Patents

Literature

106 results about "Pre delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

British Dictionary definitions for pre-delivery. delivery. noun plural-eries. the act of delivering or distributing goods, mail, etc; something that is delivered (as modifier) a delivery service; the act of giving birth to a child she had an easy delivery.

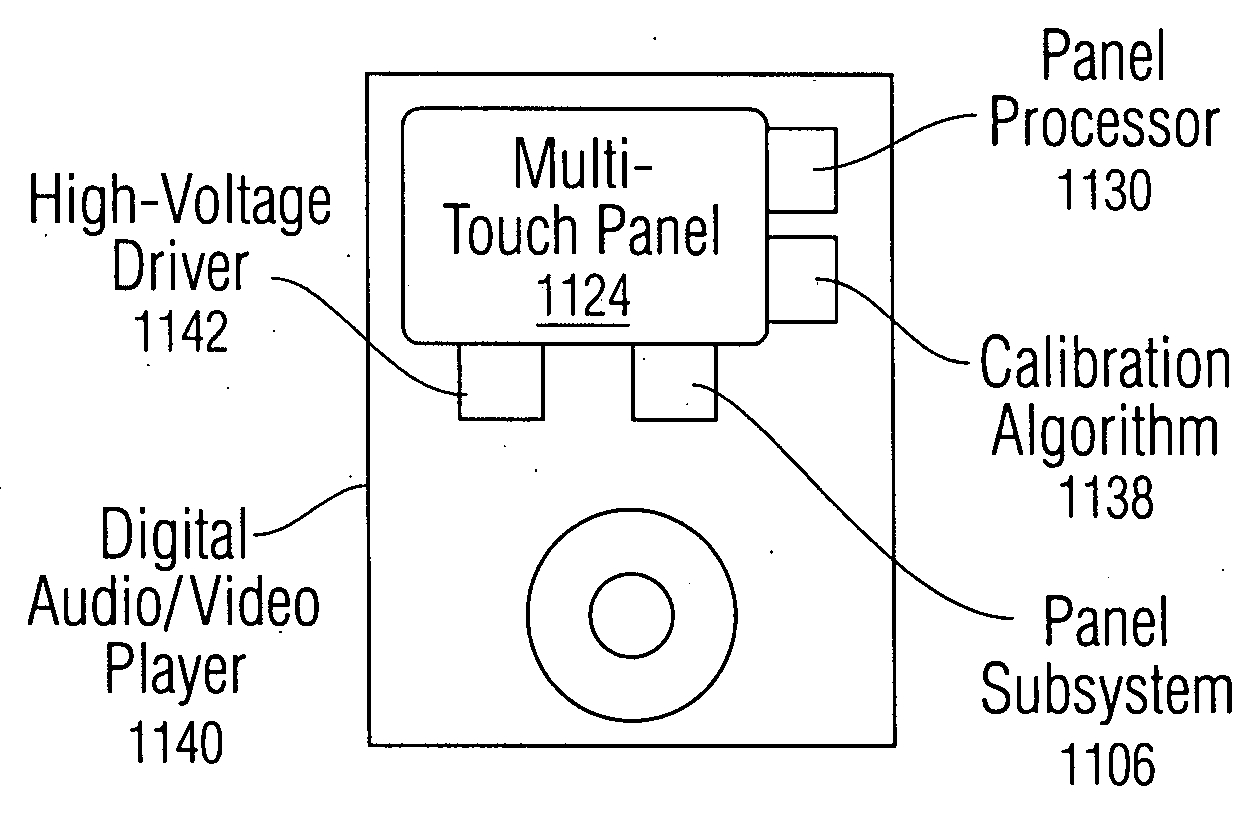

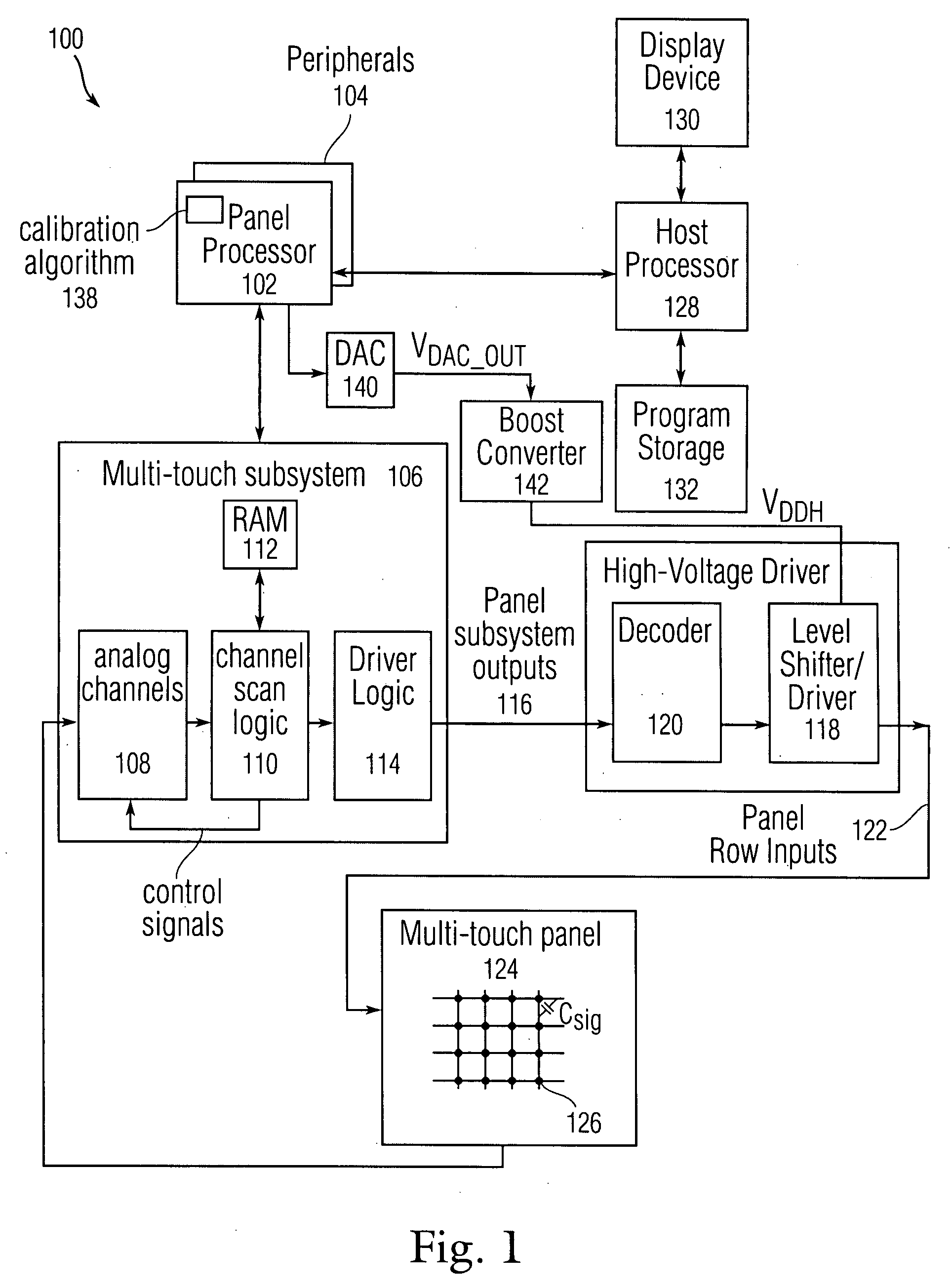

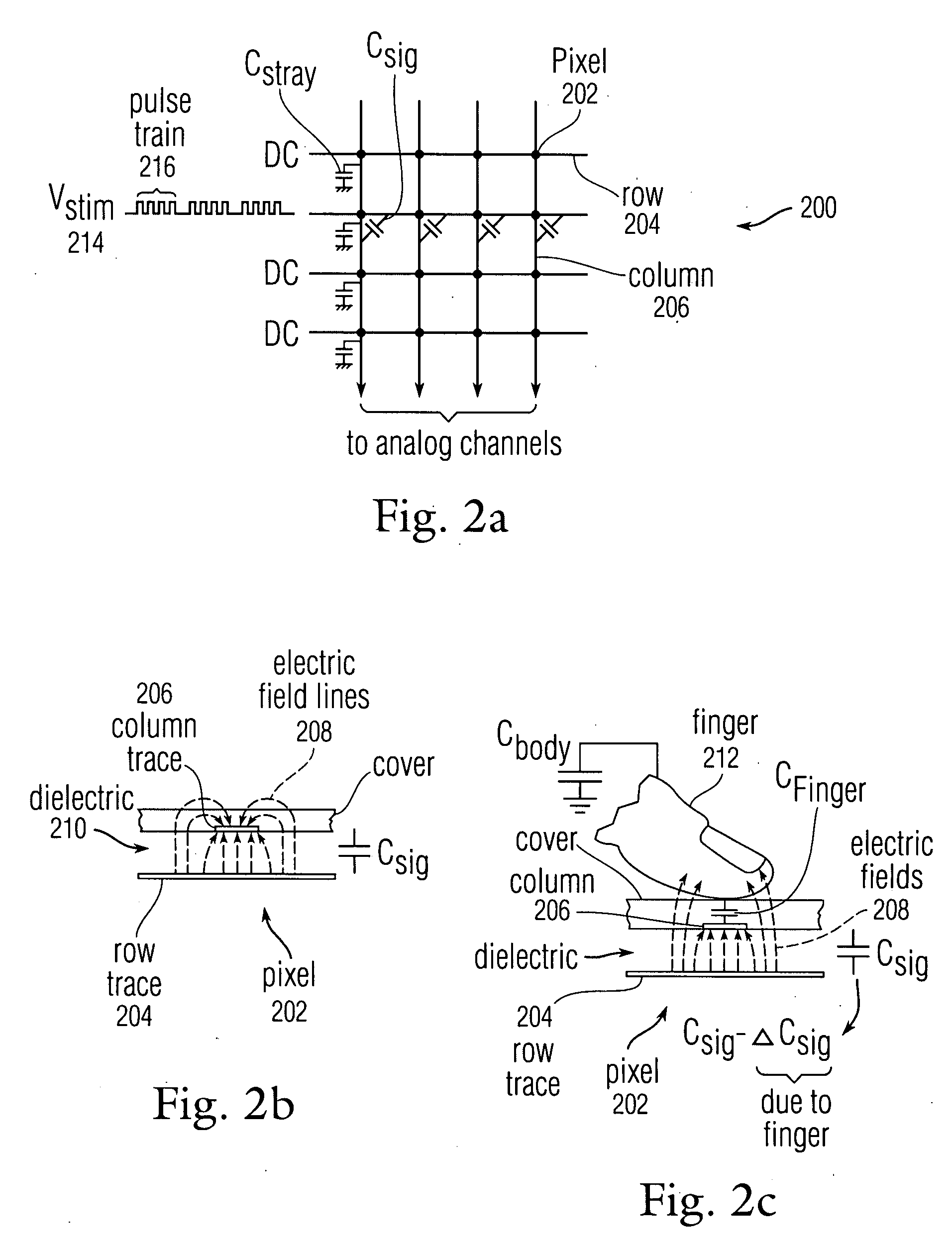

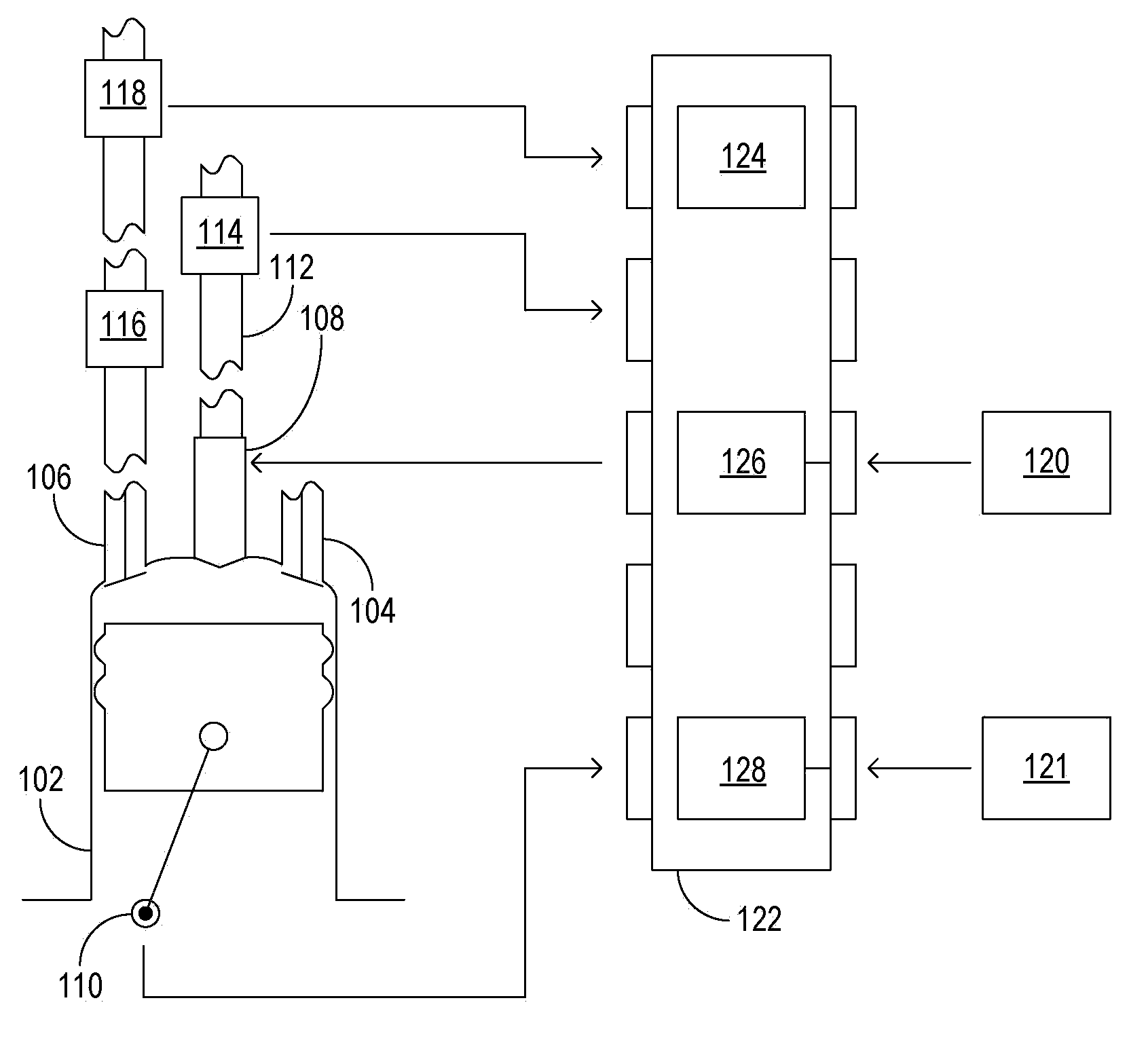

Periodic sensor autocalibration and emulation by varying stimulus level

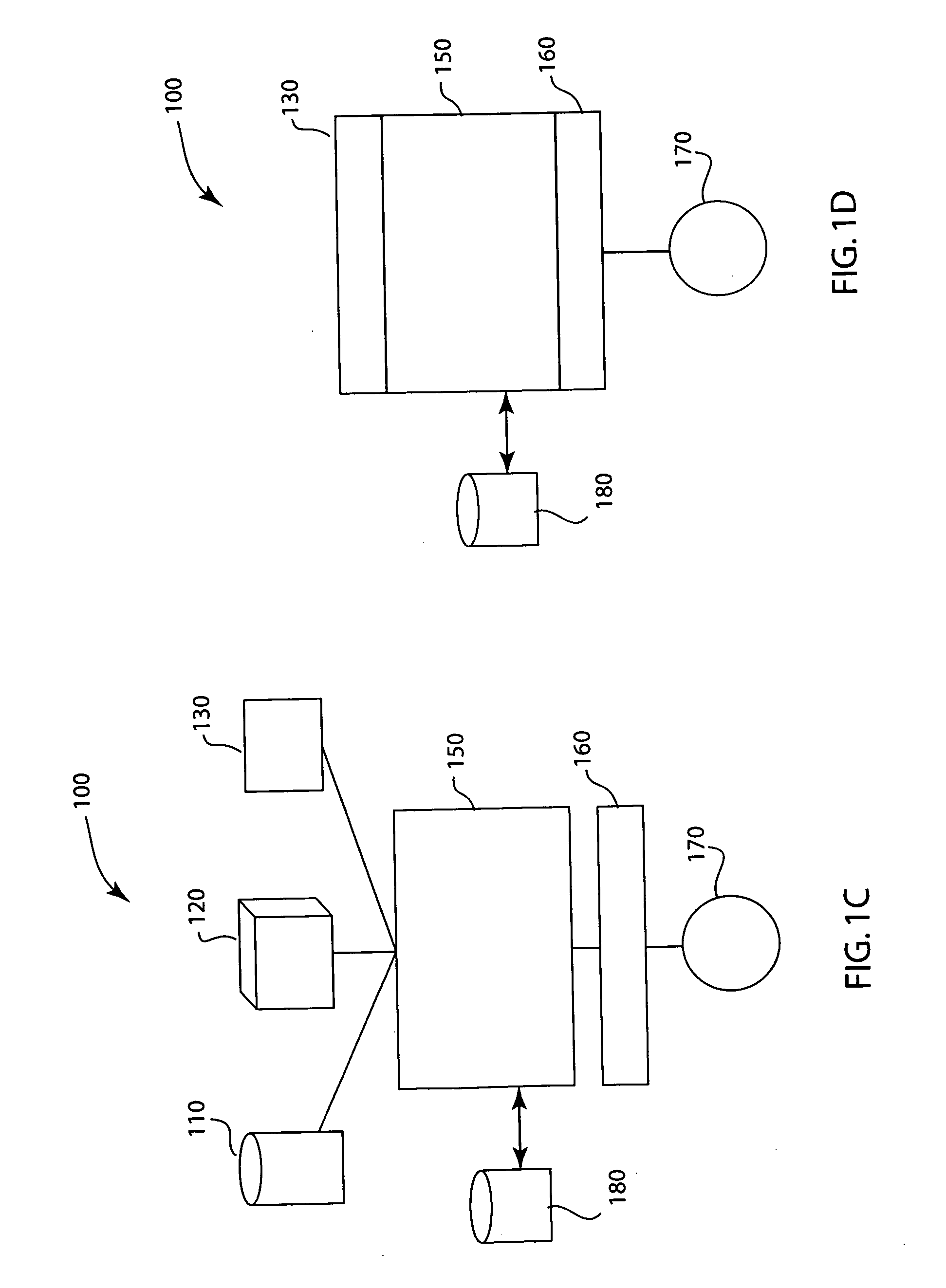

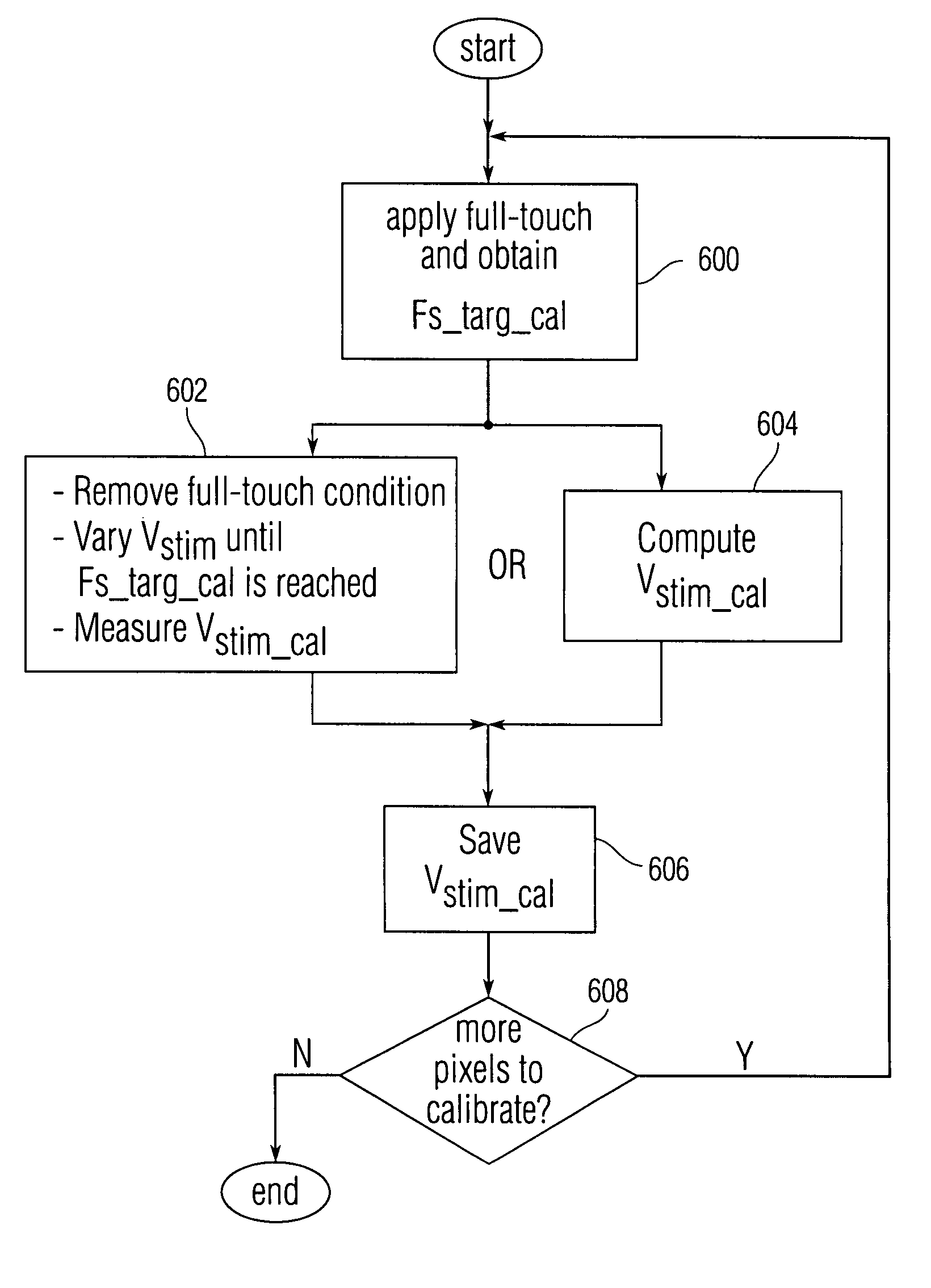

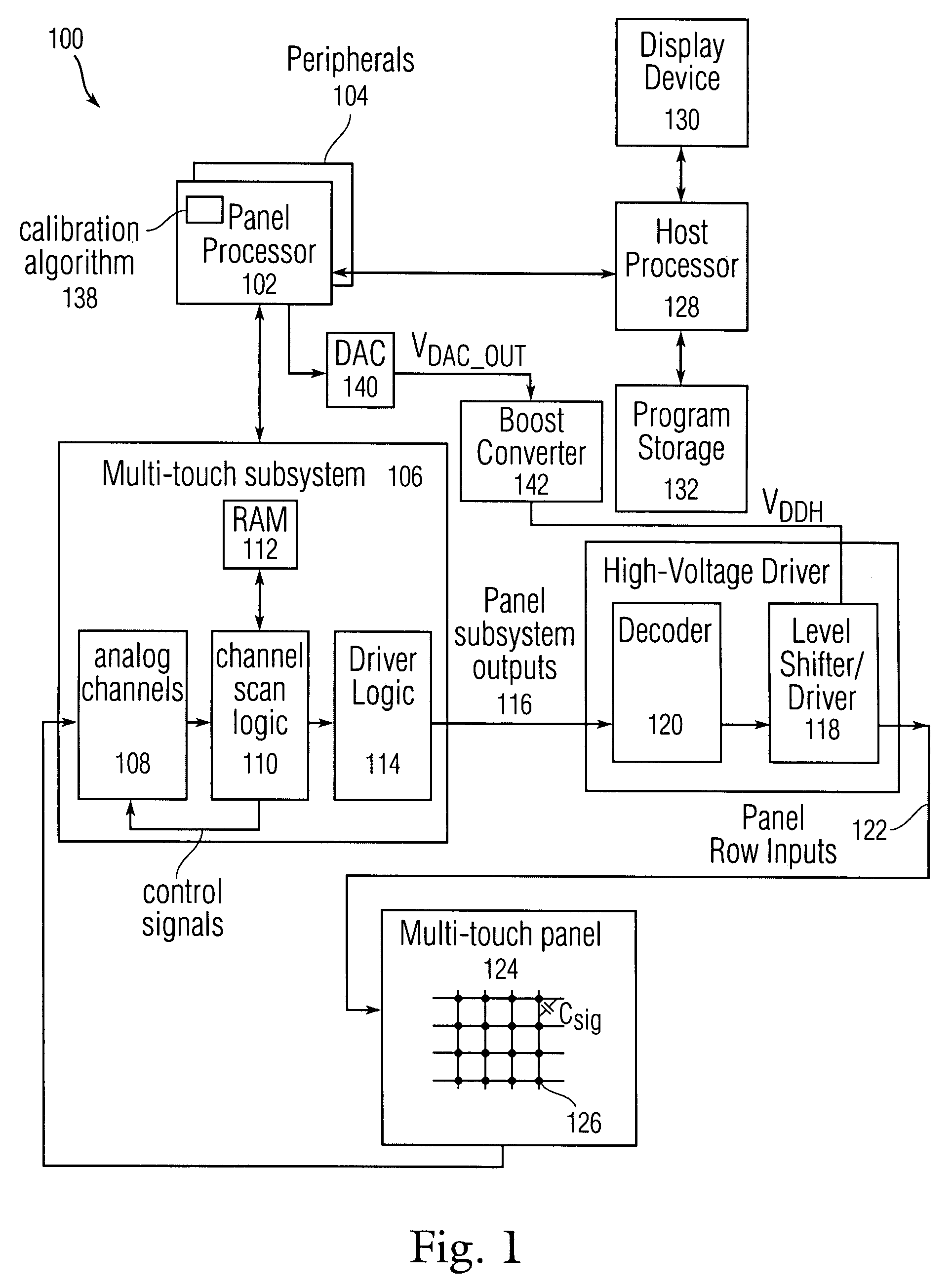

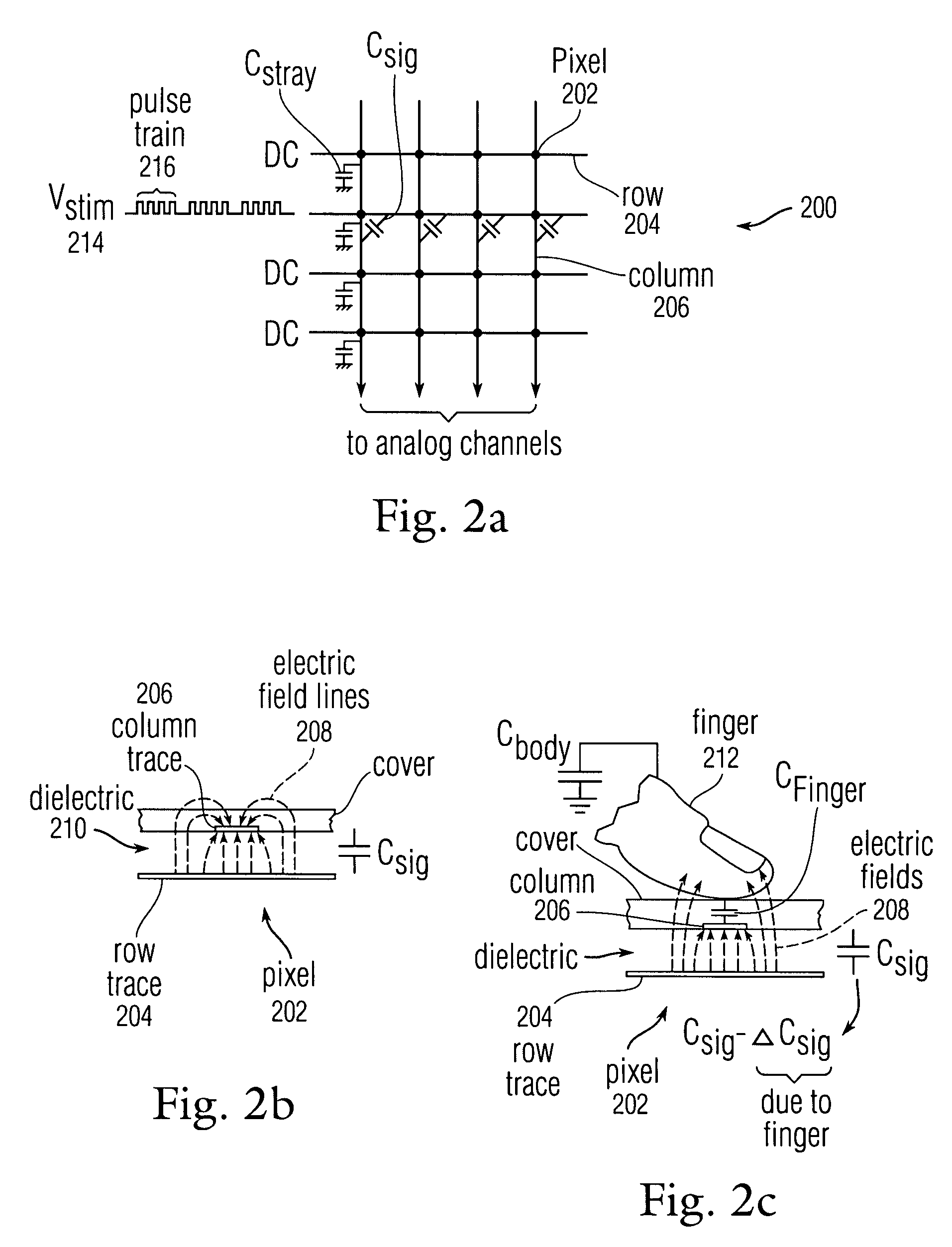

The automatic calibration of a sensor panel is disclosed by varying the amplitude of an input stimulus Vstim to simulate a full-touch condition and calibrating each pixel of the sensor panel in accordance with the difference between the simulated full-touch condition and a baseline full-touch condition. To accomplish this, a baseline full scale output FS_targ_cal can be measured at during pre-delivery calibration for each pixel using a test fixture capable of applying a no-touch to full-touch condition given a nominal Vstim. A full-touch condition can then be emulated for each pixel by lowering Vstim until the current full scale output FS_targ_current equals FS_targ_cal, and determining the Vstim value Vstim_cal at that point. During field calibration, Vstim_cal can be applied to each pixel to simulate a full-touch condition, and FS_targ_current can be obtained and compared against FS_targ_cal. Each analog channel can then be tuned so that in subsequent full-touch conditions, FS_targ_current will approximately equal FS_targ_cal.

