Patents

Literature

35 results about "Epoxy insulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cypoxy Insulators and Custom Components provide uncompromising performance in indoor and outdoor applications. Cypoxy is a cycloaliphatic epoxy resin material that won't track, even in the harshest environments.

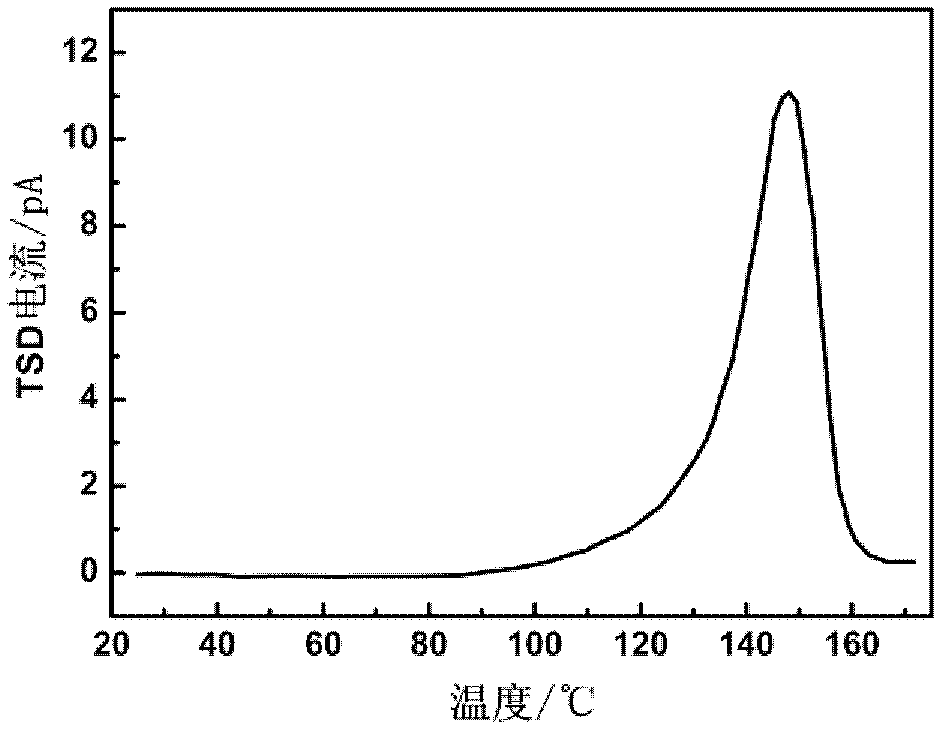

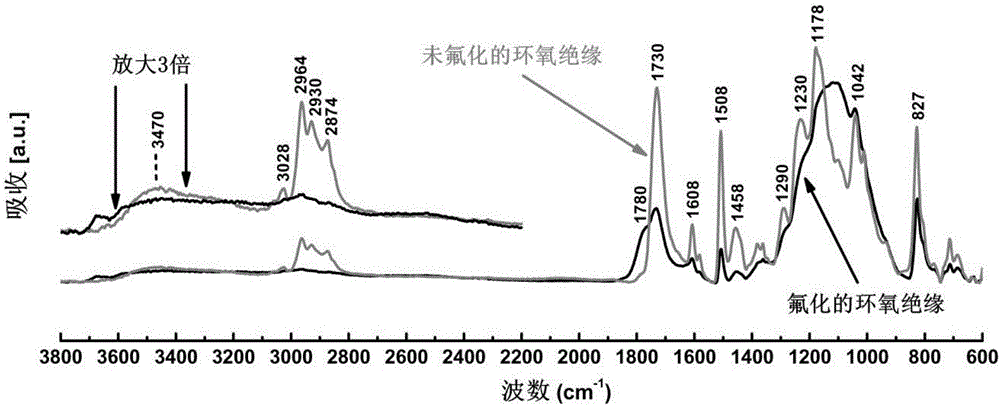

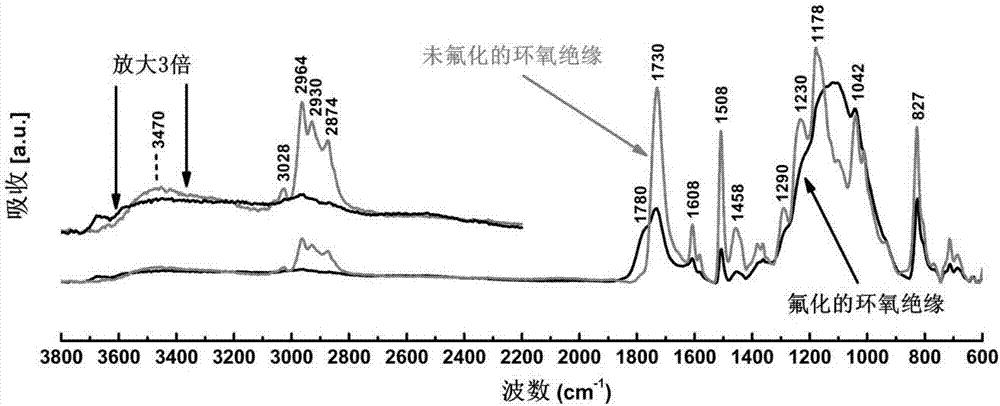

Method for inhibiting accumulation of surface charge of epoxy resin and composite materials thereof

The invention belongs to the technical field of electrical insulating materials, and relates to an extremely effective method for inhibiting the accumulation of surface charge of epoxy resin and composite materials thereof. The method comprises the following step that the epoxy resin and the composite materials thereof are subject to gas phase fluorination treatment in a closed reaction chamber. The method disclosed by the invention is applied to the inhibition of the accumulation of the surface charge of electrical insulating pieces of the epoxy resin and the composite materials thereof, so as to improve the flashover voltages and the electrical insulating performance of the electrical insulating pieces, such as epoxy insulating supports and epoxy insulators of the epoxy resin and the composite materials thereof, and static electricity resistance of the epoxy resin and the composite materials thereof when the epoxy resin and the composite materials thereof are used in other aspects.

