Storage tray cooperating with lifting mechanism for delivery conveniently and storage mechanism of vending machine

A technology for vending machines and storage trays, which is applied to coin-free or similar appliances, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc., which can solve the consumption experience. Poor, low space utilization, large storage mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

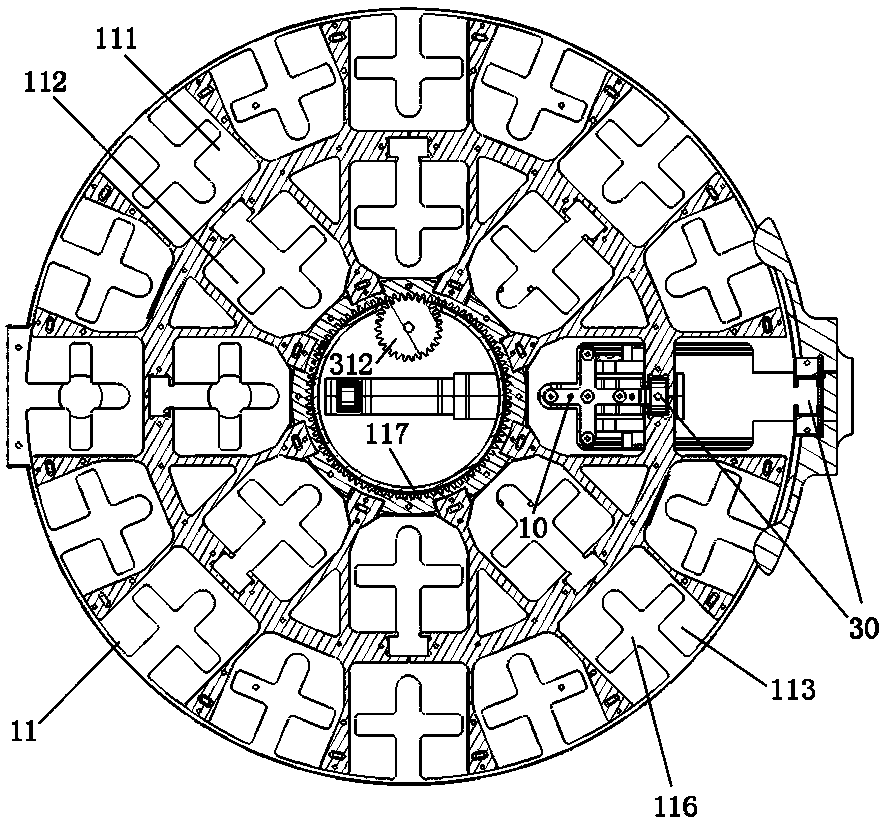

[0024] Such as figure 1 As shown, this embodiment provides a storage tray that is convenient for shipment with a lifting mechanism. The storage tray 11 is arranged with several mutually independent storage compartments 113, and each storage compartment 113 can be used to store automatic For the goods to be sold of the vending machine, the bottom of the storage compartment 113 is provided with a first opening 116 for the lifting mechanism of the vending machine to pass through from bottom to top.

[0025] Further, the storage tray 11 includes two storage rings, which are respectively the first storage ring 111 located in the inner ring and the second storage ring 112 located in the outer ring; the storage rings 111, 112 It is formed by the circular distribution of the storage compartments 113 at equal intervals.

[0026] Preferably, the first opening 116 penetrates to the edge of the storage compartment 113 . Designing the first opening 116 as a structure that penetrates to t...

Embodiment 2

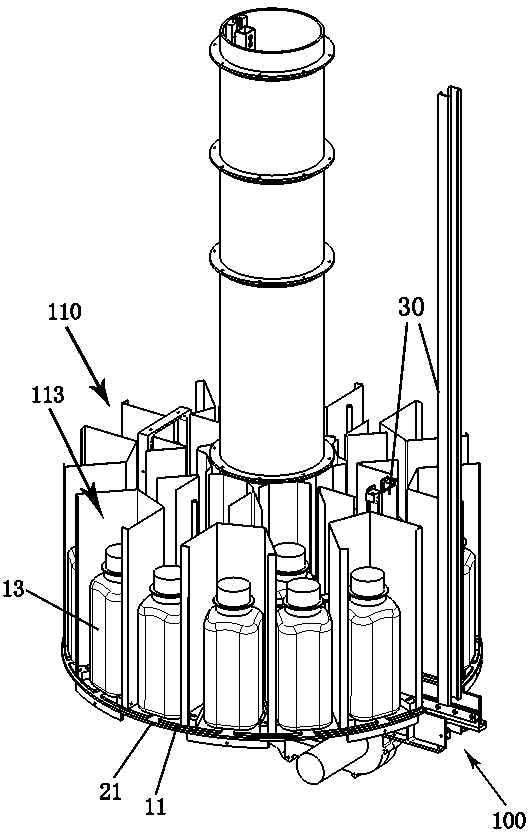

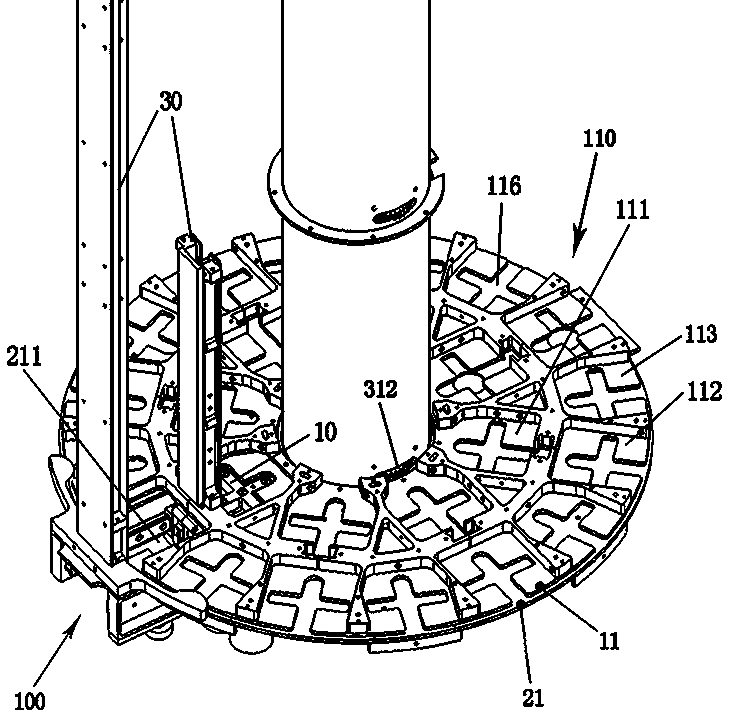

[0029] Such as Figure 1-Figure 4 As shown, this embodiment provides a storage mechanism for an automatic vending machine. The storage mechanism 110 includes the storage tray 11 described in Embodiment 1, and also includes a storage tray installed under the storage tray 11 for Load-bearing chassis 21 . The chassis 21 defines a second opening 211 for the lifting mechanism of the vending machine to pass through from bottom to top. Preferably, the second opening 211 is roughly square, such as Figure 4 shown.

[0030] Such as Figure 1-Figure 3 As shown, the goods 13 for sale are arranged in a circular shape in the storage compartment 113 of the storage tray 11 of the storage mechanism. When it is necessary to ship, the goods in a certain storage compartment 113 can be selected to pass through the lifting mechanism 100. The carriage 10 lifts it up and lifts it to the delivery port (not shown) at the top of the machine. Since the goods 13 to be sold are stored on the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com