Owner:APPLE INC

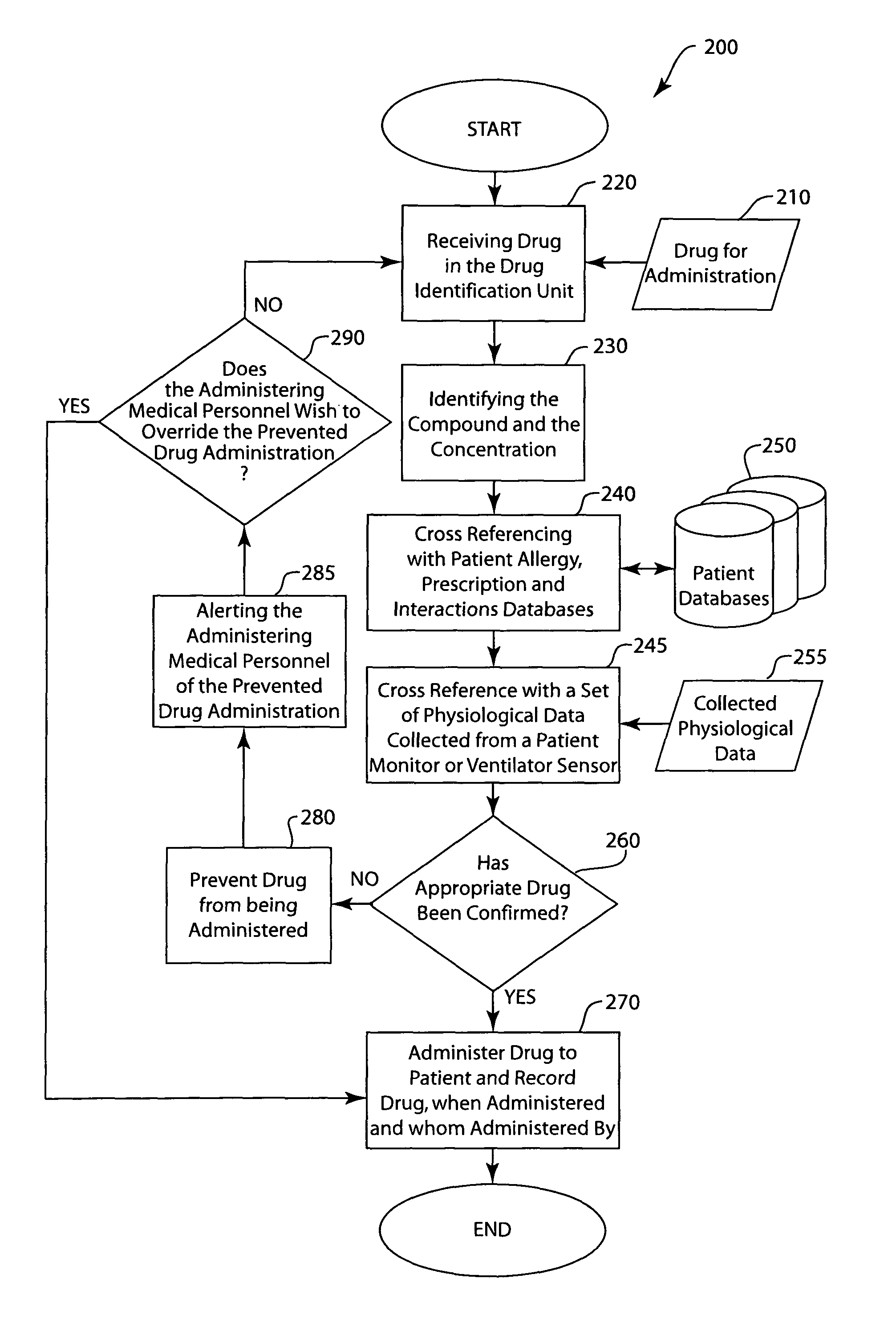

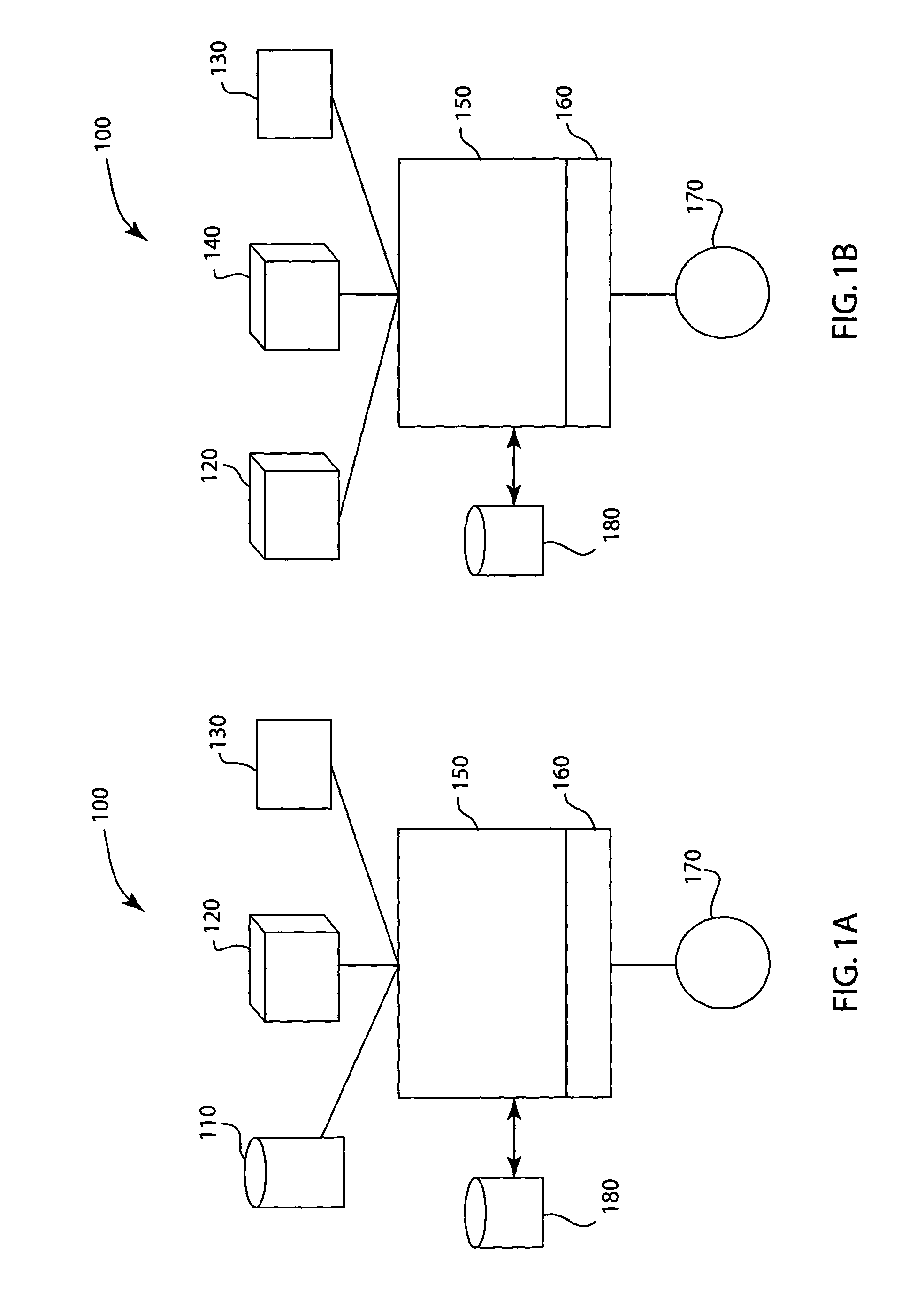

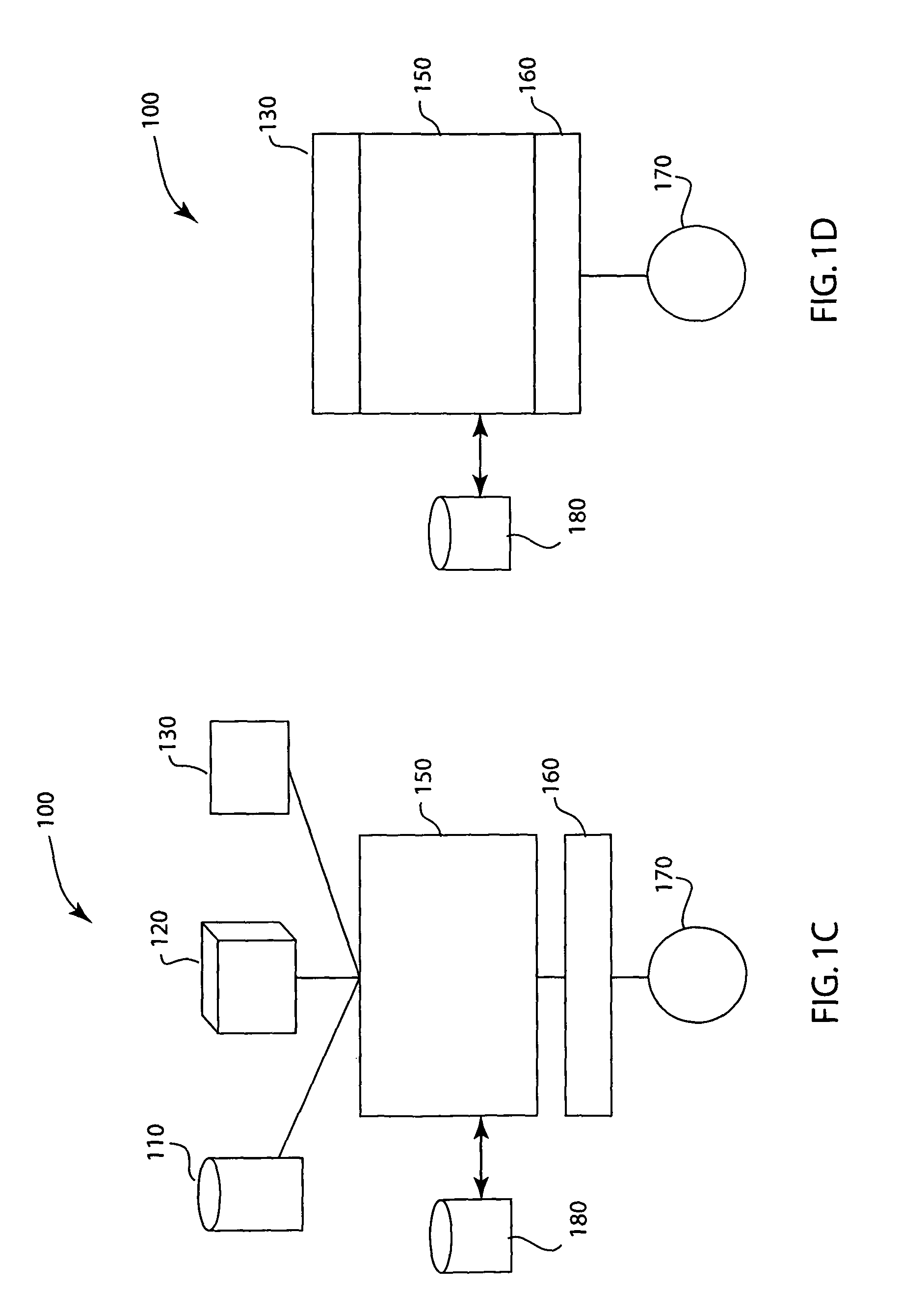

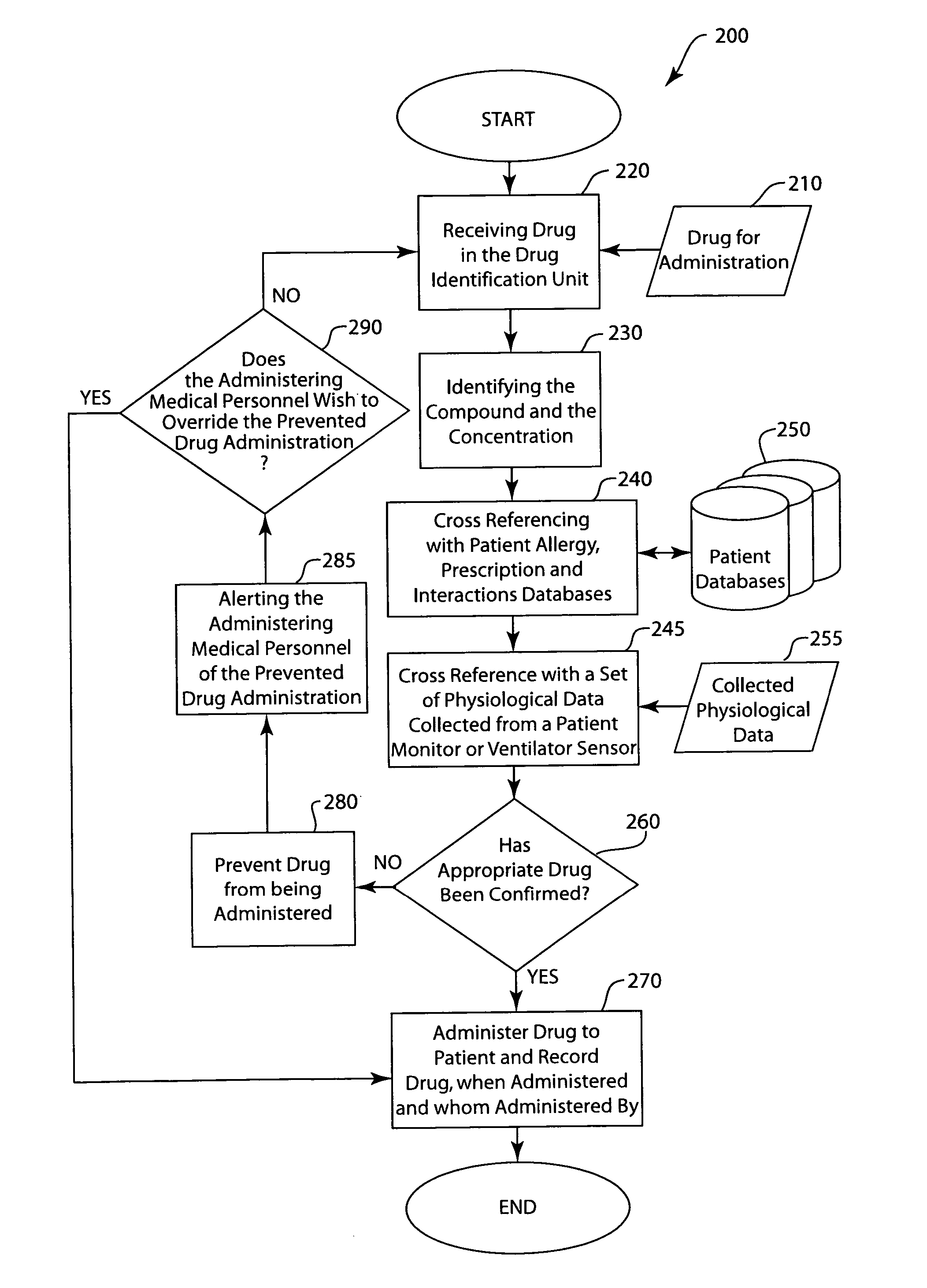

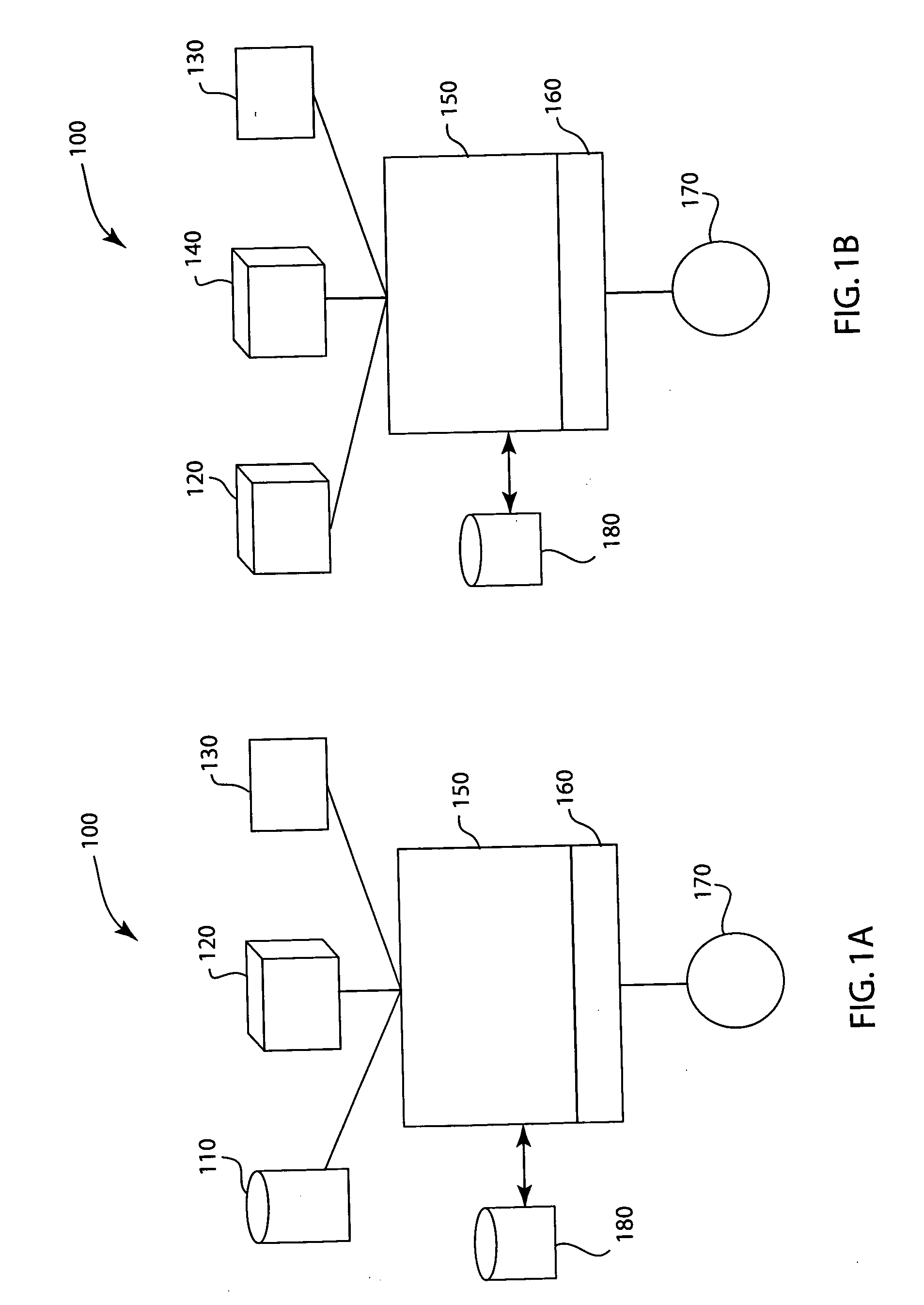

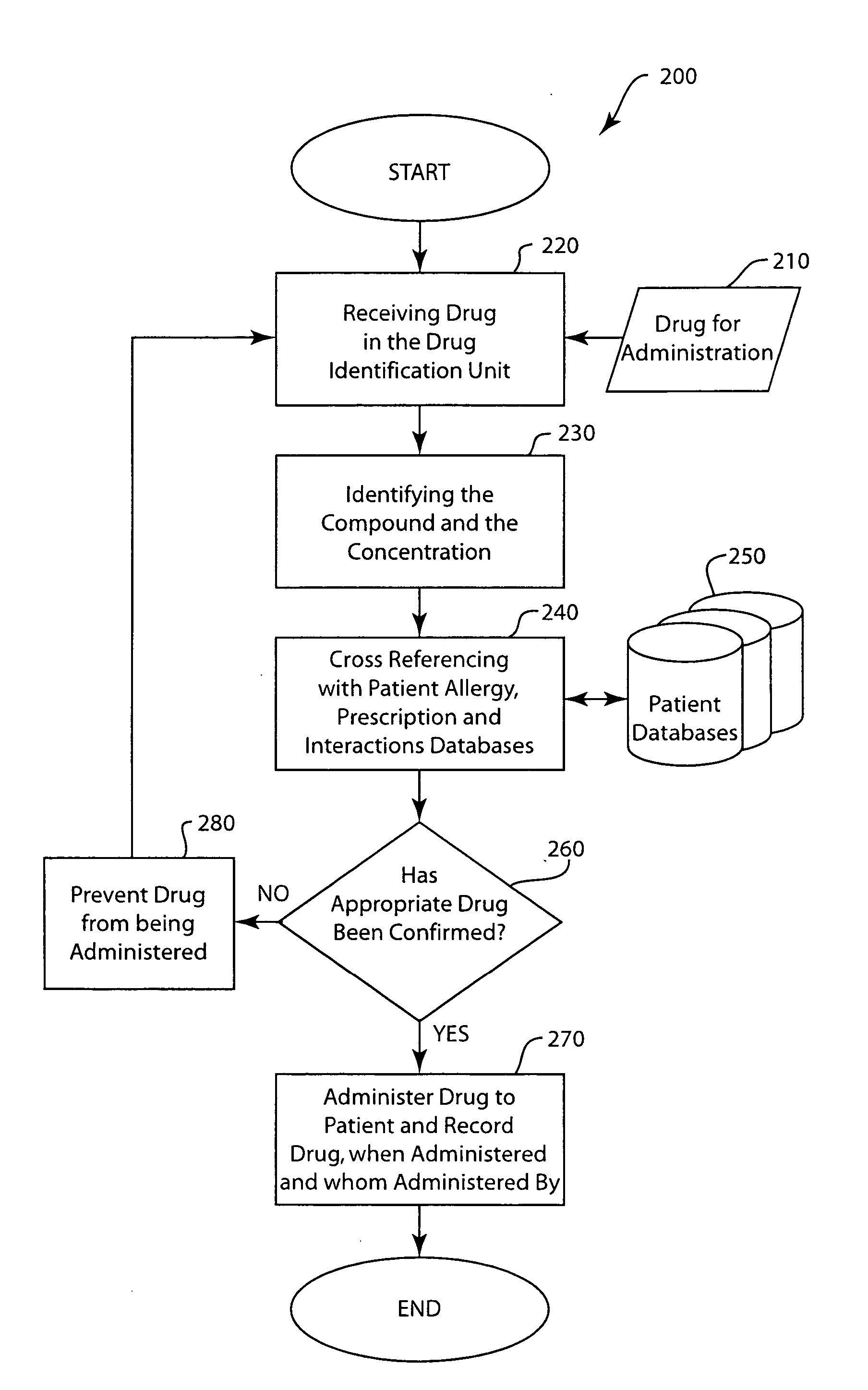

Injected drug identification and fail-safe system

The present invention is a system and method of pre-delivery drug identification. The system and method is implemented where drugs are being administered, such as in a hospital or clinic, and identifies the drug being administered to the patient before the drug reaches the patient. The system and method may utilize a sensor used for other physiologic monitoring to identify the drug. After identification, the system and method is configured to cross-reference the identified drug with the patient's prescription and allergy information, and to prevent delivery to the patient, if necessary. The system and method also utilizes data collected from the patient with a physiological monitor or a ventilator sensor to further determine whether the drug is appropriate for the patient. The method and system may also include an override system for medical personnel. The method described may be carried out by a software application.

Owner:GENERAL ELECTRIC CO

Injected drug identification and fail-safe system

ActiveUS20060287887A1Prevented being administeredData processing applicationsDrug and medicationsAllergyInjected drug

The present invention is a system and method of pre-delivery drug identification. The system and method is implemented where drugs are being administered, such as in a hospital or clinic, and identifies the drug being administered to the patient before the drug reaches the patient. The system and method may utilize a sensor used for other physiologic monitoring to identify the drug. After identification, the system and method is configured to cross-reference the identified drug with the patient's prescription and allergy information, and to prevent delivery to the patient, if necessary. The system and method also utilizes data collected from the patient with a physiological monitor or a ventilator sensor to further determine whether the drug is appropriate for the patient. The method and system may also include an override system for medical personnel. The method described may be carried out by a software application.

Owner:GENERAL ELECTRIC CO

Periodic sensor autocalibration and emulation by varying stimulus level

The automatic calibration of a sensor panel is disclosed by varying the amplitude of an input stimulus Vstim to simulate a full-touch condition and calibrating each pixel of the sensor panel in accordance with the difference between the simulated full-touch condition and a baseline full-touch condition. To accomplish this, a baseline full scale output FS_targ_cal can be measured at during pre-delivery calibration for each pixel using a test fixture capable of applying a no-touch to full-touch condition given a nominal Vstim. A full-touch condition can then be emulated for each pixel by lowering Vstim until the current full scale output FS_targ_current equals FS_targ_cal, and determining the Vstim value Vstim_cal at that point. During field calibration, Vstim_cal can be applied to each pixel to simulate a full-touch condition, and FS_targ_current can be obtained and compared against FS_targ_cal. Each analog channel can then be tuned so that in subsequent full-touch conditions, FS_targ_current will approximately equal FS_targ_cal.

