Ultrasonic testing method and ultrasonic testing system for internal defects of GIS epoxy insulator

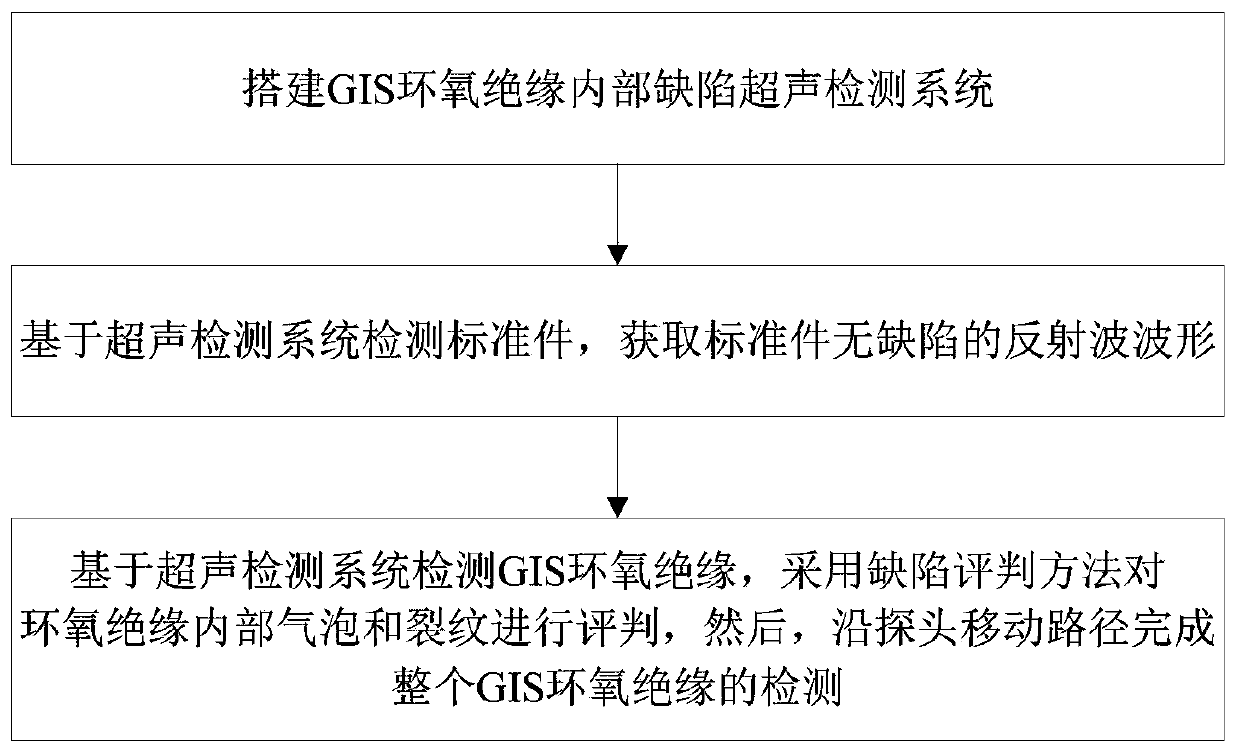

An epoxy insulation and ultrasonic testing technology, which is applied to the analysis of solids, instruments, and analysis materials using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as low detection efficiency, inaccurate positioning, and large equipment volume, and achieve detection accuracy and efficiency. High, accurate defect positioning, and the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following describes the present invention in further detail through specific embodiments, but the embodiments of the present invention are not limited thereto.