Owner:TONGJI UNIV

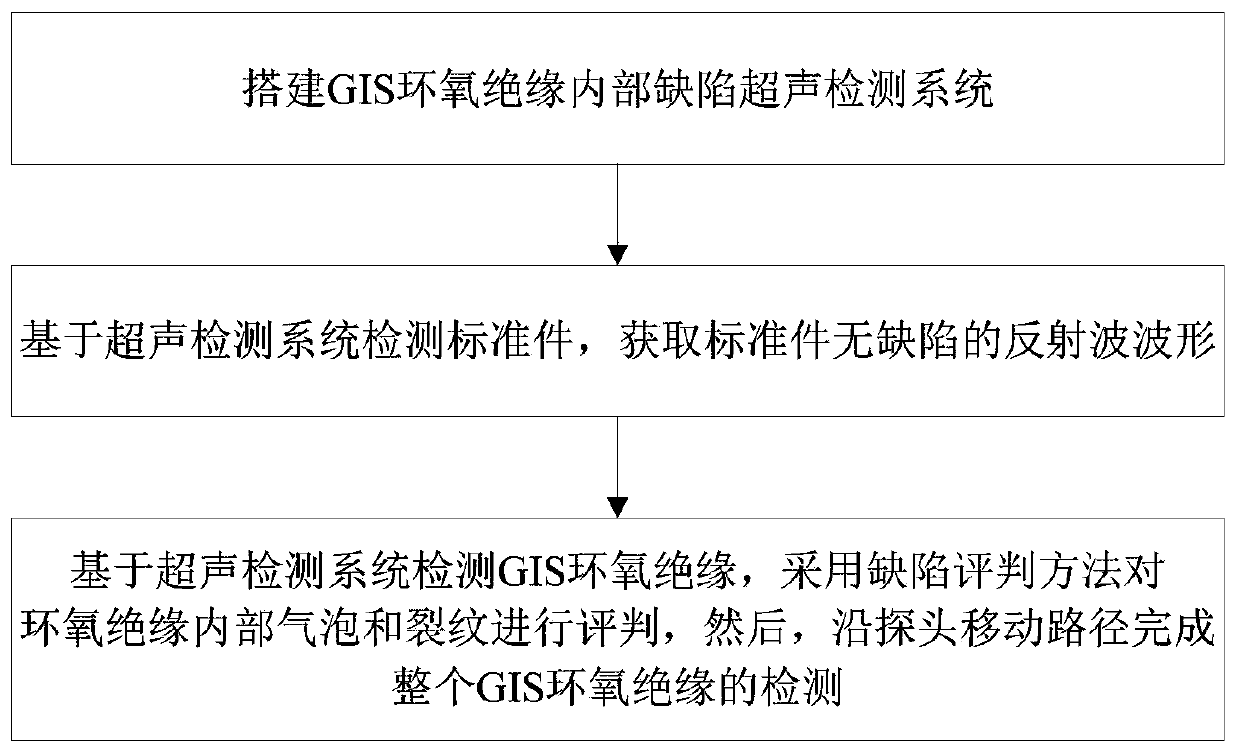

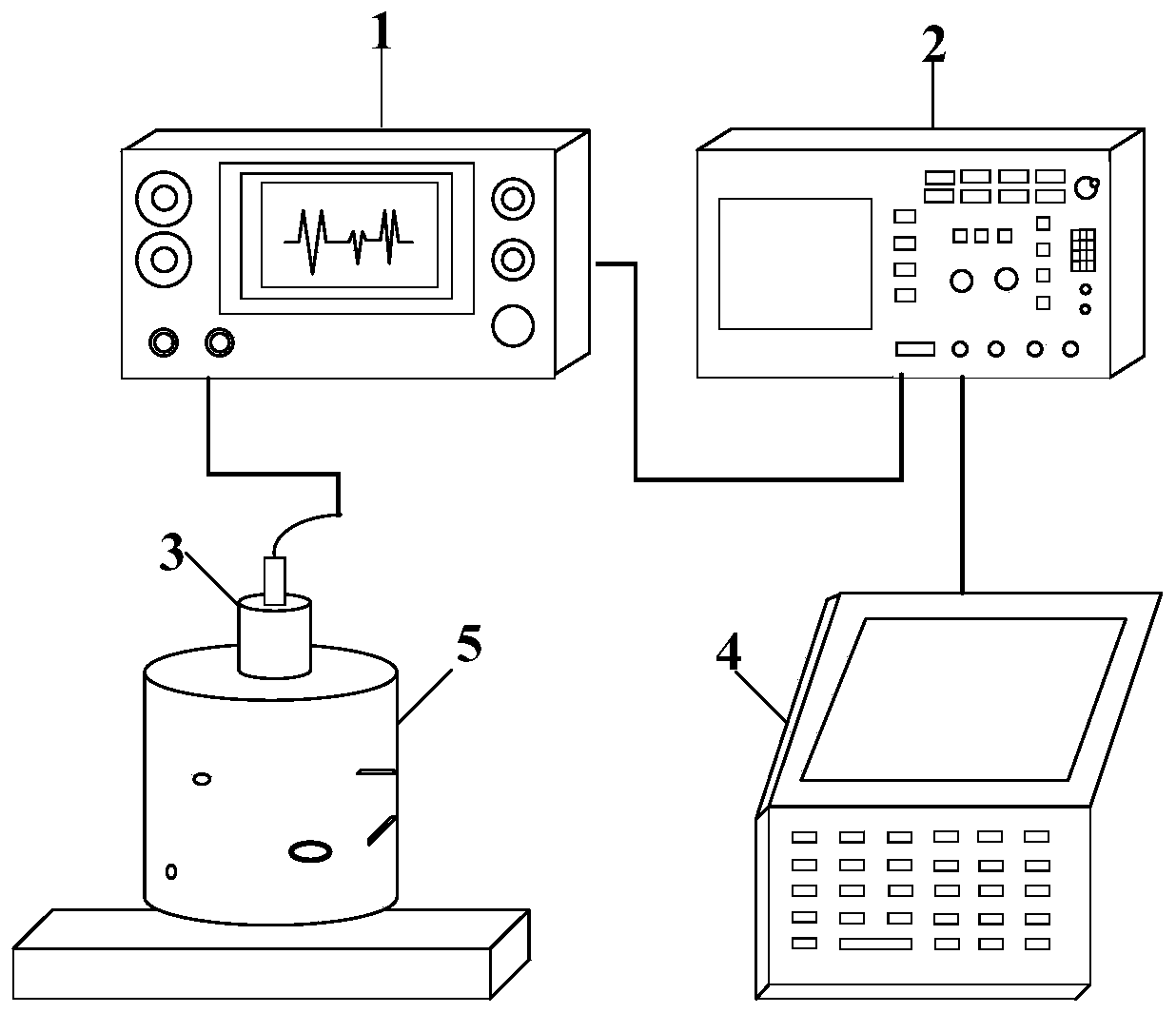

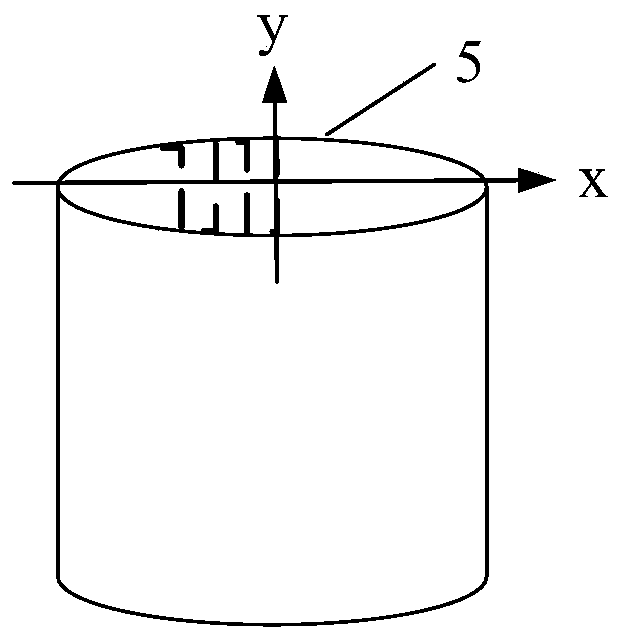

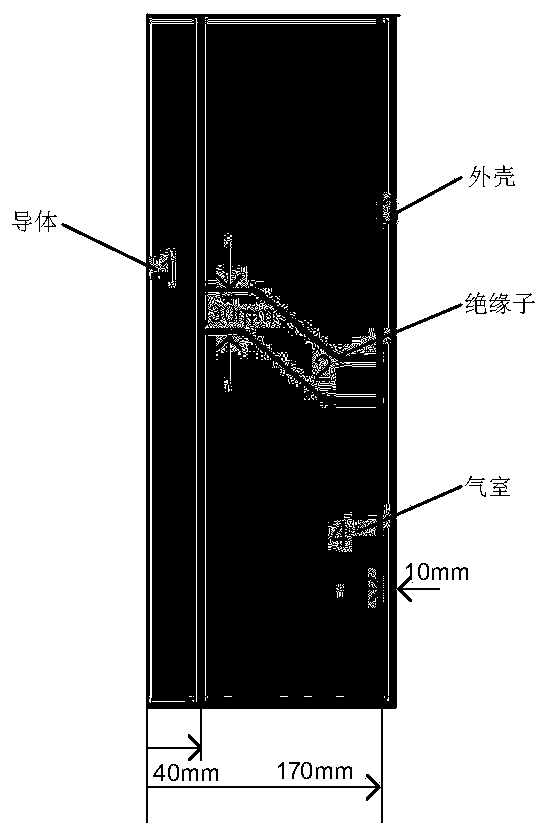

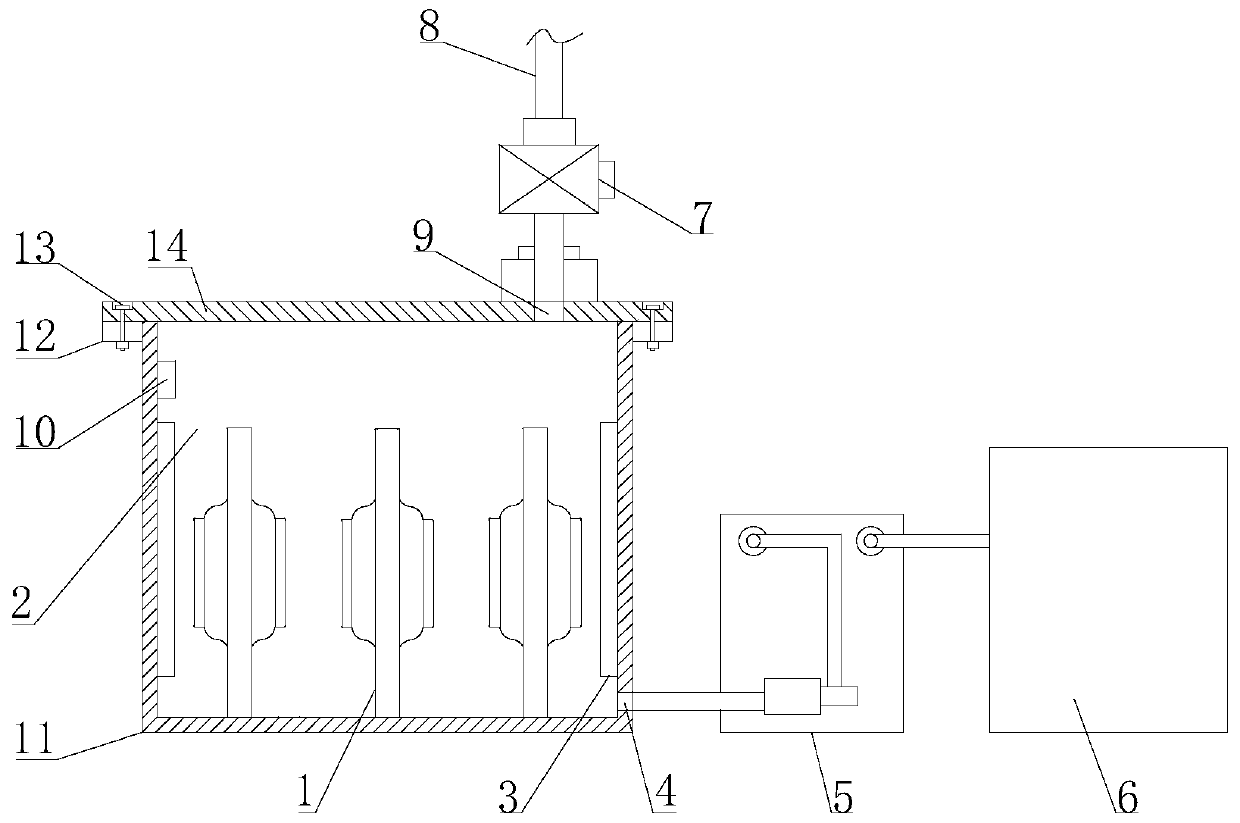

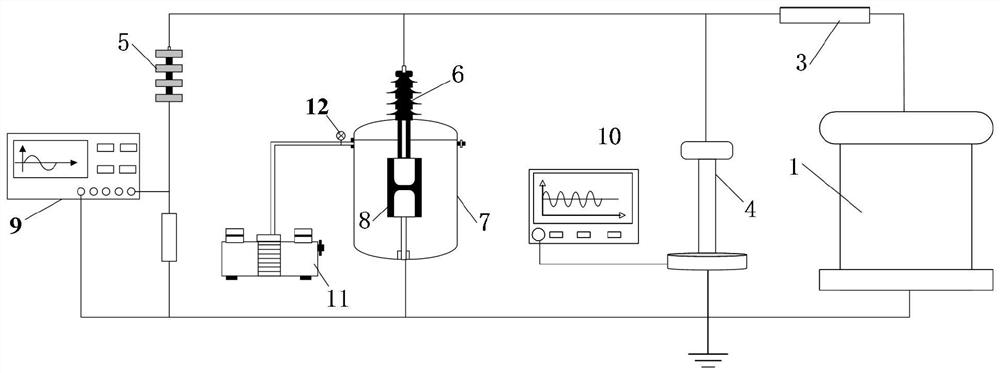

Ultrasonic testing method and ultrasonic testing system for internal defects of GIS epoxy insulator

InactiveCN110243935AImprove detection accuracyImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesLongitudinal waveUltrasonic attenuation

The invention belongs to the technical field of power transmission and transformation insulation equipment, and relates to an ultrasonic testing method and an ultrasonic testing system for internal defects of a GIS epoxy insulator. The ultrasonic testing method for internal defects of the GIS epoxy insulator comprises the following steps: constructing the ultrasonic testing system for internal defects of the GIS epoxy insulator; testing a testing standard component based on the ultrasonic testing system, and obtaining a non-defective reflected wave waveform of the standard component; testing the GIS epoxy insulator based on the ultrasonic testing system, judging interior bubbles and cracks of the epoxy insulator by using a defect judgment method, and then continuously testing the GIS epoxy insulator along the moving path of a probe. The method is high in testing precision and efficiency and accurate in defect positioning, small-sized bubbles and cracks can be tested, and the method can be used for pre-delivery inspection of insulators and also can be used for assembling field test of insulators. The ultrasonic testing system for internal defects of the GIS epoxy insulator comprises an ultrasonic instrument, an oscilloscope, an ultrasonic longitudinal wave normal probe, a computer and the GIS epoxy insulator. The system is low in cost, small in equipment volume, high in testing precision and efficiency and accurate in defect positioning.