Owner:APPLE INC

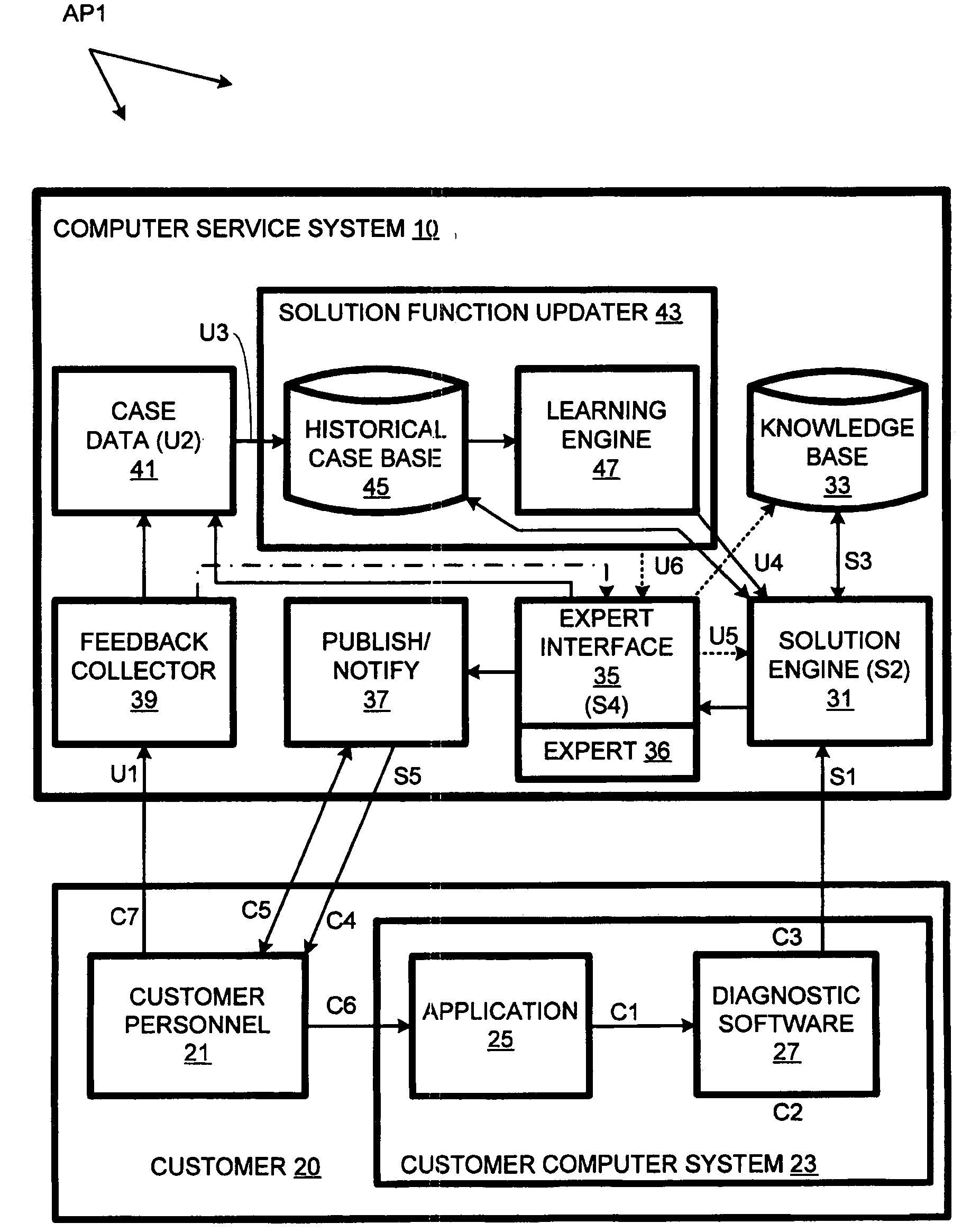

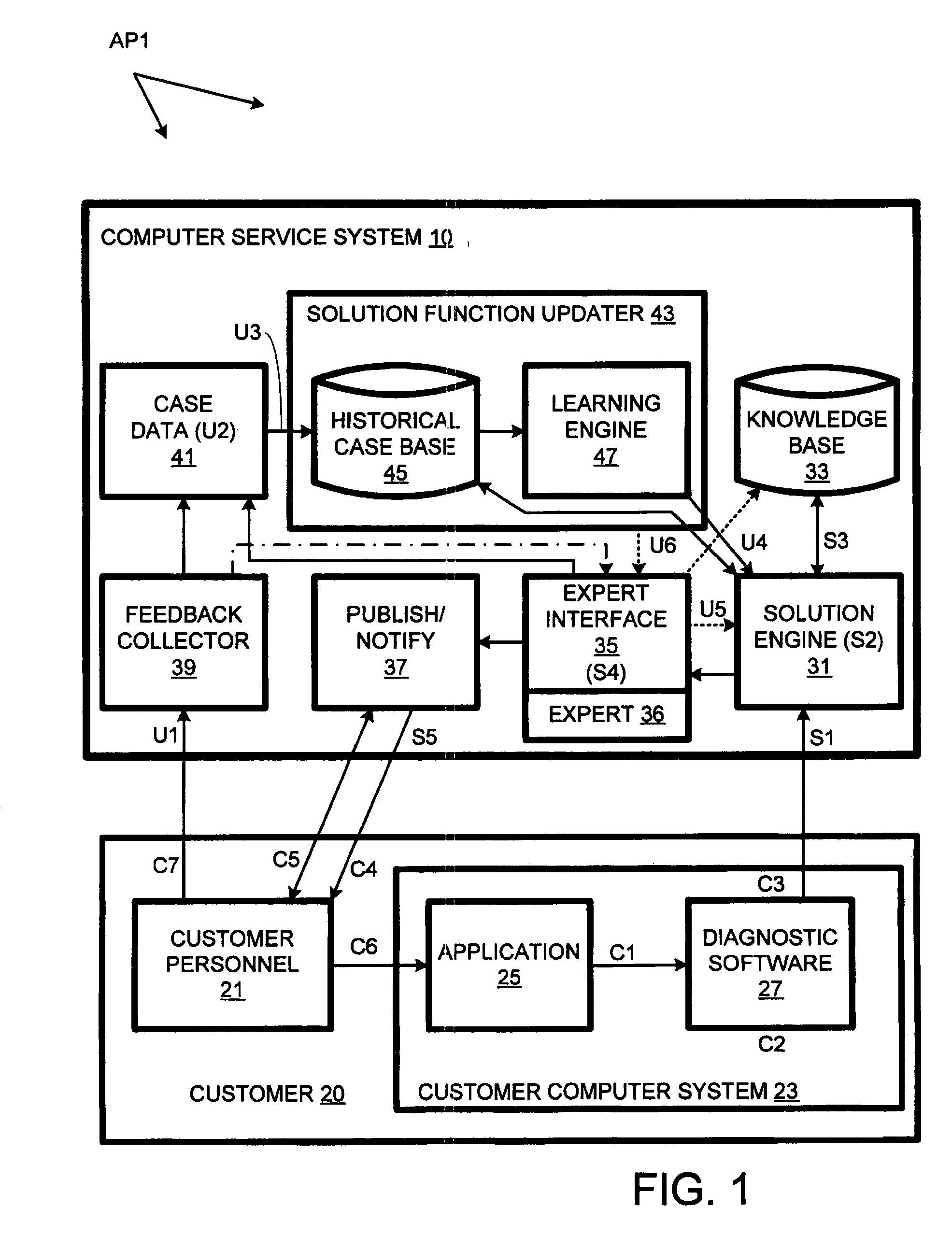

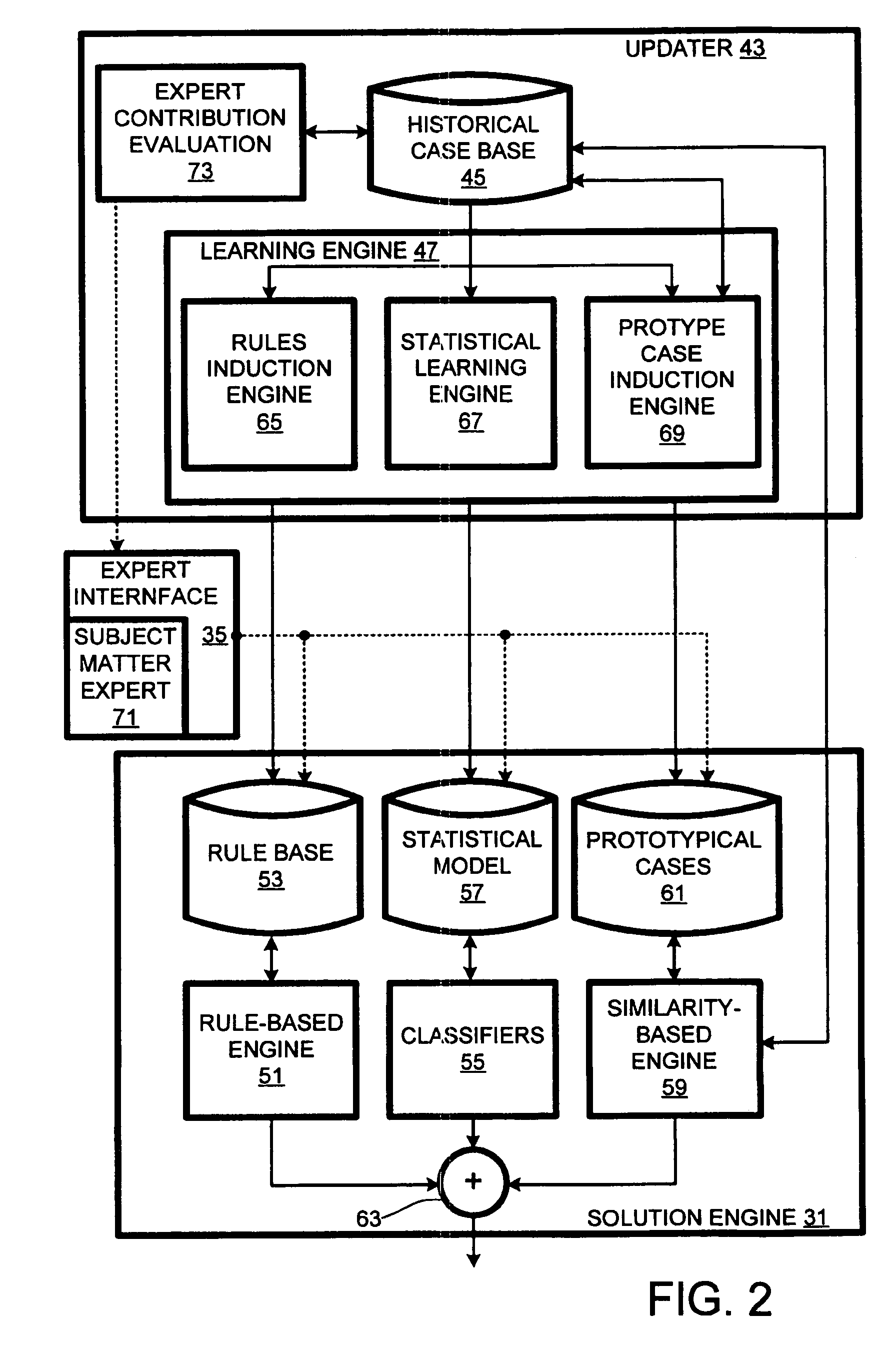

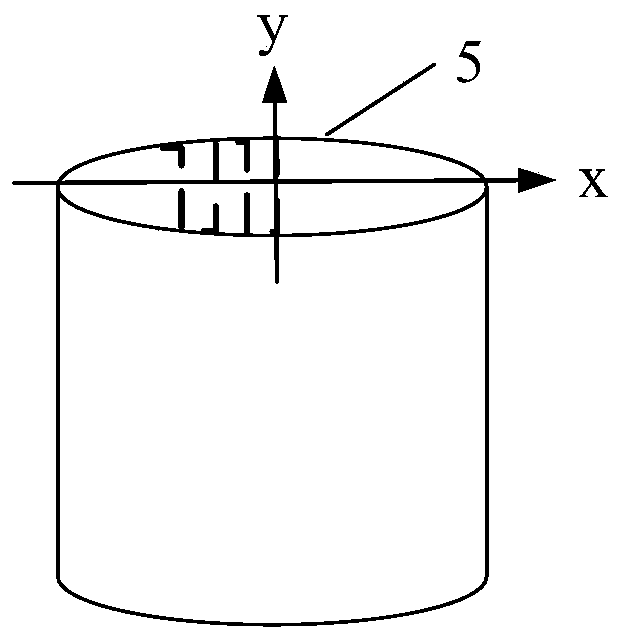

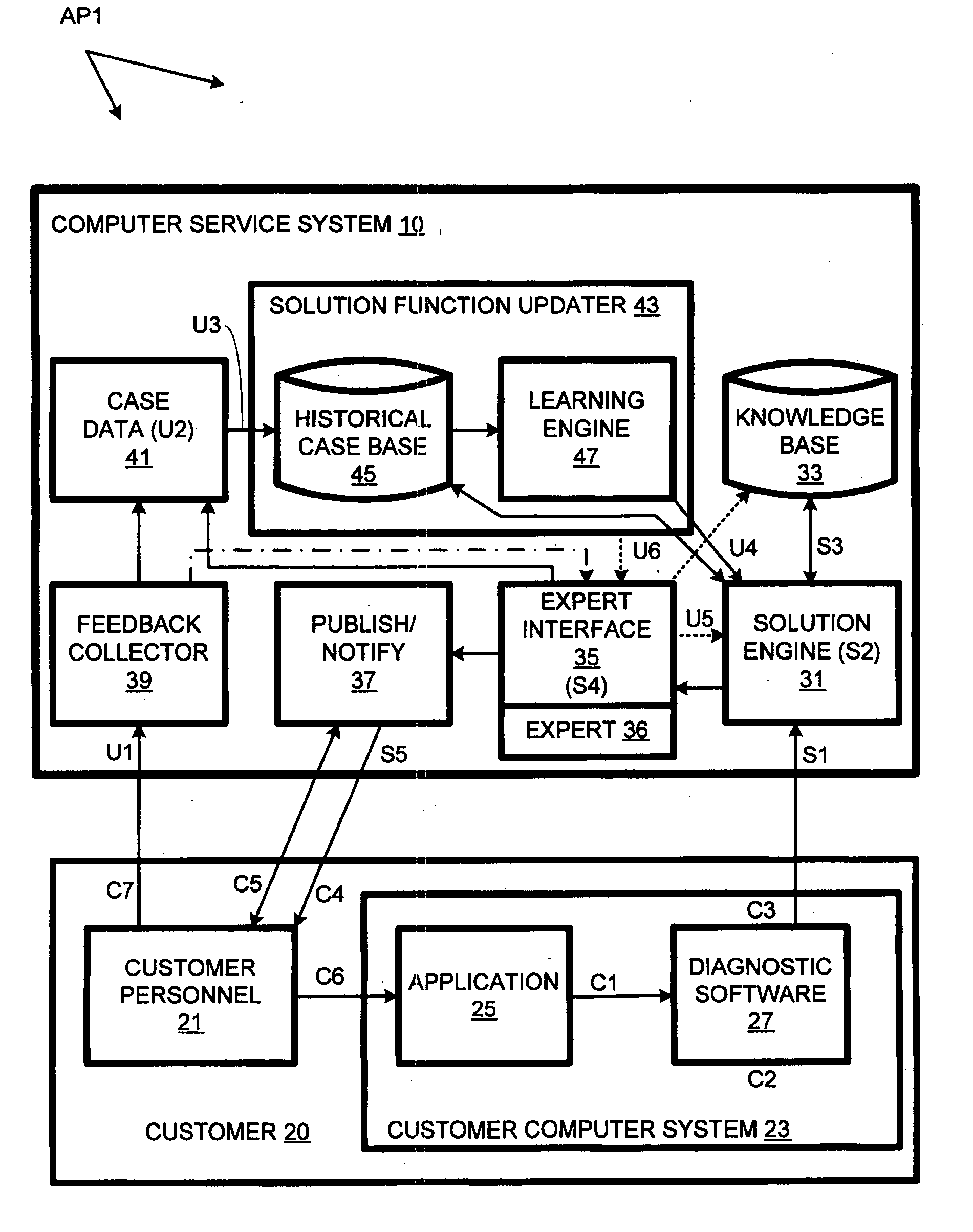

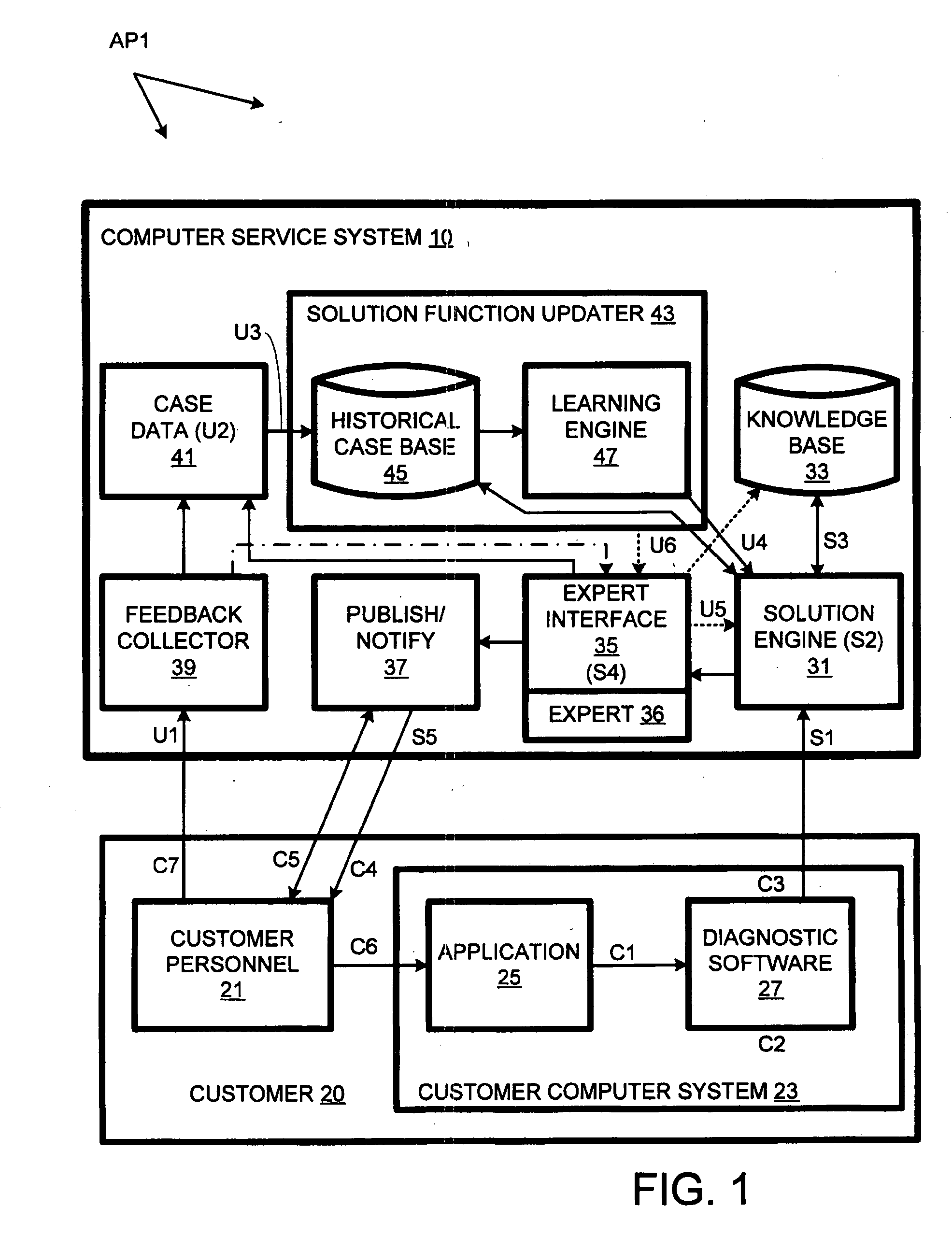

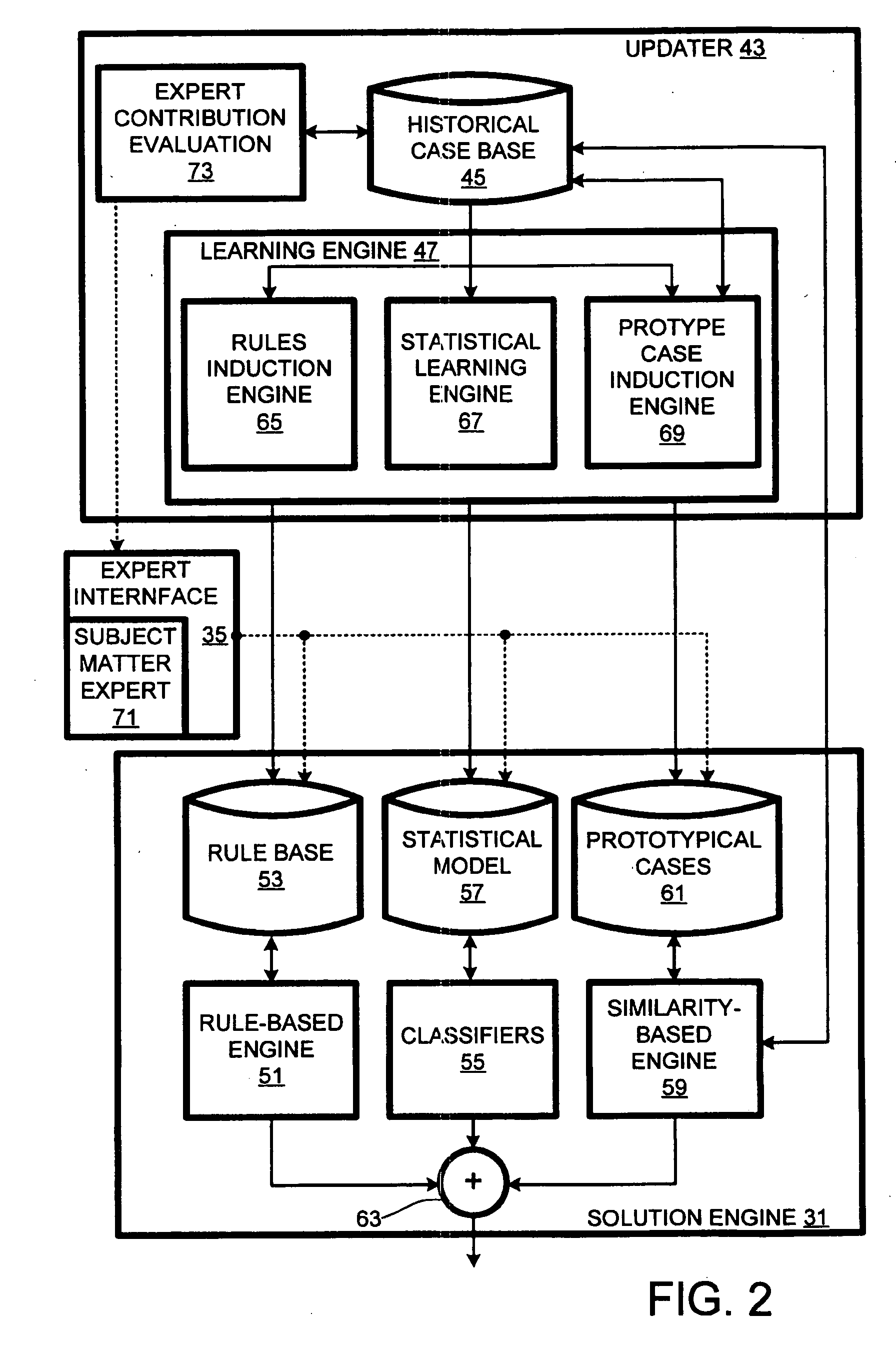

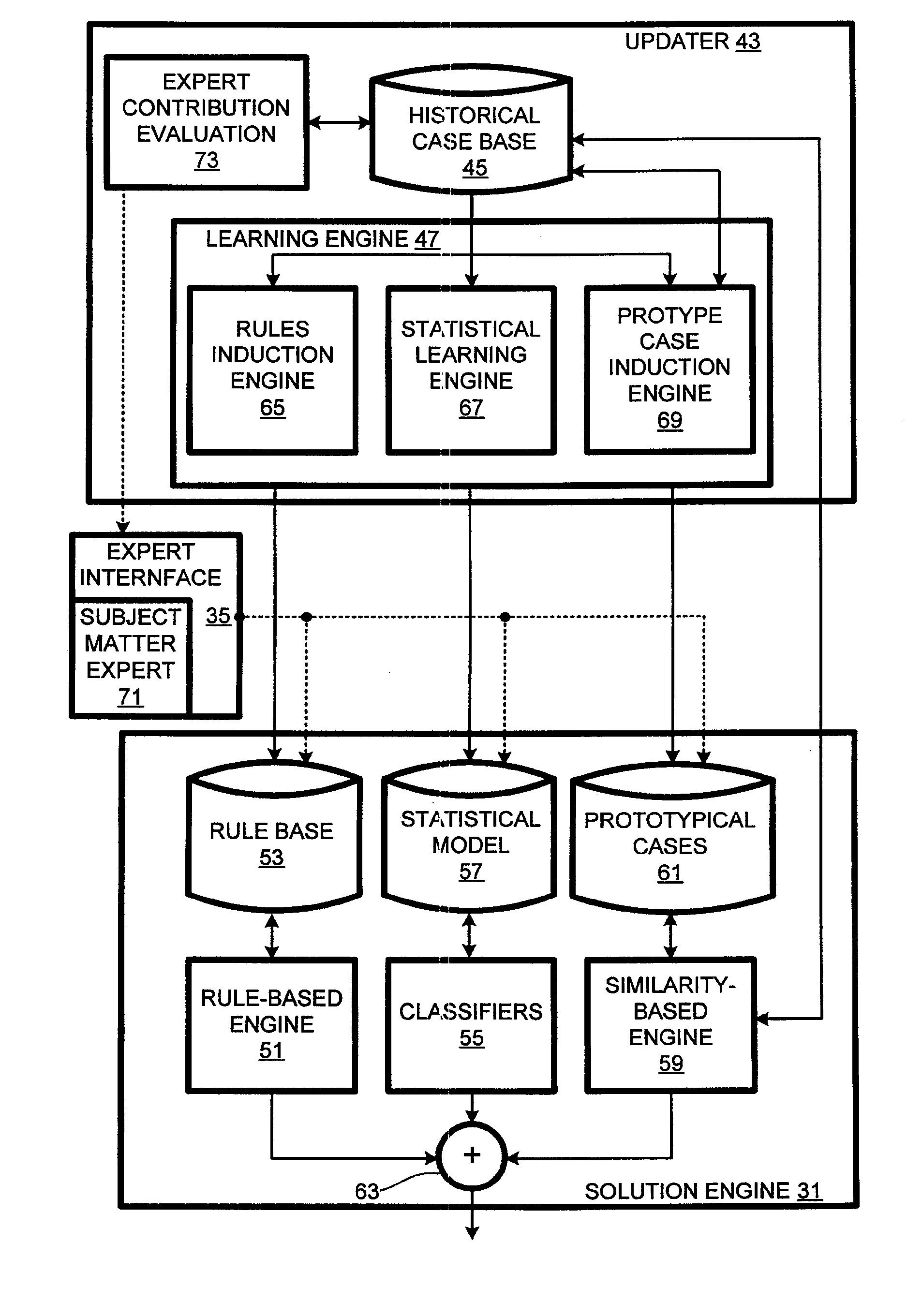

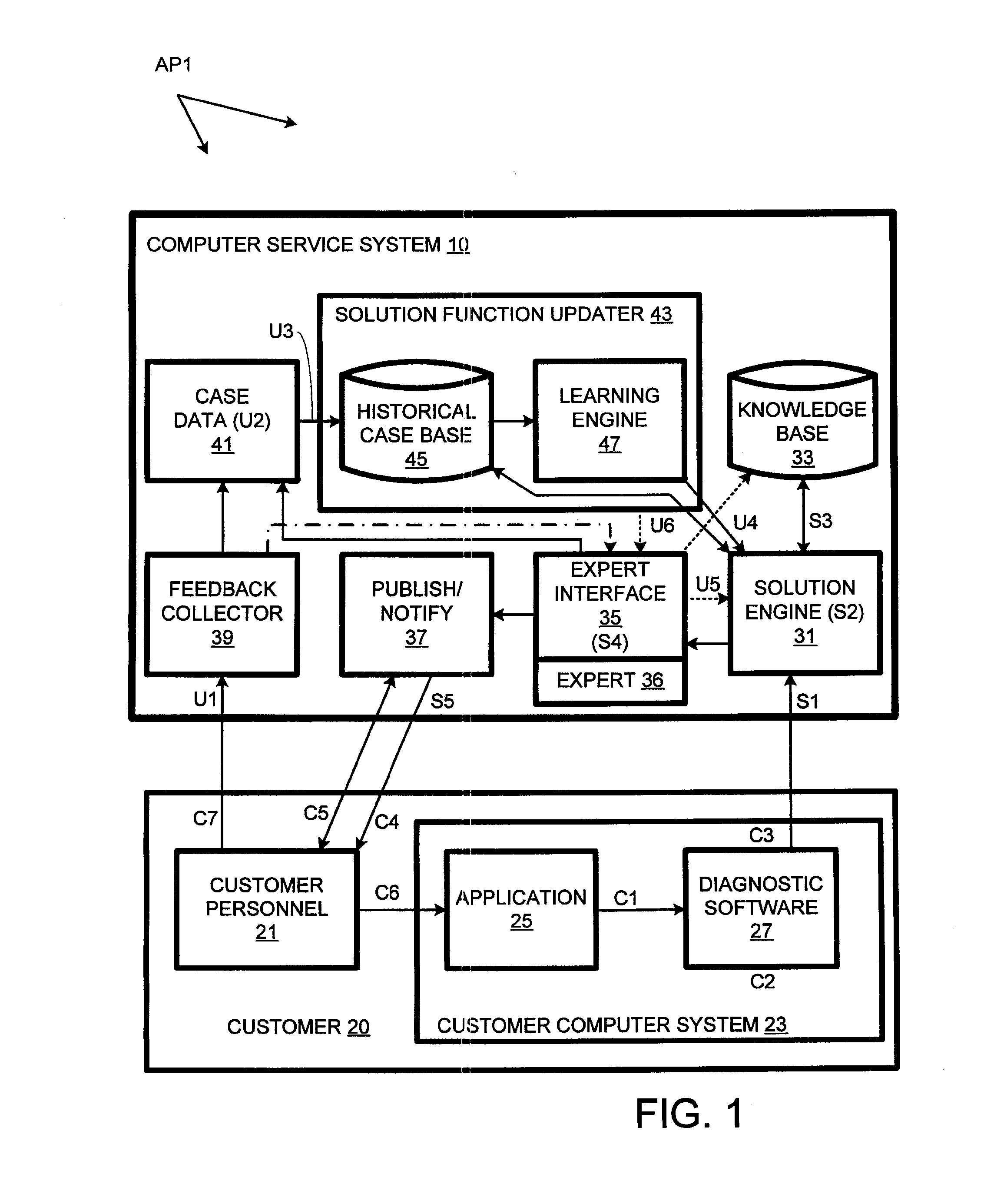

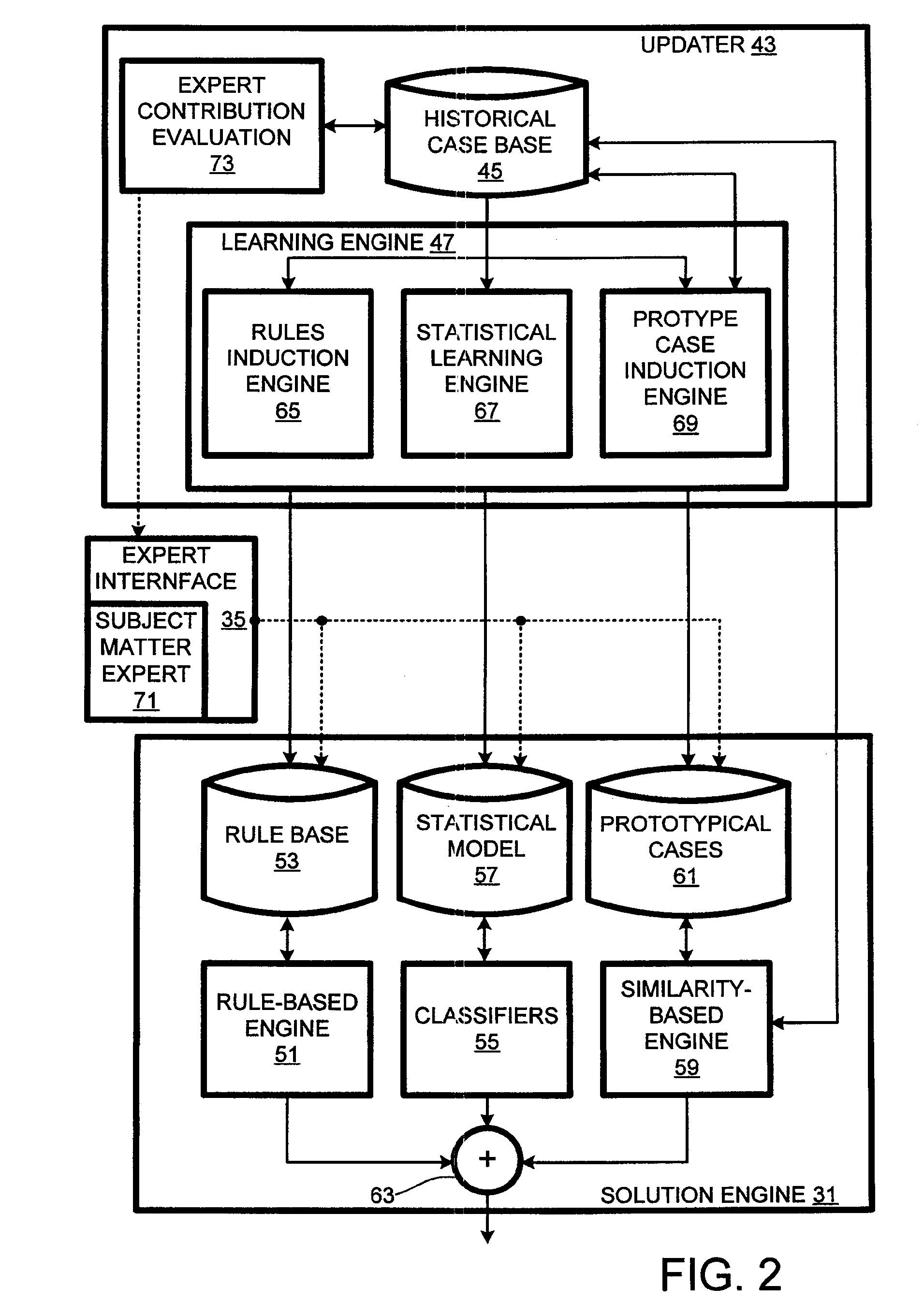

Computer support service with solution function updates as a function of pre-delivery expert changes to automatically generated solutions

A solution engine (31) of a vendor's highly-automated adaptive computer support system (10) for a remote customer (20) automatically generates proposed solutions, e.g., sets of support documents, as a function of diagnostic data received from a customer's computer system (23). The automatically generated solution can be subject to expert review (35) prior to publication (37) to the customer, e.g., when the automated system assigns a low confidence level to the solution. In addition, expert review can be triggered by feedback (39) from the customer once a proposed solution is communicated. The diagnostic data, solutions and feedback for an incident are packaged (at 41) as a “case” and entered into an historical case database (45). A solution function updater (43) updates the solution function as a function, at least in part, of the expert review and customer feedback.

Owner:MICRO FOCUS LLC

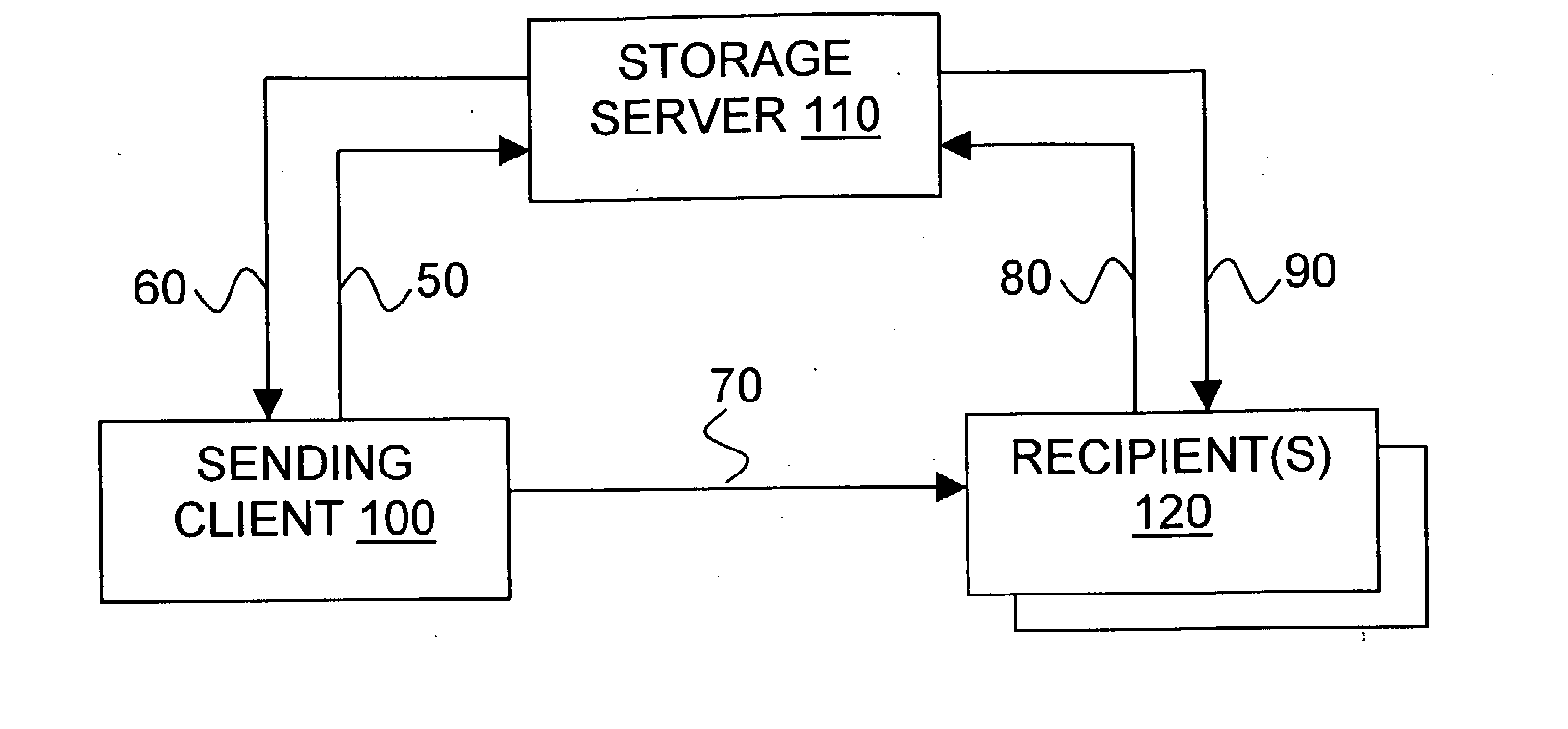

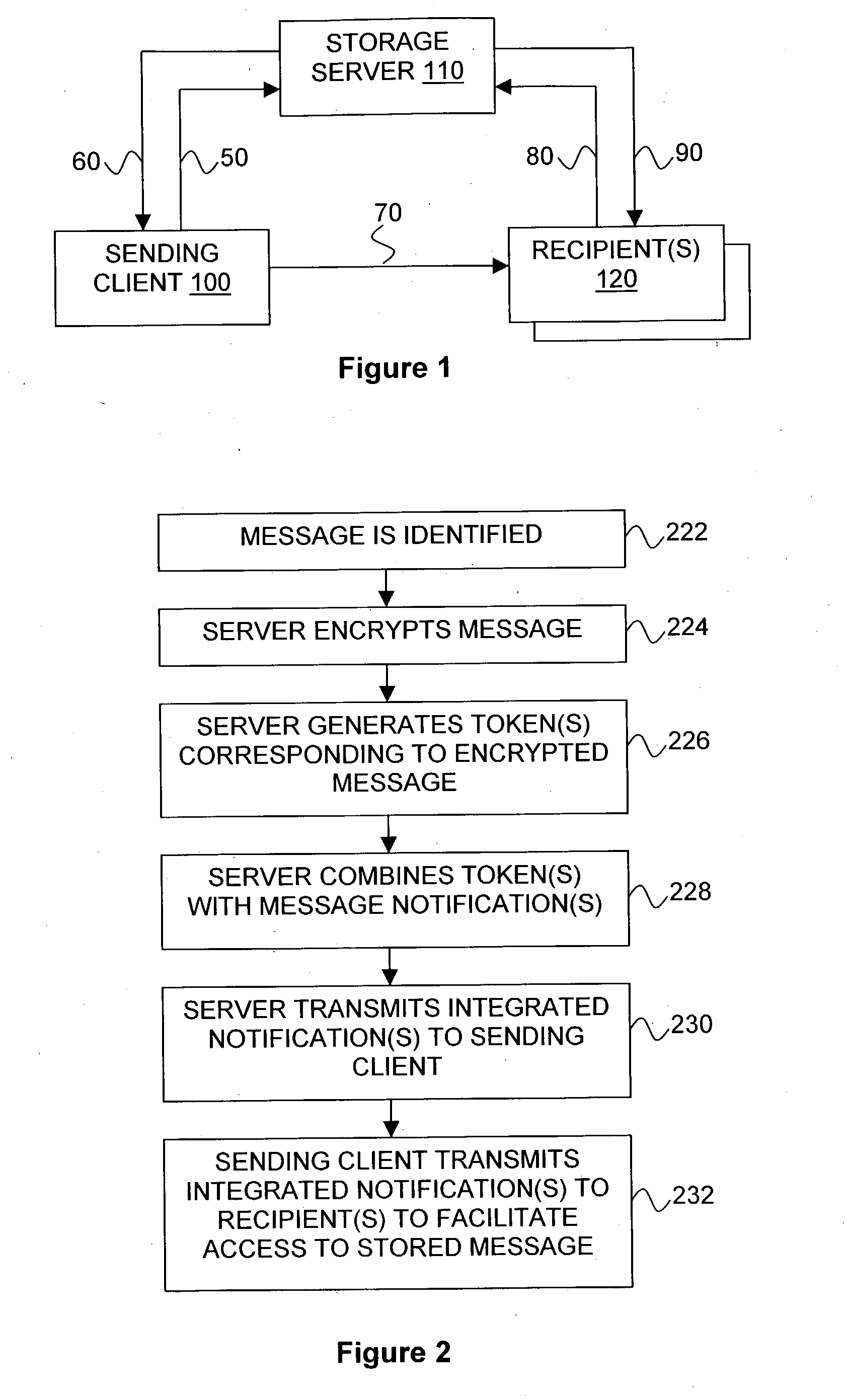

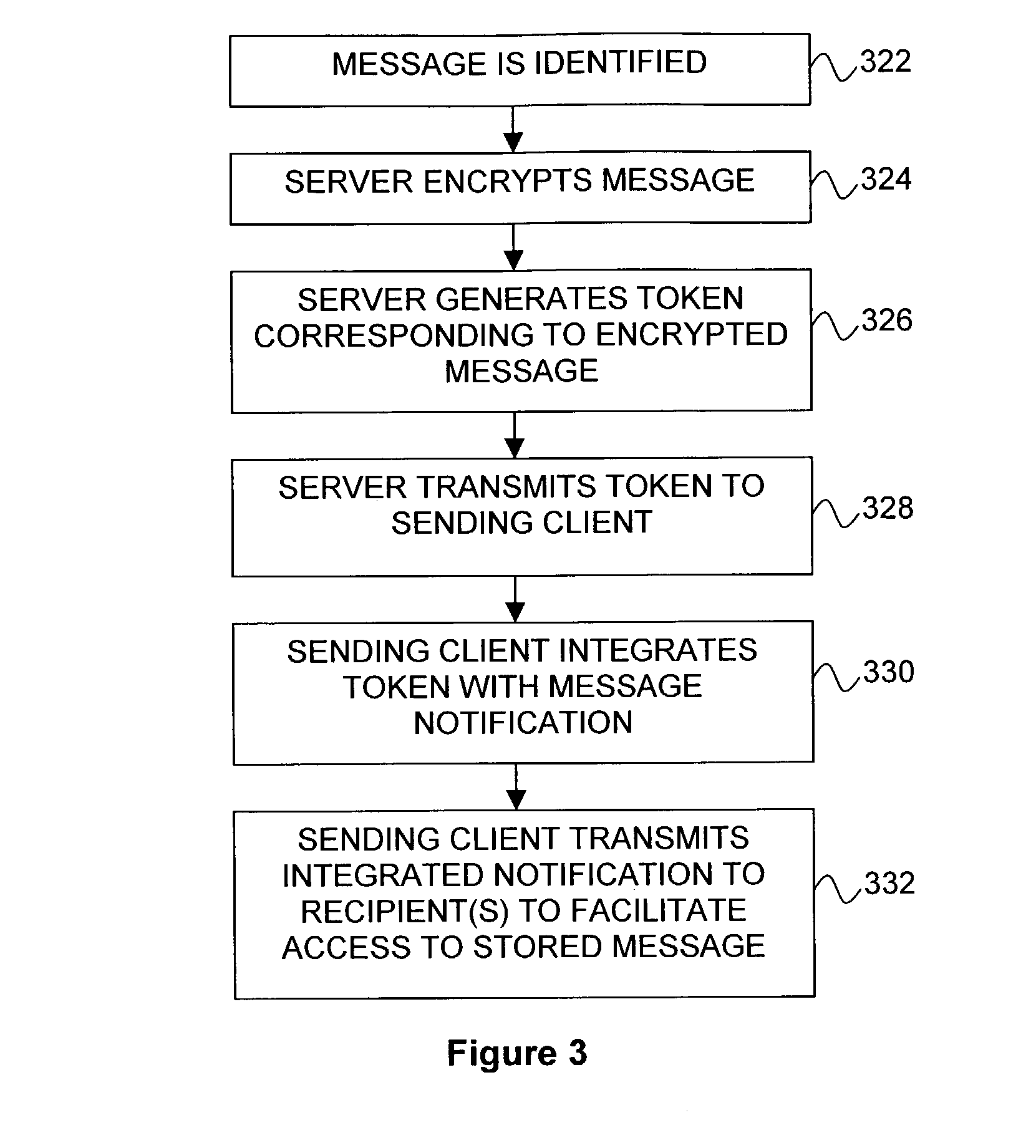

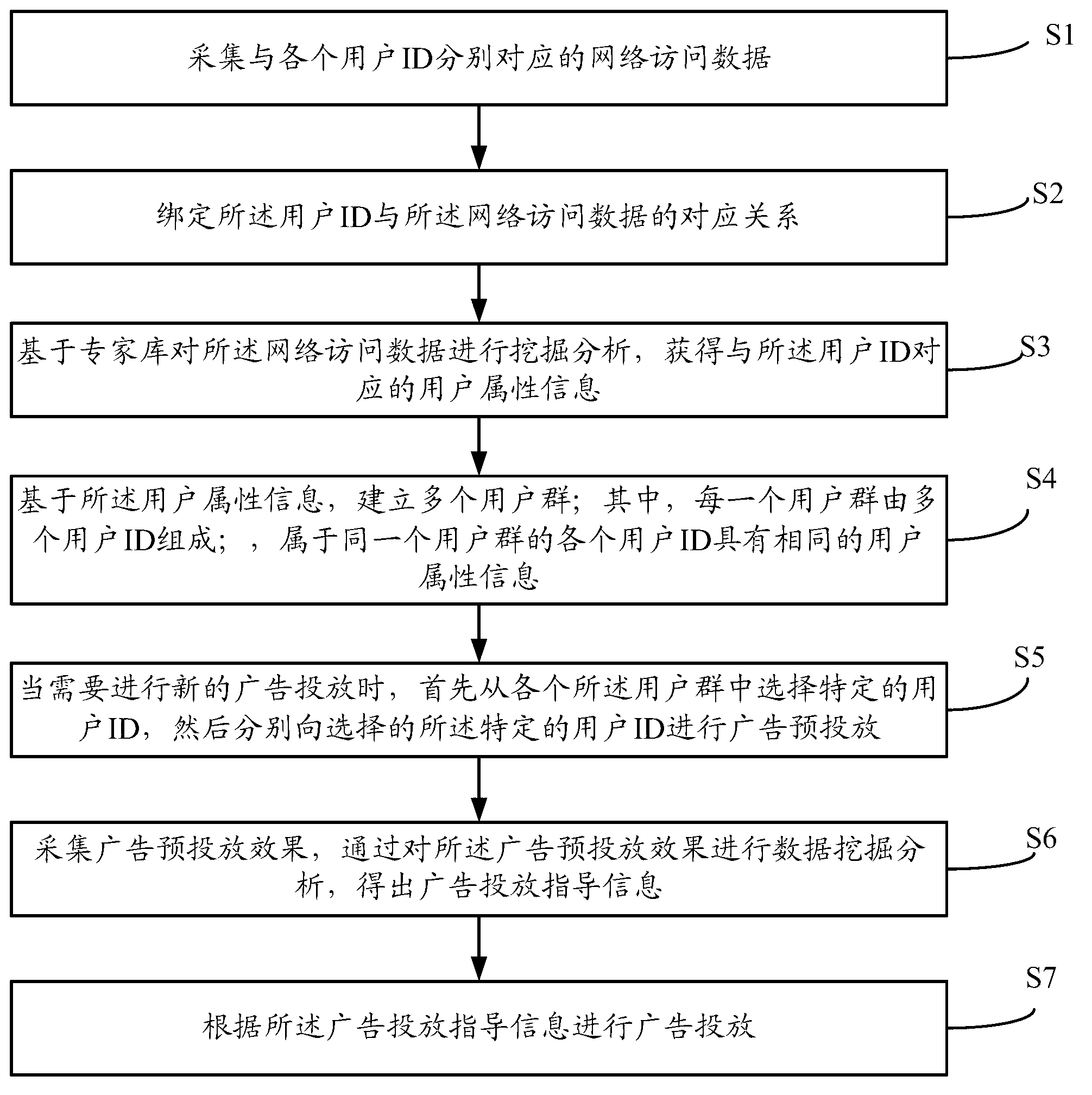

Preemptive and interactive data solicitation for electronic messaging

InactiveUS20040030916A1Key distribution for secure communicationDigital data processing detailsClient-sideElectronic messaging

A system includes a sending client equipped to deliver a message notification including recipient input facilities for soliciting pre-delivery information from the recipient, and a server to dynamically determine at least a portion of the message to be delivered based to be delivered to the recipient based at least in part upon the pre-delivery information received from the recipient.

