Electromagnetic nondestructive testing method and device for elevator steel belt

A non-destructive testing, steel strip technology, applied in the direction of material magnetic variables, etc., can solve the problems affecting the safety of elevator use, easy to scratch the surface of rubber materials, etc., to achieve the effect of convenient sensor layout and wiring, high detection accuracy, and precise positioning detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] According to the thought of detection method provided by the present invention, design idea is as follows:

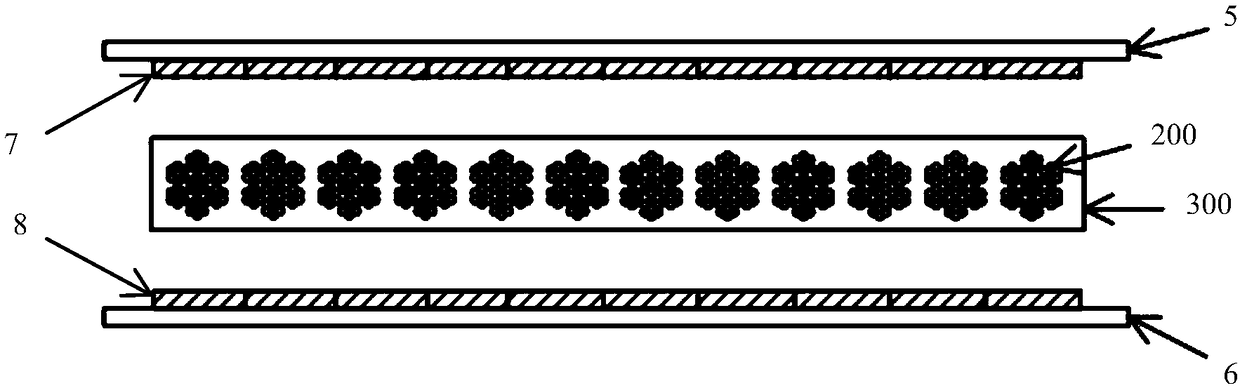

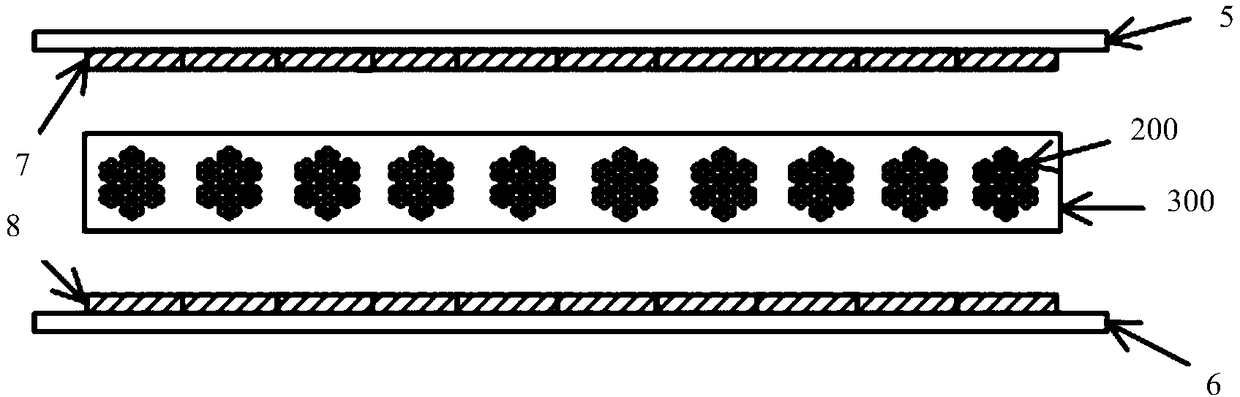

[0038] (1) It is planned to excite the steel strip to be tested as a whole. Since the diameter of the internal steel wire rope is relatively small, the internal steel wire rope can be excited to a near-saturated state without a large excitation intensity. Compared with traditional electromagnetic detection, the yoke can be removed. Use, reserve more space for the detection circuit board where the sensor is placed, and facilitate the installation of data output leads.

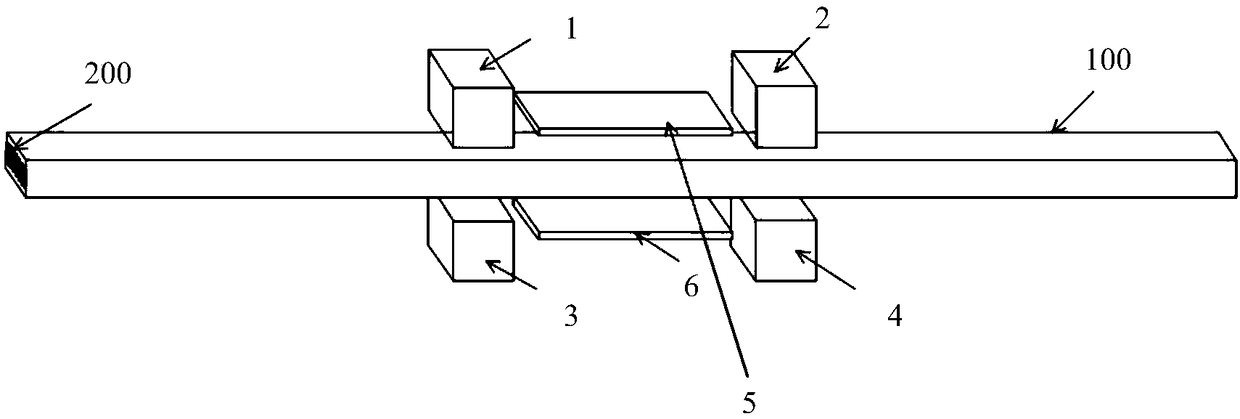

[0039] (2) if figure 1 As shown, the magnetization direction of the magnet is perpendicular to the surface of the steel strip to be tested. The magnetization directions of the two magnets on the upper side of the steel strip to be tested are opposite, and the magnetization directions of the two magnets on the lower side are also opposite. The magnetization directions of the two magnets at the same...

Embodiment 2

[0053] Embodiment 1 provides a principle framework and steps of an elevator steel strip electromagnetic nondestructive testing method, but in actual operation, in order to facilitate sensor arrangement and wiring, the following elevator steel strip electromagnetic nondestructive testing device can be designed.

[0054] According to the idea of the detection device provided by the present invention, the design concept is as follows:

[0055] Step1: Design the size of the magnet and the spacing between the magnets through simulation to ensure that each wire rope is excited to a nearly saturated state;

[0056] Step2: In order to realize the detection and resolution of small defects, a magnetic detection sensor with high sensitivity can be selected, and the detection circuit should be designed to ensure that there is at least one sensor on each wire rope;

[0057] Step3: Design the detection device according to the size and placement of the magnet and the structure of the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com