Owner:SOUTH CHINA UNIV OF TECH

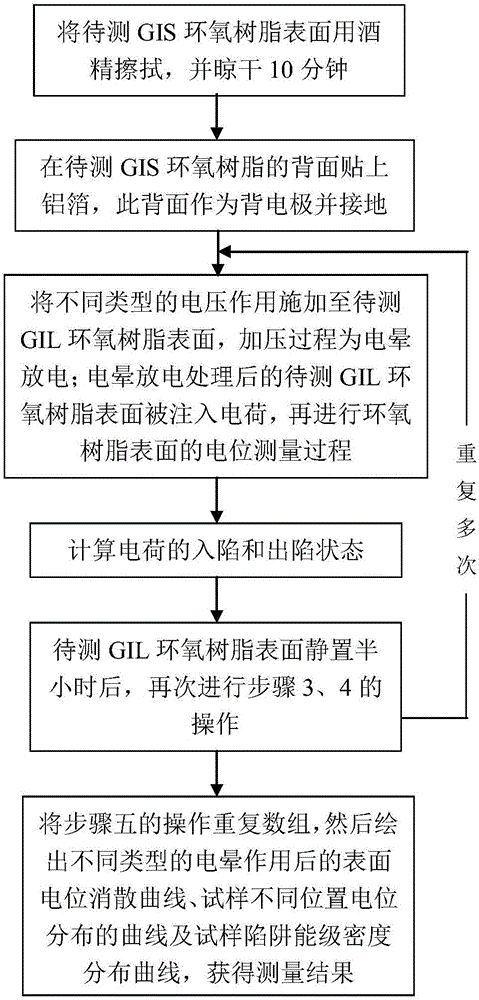

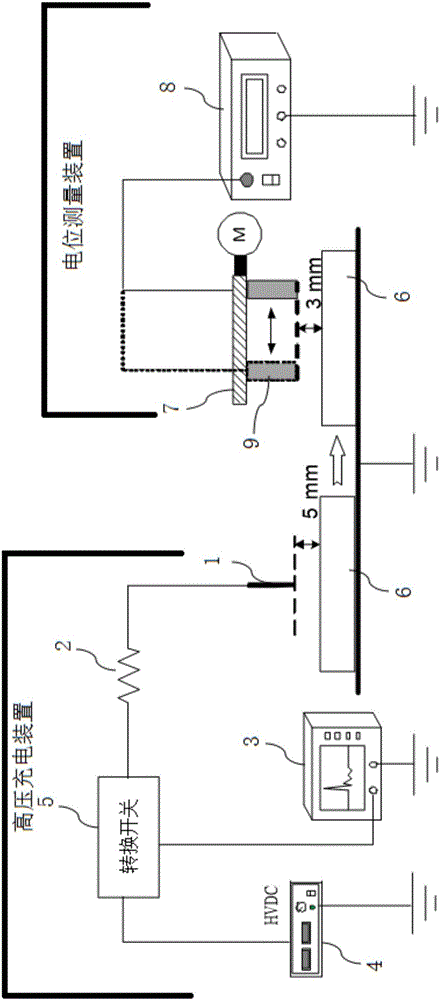

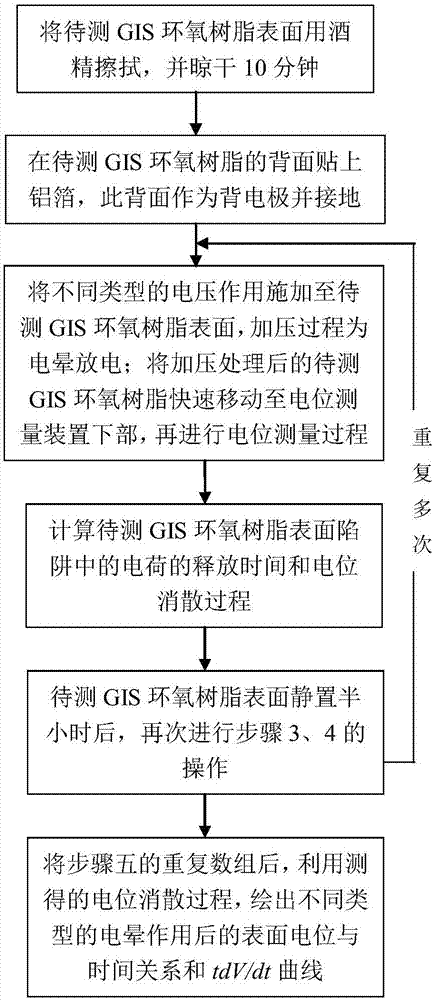

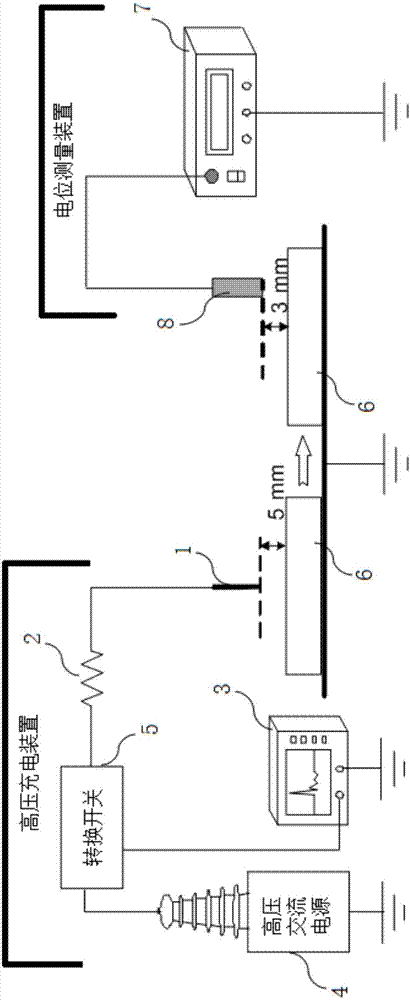

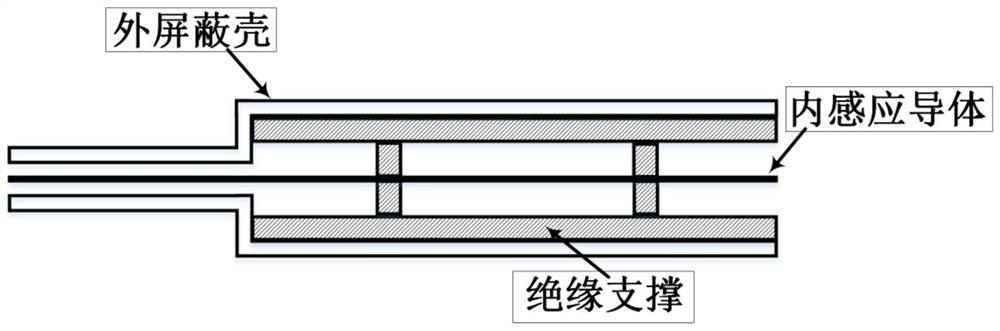

GIL (gas insulated metal enclosed transmission line) epoxy resin surface charge measuring device and method

InactiveCN106771685AFind out the transport characteristicsFigure out transport propertiesElectrical measurementsPotential measurementCorona discharge

The invention discloses a GIL (gas insulated metal enclosed transmission line) epoxy resin surface charge measuring device and method. The device comprises a high-voltage charging device and a potential measurement device; different types of voltage actions are exerted on the GIL epoxy resin surface to be measured; a voltage boosting process is corona discharge; the charge trapping and trapping-out states are calculated; the specimen surface potential dissipation curves, different position potential distribution curves and the specimen trap energy level density distribution curves after the action by different types of corona are drawn; a GIL epoxy resin surface charge measuring result is obtained; the charge transportation characteristics are analyzed; the aging state and the service life of epoxy resin are accurately judged. By using a surface potential measuring technology and the existing instruments, the epoxy resin specimen surface charges under the actions of different voltage types are measured; the measuring data is subjected to mathematical processing; the transportation characteristics of the charges inside the epoxy resin are found out; the important theoretical basis is provided for solving the epoxy insulator surface flashover problem and the aging state evaluation problem; typical engineering practical guiding significance is realized.

Owner:TIANJIN UNIV

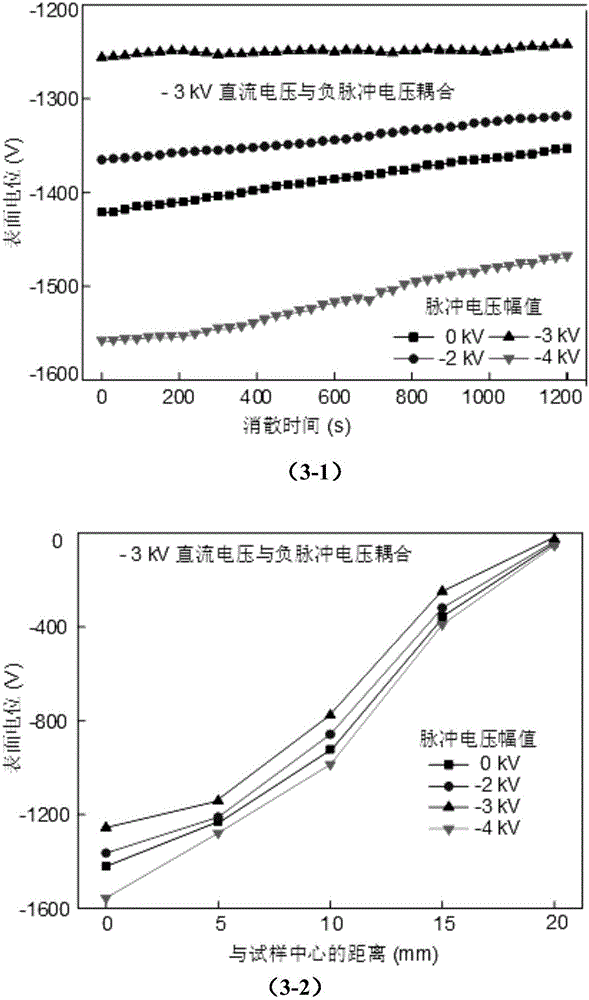

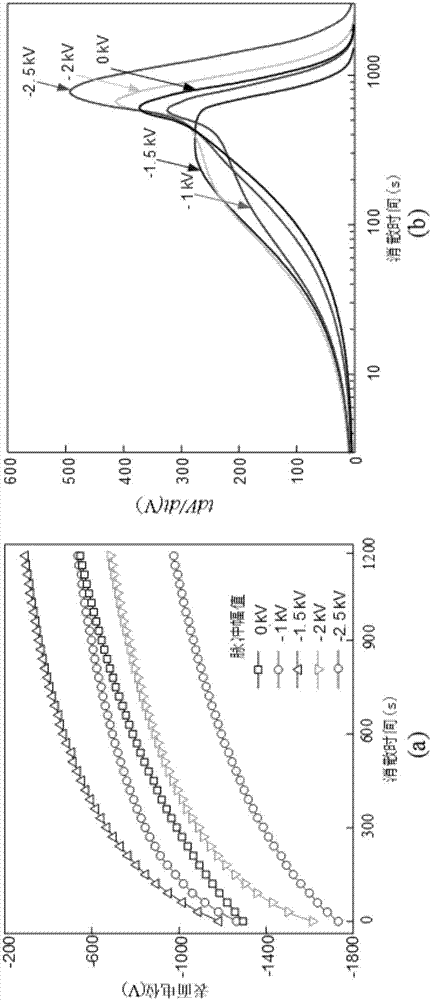

GIS epoxy resin surface charge characteristic and trap energy level distribution representing device and method

InactiveCN107045096AFind out the transport characteristicsFigure out transport propertiesTesting dielectric strengthPotential measurementRelease time

The invention discloses a GIS epoxy resin surface charge characteristic and trap energy level distribution representing device and method. The device comprises a high voltage charging device and a potential measuring device. Different types of voltage are applied to the surface of epoxy resin, wherein the applying process is corona discharge. The release time of charges and the potential dissipation process in an epoxy resin insulator trap are calculated. A tdV / dt curve is drawn by analyzing and calculating the measured potential dissipation process to represent the dynamic characteristic of charges on the surface of the epoxy resin insulator and the trap energy level distribution. According to the invention, a surface potential measurement technology and the existing instrument are used to measure the surface charges of an epoxy resin sample under different voltage types; the measurement data are processed mathematically to clarify the transport characteristic of the charges inside the epoxy resin; and the device and the method provide an important theoretical basis for solving the problem of flashover of the epoxy insulator surface and evaluating the aging state, and have the typical guiding significance of engineering practice.