Owner:KRYPTIQ

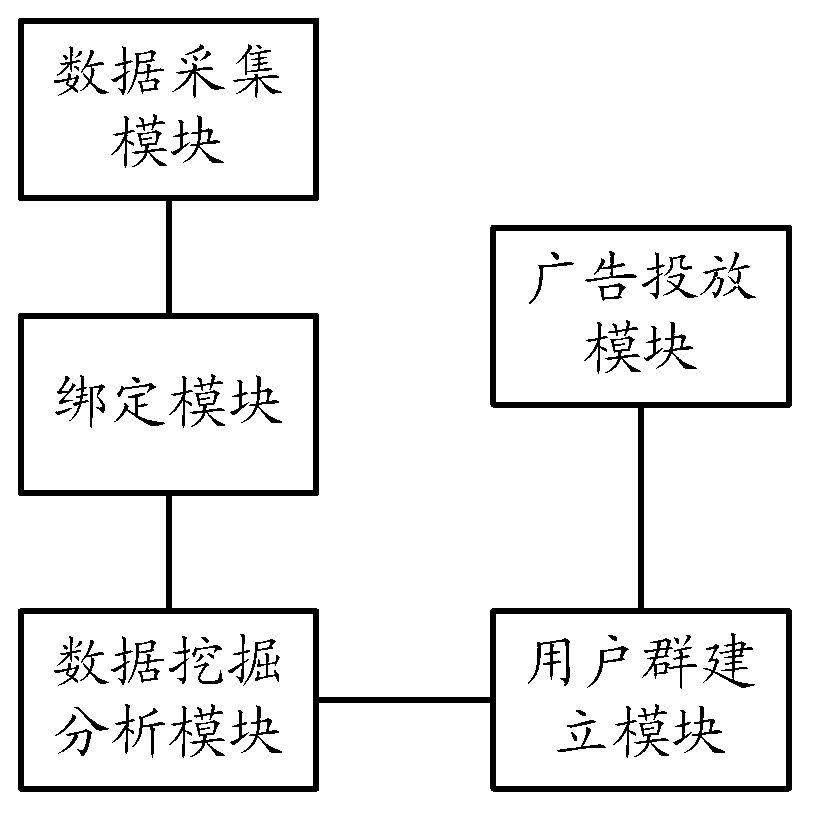

Method and device for optimizing advertisement delivery effect by combining user groups and pre-delivery

InactiveCN103177380AHigh precisionMarketingSpecial data processing applicationsUser identifierAd serving

The invention provides a method and a device for optimizing advertisement delivery effect by combining user groups and pre-delivery. The method includes: acquiring network access data corresponding to user IDs (identities); binding corresponding relations of the user IDs and the network access data; on the basis of an expert database, mining and analyzing the network access data to obtain user attribute information corresponding to the user IDs; on the basis of the user attribute information, setting up multiple user groups; when new advertisement delivery is needed, selecting specific user IDs from each user group, and then performing advertisement pre-delivery for the selected specific user IDs; collecting advertisement pre-delivery effects, and performing data mining and analysis for the advertisement pre-delivery effects to obtain advertisement delivery guide information; and delivering advertisements according to the advertisement delivery guide information. By the method, accuracy of advertisement delivery can be improved effectively.

Owner:BEIJING GEO POLYMERIZATION TECH

Pre-delivery drug identification system

InactiveUS20060287884A1Block deliveryData processing applicationsDrug and medicationsAllergyDrug product

The present invention is a system and method of pre-delivery drug identification. The system and method is implemented where drugs are being administered, such as in a hospital or clinic, and identifies the drug being administered to the patient before the drug reaches the patient. After identification, the system and method is configured to cross-reference the identified drug with the patient's prescription and allergy information, and to prevent delivery to the patient, if necessary.

Owner:GENERAL ELECTRIC CO

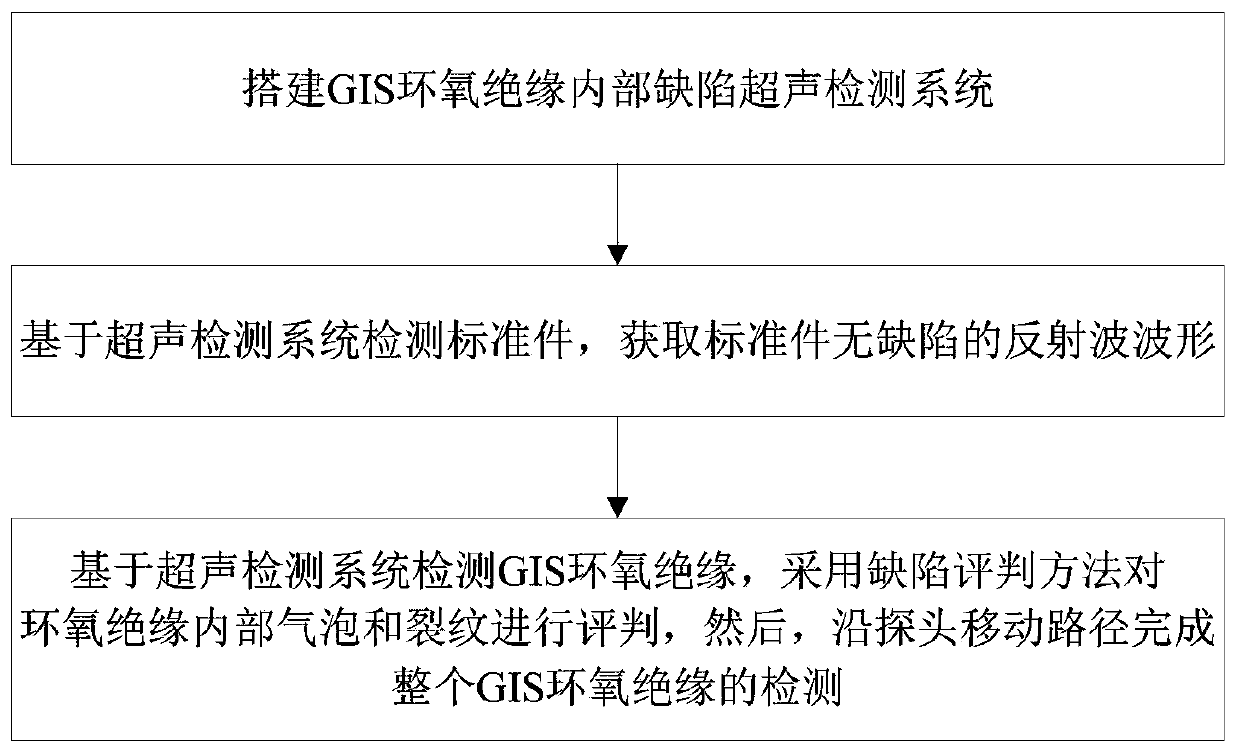

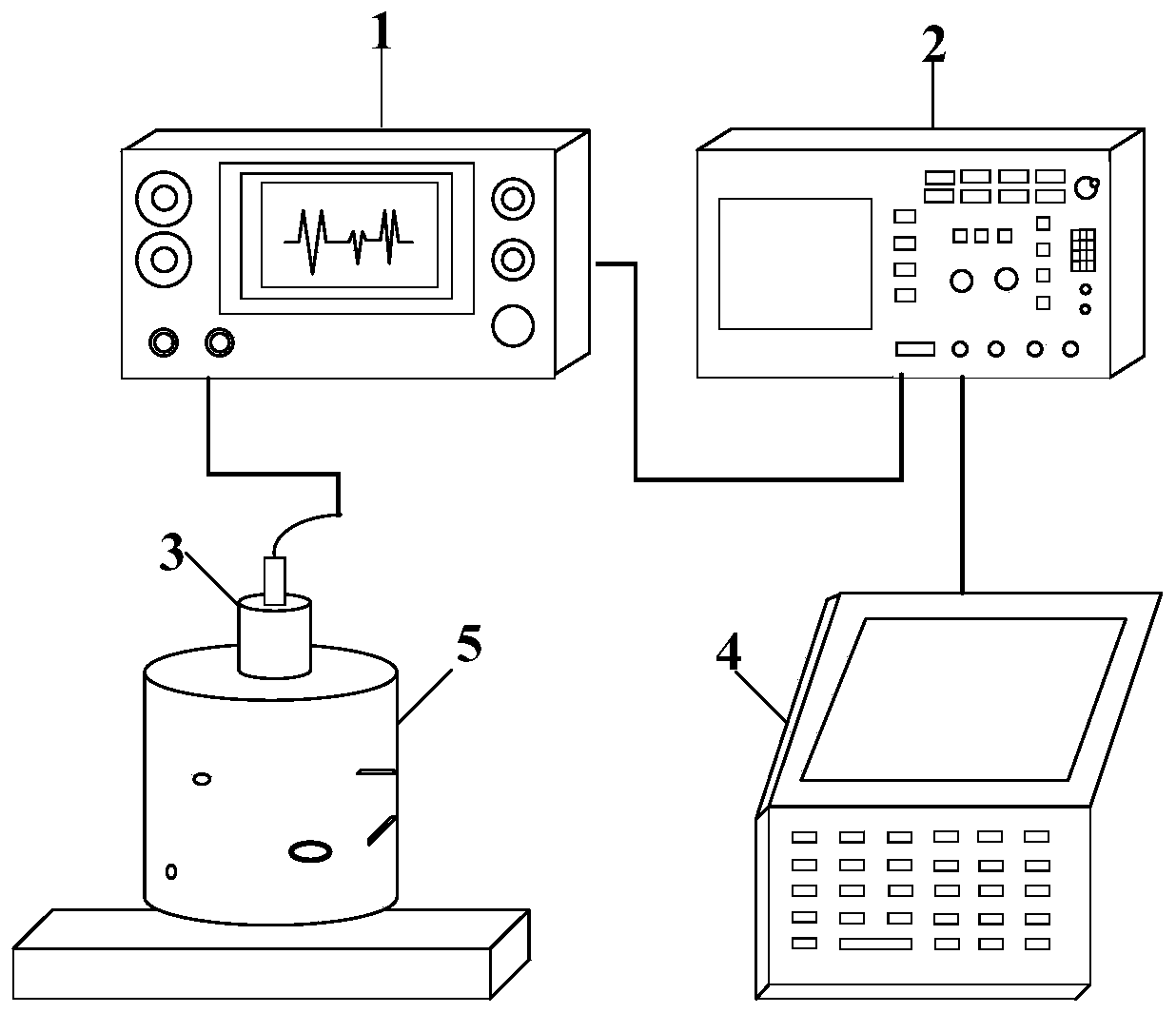

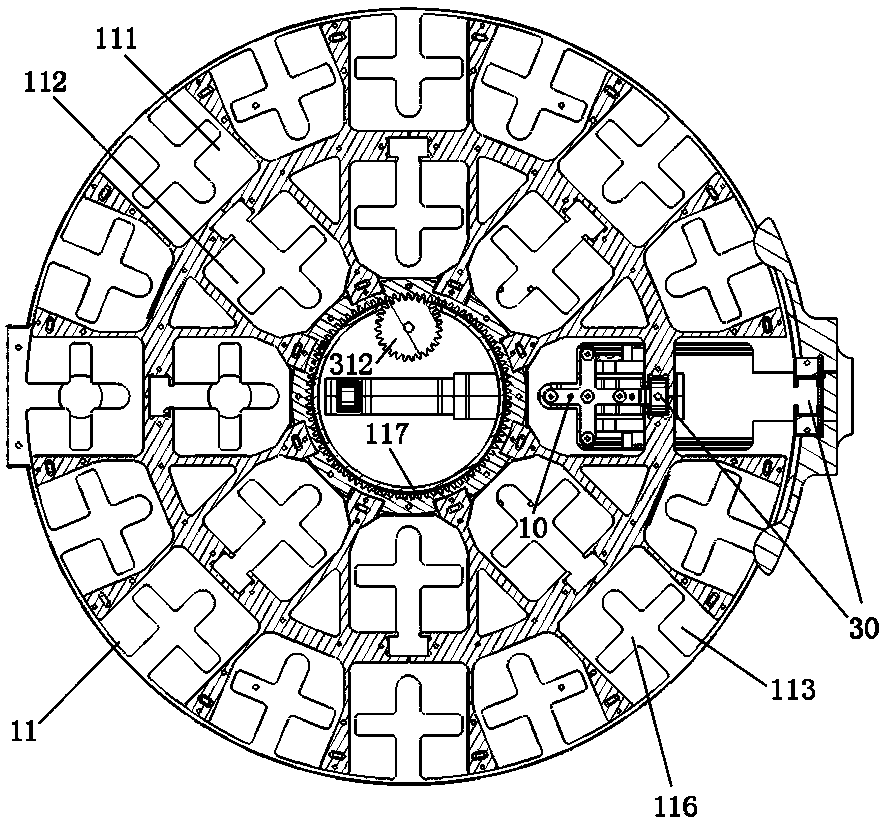

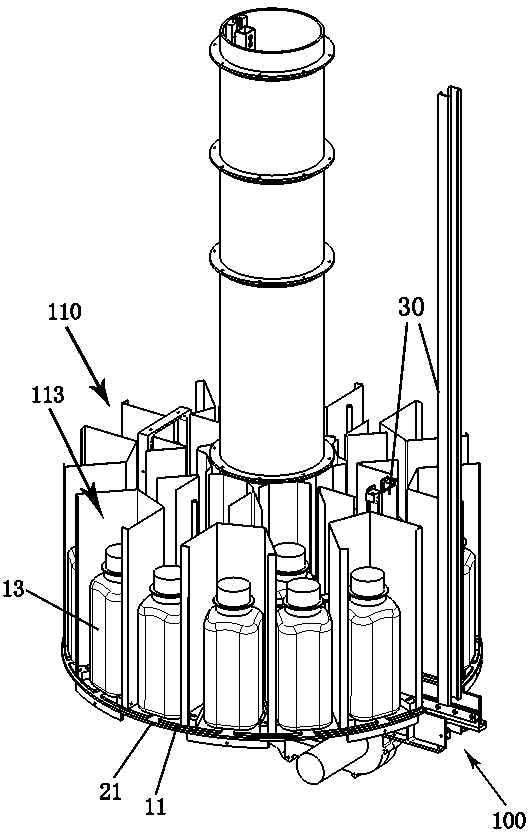

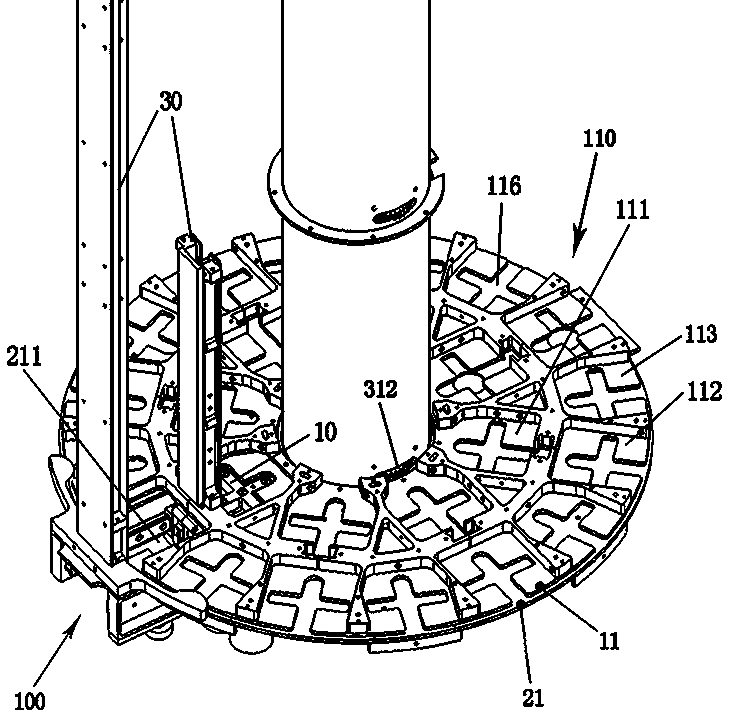

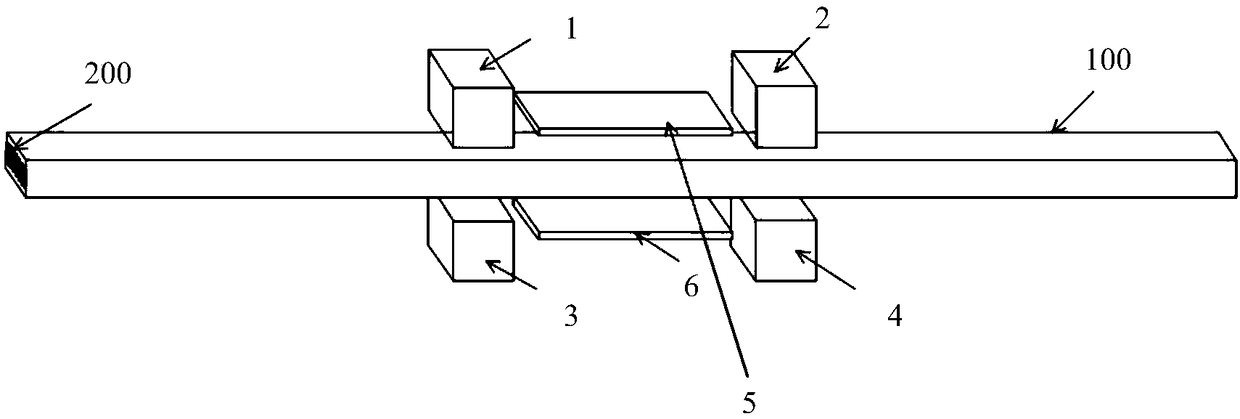

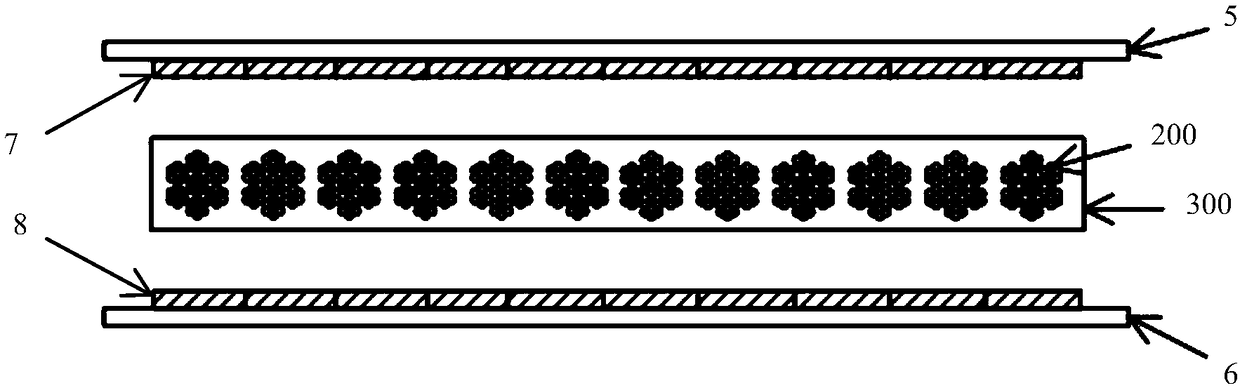

Ultrasonic testing method and ultrasonic testing system for internal defects of GIS epoxy insulator

InactiveCN110243935AImprove detection accuracyImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesLongitudinal waveUltrasonic attenuation

The invention belongs to the technical field of power transmission and transformation insulation equipment, and relates to an ultrasonic testing method and an ultrasonic testing system for internal defects of a GIS epoxy insulator. The ultrasonic testing method for internal defects of the GIS epoxy insulator comprises the following steps: constructing the ultrasonic testing system for internal defects of the GIS epoxy insulator; testing a testing standard component based on the ultrasonic testing system, and obtaining a non-defective reflected wave waveform of the standard component; testing the GIS epoxy insulator based on the ultrasonic testing system, judging interior bubbles and cracks of the epoxy insulator by using a defect judgment method, and then continuously testing the GIS epoxy insulator along the moving path of a probe. The method is high in testing precision and efficiency and accurate in defect positioning, small-sized bubbles and cracks can be tested, and the method can be used for pre-delivery inspection of insulators and also can be used for assembling field test of insulators. The ultrasonic testing system for internal defects of the GIS epoxy insulator comprises an ultrasonic instrument, an oscilloscope, an ultrasonic longitudinal wave normal probe, a computer and the GIS epoxy insulator. The system is low in cost, small in equipment volume, high in testing precision and efficiency and accurate in defect positioning.

Owner:SOUTH CHINA UNIV OF TECH

Computer support service with solution function updates as a function of pre-delivery expert changes to automatically generated solutions

ActiveUS20050278213A1Efficient integrationLogical operation testingNuclear monitoringDiagnostic dataPaper document

A solution engine (31) of a vendor's highly-automated adaptive computer support system (10) for a remote customer (20) automatically generates proposed solutions, e.g., sets of support documents, as a function of diagnostic data received from a customer's computer system (23). The automatically generated solution can be subject to expert review (35) prior to publication (37) to the customer, e.g., when the automated system assigns a low confidence level to the solution. In addition, expert review can be triggered by feedback (39) from the customer once a proposed solution is communicated. The diagnostic data, solutions and feedback for an incident are packaged (at 41) as a “case” and entered into an historical case database (45). A solution function updater (43) updates the solution function as a function, at least in part, of the expert review and customer feedback.