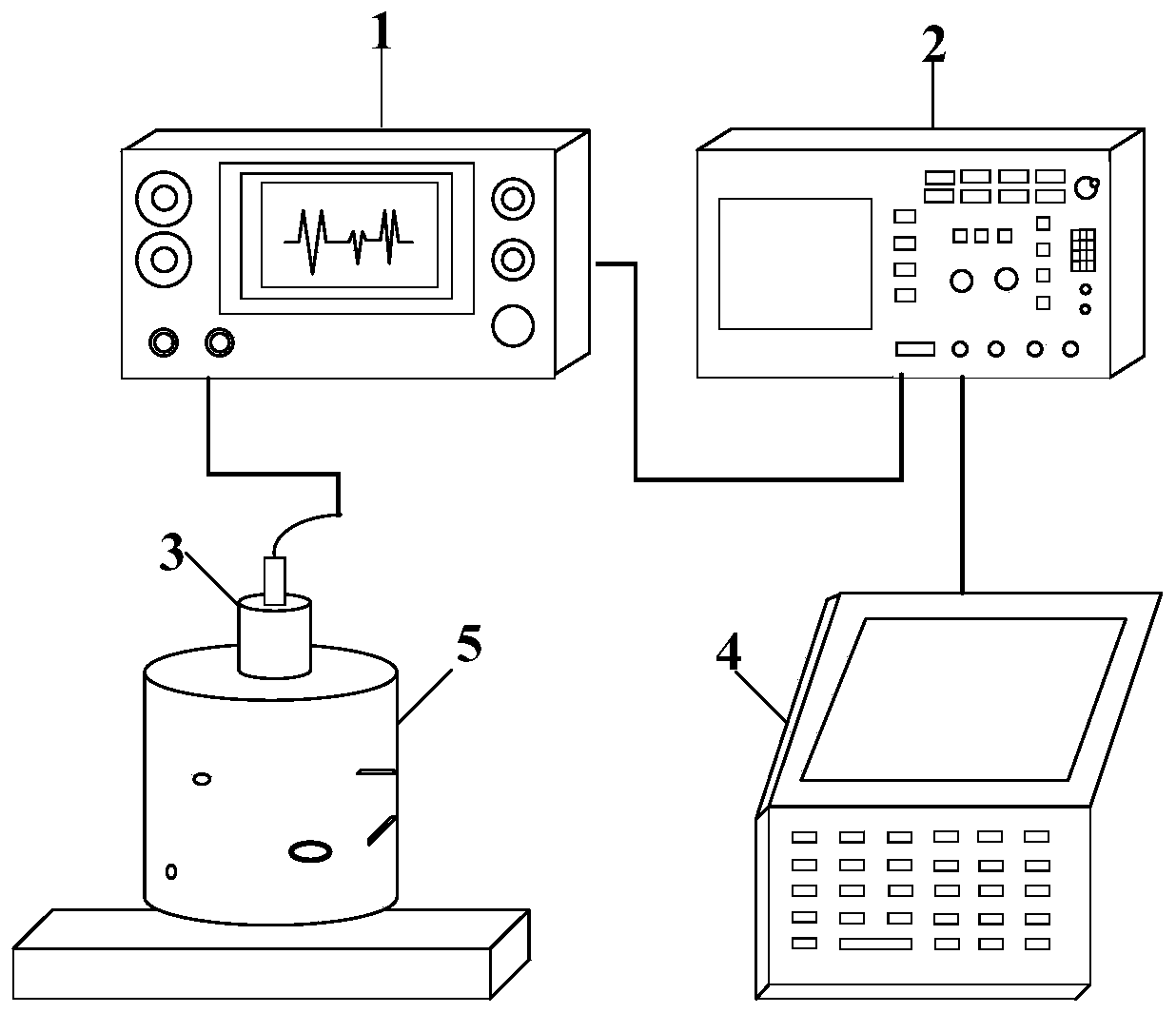

[0044] The detection principle of the ultrasonic detection method for the internal defects of GIS epoxy insulation is: the ultrasonic wave emitted by the ultrasonic longitudinal wave straight probe enters the epoxy resin perpendicularly, there is no defect in the propagation process, and it reaches the bottom surface of the epoxy resin. When a crack occurs, the ultrasonic wave is reflected and refracted at the epoxy-bubble or epoxy-crack interface, and the reflected part of the ultrasonic wave returns along the original path, and the defect reflected wave is displayed on the oscilloscope.

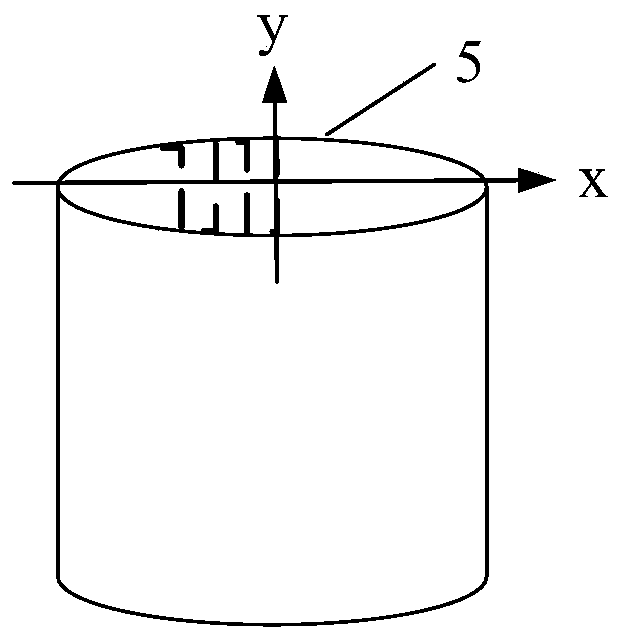

[0045] The standard parts and epoxy insulation to be tested are epoxy composite samples of the same material and technology as the GIS basin insulator. There are no bubbles and cracks inside the standard parts, and the inside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com