Owner:TIANJIN UNIV

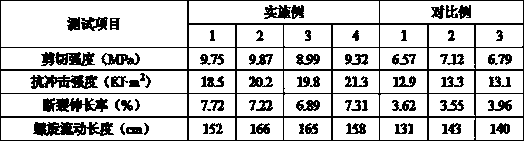

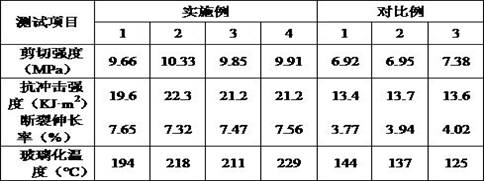

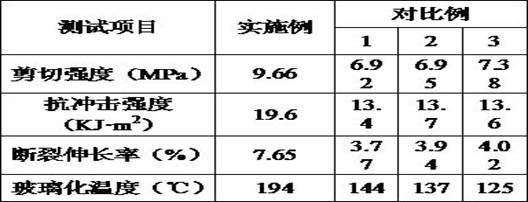

High-strength epoxy insulator material and preparation method thereof

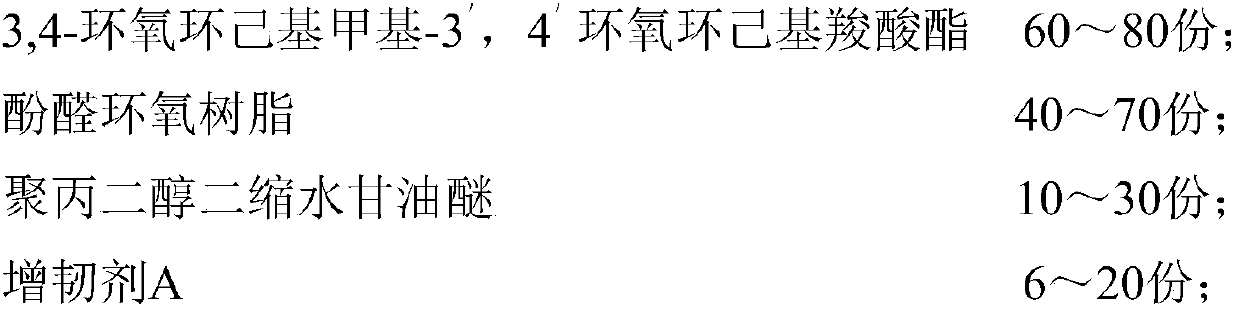

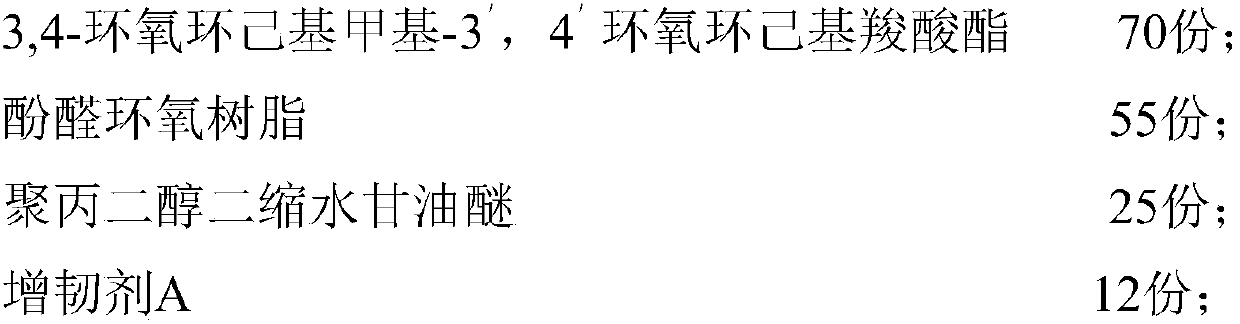

The invention discloses a high-strength epoxy insulator material and a preparation method thereof and relates to the technical field of insulator materials. The high-strength epoxy insulator materialdisclosed by the invention is prepared by reacting a modified resin composition and a curing agent composition, wherein the modified resin composition comprises 60-80 parts of 3,4-epoxy cyclohexylmethyl-3', 4'-epoxy cyclohexyl carboxylate ester, 40-70 parts of novolac epoxy resin, 10-30 parts of polypropylene glycol diglycidyl ether and 6-20 parts of a flexibilizer A; and the curing agent composition comprises methylhexahydrophthalic anhydride, maleic anhydride and a flexibilizer B. The preparation method comprises the following steps: preparing the modified resin composition, preparing the curing agent composition, and performing APG injection molding. The insulator material disclosed by the invention has excellent impact strength, bending strength, impact strength and elongation at break, is heat-resistant and flame retardant and can be widely applied to the field of materials for machine electricity and electric appliances.