Owner:MICRO FOCUS LLC

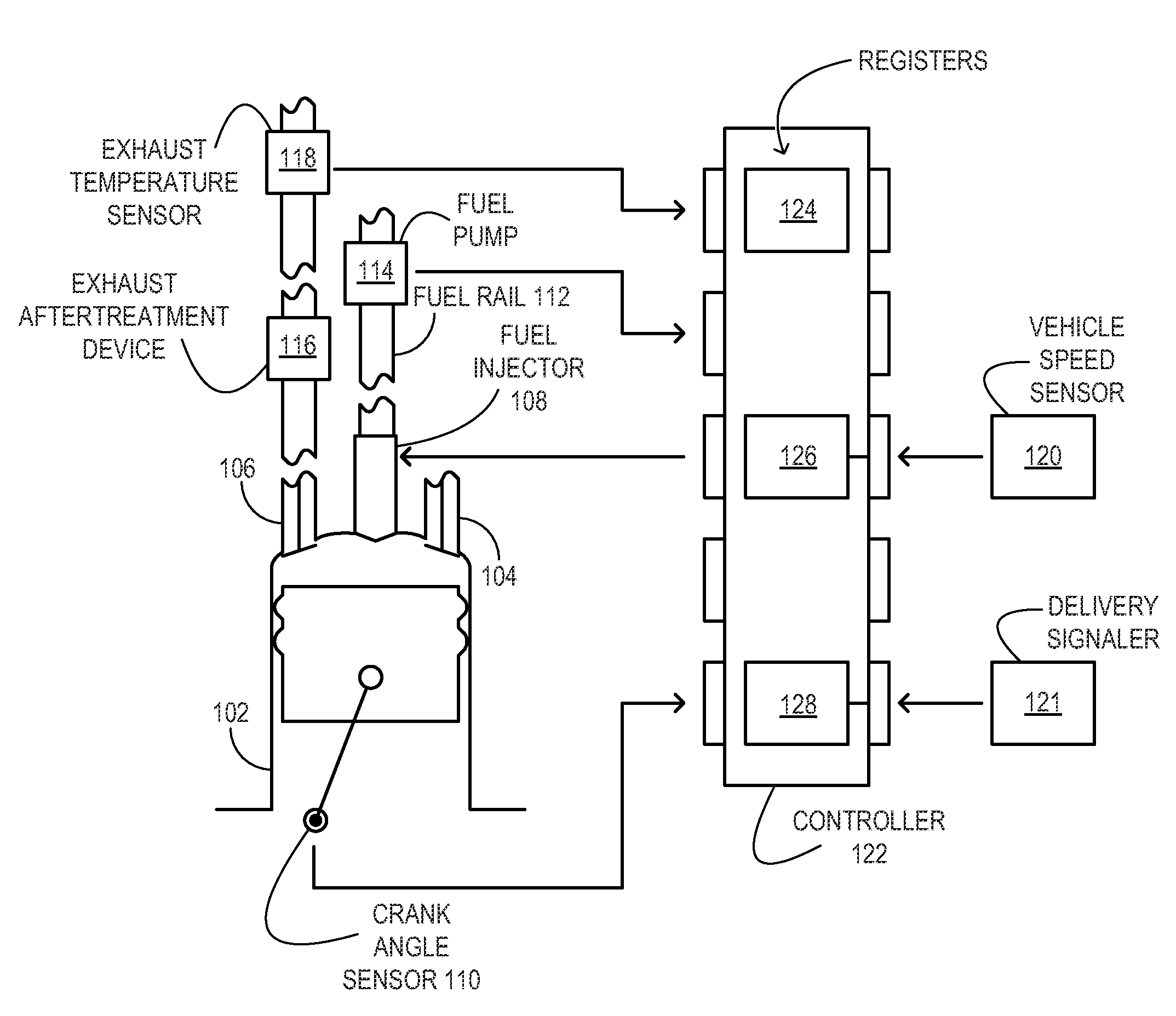

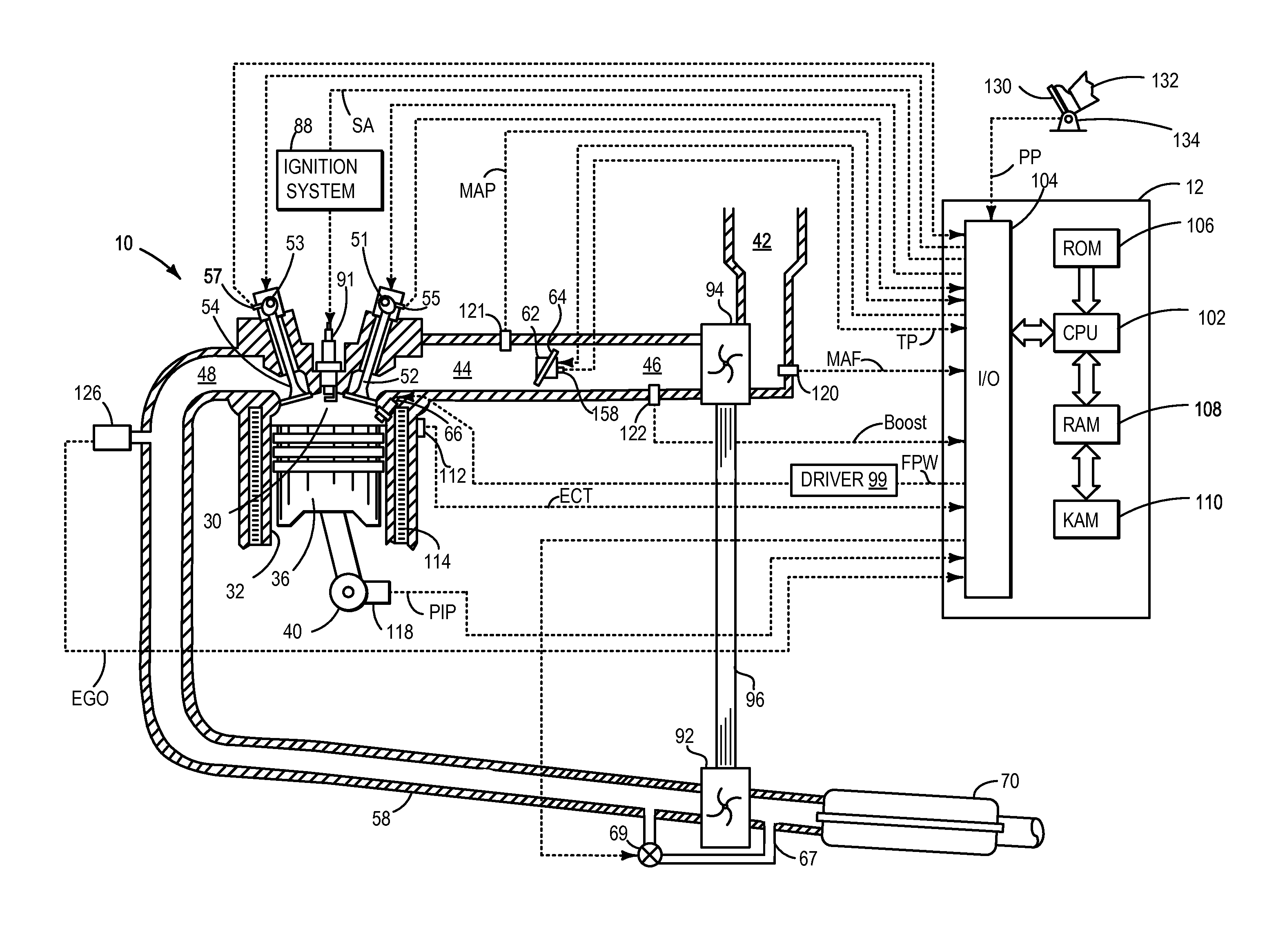

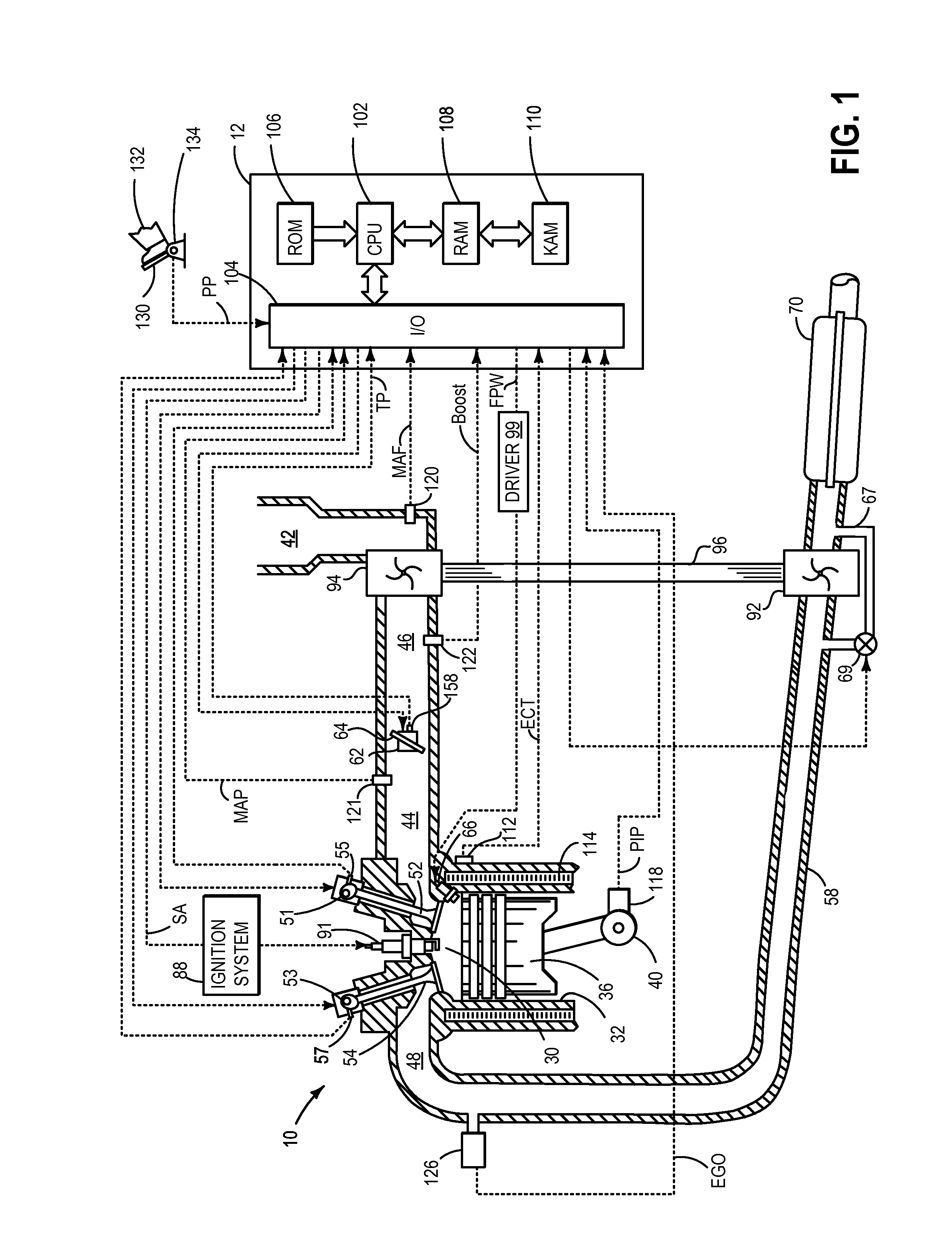

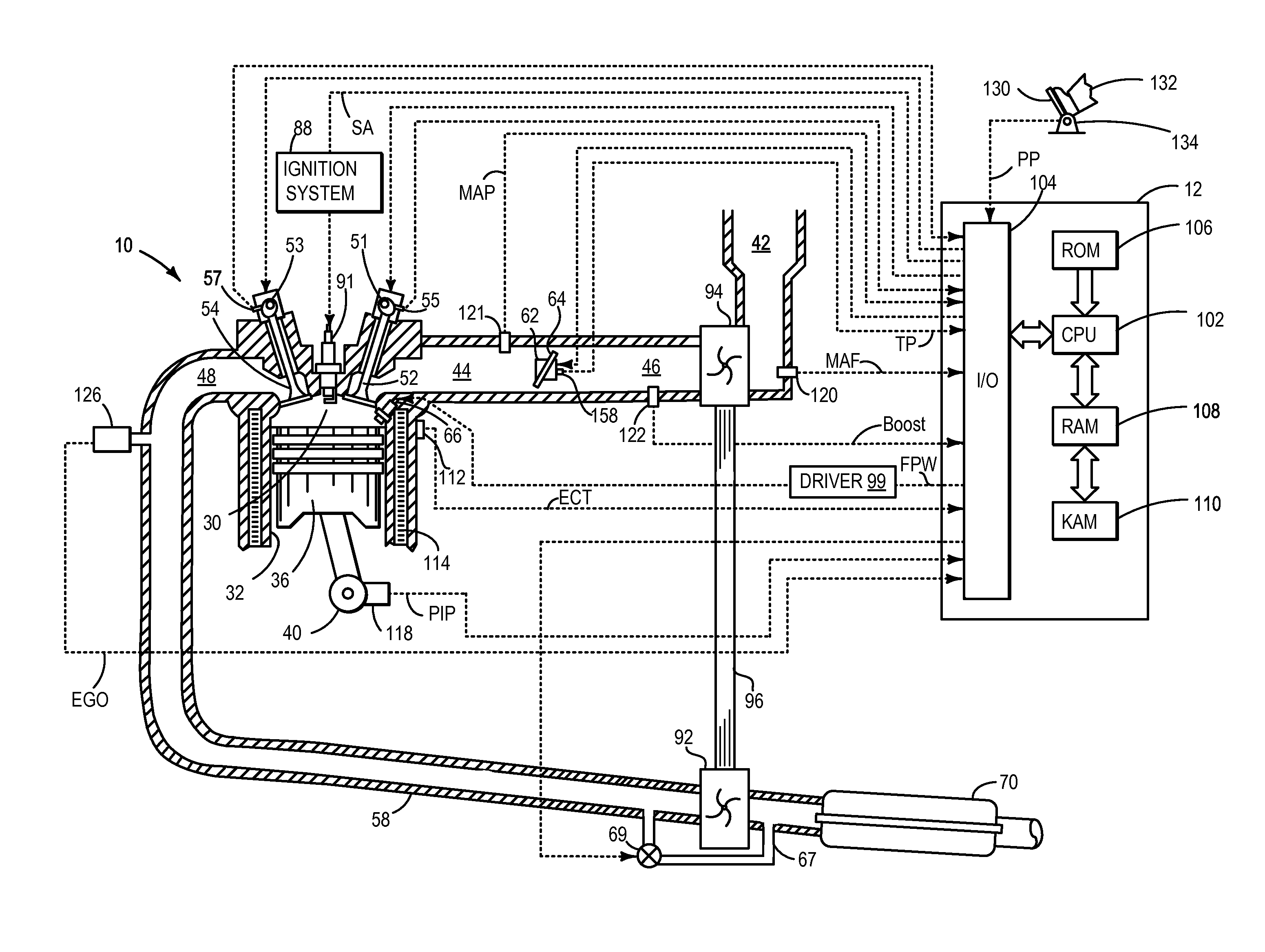

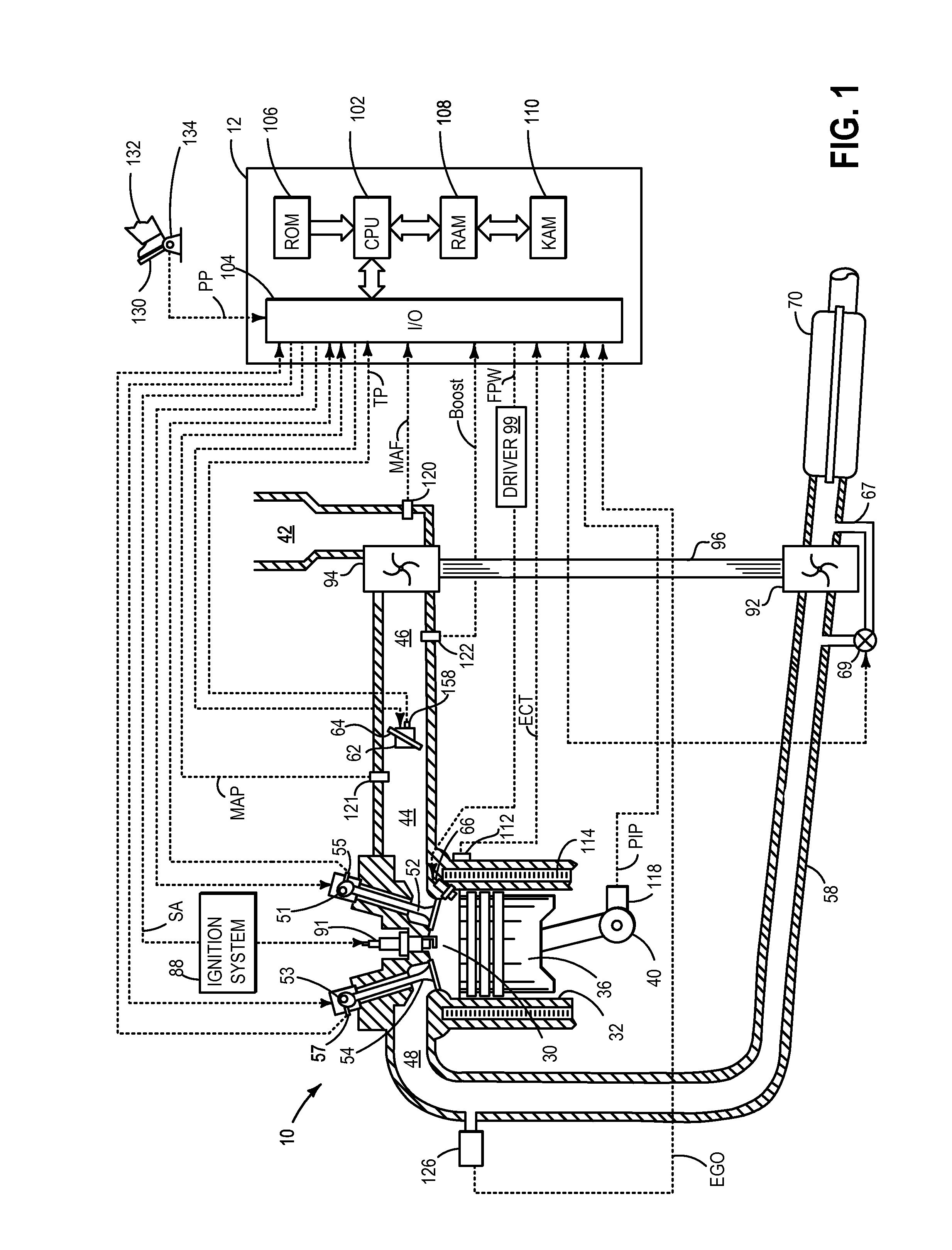

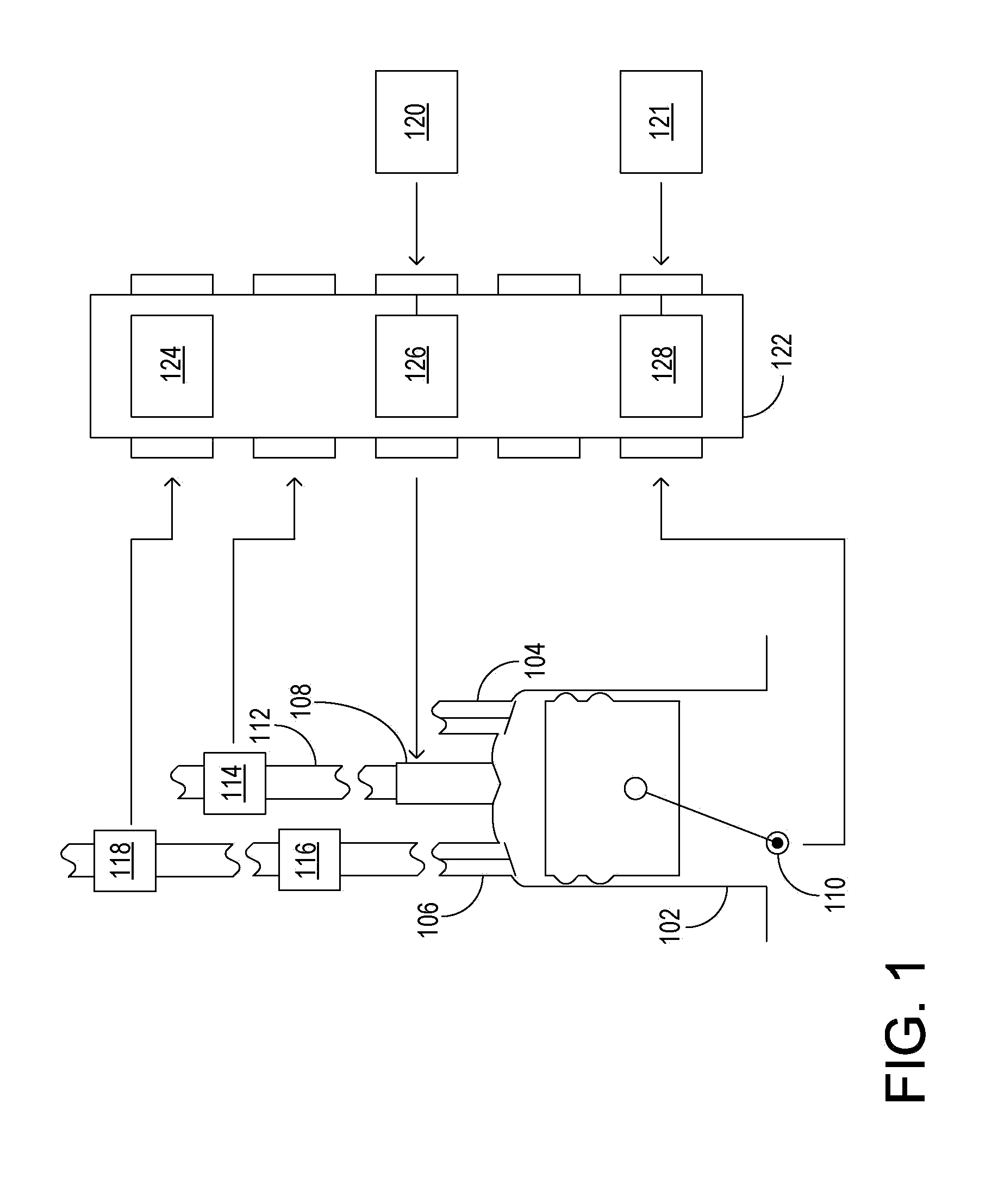

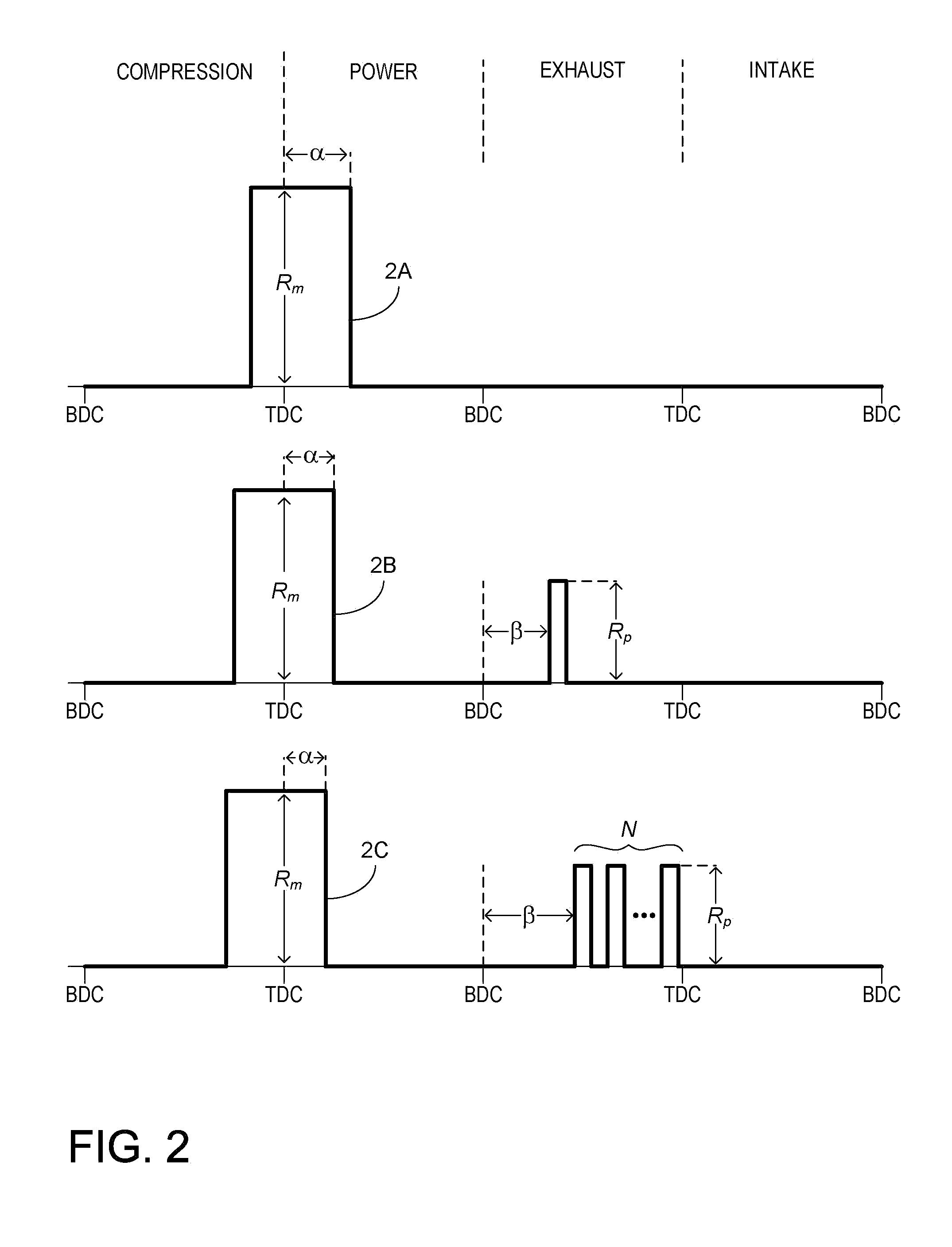

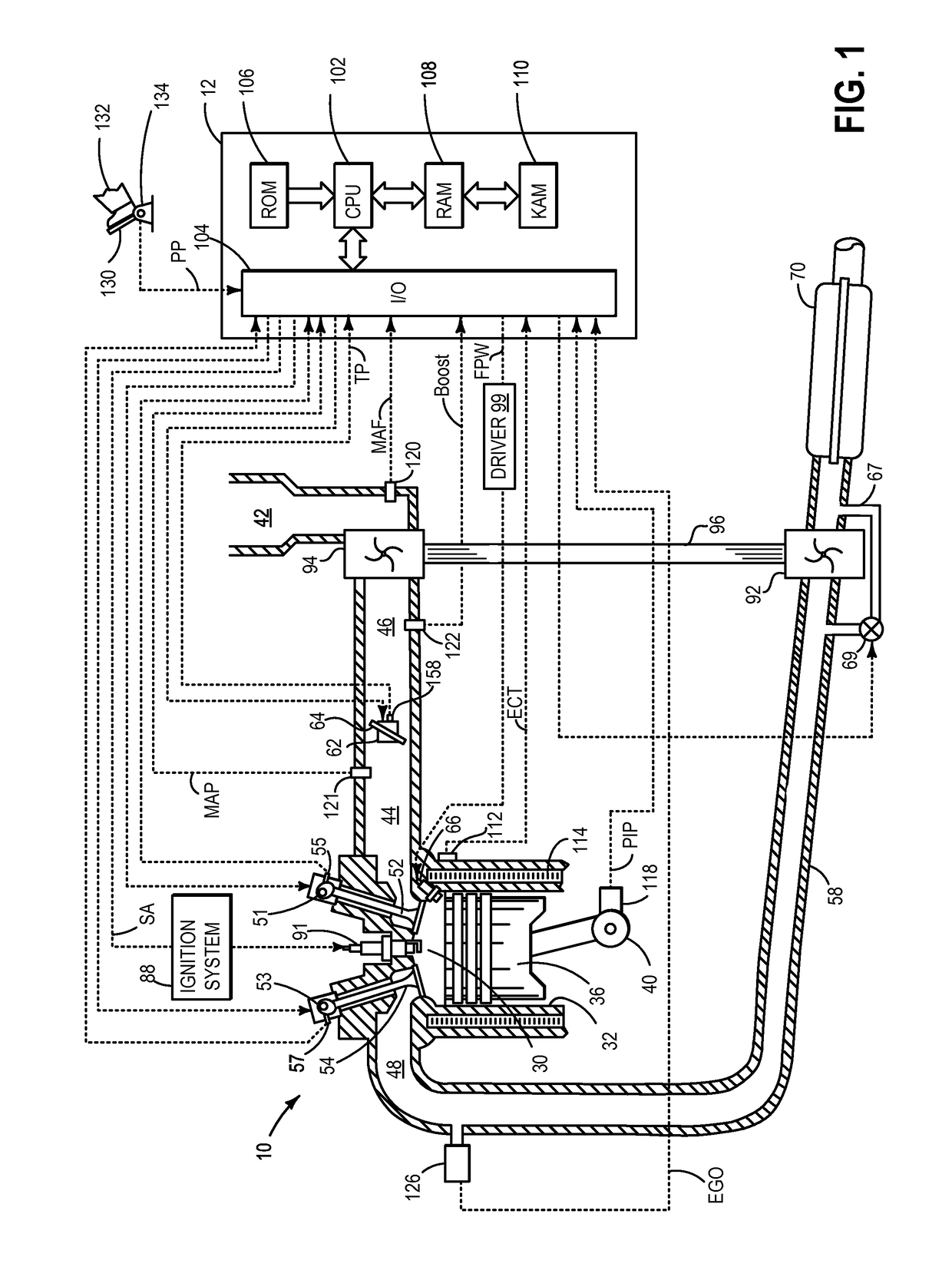

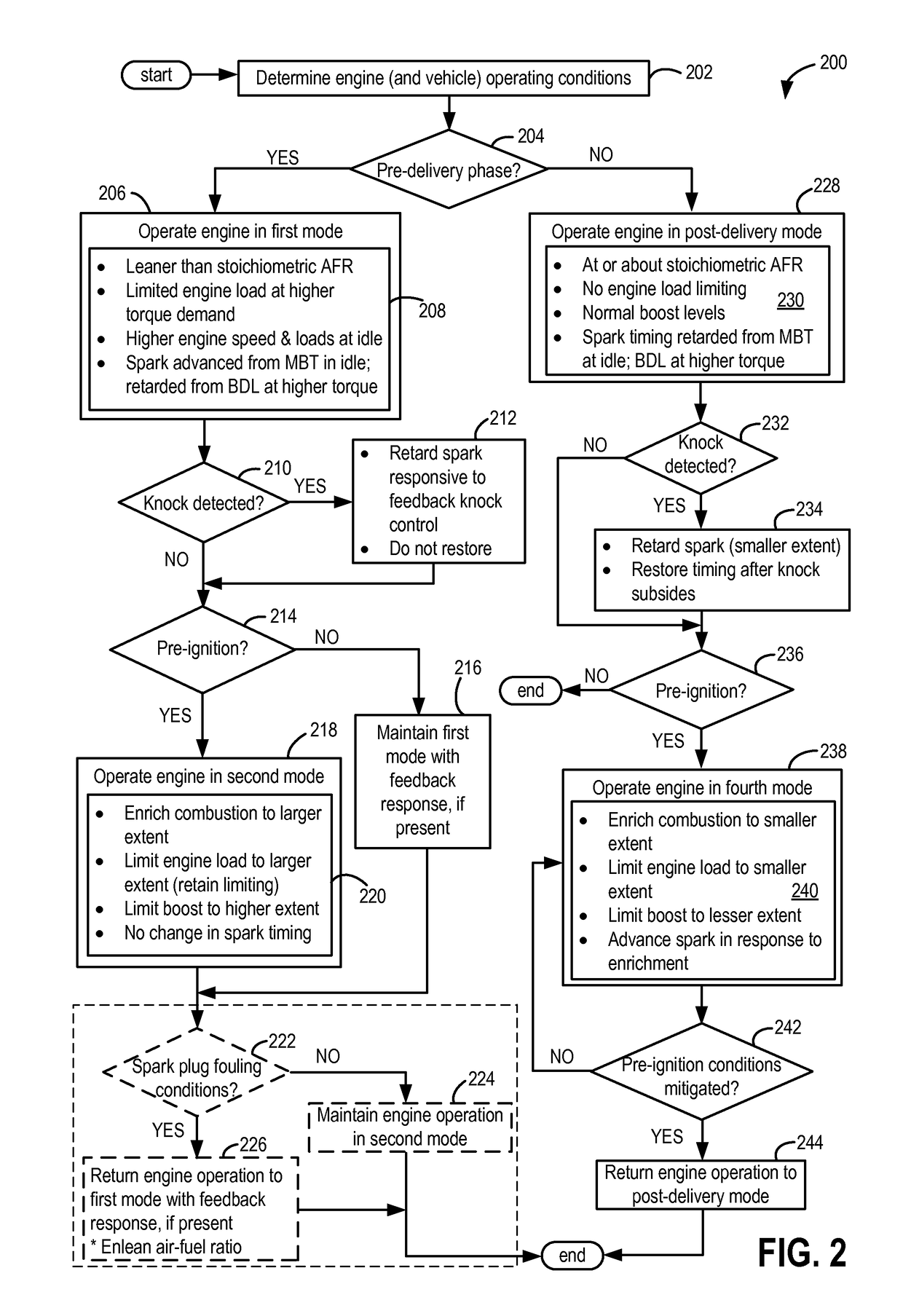

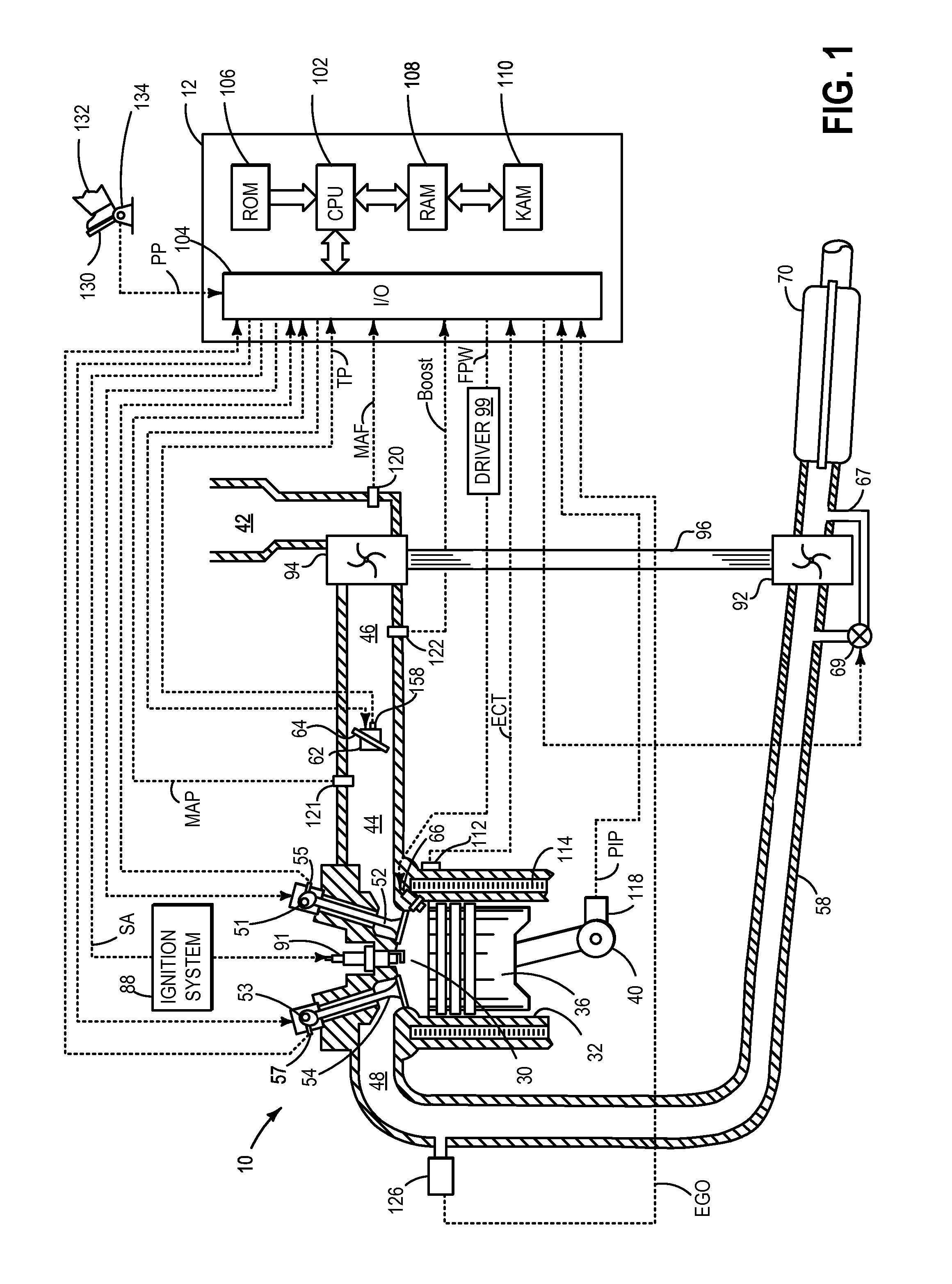

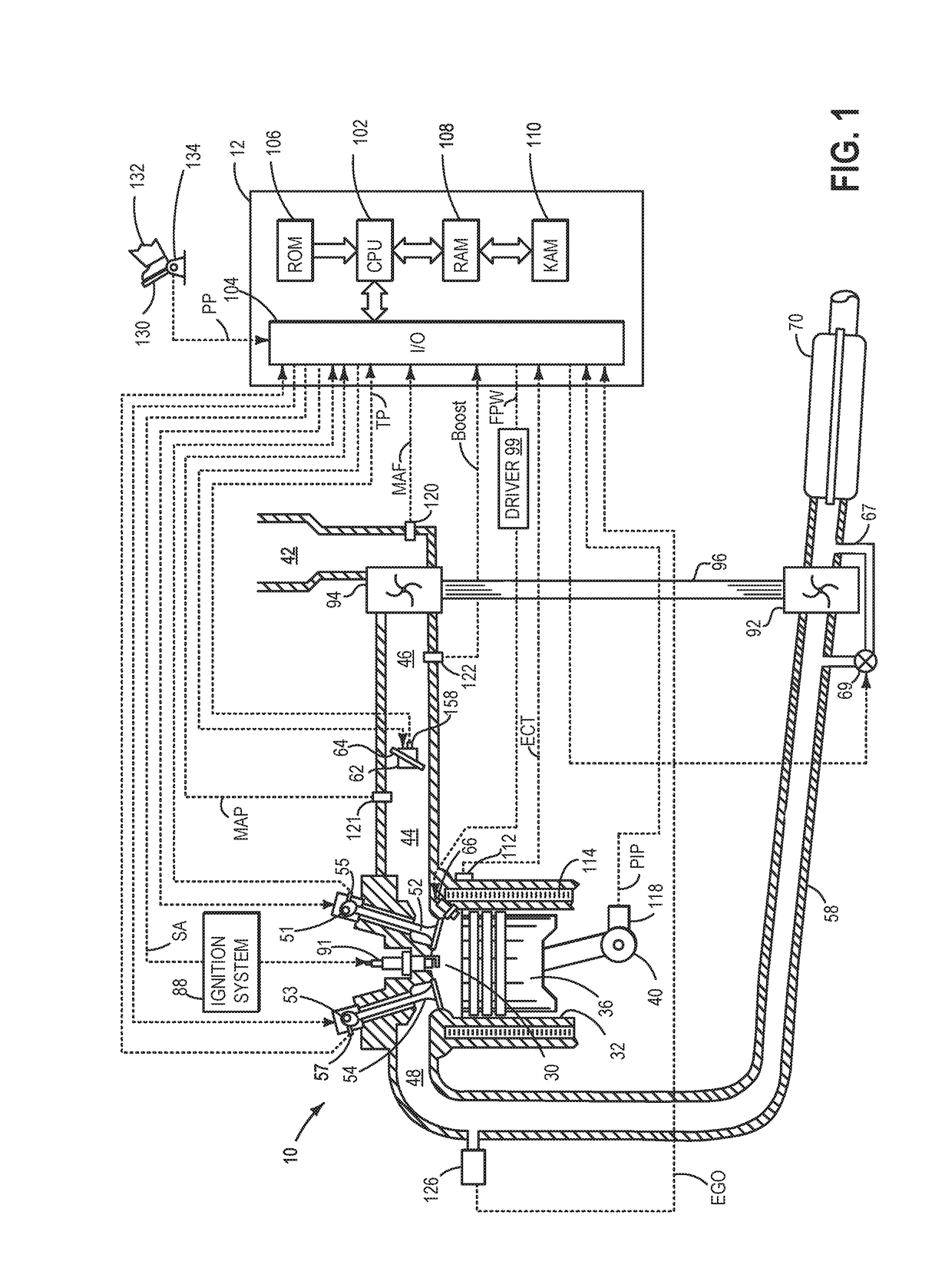

Pre-delivery strategy for diesel-engine vehicles

ActiveUS8050844B2Improve efficiencyReducing spark-plug foulingElectrical controlInternal combustion piston enginesDiesel engineLubricant

Owner:FORD GLOBAL TECH LLC

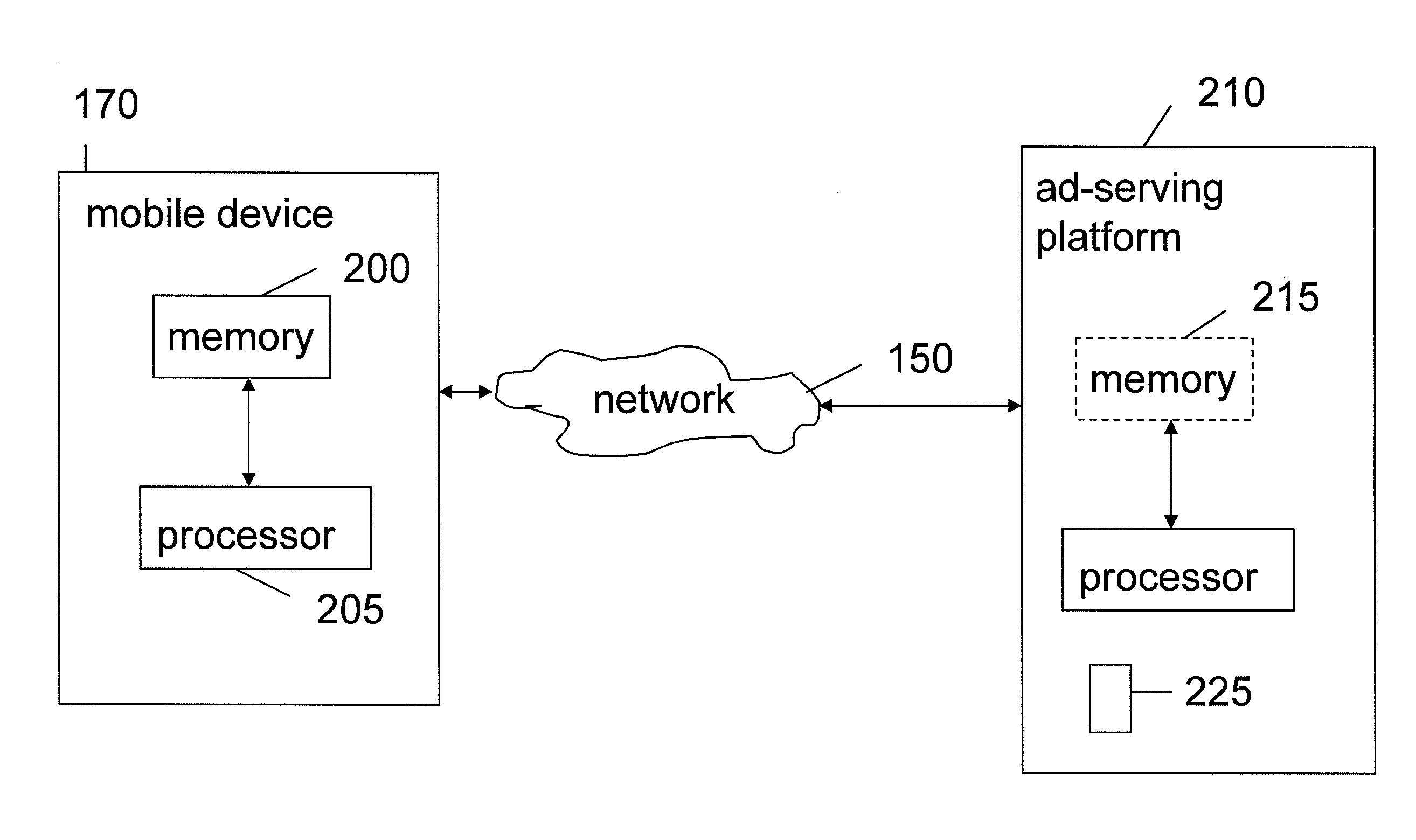

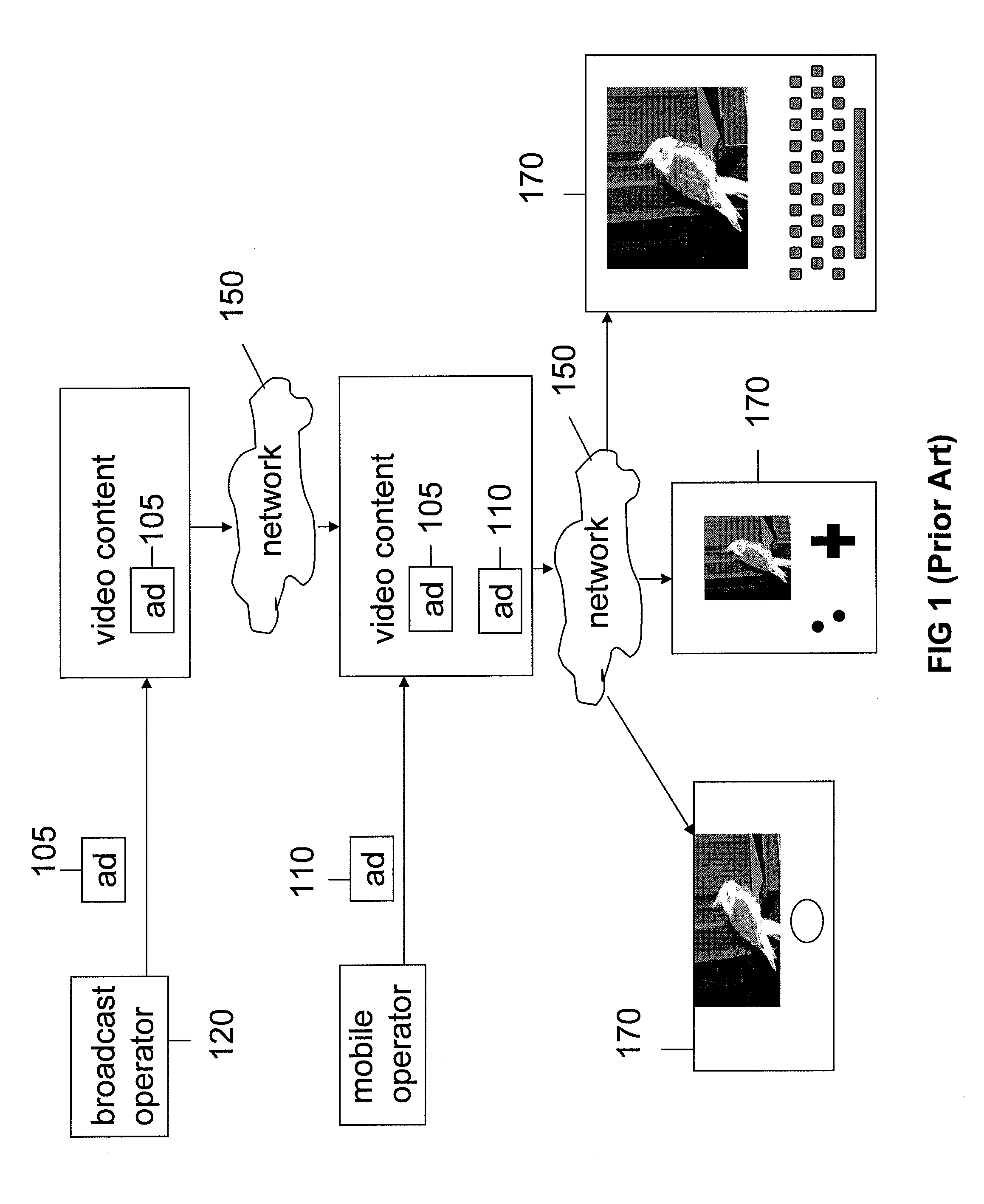

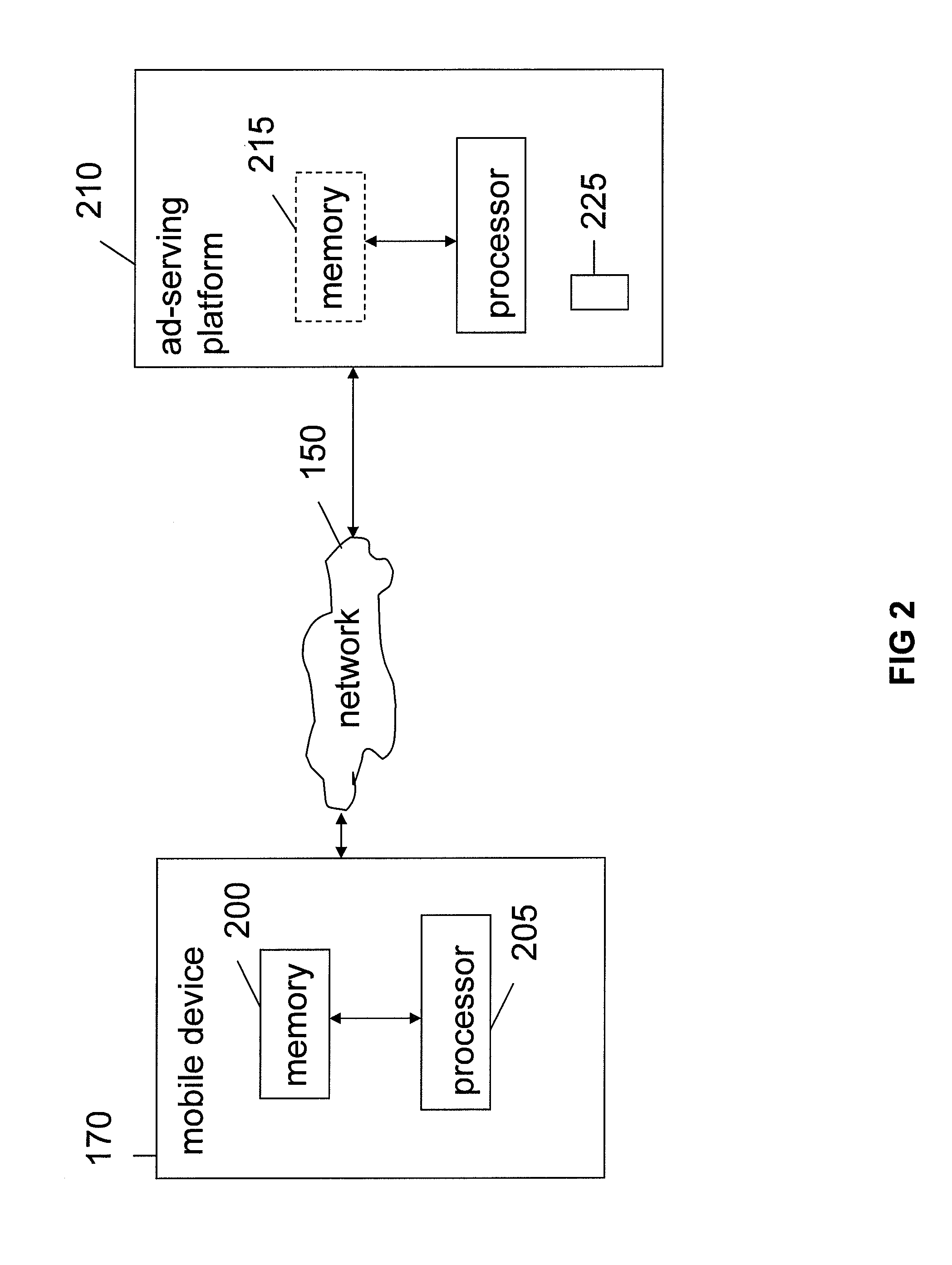

Targeted Advertisement Transmission and Delivery in a Bandwidth Limited Multicast Wireless System

InactiveUS20090070217A1Reduce loadLarge storage capacityAdvertisementsWireless videoVideo transmission

A system and method thereof for the delivery of focused alternate content and advertisements to mobile devices that selectively targets groups in a bandwidth limited multicast wireless video transmission. The limited wireless bandwidth does not allow multiple focused alternate content to be transmitted during allowed spot time to effectively cover all the target groups. Thus, the invention enables the pre-delivery and selective buffering of alternate content files on a mobile device for each target group. Accordingly, one embodiment of the invention enables viewing of targeted advertisements and alternate content by the target groups by attaching metadata to the targeted advertisements that contain instructions for filtering and insertion into a video stream.

