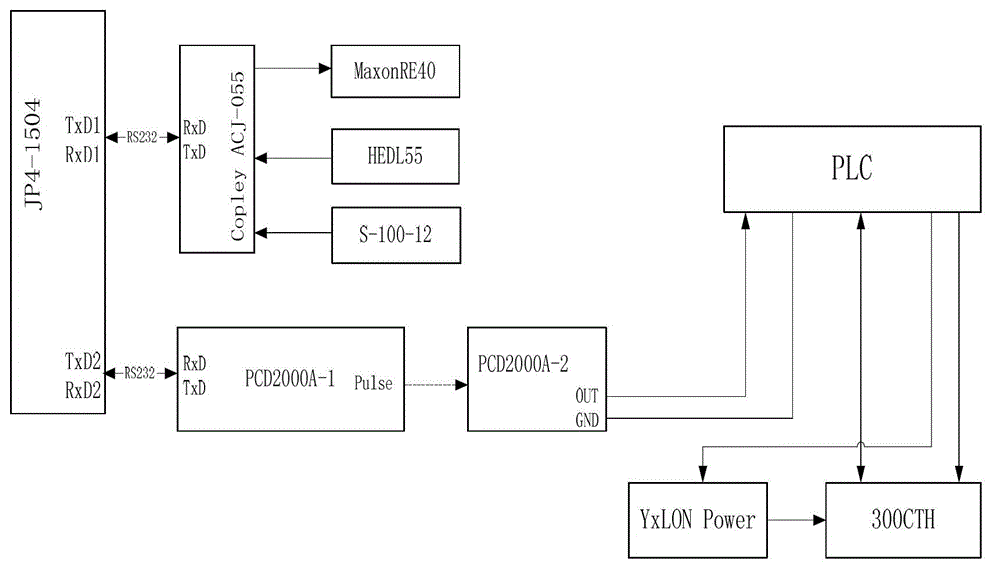

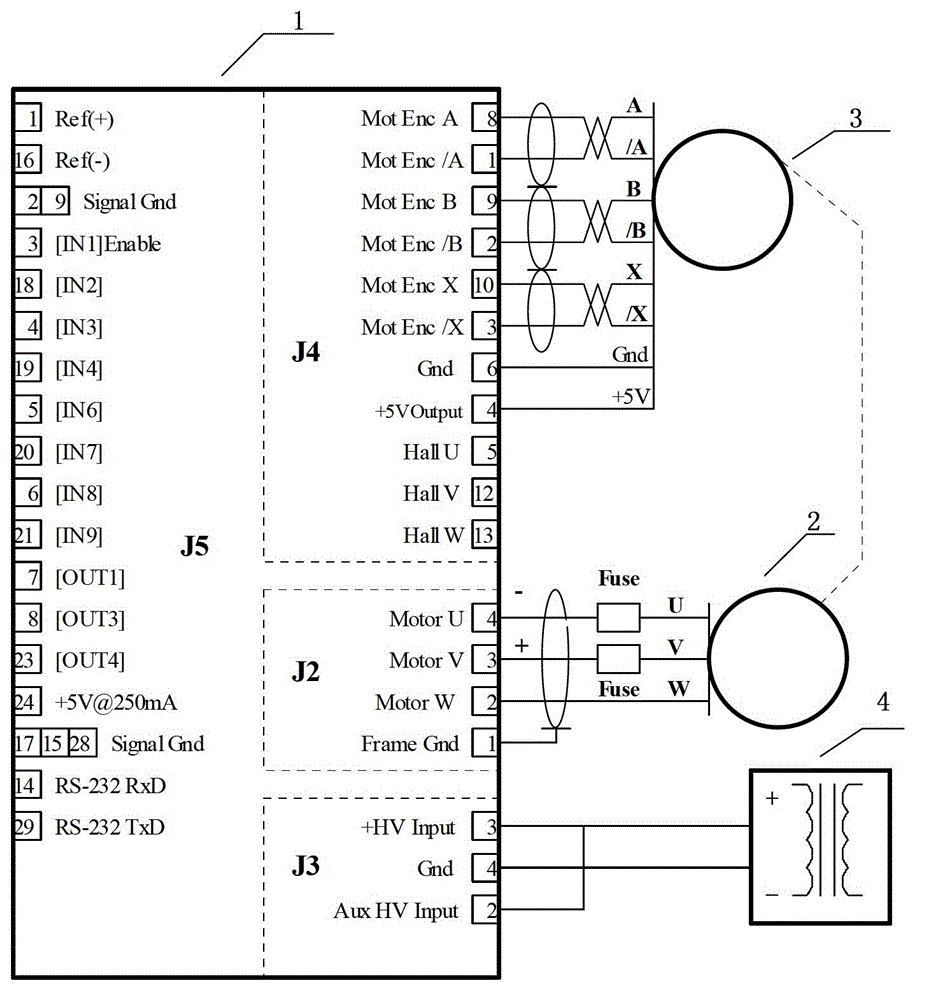

Synchronous control system for digital rays of circular welding seam on pipe

ActiveCN102289215BSolve the technical problems of exposure synchronization controlEasy to detectProgramme control in sequence/logic controllersDigital RaySynchronous motor

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Defect location method for t-shaped stringers based on ultrasonic guided waves

ActiveCN108152375BAccurate defect locationFast defect locationAnalysing solids using sonic/ultrasonic/infrasonic wavesWave structureEngineering

The invention discloses a method for positioning defects of a T-type stringer on the basis of ultrasonic guided waves. The method comprises the following specific steps of: (S1) analyzing by the semi-analytical finite element method theory to obtain a guided-wave characteristic propagating on the T-type stringer; (S2) selecting all frequencies and modes for detection by frequency dispersion curvesand wave structures; (S3) carrying out excitation and reception of guided waves on the ends of the T-type stringer along guided-wave sensors arranged along the circumferential direction, wherein thesensors are fixed by clamps and are coupled with the surface of the stringer; (S4) using signal excitation equipment to generate guided-wave signals with the selected frequencies; (S5) determining longitudinal positions of the damages by time difference between peak values of echo signals and excitation signals according to the excitation frequency and the mode wave velocity selected every time, and determining positions of horizontal defects according to detection results of all frequencies and modes with different horizontal-defect sensitivity.

Owner:DALIAN UNIV OF TECH

A flaw detection device for post insulators

ActiveCN105116058BFree from damageNot hurtMaterial analysis using sonic/ultrasonic/infrasonic wavesMott insulatorTesting equipment

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com