Owner:安徽众博新材料有限公司

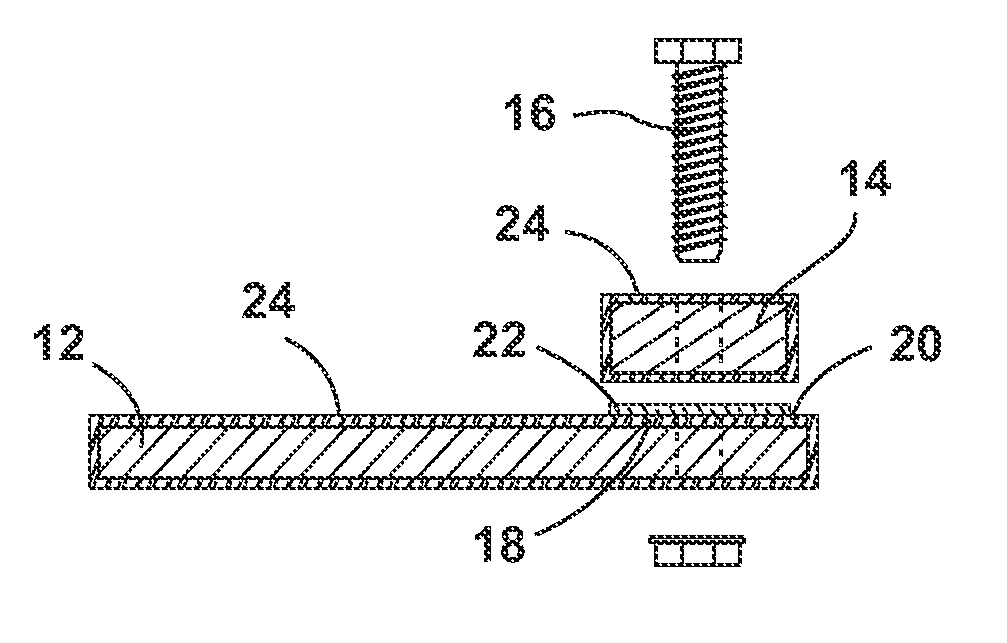

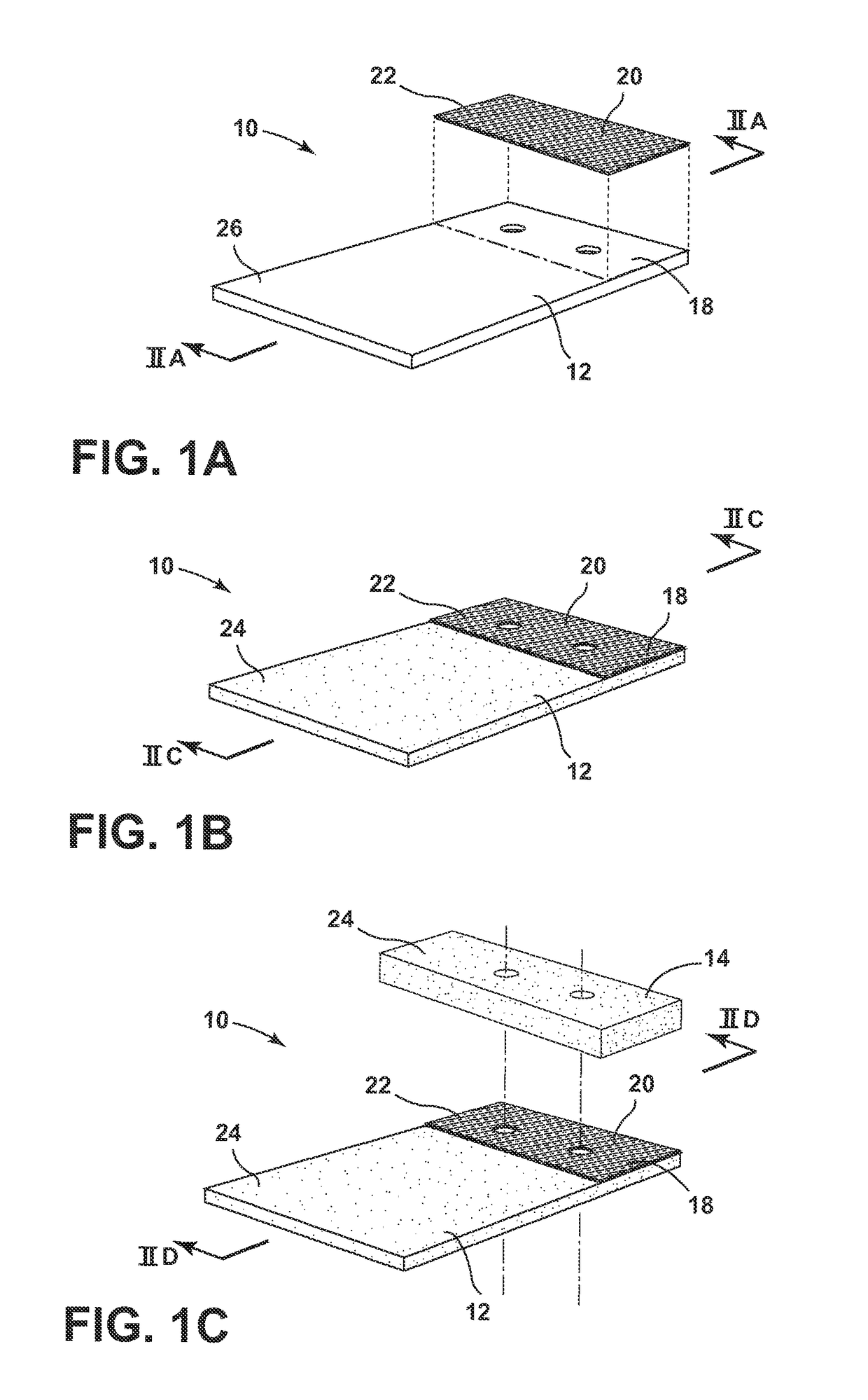

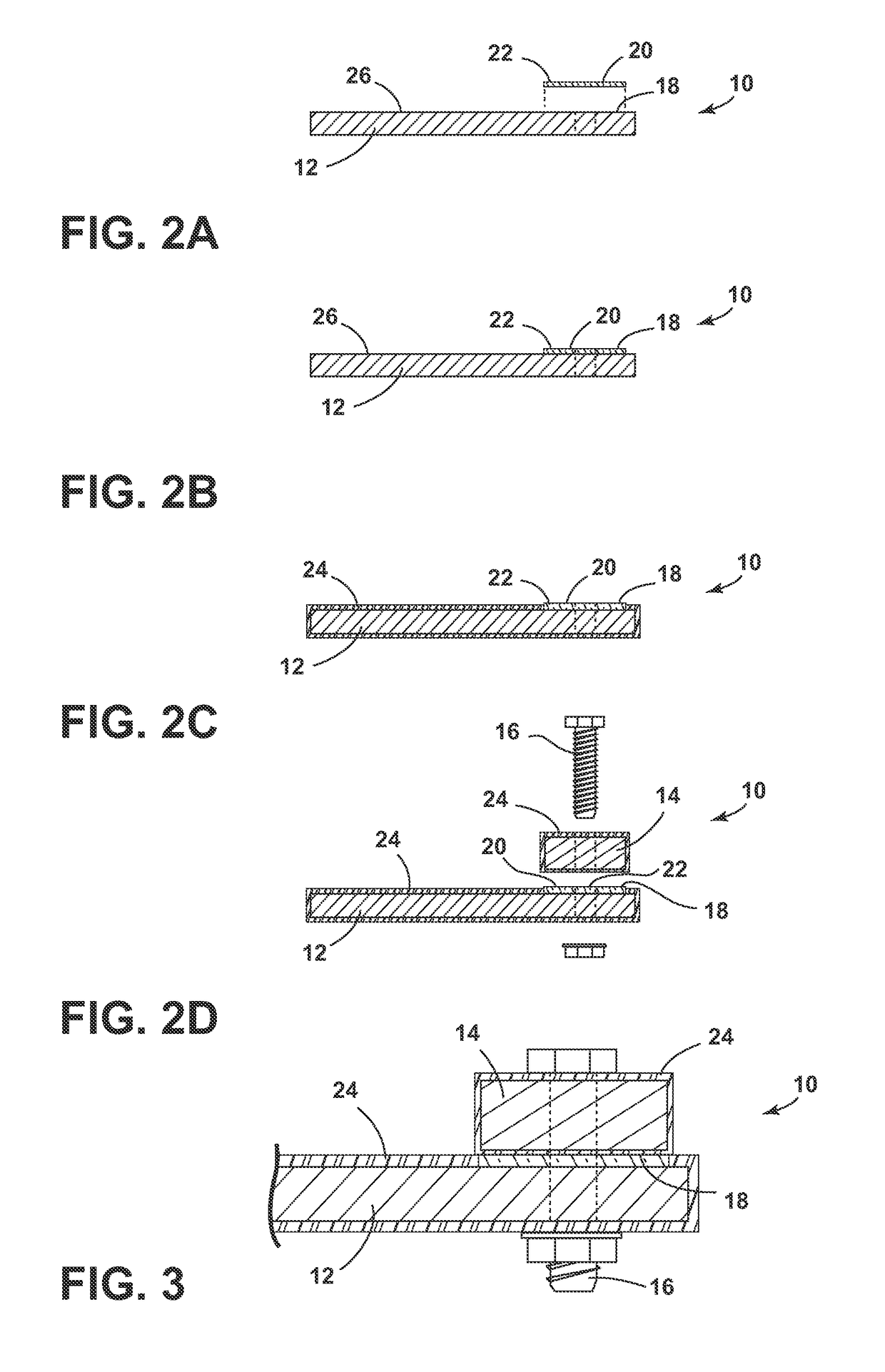

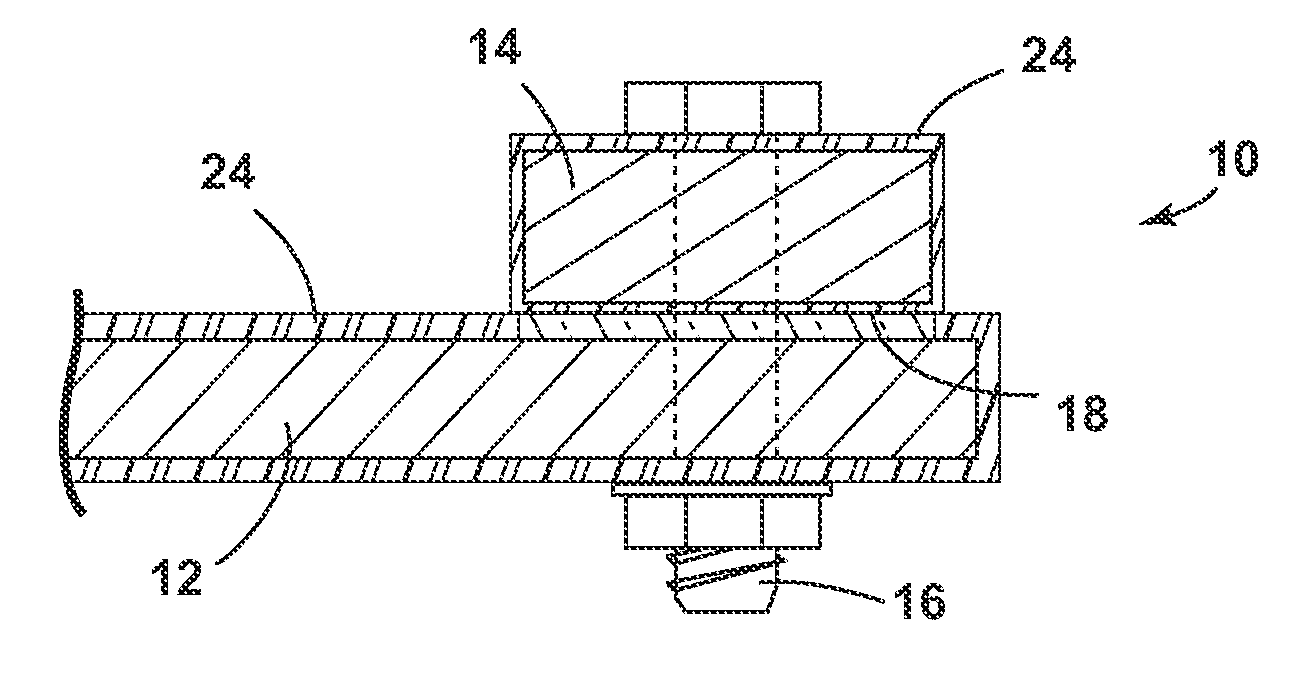

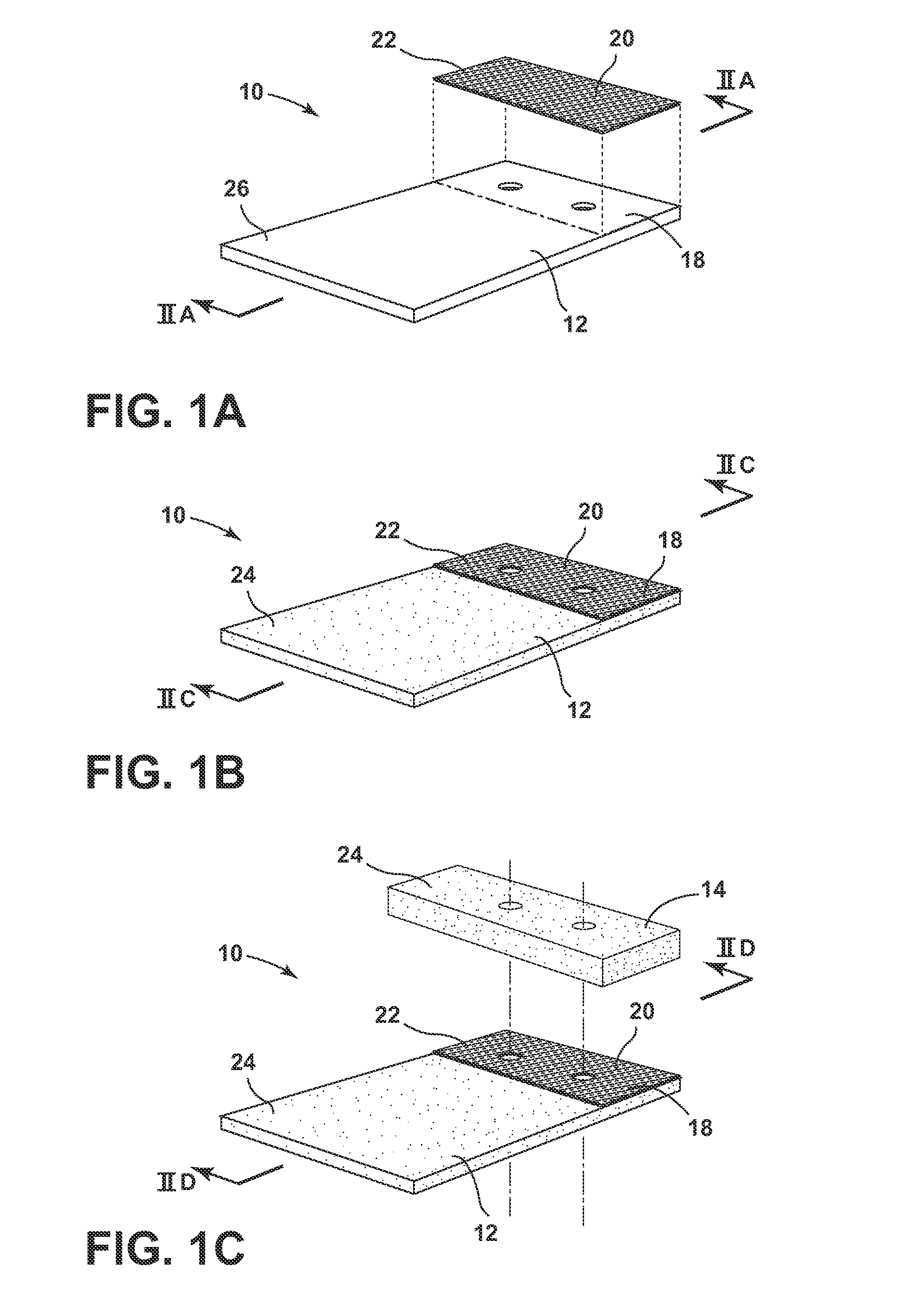

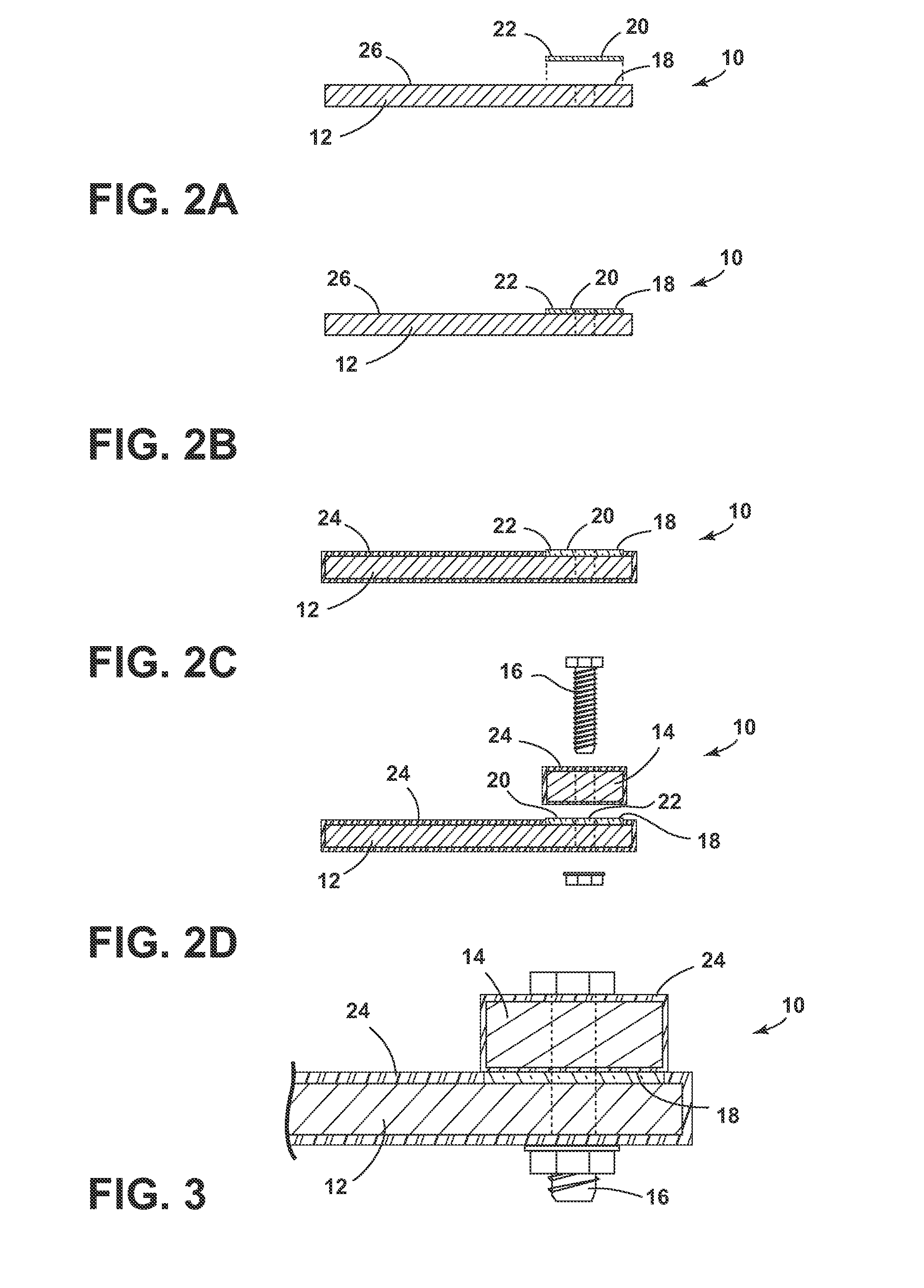

Method of providing a corrosion barrier between dissimilar metals with an epoxy insulator

A method for providing a corrosion-resistant barrier between bolted dissimilar metals comprising the steps of disposing epoxy adhesive tape on at least one of a first and second metal member, curing the epoxy adhesive tape, applying a corrosion-resistant layer to the first and second metal members, and bolting the first and second metal members together such that the cured epoxy adhesive tape is positioned between the first and second metal members.