Owner:NEC ELECTRONICS CORP +1

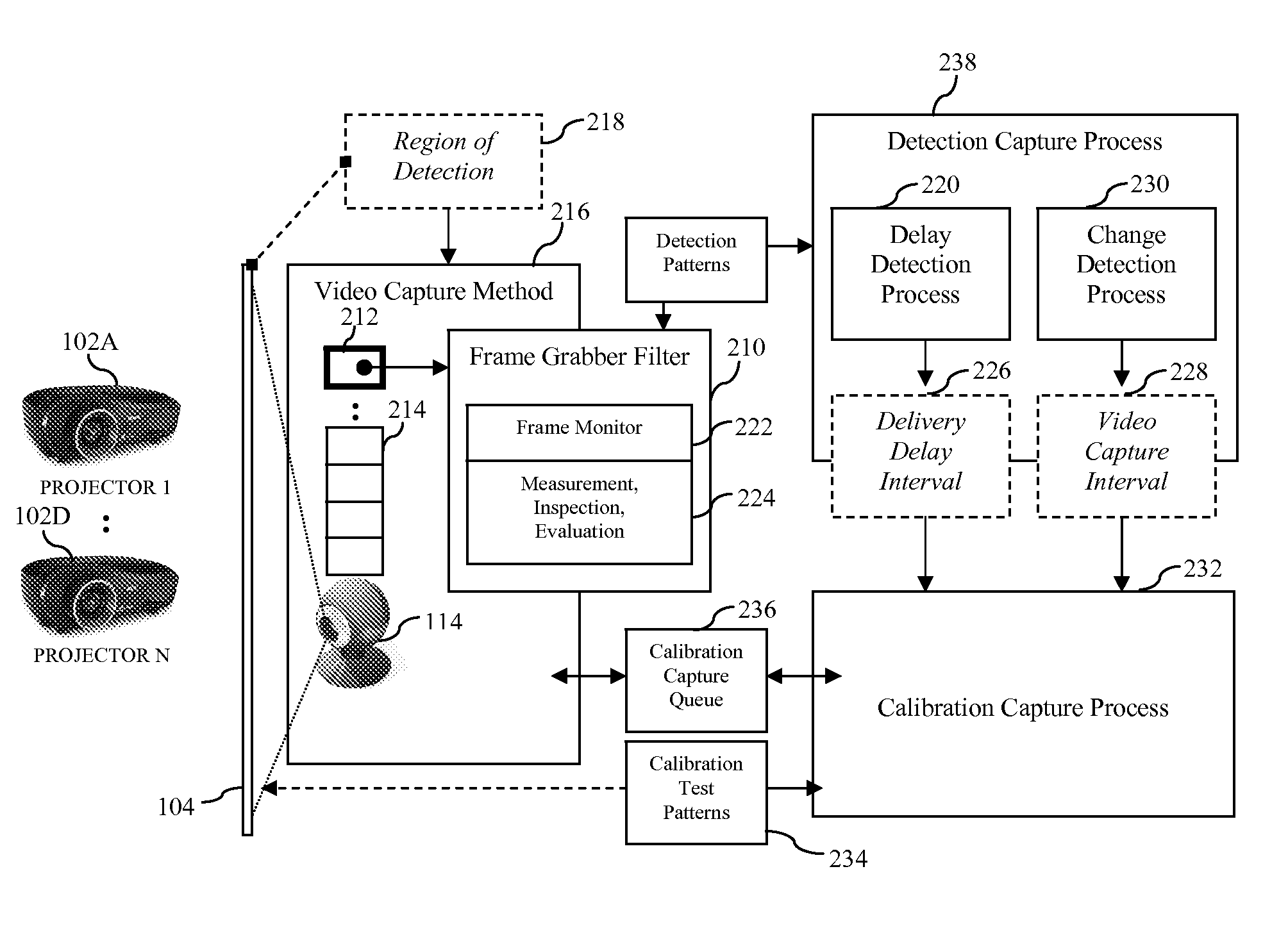

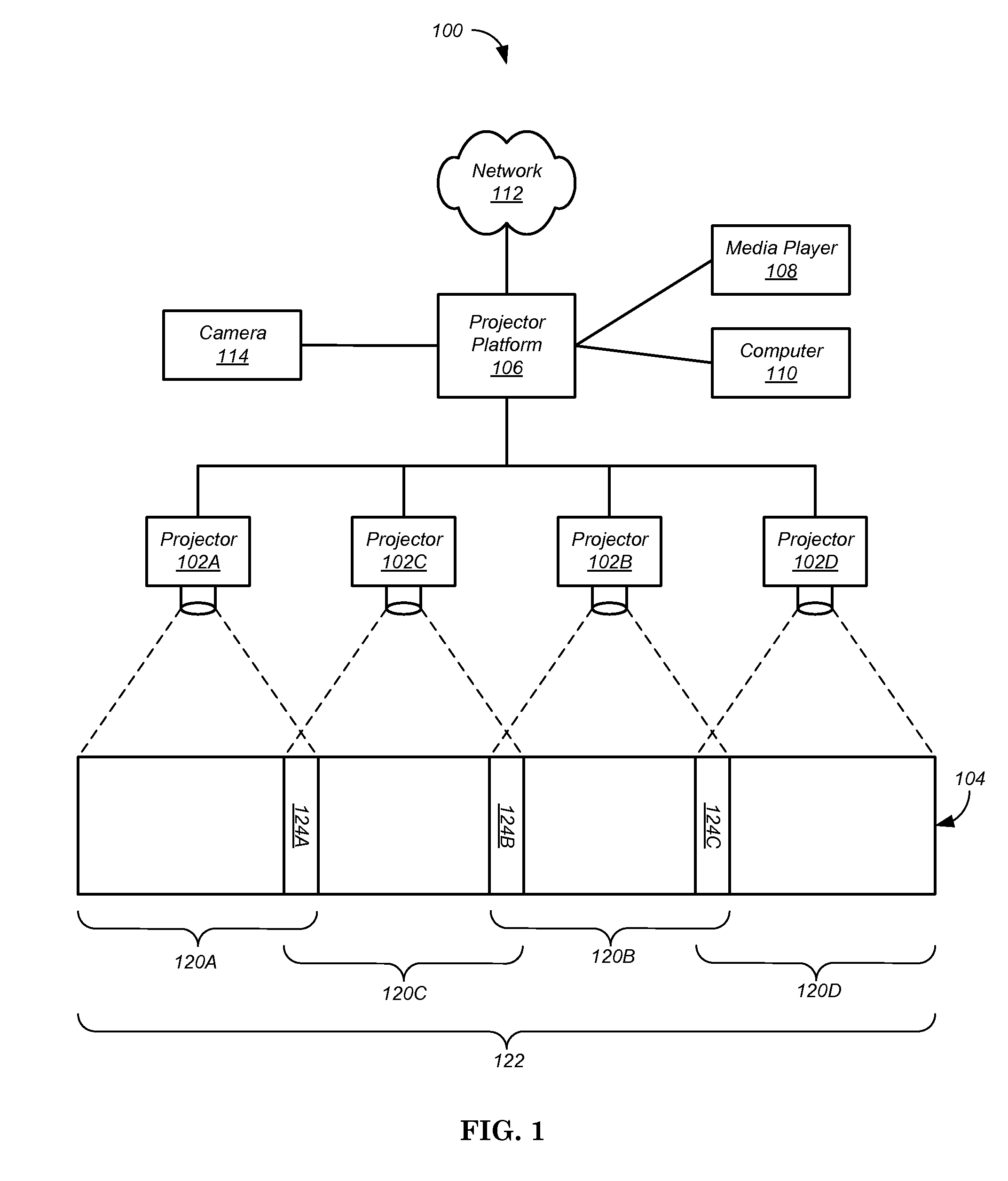

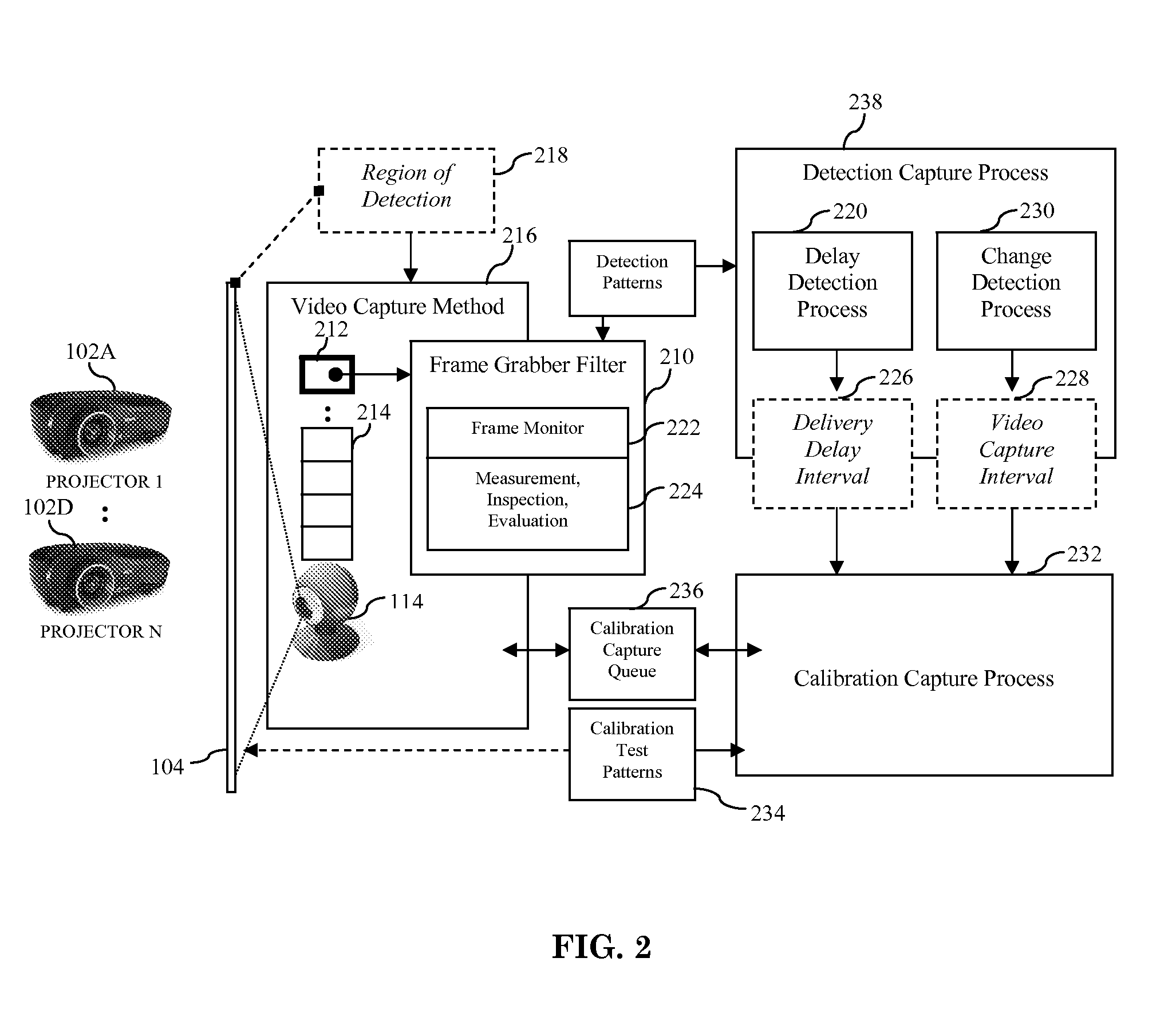

Method For Determining A Video Capture Interval For A Calibration Process In A Multi-Projector Display System

InactiveUS20120242910A1Television system scanning detailsPulse generatorTime segmentComputer graphics (images)

First, a delivery delay, i.e. the time it takes for a content to be captured and a representative frame made available (i.e. delivered), is determined. Second, a video capture interval, i.e. a minimum time delay requirement between stable captured content frames, is determined. In other words, the recycle time-period after which it is safe to change frame content during a capture interval without impacting a prior stable video frame in the pre-delivery stage is determined.

Owner:SEIKO EPSON CORP

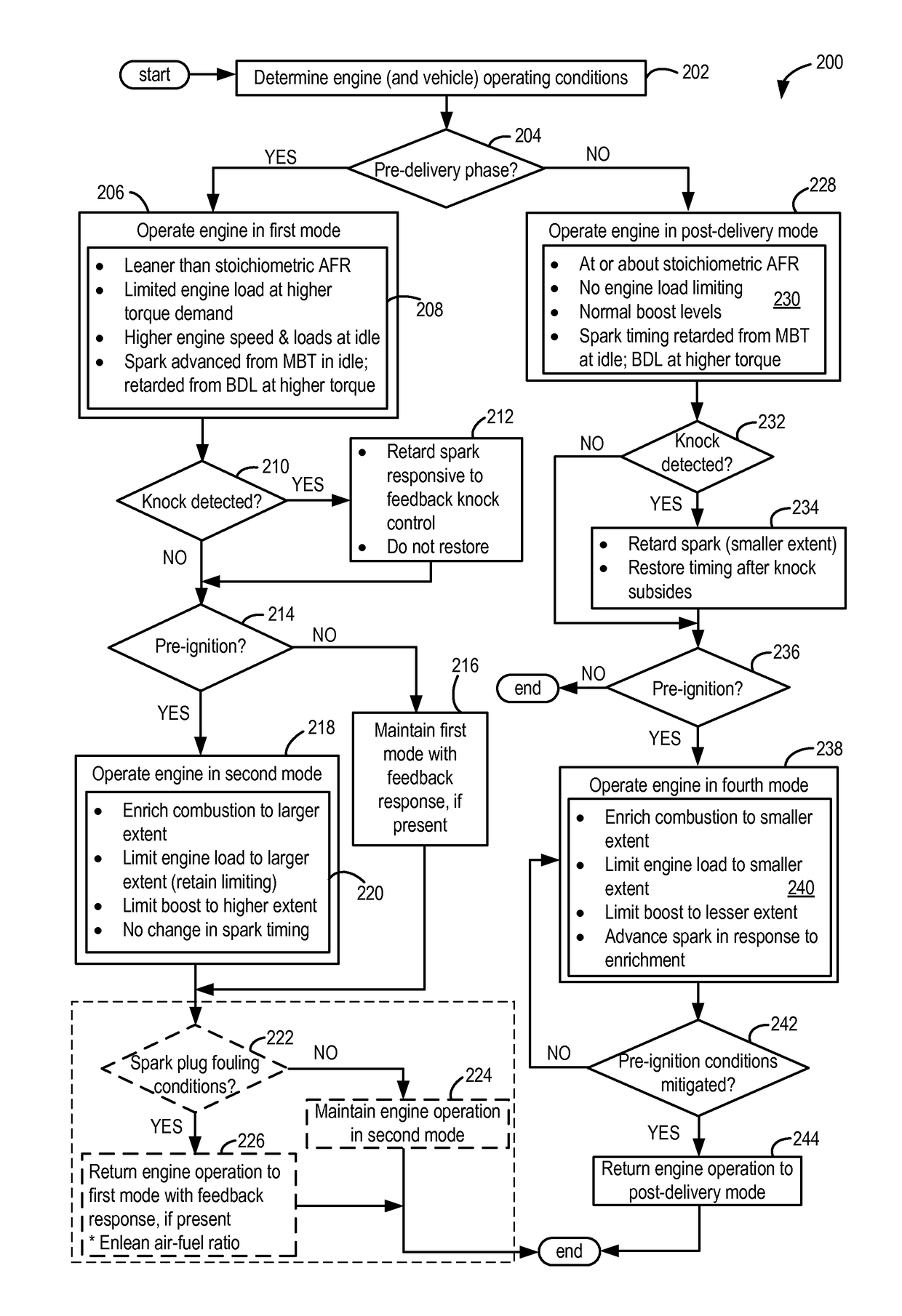

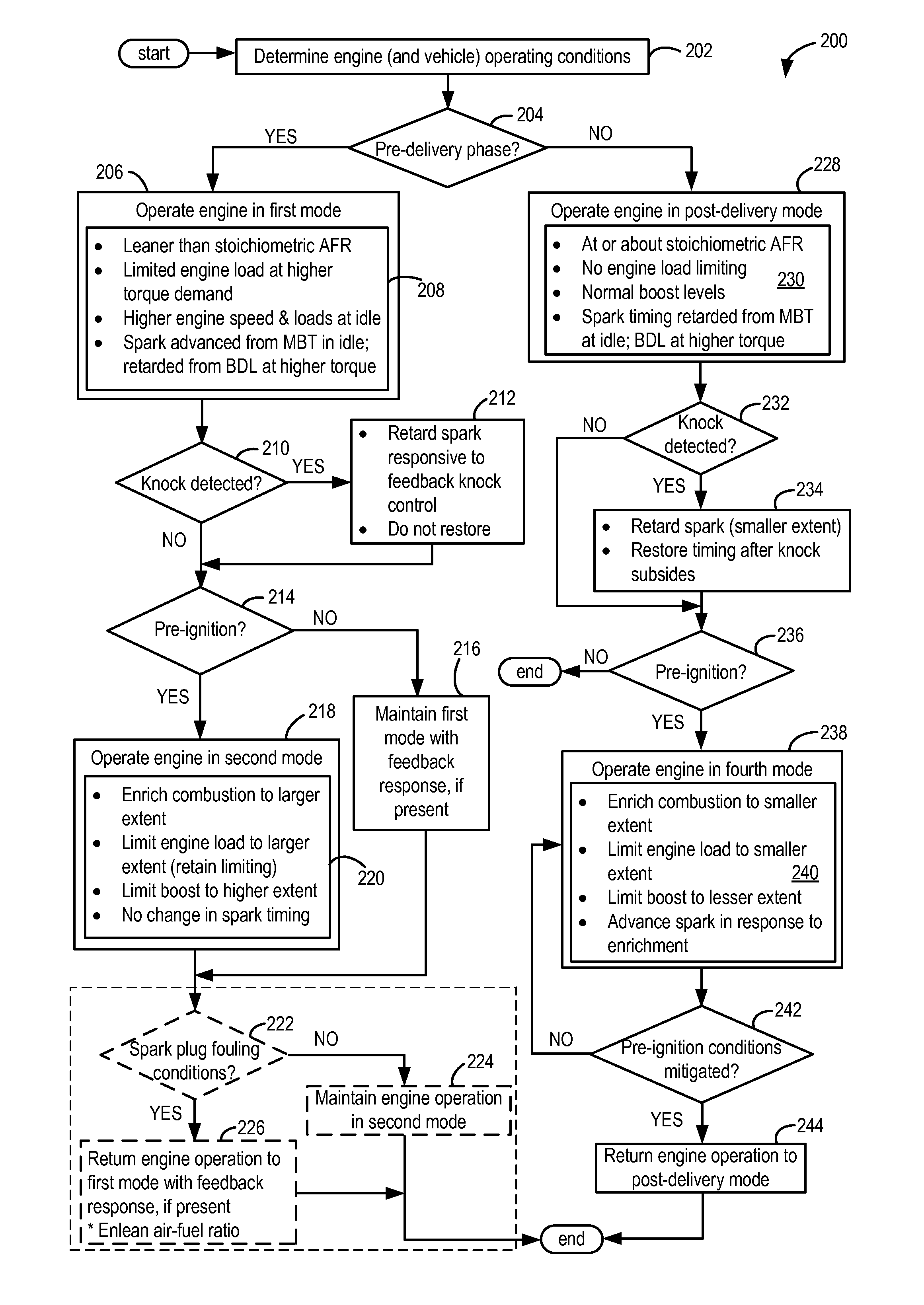

Method for pre-ignition control

ActiveUS20160146127A1Quality improvementImprove performanceValve arrangementsElectrical controlIgnition coilEngineering

Owner:FORD GLOBAL TECH LLC

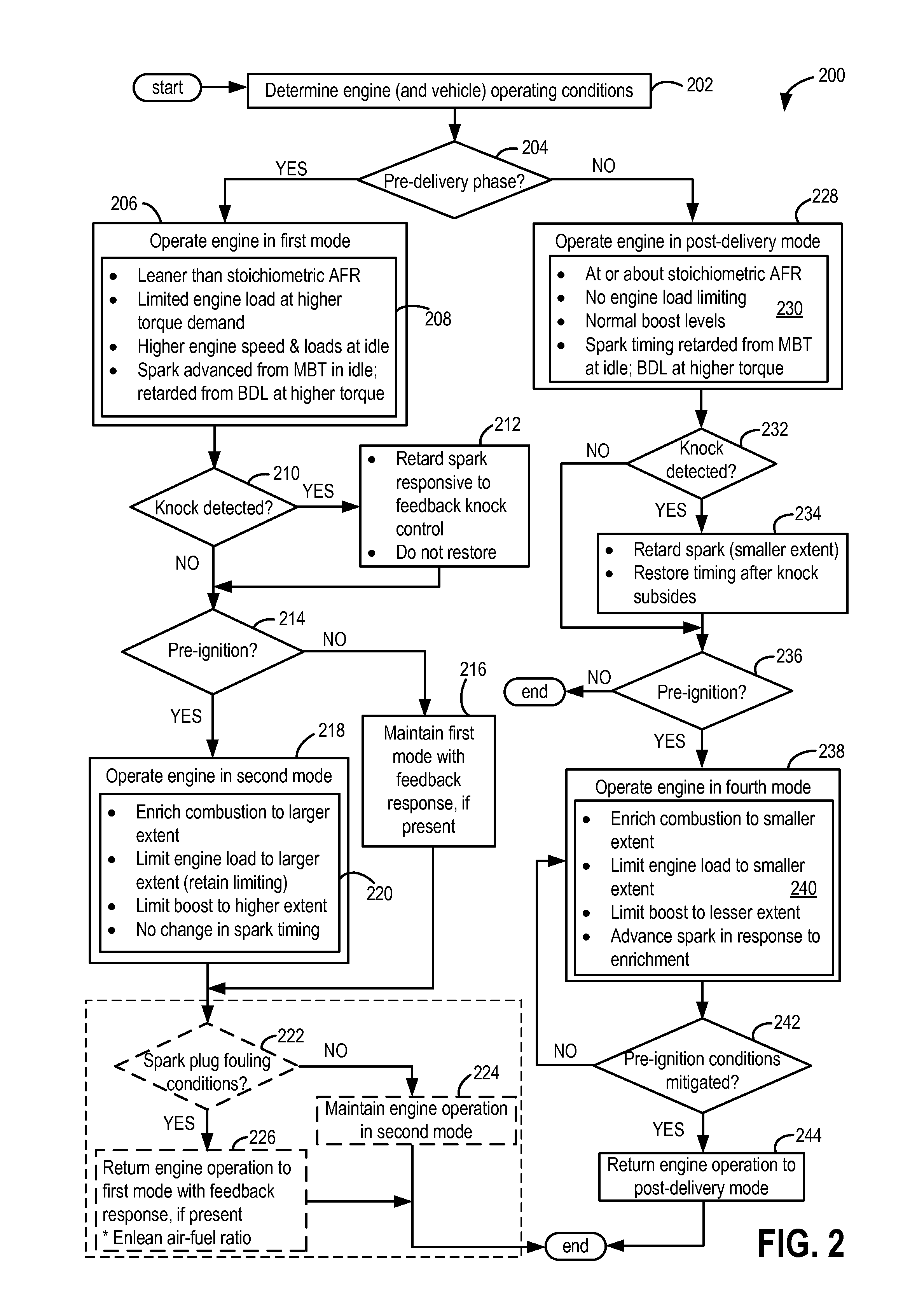

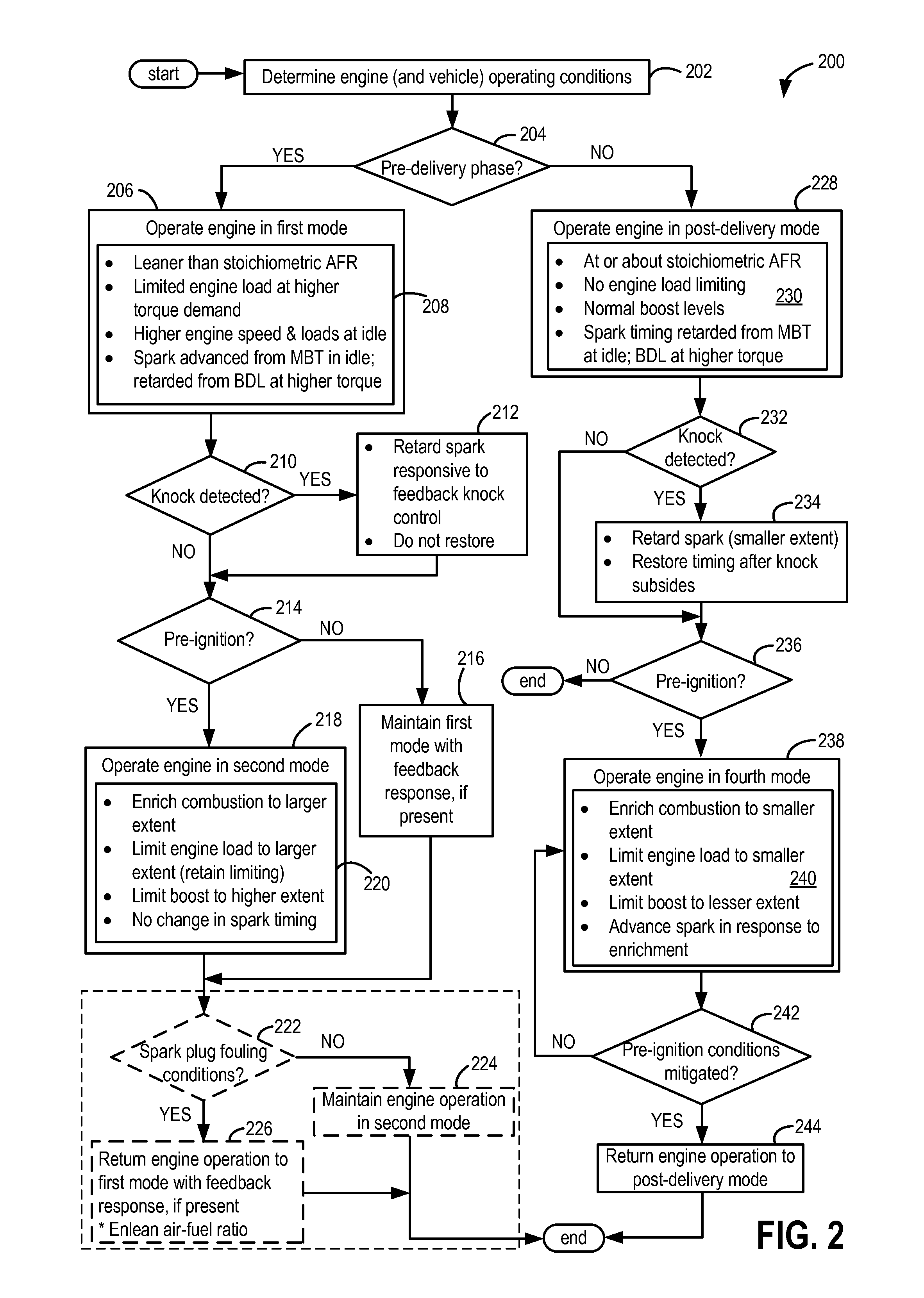

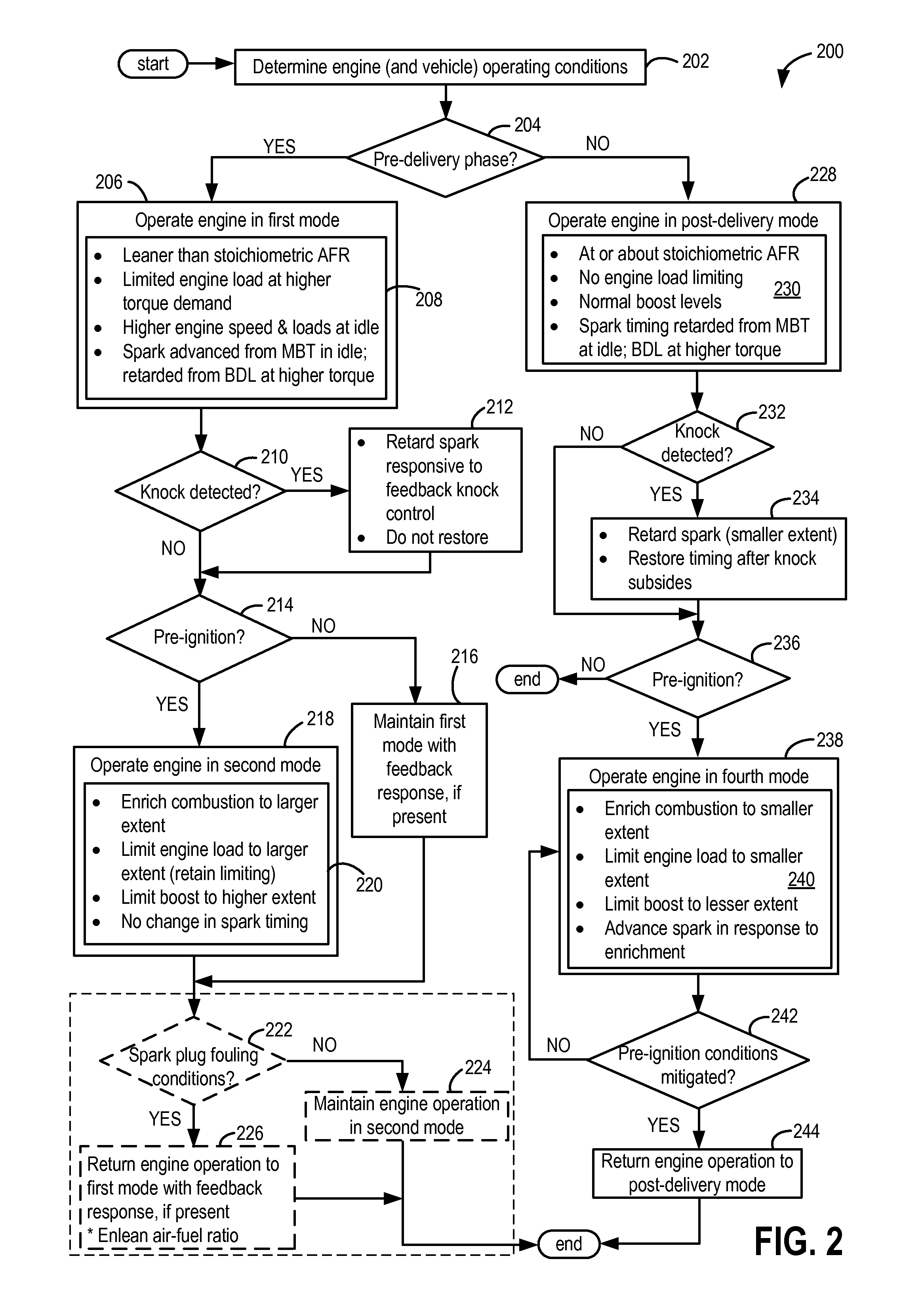

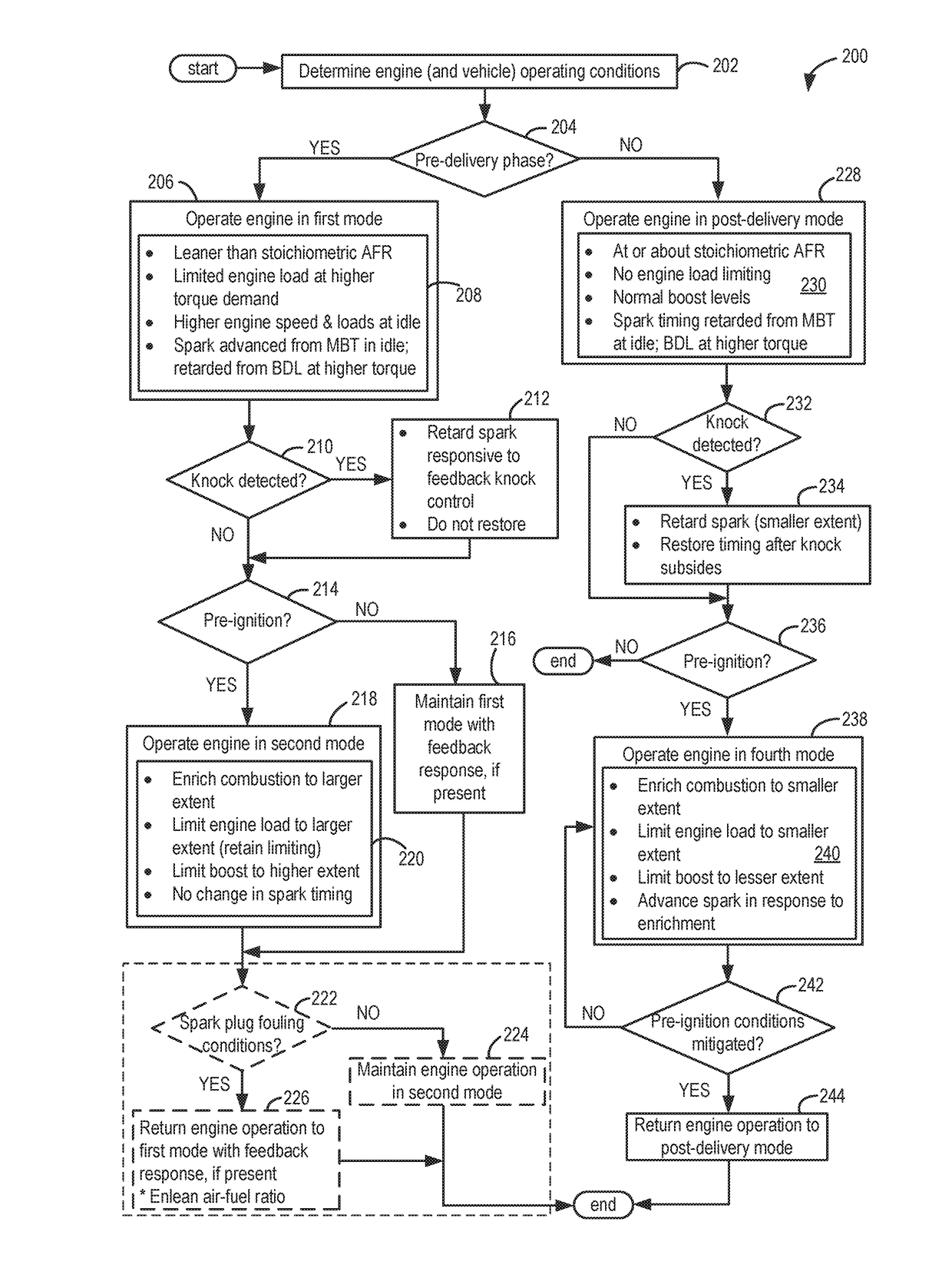

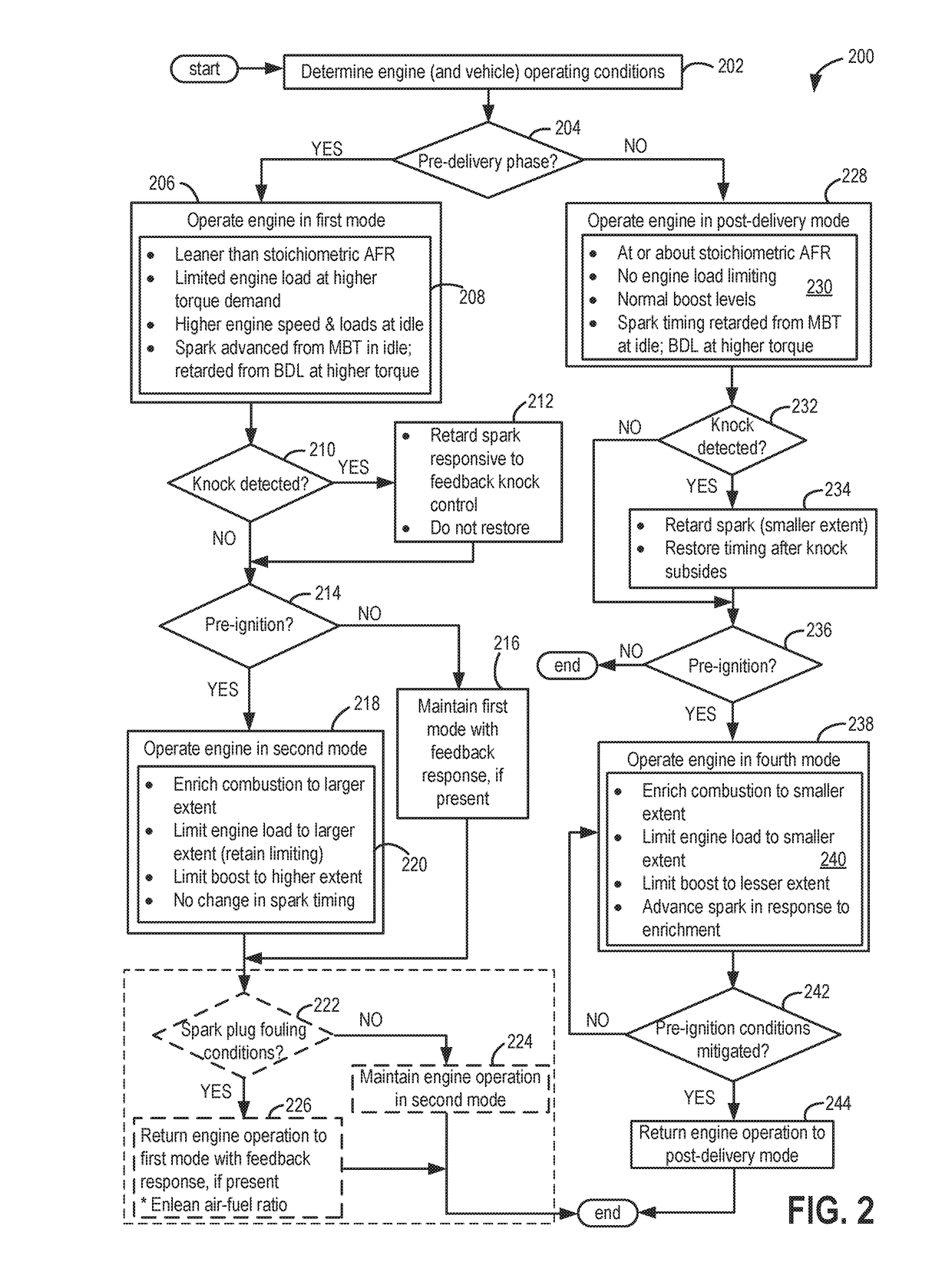

Method for pre-ignition control in a pre-delivery phase

ActiveUS20160146126A1Diminish pre-ignitionDiminish spark plug foulingValve arrangementsElectrical controlIgnition coilControl theory

Various systems and methods are described for controlling spark plug fouling and pre-ignition in a newly manufactured vehicle. One method comprises, during a pre-delivery phase of the newly manufactured vehicle including an engine, operating the engine with a first setting for air / fuel ratio to reduce spark plug fouling, and adjusting the first setting of the air / fuel ratio responsive to pre-ignition.

