Environment-friendly heat treatment system

A heat treatment system, an environmentally friendly technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of energy consumption, non-environmental protection, uneven heating of waste, and lack of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

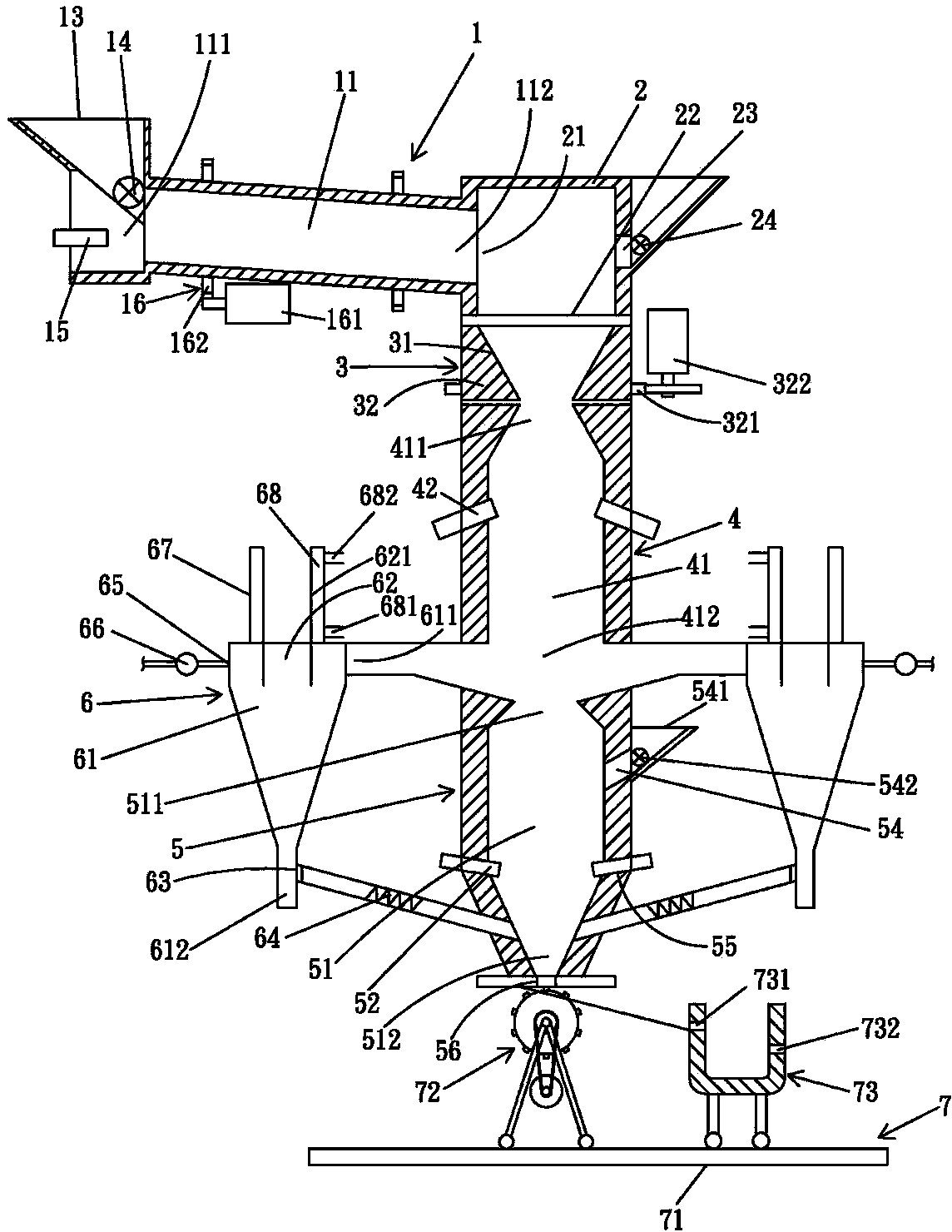

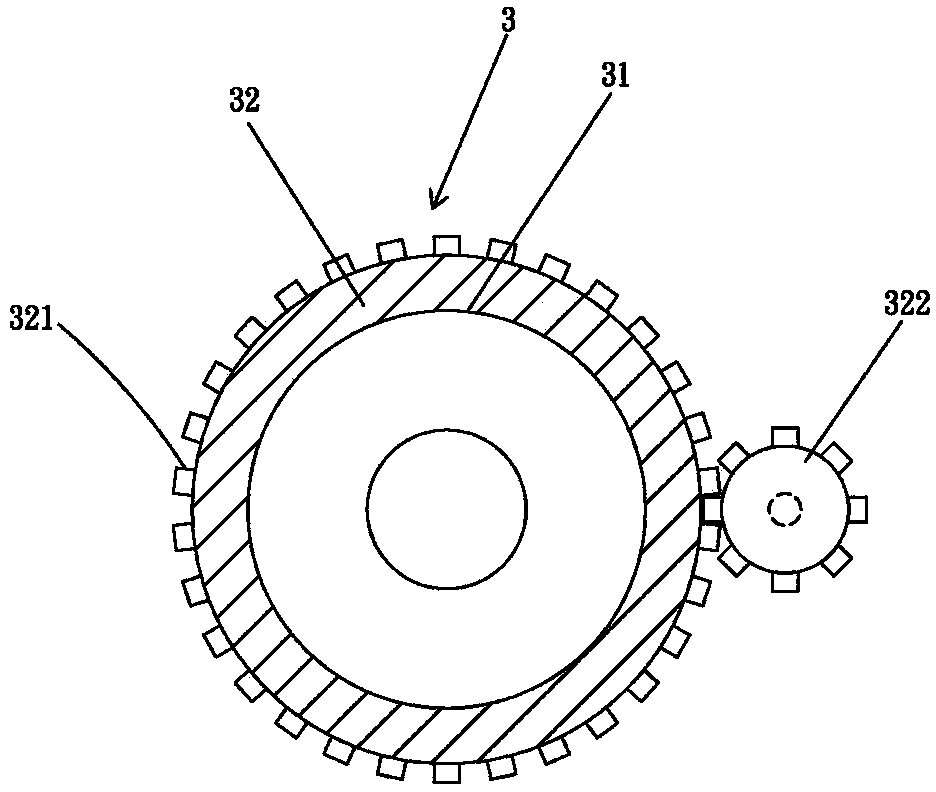

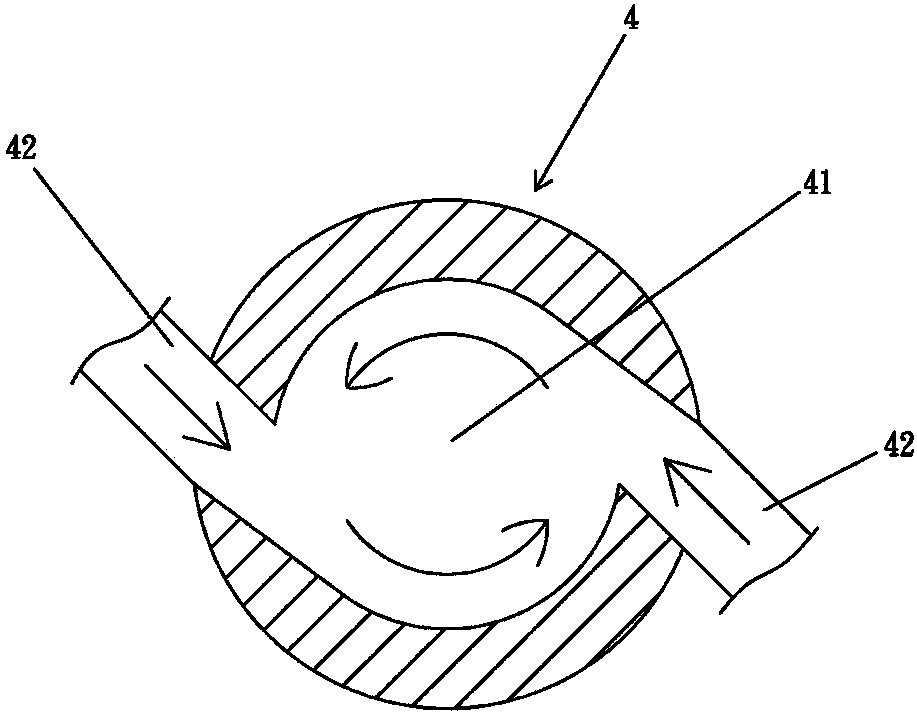

[0046] See Figure 1 to Figure 3 , The present invention includes a first heating furnace 1, a buffer chamber 2, a sprinkling device 3, a second heating furnace 4, a third heating furnace 5, at least one dust collecting device 6, a collecting device 7 , The first heating furnace 1 has a first heating chamber 11, the first heating chamber 11 has an inlet 111, an outlet 112, and a hopper 13 and a feeder 14 are connected to the inlet 111 to provide quantitative feeding. A heating chamber 11 is provided with a heater 15, and the first heating furnace 1 is connected to a rotating device 16. The rotating device 16 has a power motor 161 and a gear 162 to provide the first heating furnace 1 rotating action, which can provide general incineration operations or soil 81 dry preheating, and its heating temperature can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com