Owner:FORD GLOBAL TECH LLC

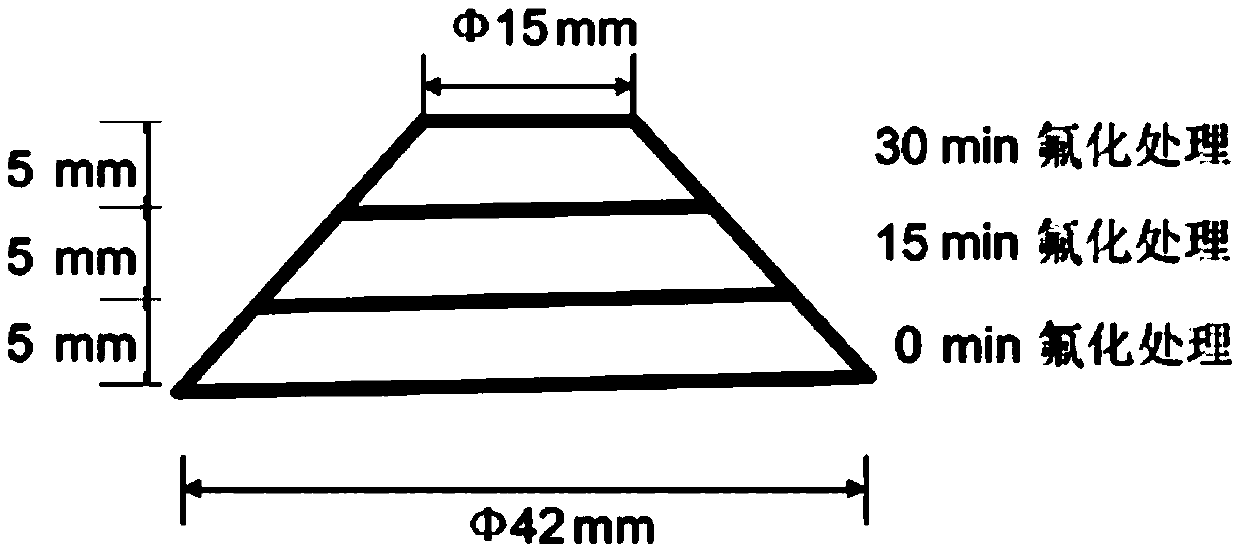

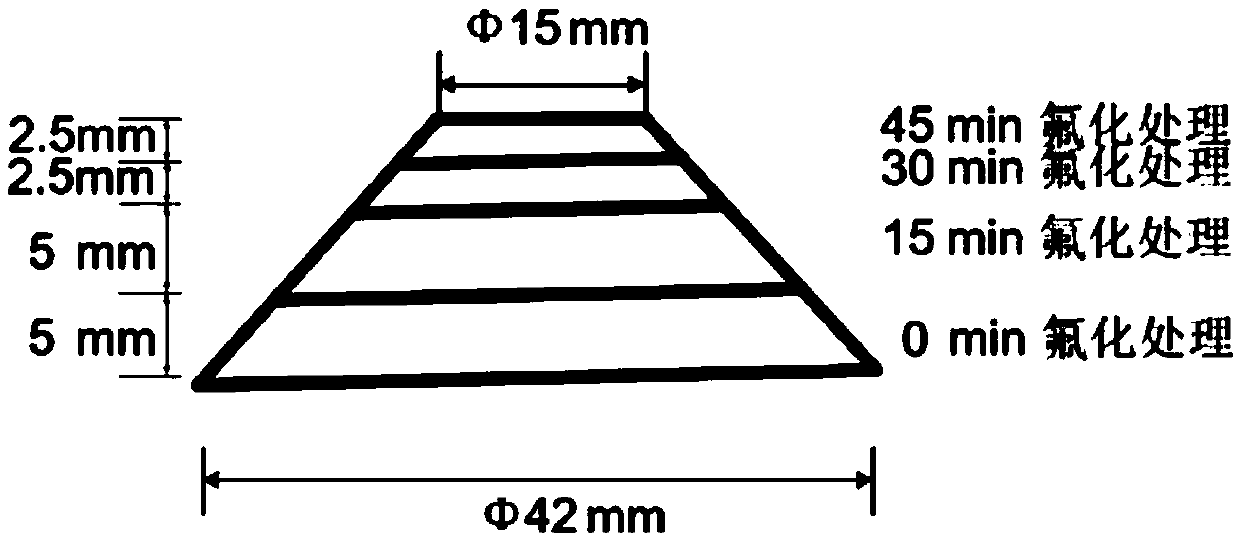

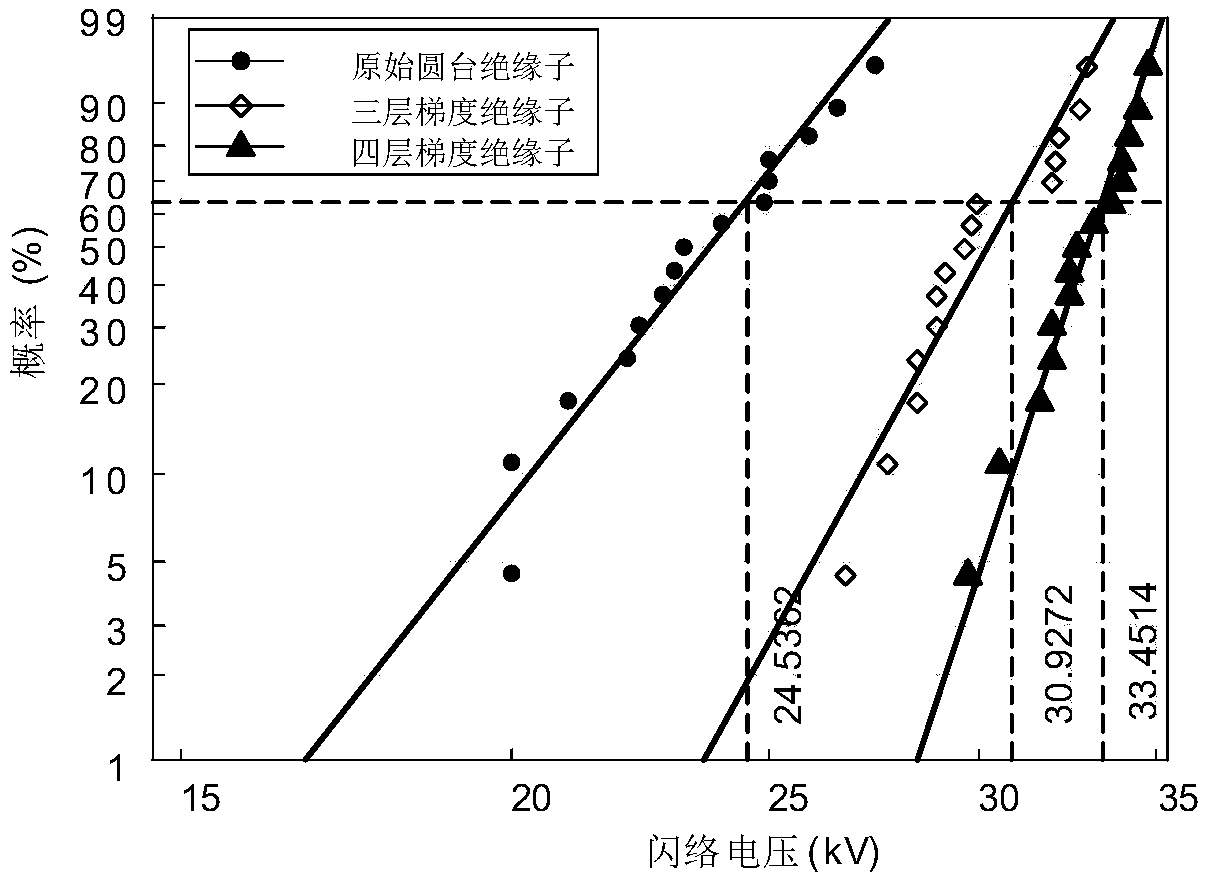

GIL insulator flashover voltage increasing method based on gas-solid interface electric field optimization

InactiveCN109659102AIncrease the flashover voltageSimple structureInsulatorsSurface conductivityJunction point

The invention discloses a GIL insulator flashover voltage increasing method based on gas-solid interface electric field optimization. A surface of an epoxy insulator is partitioned, different parts ofthe epoxy insulator are respectively subjected to fluorination treatment at different degrees, and the surface conductivity of the insulator is high at three junction points where an electric field distorts, so that electric field distribution is improved, flashover voltage of the insulator along the surface is improved, and the insulating property of the insulator is improved.