Owner:FORD GLOBAL TECH LLC

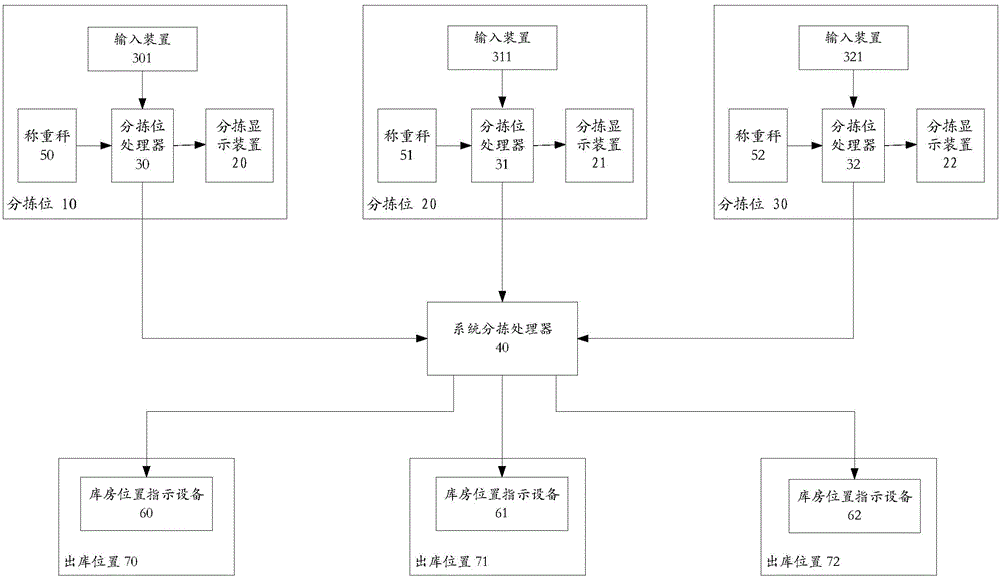

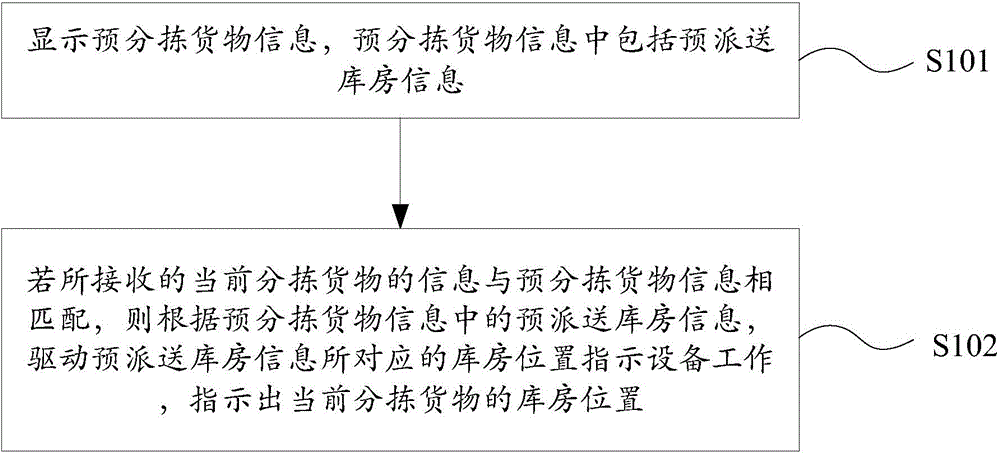

Efficient sorting method and efficient sorting system

The invention relates to an efficient sorting method which comprises the following steps: displaying pre-sorted cargo information comprising pre-delivery warehouse information; if the received current sorted cargo information is matched with the pre-sorted cargo information, driving indicating equipment of a warehouse position corresponding to the pre-delivery warehouse information to work to indicate the warehouse position of the current sorted cargo according to the pre-delivery warehouse information in the pre-sorted cargo information. The problems that the existing sorting process is complicated and has a long period are solved. In the cargo sorting process, a specific indication can be given to an operator, so that the sorting error is prevented and the sorting efficiency is improved. The sorted commodities are photoelectrically indicated, so that the stacking and arrangement process of cargo is shortened. Therefore, the sorting time is shortened, the manual taking step is simplified, the possibility of deterioration of fresh commodities, especially for products of which the quality is greatly influenced by temperature, is reduced, and the timely sorting of cargo is ensured, and thus the logistics period and the transaction validity are improved.

Owner:北京任我在线电子商务有限公司

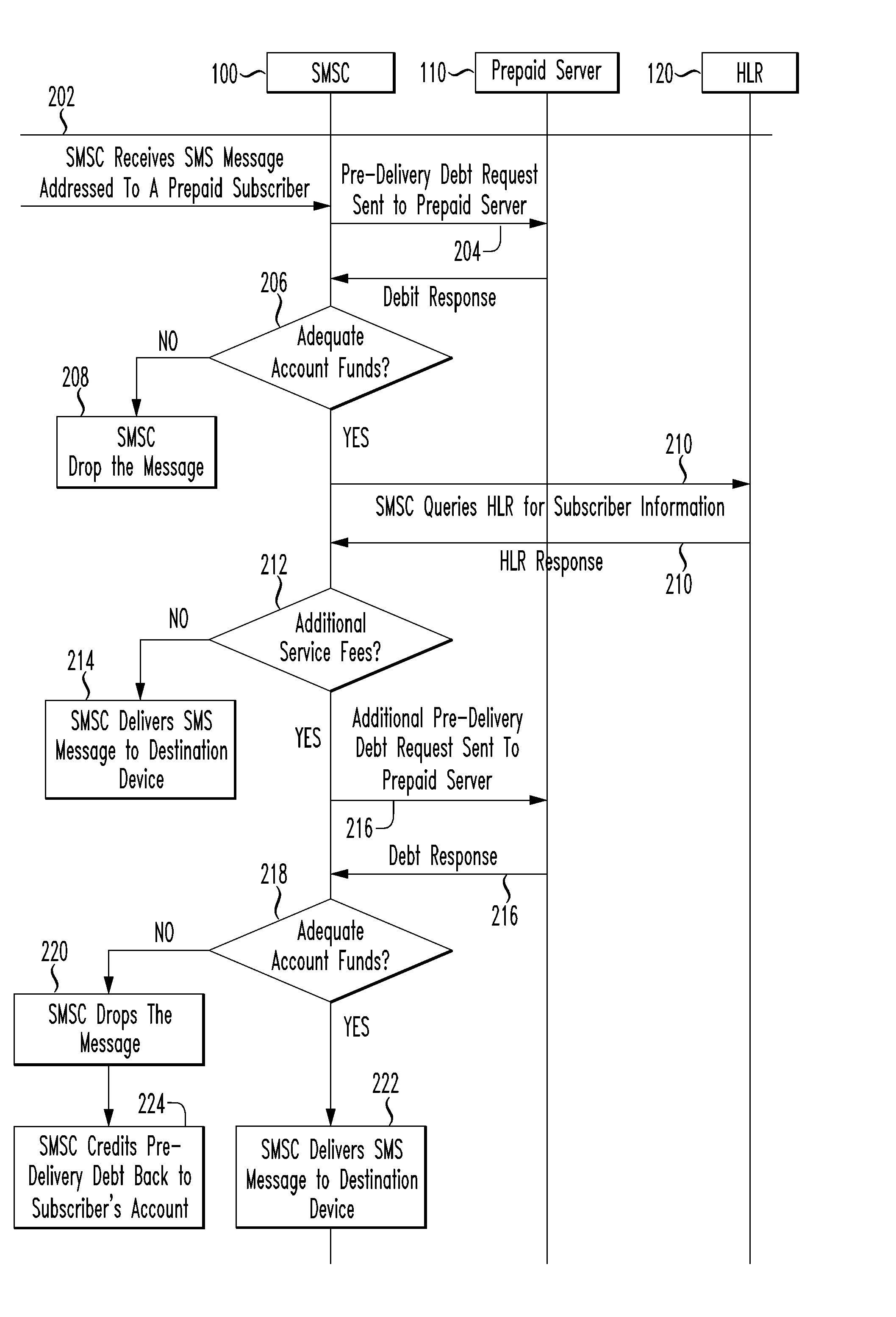

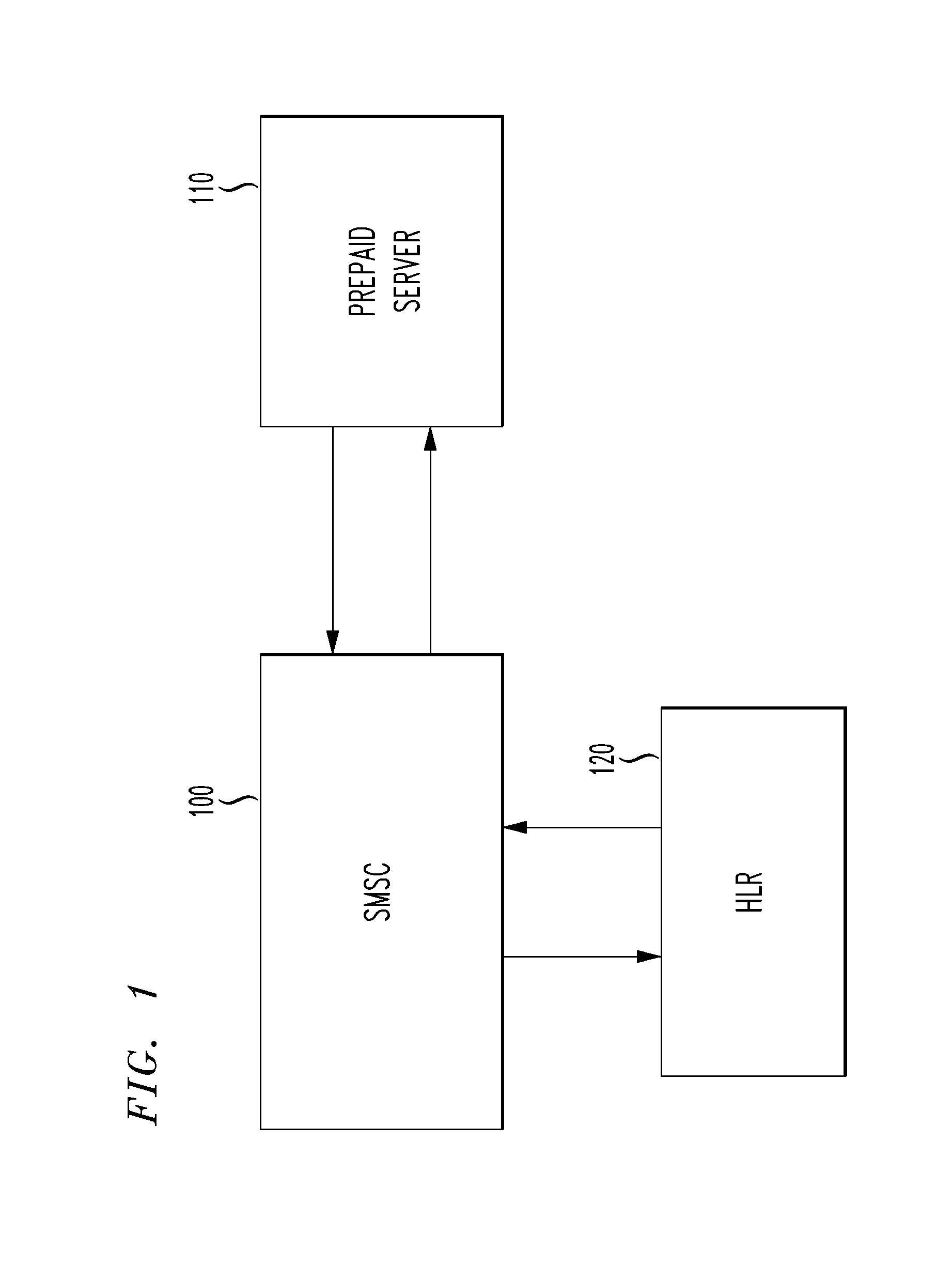

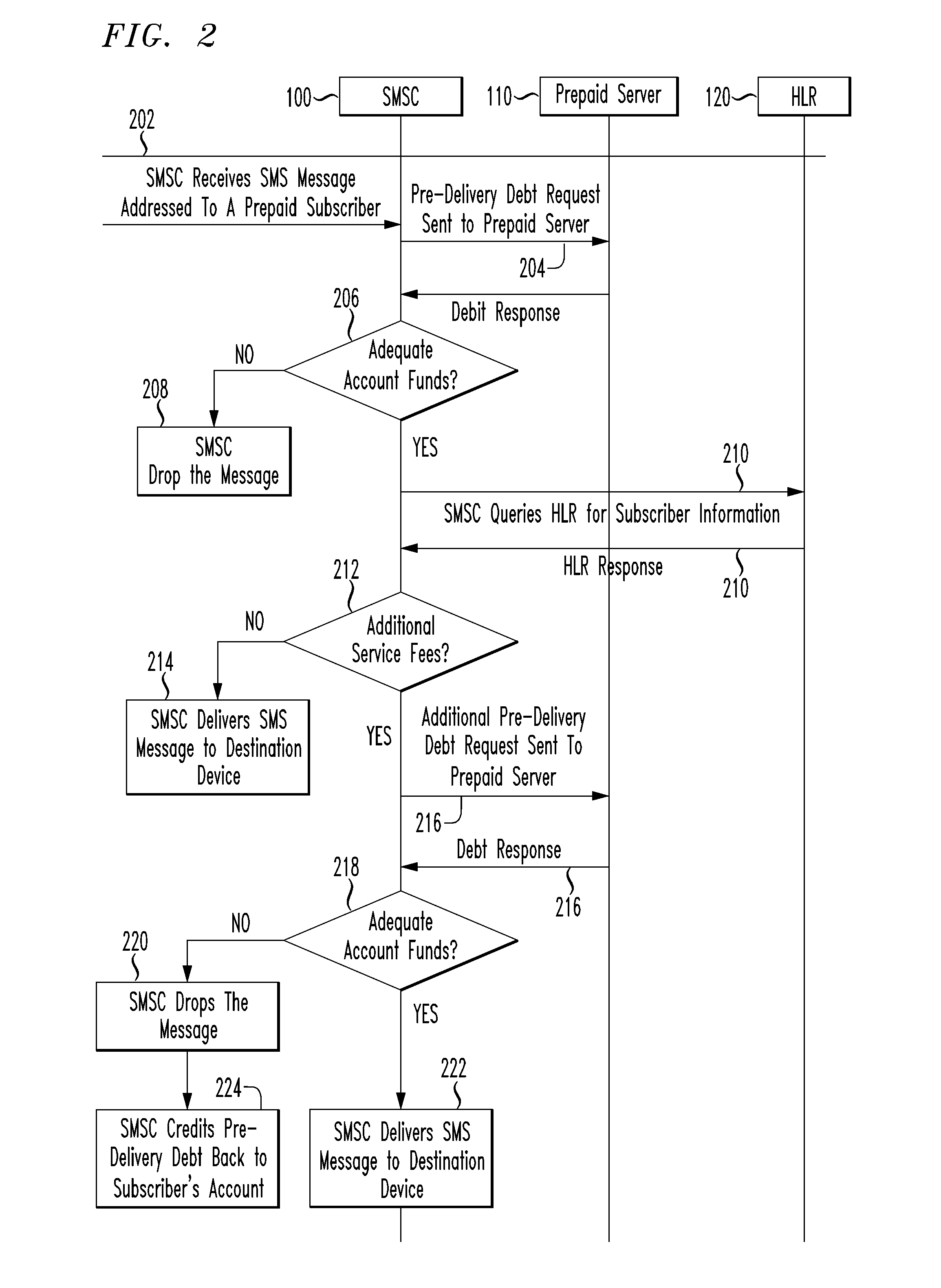

Prepaid Short Message Services Revenue Capture

InactiveUS20130045711A1Sufficient account balanceSolve the lack of balanceAccounting/billing servicesCredit schemesMessage deliveryDatabase

A prepaid messaging solution that utilizes a pre-delivery debit query to tariff a short message, coupled with an additional debit query performed once necessary billing information has been acquired. A short message is tariffed prior to message delivery via a pre-delivery debit query to a prepaid server. During message delivery, the prepaid server is queried a second time, following the HLR query performed by the Short Message Service Center (SMSC). This subsequent debit query bills a subscriber for any additional service fees discovered throughout message delivery, e.g., international / roaming fees, etc. If either the pre-delivery debit query or the subsequent debit query indicates that a subscriber has insufficient account balance to deliver a short message, the message is prevented from being delivered. If a message is dropped due to lack of account balance, any funds debited throughout the attempted message delivery may be credited back to the subscriber's prepaid account.

Owner:TELECOMM SYST INC

Computer Support Service with Solution Function Updates as a Function of Pre-Delivery Expert Changes to Automatically Generated Solutions

InactiveUS20080040299A1Logical operation testingDigital computer detailsDiagnostic dataPaper document

A solution engine of a vendor's highly-automated adaptive computer support system for a remote customer automatically generates proposed solutions, e.g., sets of support documents, as a function of diagnostic data received from a customer's computer system. The automatically generated solution can be subject to expert review prior to publication to the customer, e.g., when the automated system assigns a low confidence level to the solution. In addition, expert review can be triggered by feedback from the customer once a proposed solution is communicated. The diagnostic data, solutions and feedback for an incident are packaged as a “case” and entered into a historical case database. A solution function updater updates the solution function as a function, at least in part, of the expert review and customer feedback.

Owner:MICRO FOCUS LLC

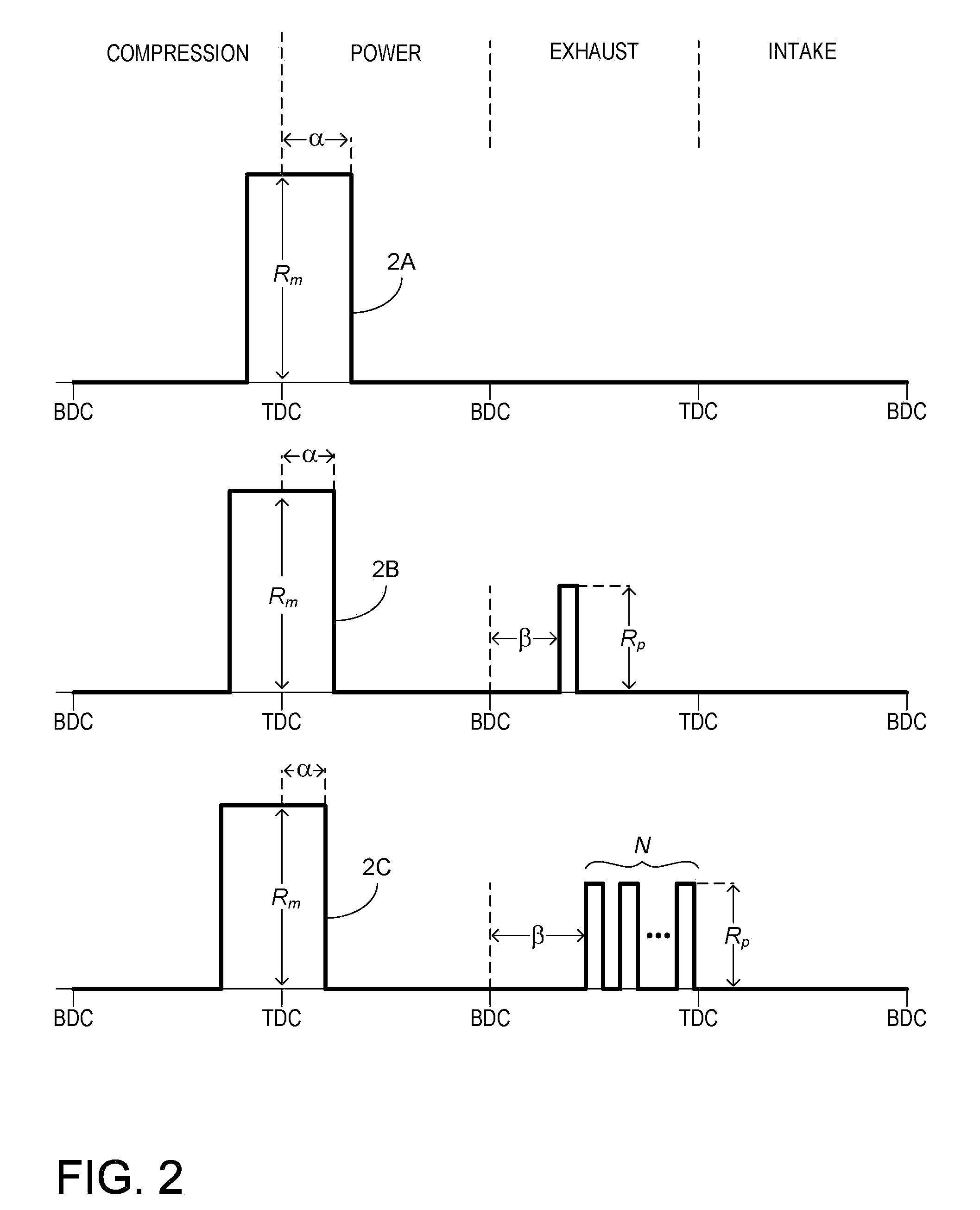

Pre-Delivery Strategy for Diesel-Engine Vehicles

ActiveUS20090240419A1Emission reductionImprove efficiencyElectrical controlInternal combustion piston enginesRunning timeTime table

A method to supply fuel to an engine of a vehicle is provided. The method includes adjusting a direct injection of fuel into a cylinder of the engine based on whether the vehicle is in a pre-delivery state. In one example, the method includes reducing an amount of fuel in a post injection. In other examples, the method includes changing a timing of a post injection. In still other examples, the method includes changing an amount and / or a timing of a main injection of fuel, or suppressing a post injection. By using a modified post injection schedule during pre-delivery, cylinder bore wetting effects may be reduced. After pre-delivery, a normal post injection schedule may be used to reduce emissions. Pre-delivery may be identified in a variety of ways: based on a number of miles driven, a maximum vehicle speed, an engine run time, or combinations thereof, as examples. Further, a vehicle retailer may actuate a delivery-indicating signal once the vehicle has been delivered.

Owner:FORD GLOBAL TECH LLC

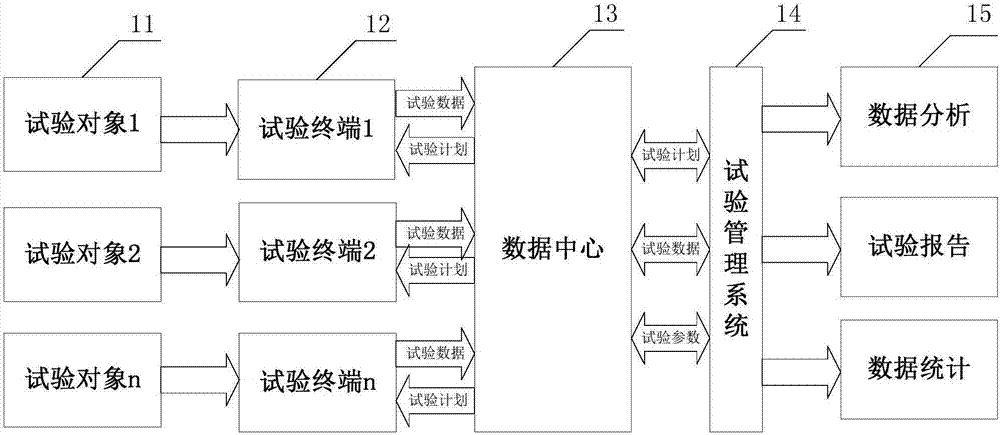

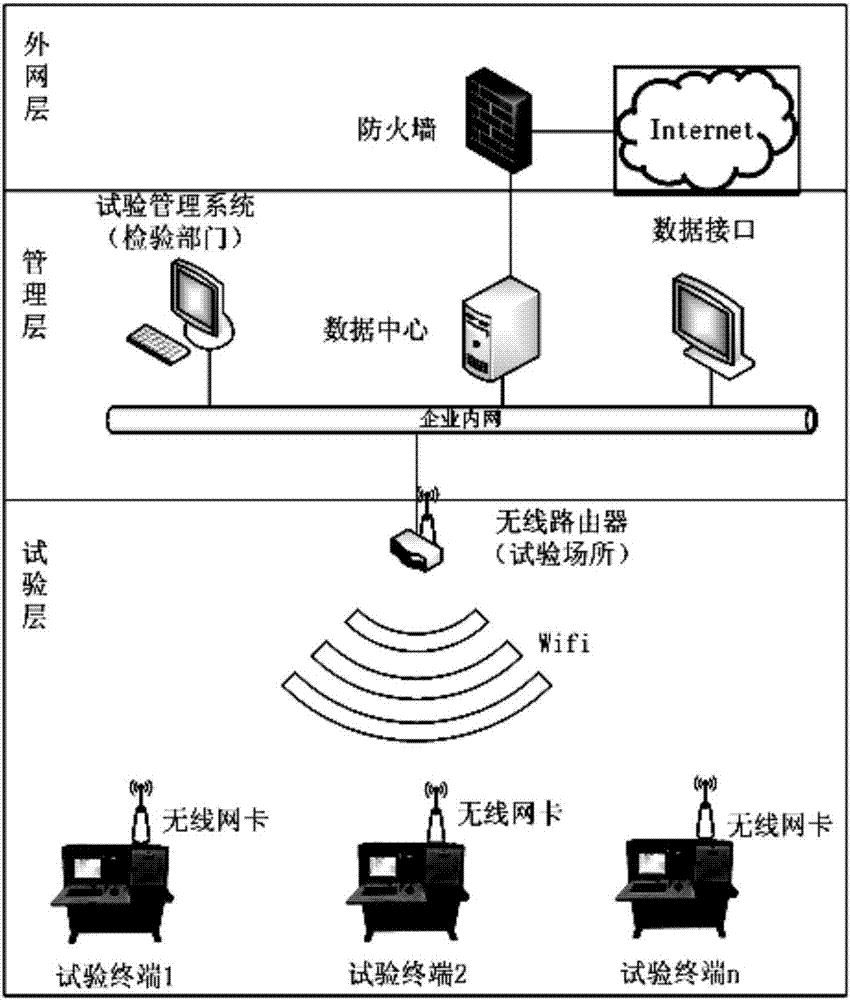

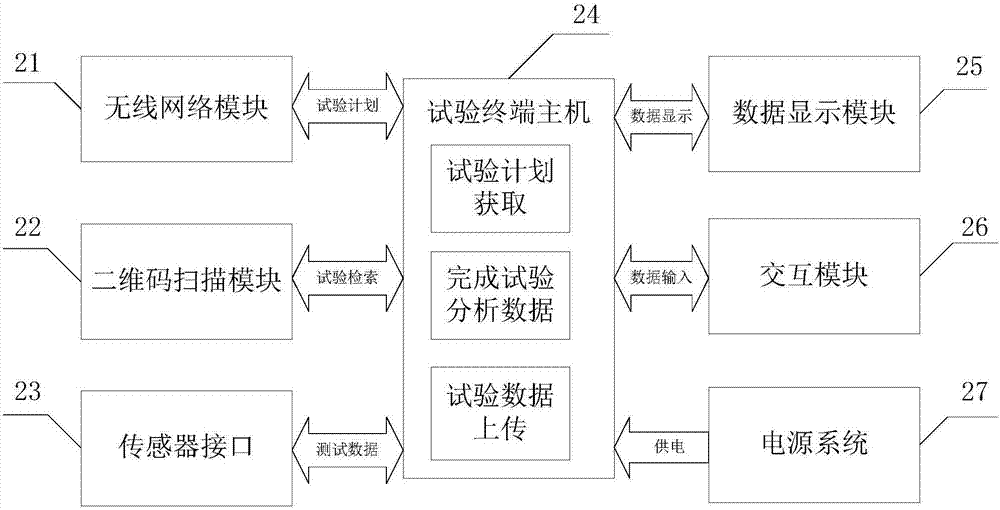

Network-based high-voltage switchgear test management system and method

InactiveCN107192945AQuick searchImprove accuracyCircuit interrupters testingTest efficiencyTest flow

The invention provides a network-based high-voltage switchgear test management system and method. With the system adopted, the digital and network-based management of high-voltage switchgear pre-delivery tests can be realized, a test flow can be simplified, test efficiency can be improved, and the security and authenticity of test data can be ensured. Computer technology, database technology, network technology and the like are adopted to realize the network-based and digital management of the high-voltage switchgear pre-delivery tests; and the system can realize work such as test terminal parameter automatic configuration, the database management of test the data, the automatic generation of test plans and the generation of test reports, simplify the test flow, improve the accuracy of the tests and ensure the authenticity and security of the test data.

Owner:CHINA XD ELECTRIC CO LTD

Method for pre-ignition control in a pre-delivery phase

ActiveUS9719436B2Reduce spark plug foulingAvoid excessive depositionValve arrangementsElectrical controlIgnition coilControl theory

Various systems and methods are described for controlling spark plug fouling and pre-ignition in a newly manufactured vehicle. One method comprises, during a pre-delivery phase of the newly manufactured vehicle including an engine, operating the engine with a first setting for air / fuel ratio to reduce spark plug fouling, and adjusting the first setting of the air / fuel ratio responsive to pre-ignition.

Owner:FORD GLOBAL TECH LLC

Storage tray cooperating with lifting mechanism for delivery conveniently and storage mechanism of vending machine

PendingCN108205842AExport smoothlyQuick exportCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringPre delivery

The invention relates to the field of vending machines, and discloses a storage tray cooperating with a lifting mechanism for delivery conveniently. Multiple mutually independent storage cases are arranged on the storage tray, all the storage cases can be used for storing to-be-sold cargoes of the vending machine, and first openings allowing the lifting mechanism to penetrate through from bottom to top are formed in the bottoms of the storage cases. The invention further discloses a storage mechanism of the vending machine, and the storage mechanism comprises the storage tray. In the deliveryprocess, after the storage tray rotates the pre-delivery cargoes to the delivery position, due to the fact that the first openings are formed in the storage cases, the lifting mechanism can penetratethrough the storage cases from bottom to top through the openings to lift the cargoes in the storage cases, and then continue to move upwards to make the cargoes delivered to a delivery port formed inthe top; by means of the first opening, it is guaranteed that the lifting mechanism can export the cargoes in the storage cases out smoothly and rapidly.

Owner:CHENGDU EVENTEC SCI & TECH CO LTD

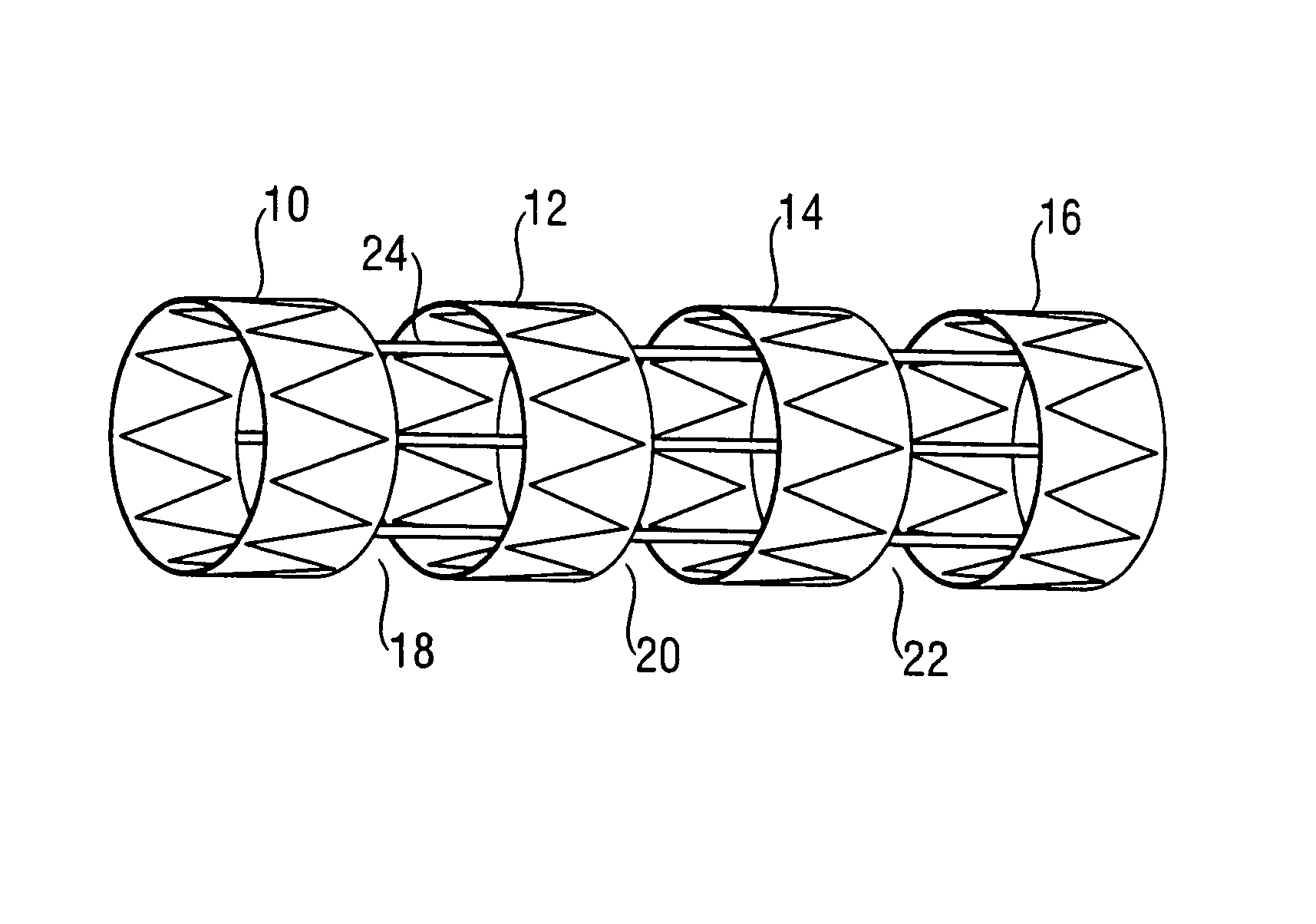

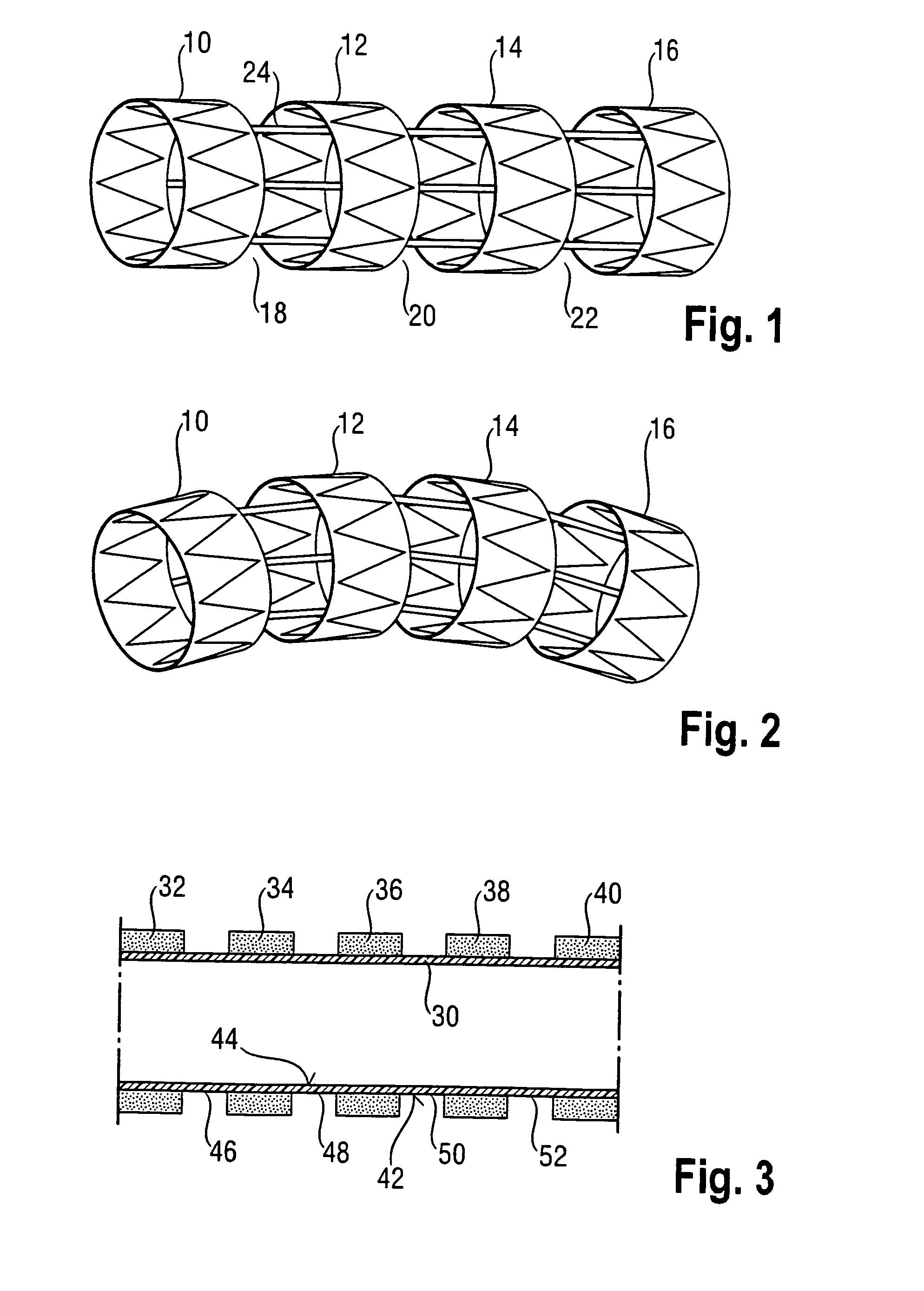

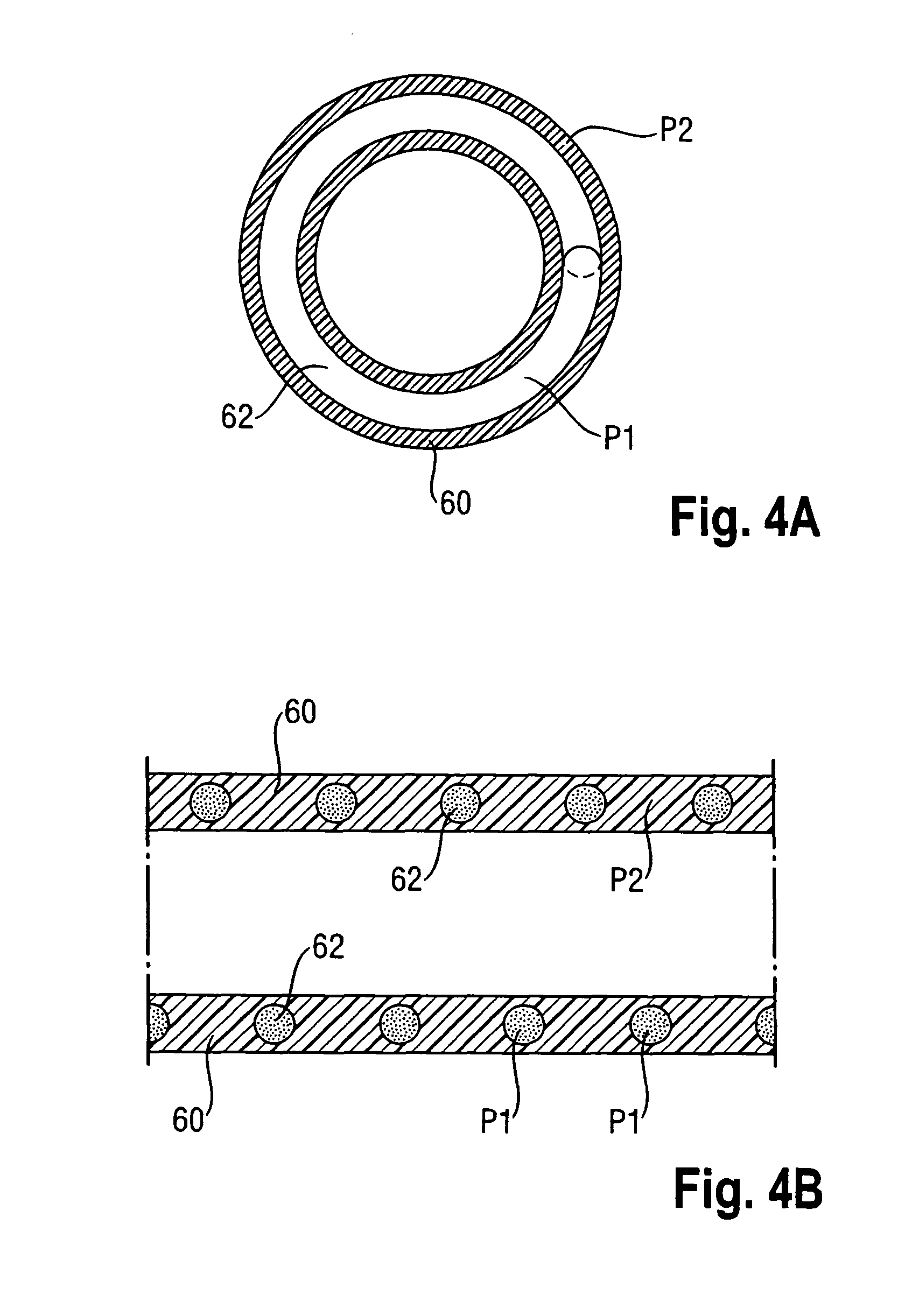

Polymer prosthesis

A polymer prosthesis with lumen and an axial length and having in a pre-delivery condition a plurality of relatively stiff stenting segments spaced from each other along the length of the prosthesis, the spaces between the relatively stiff stenting segments of a first polymer being bridged by relatively flexible linking segments of a second polymer, different from the first, the relatively stiff stenting segments and the relatively flexible linking segments being alternately arranged along the length of the prosthesis.

Owner:CR BARD INC

Novel method used for recycling urban industrial sludge

InactiveCN106277692AMain modes of widening processingLow priceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCombustionExpanded clay aggregate

The invention discloses a novel method used for recycling urban industrial sludge. The novel method comprises following steps: water content of urban industrial sludge obtained via sewage treatment plant mechanical dewatering is reduced to 50 to 65% using a drying device, wherein an independent heat source or gas waste heat is adopted by the drying device as a heat source; the dewatered sludge, an auxiliary material, and a certain amount of an additive are mixed at a certain ratio, wherein the above materials are delivered into corresponding feed hoppers, and automatic induction weighing machines arranged under the feed hoppers are used for realizing material automatic compounding measuring; an obtained mixture is delivered into a blender for stirring, is conveyed using a conveying belt, and is made into material balls via twisting; the material balls are delivered into a rotary kiln with a certain gradient for calcination, wherein with rotating of the rotary kiln, the material balls roll to a kiln head, 2mm bran is sprayed into the rotary kiln for combustion, and the material balls are transformed into ceramsite via calcination in the kiln; and at last the obtained ceramsite is subjected to drying, natural cooling, sieving and grading, and finished product pre-delivery inspection. The novel method possesses following advantages: waste sludge is changed into valuable things, sludge treatment mode is widened, and sludge is cheap, so that enterprise cost is reduced.

Owner:NINGBO PINGHAI BUILDING MATERIALS

Method for pre-ignition control

ActiveUS9541014B2Quality improvementImprove performanceValve arrangementsElectrical controlEngineeringControl theory

Owner:FORD GLOBAL TECH LLC

Method for pre-ignition control

ActiveUS20170082081A1Quality improvementImprove performanceValve arrangementsElectrical controlIgnition coilControl theory

Owner:FORD GLOBAL TECH LLC

Electromagnetic nondestructive testing method and device for elevator steel belt

PendingCN109374725ASimple structureDoes not affect the detection effectMaterial magnetic variablesEngineeringSteel belt

The invention provides an electromagnetic nondestructive testing method and device for an elevator steel belt. The testing method comprises the following steps: installing an excitation circuit, installing a detection unit, installing multiple sensing units and testing. The testing device comprises an excitation circuit, a detection unit, multiple sensing units, a device main body and an end cover. Compared with the traditional steel wire rope detection, the testing method and device disclosed by the invention have the advantages that a magnet yoke is not needed, the sensor layout and wiring are convenient, the size is small, the weight is light, and the testing accuracy is high; which specific steel wire rope has defects can be distinguished, and accurate positioning and testing can be realized. The testing method and device disclosed by the invention can be applied to online elevator steel belt detection, and are also applicable to periodic detection of the steel wire rope in the pre-delivery inspection and application processes.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

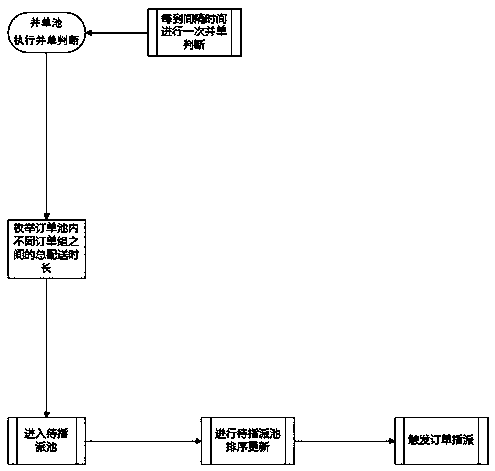

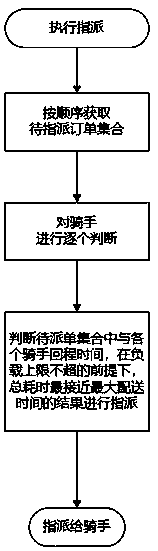

An intelligent consolidation and dispatching method

The invention discloses an intelligent consolidation and dispatching method, comprising the following steps: S1. Setting a preset angle, a maximum pre-delivery time, an order quantity upper limit anda maximum distribution time; S2. The new order enters the consolidation pool; S3. Consolidating the orders in the consolidated pool, the judging steps are as follows: S4. The orders after consolidating enters the pool to be assigned, and then the pool to be assigned is sorted and updated; 5, obtaining a set of orders to be assign in sequence when that assignment is executed; 6, judging that riderone by one, judging the return time between each rider and the order set to be dispatched, and assigning the result that the total time consuming is closest to the maximum distribution time on the premise that the load upper limit is not exceeded; Efficient combination of orders is realized by intelligent order splicing planning, and the most suitable rider assignment is judged by intelligent order dispatching rules. The average delivery time of each order is shortened by 20 minutes, which greatly increases the total limit of daily order fulfillment for riders, and improves efficiency and saves cost for restaurants.

Owner:餐道信息科技有限公司

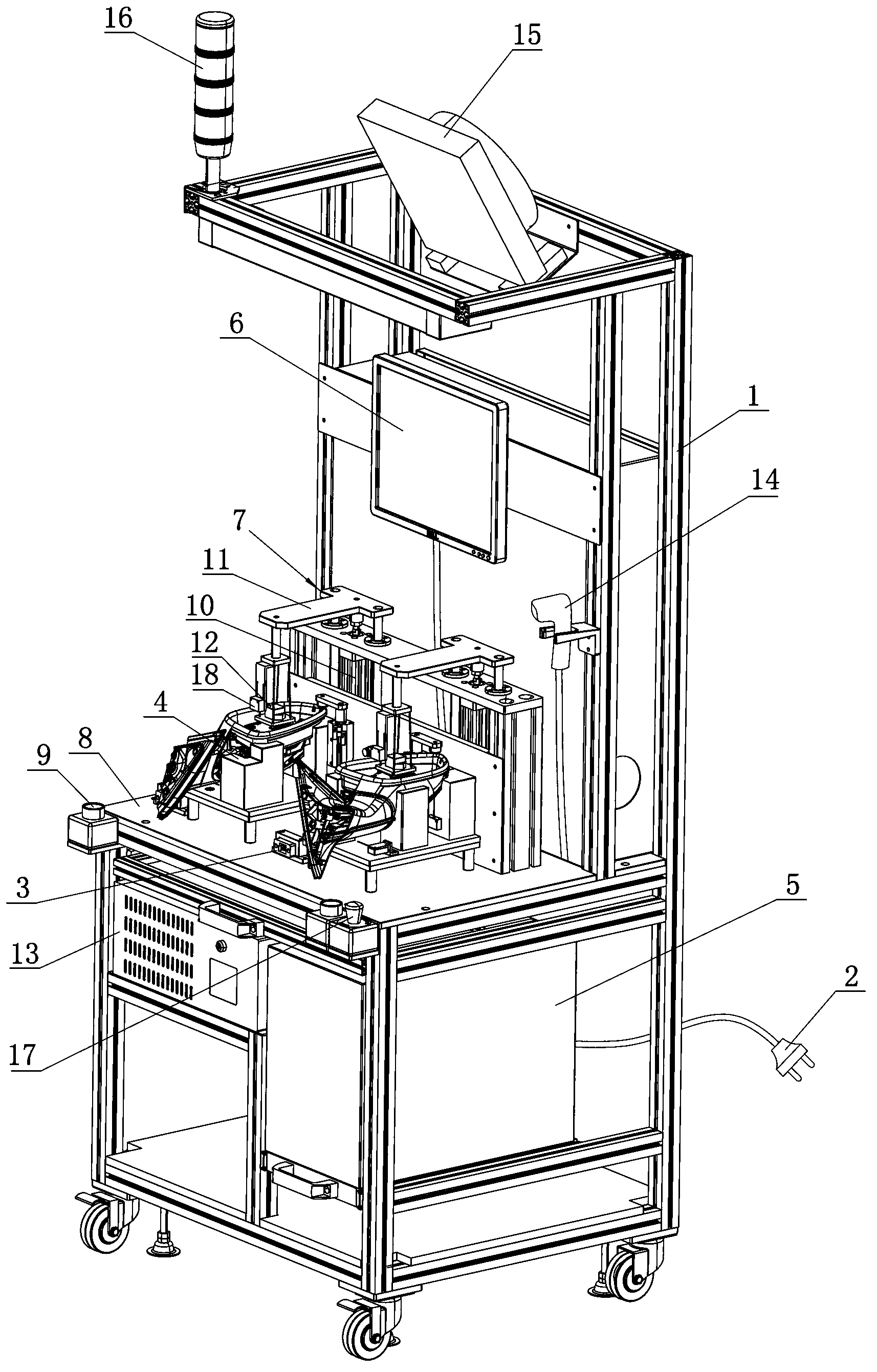

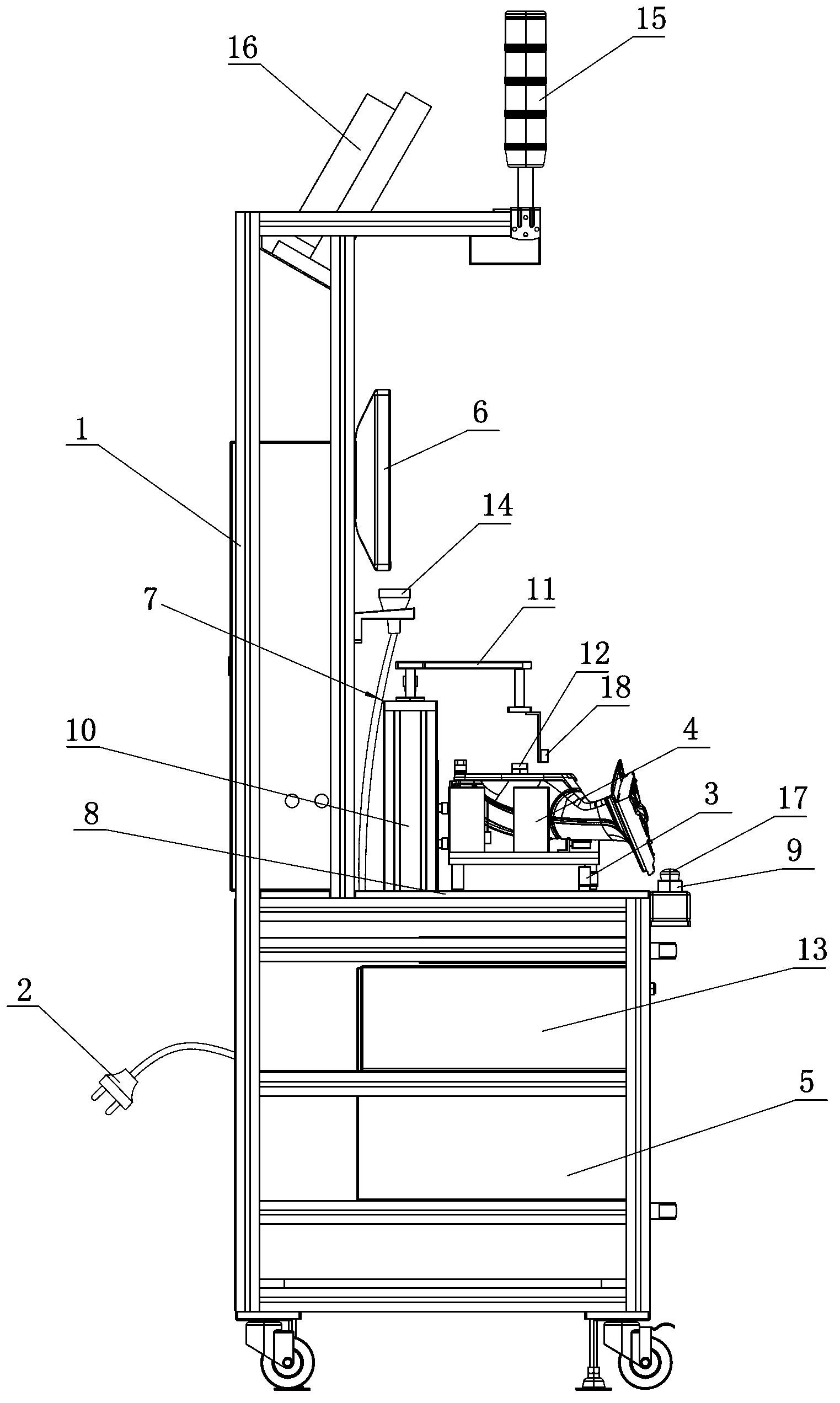

Vehicle rearview mirror pre-delivery detection device

A vehicle rearview mirror pre-delivery detection device comprises a control cabinet (5), a display screen (6) and a mirror surface position sensing mechanism (7). A workbench (8) is arranged on a machine frame (1); a rearview mirror clamp (4) and the mirror surface position sensing mechanism (7) are connected to the workbench (8); the control cabinet (5) is connected with the machine frame (1) and is located below the workbench (8); a power connector (2), a rearview mirror connector (3) and the mirror surface position sensing mechanism (7) are respectively and electrically connected with the control cabinet (5); the display screen (6) is fixed to the machine frame (1), located above the workbench (8) and electrically connected with the control cabinet (5); a starting switch (9) is arranged on the workbench (8) and is electrically connected with the control cabinet (5). Compared with the prior art, the vehicle rearview mirror pre-delivery detection device has the advantages of being full automatic in judgment and high in detection rate and detection efficiency.

Owner:NINGBO SMR HUAXIANG AUTOMOTIVE MIRRORS LTD

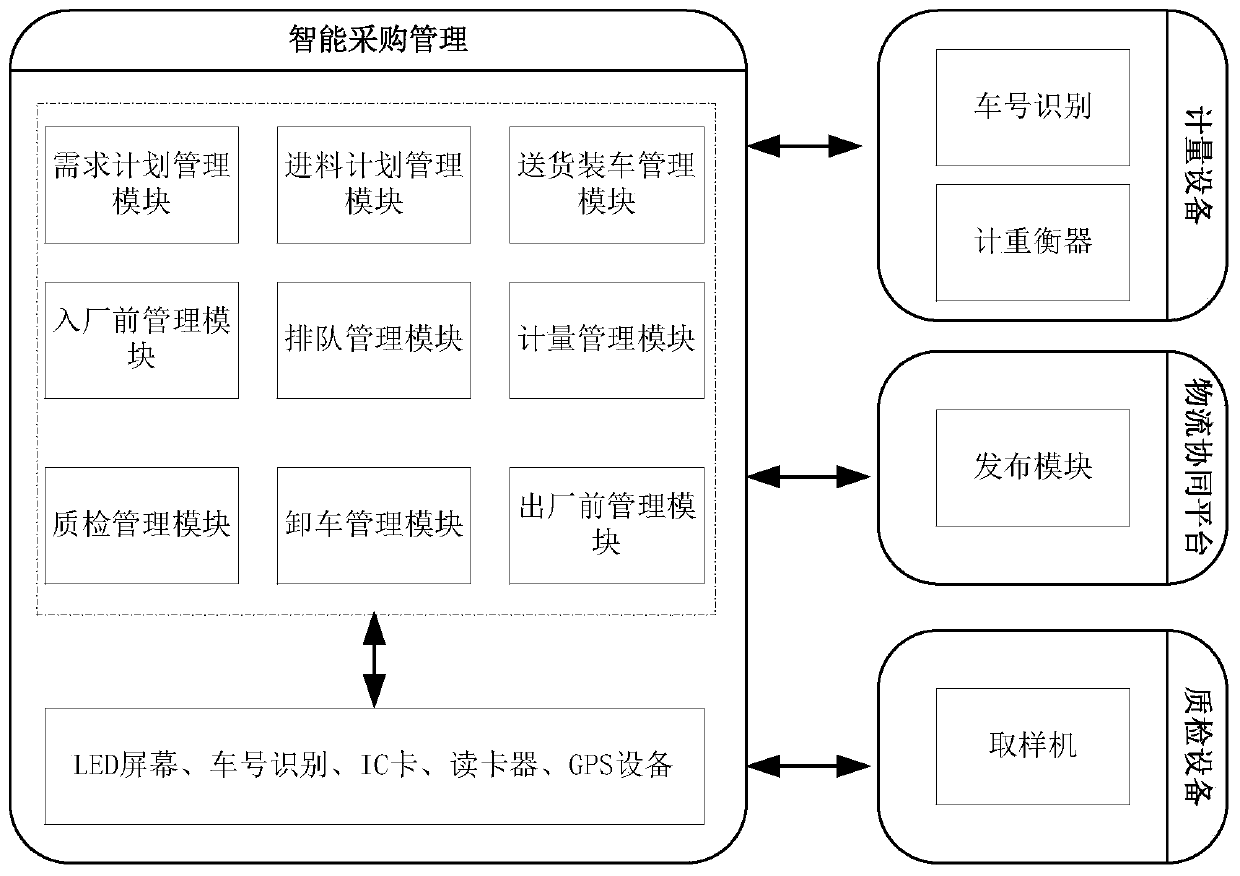

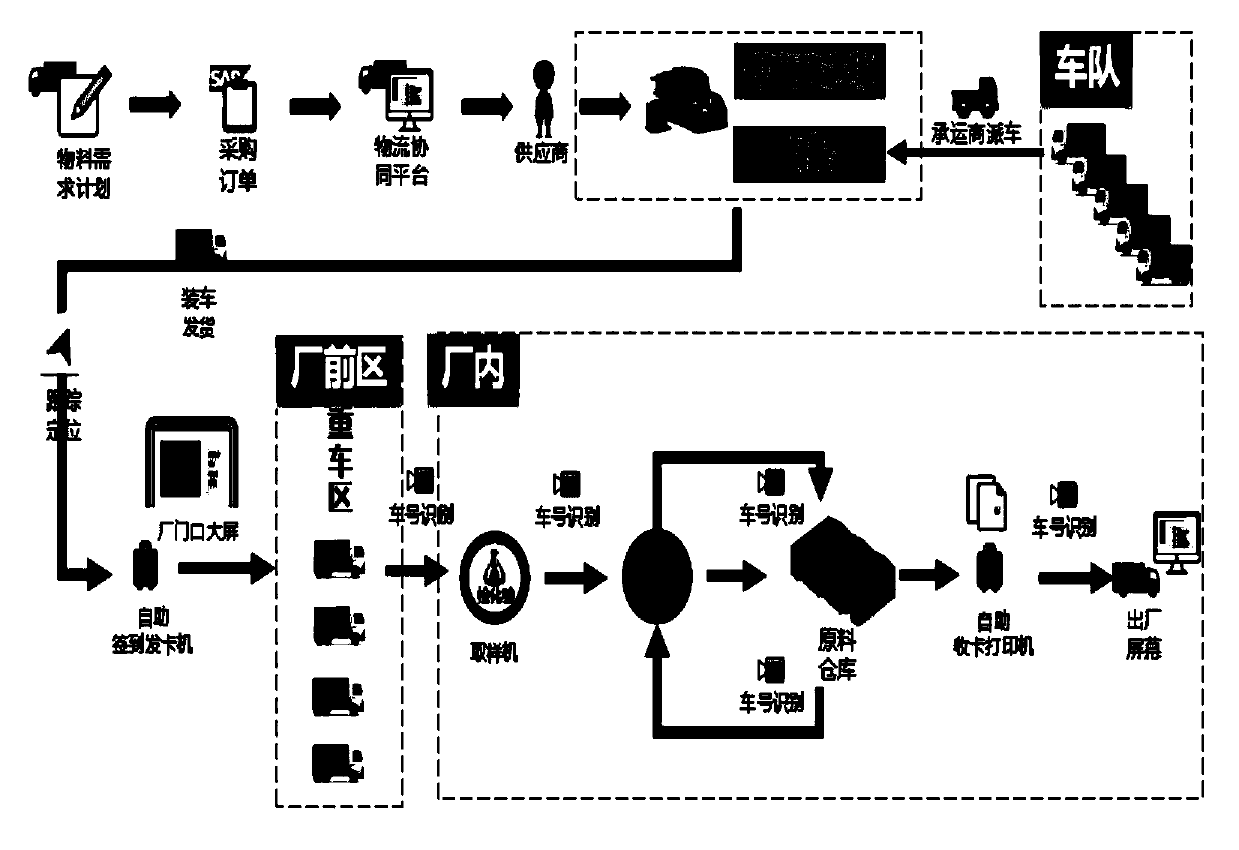

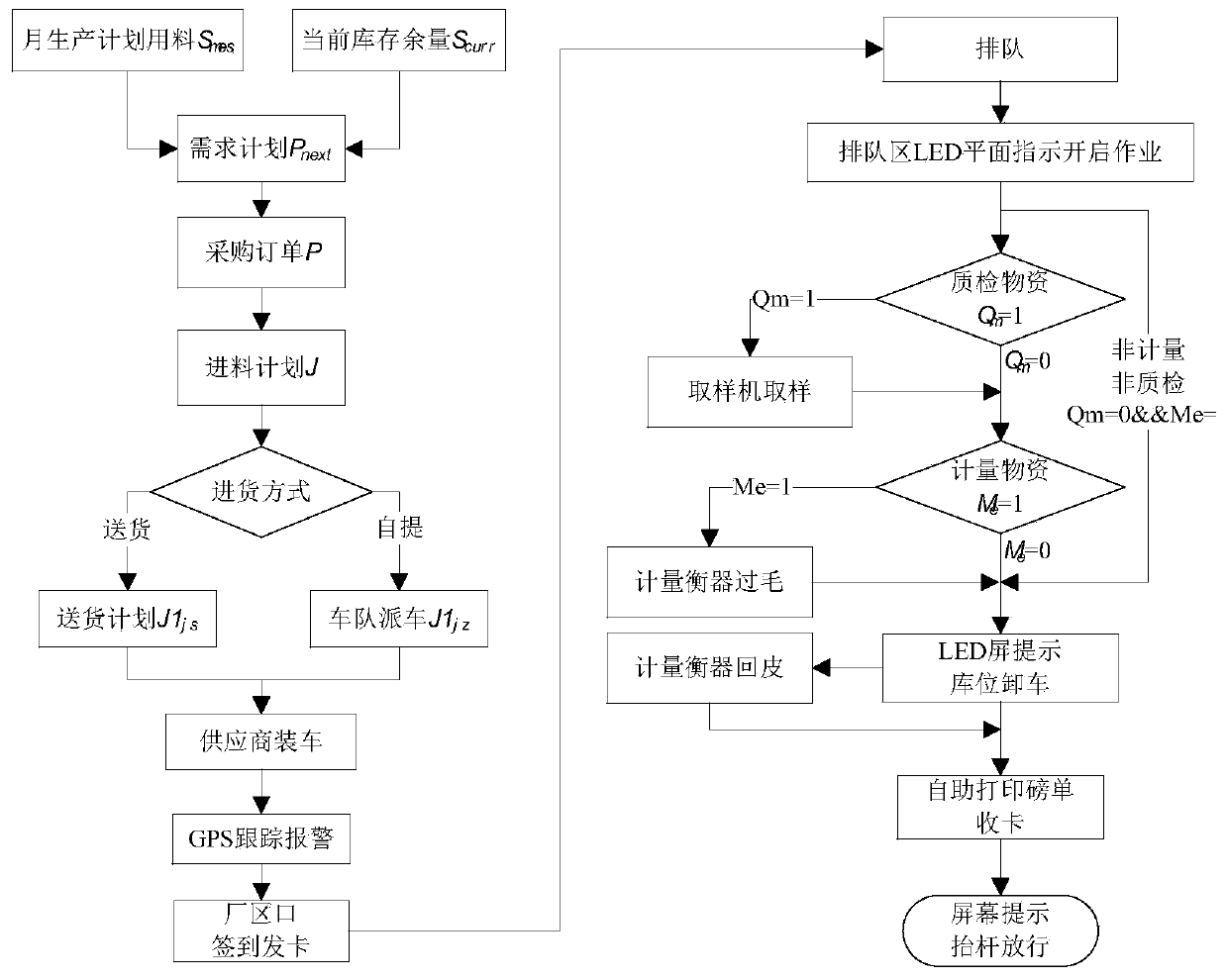

System and method for achieving intelligent purchasing management

InactiveCN110458307AStandardize the operation processLow costReservationsIndividual entry/exit registersLogistics managementProgram planning

The invention relates to a system and method for achieving intelligent procurement management. The system comprises a demand plan management module, a feeding plan management module, a logistics cooperation platform, a delivery and loading management module, a per-incoming management module, a queuing management module, a quality inspection management module, a metering management module, an unloading management module and a pre-delivery management module. All purchasing actions are strictly controlled, various services are standardized, vehicle transportation lines are standardized, anti-cheating verification is carried out by software and hardware means, manual operation is replaced by automatic equipment, operation is guided by an LED screen, the labor cost is reduced, the purchasing logistics operation efficiency is improved, and unmanned intelligent purchasing is realized.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com