Owner:TIANJIN UNIV +1

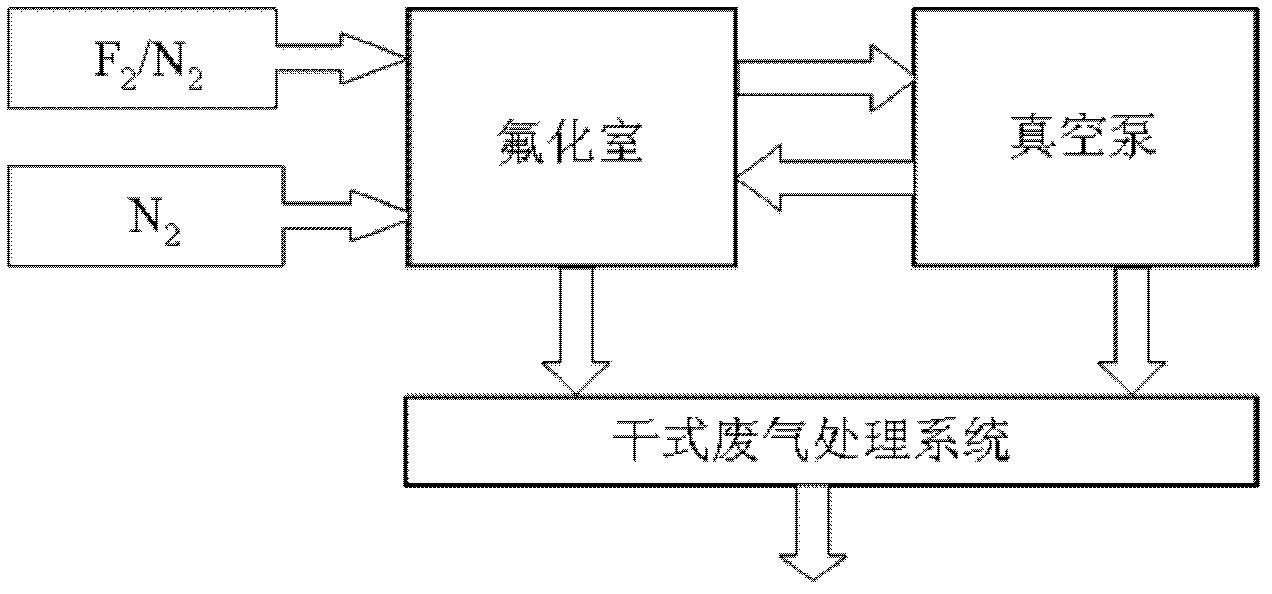

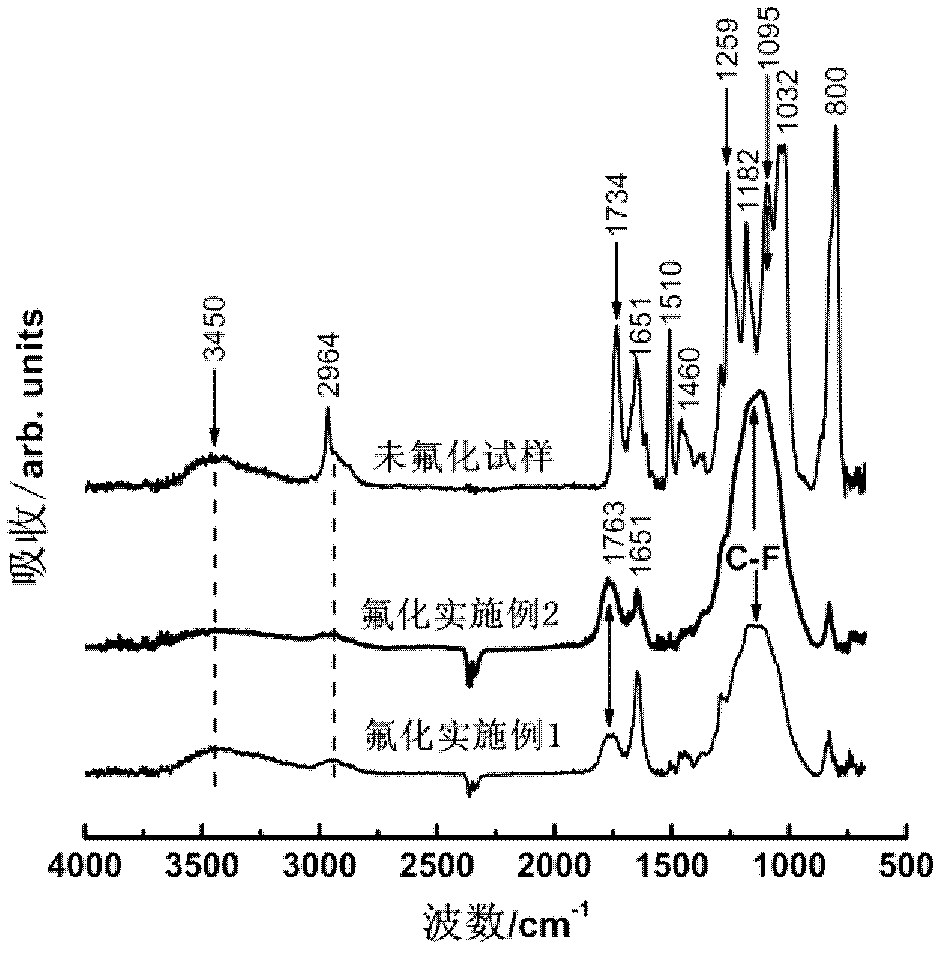

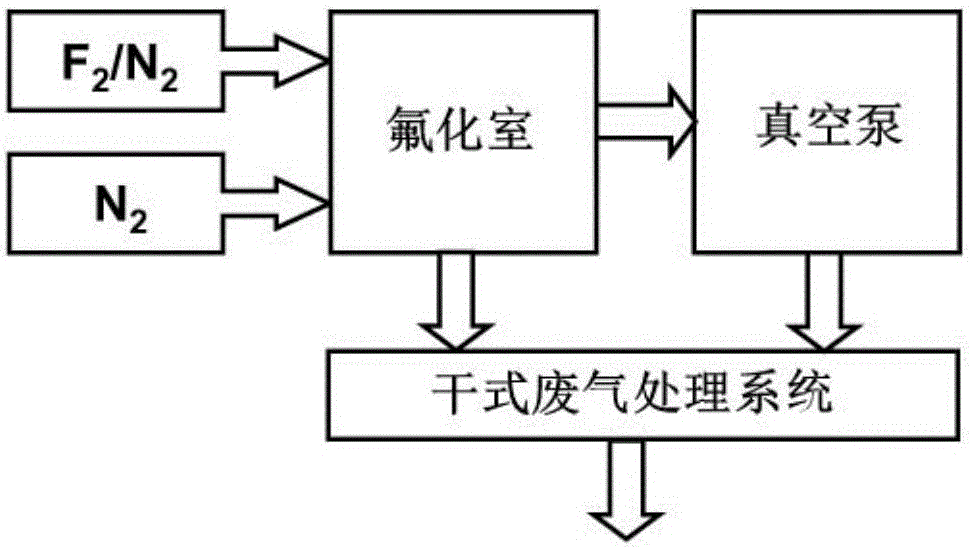

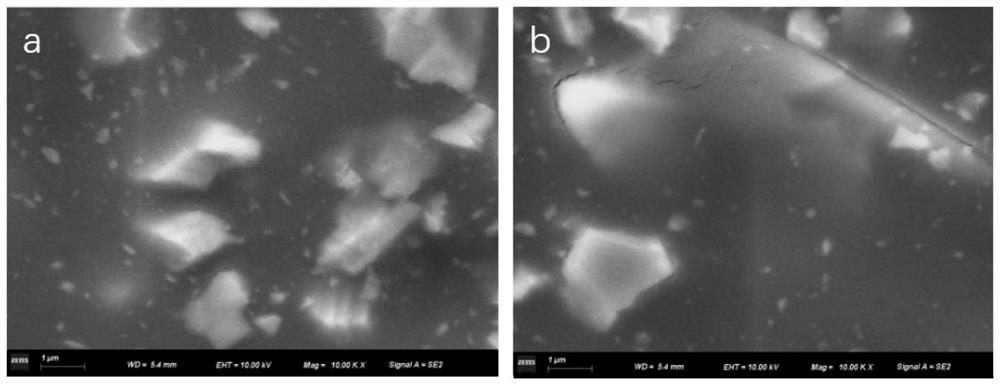

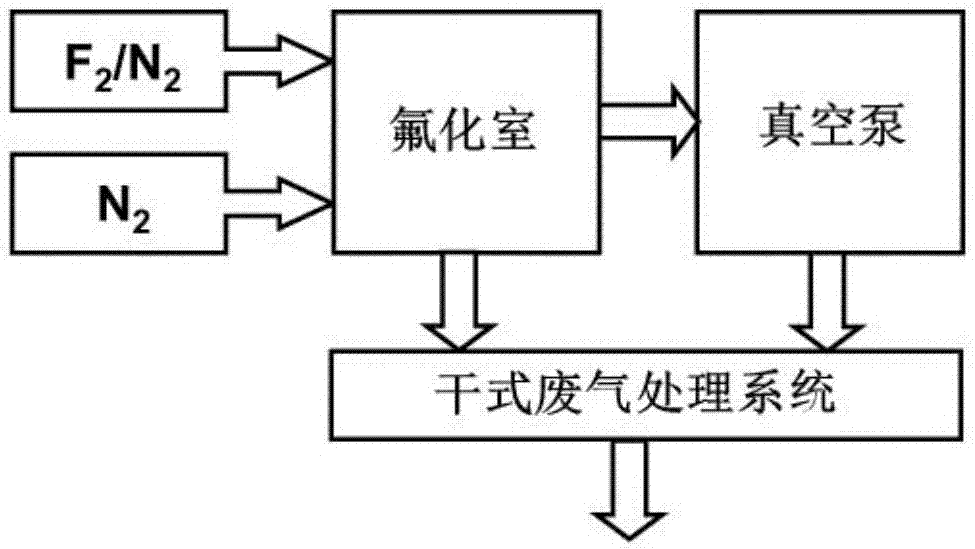

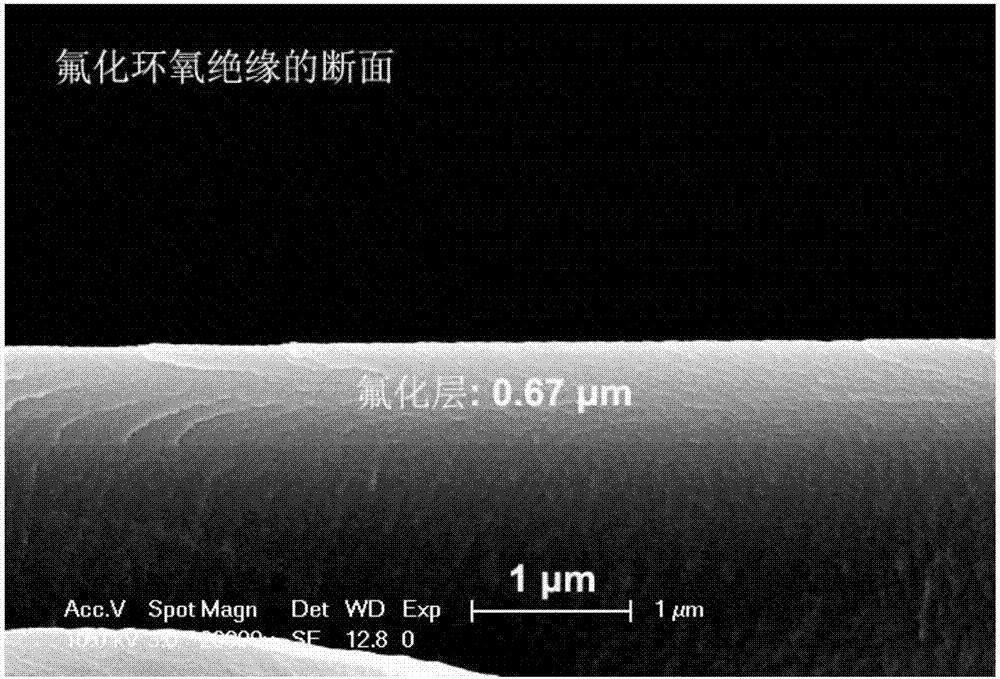

Method for improving discharge resistance of epoxy insulator in gas insulation system

ActiveCN106782941AChange physical and chemical characteristicsSimple processInsulatorsEpoxy insulatorsNitrogen gas

The invention relates to a method for improving the discharge resistance of an epoxy insulator in a gas insulation system. According to the method, fluoridation is carried out on the epoxy insulator by using a gas mixture of fluorine gas and nitrogen gas or a gas mixture of fluorine gas and inert gas under the conditions of appropriate temperature and pressure in a closed reaction chamber, a fluoridation layer containing C-F bonds is formed on the surface of the epoxy insulator, so that the method is used for improving the discharge resistance of the epoxy insulator. Compared with the prior art, the method disclosed by the invention is simple in processing steps, good in controllability and low in economic cost, the epoxy insulators with arbitrary shapes and dimensions can be uniformly modified in batches, and the method is specially applicable for commercial application.

Owner:TONGJI UNIV

Method of providing a corrosion barrier between dissimilar metals with an epoxy insulator

A method for providing a corrosion-resistant barrier between bolted dissimilar metals comprising the steps of disposing epoxy adhesive tape on at least one of a first and second metal member, curing the epoxy adhesive tape, applying a corrosion-resistant layer to the first and second metal members, and bolting the first and second metal members together such that the cured epoxy adhesive tape is positioned between the first and second metal members.

Owner:FORD GLOBAL TECH LLC

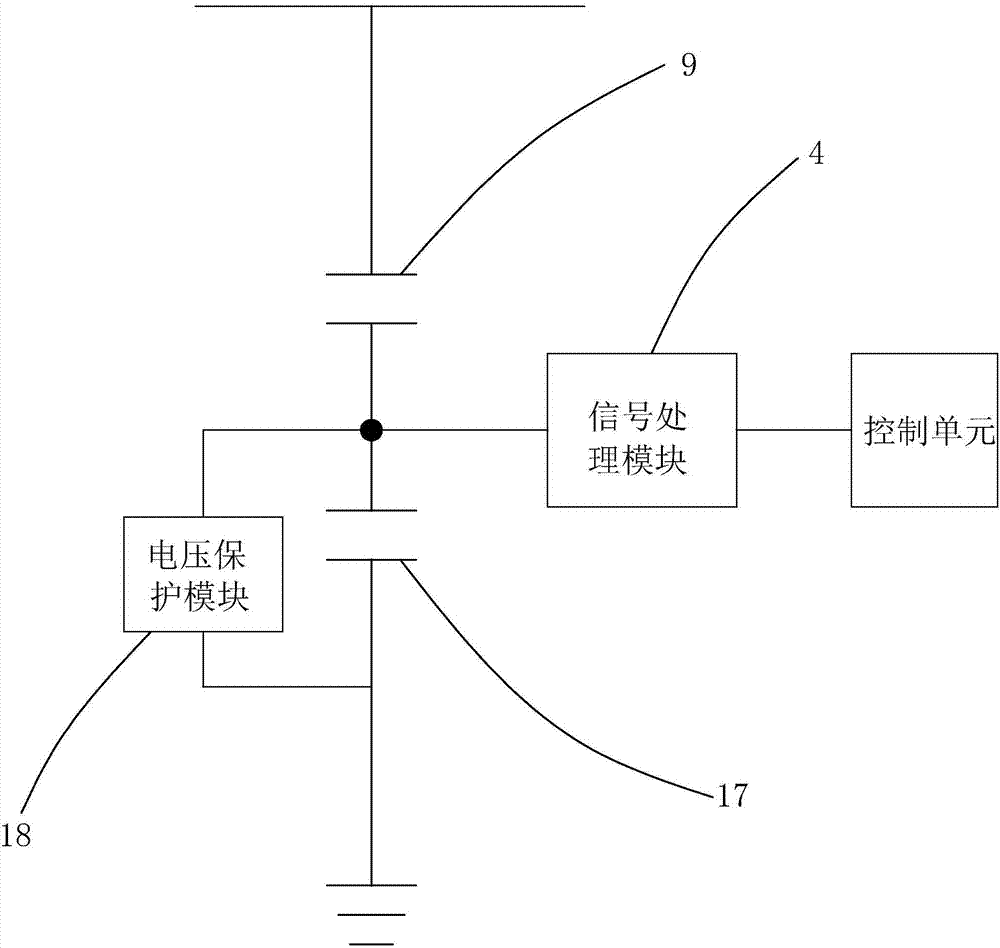

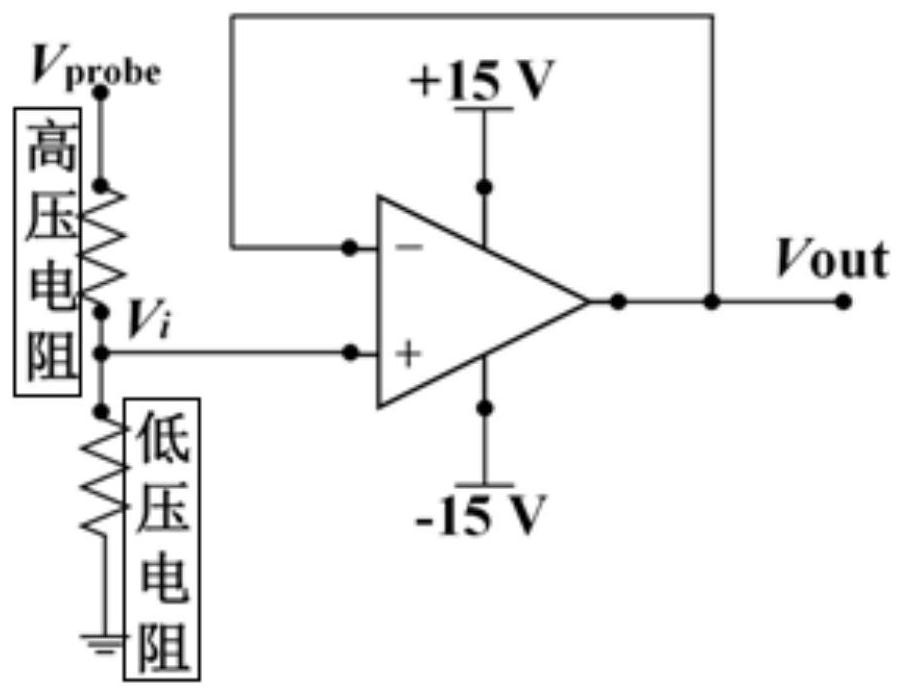

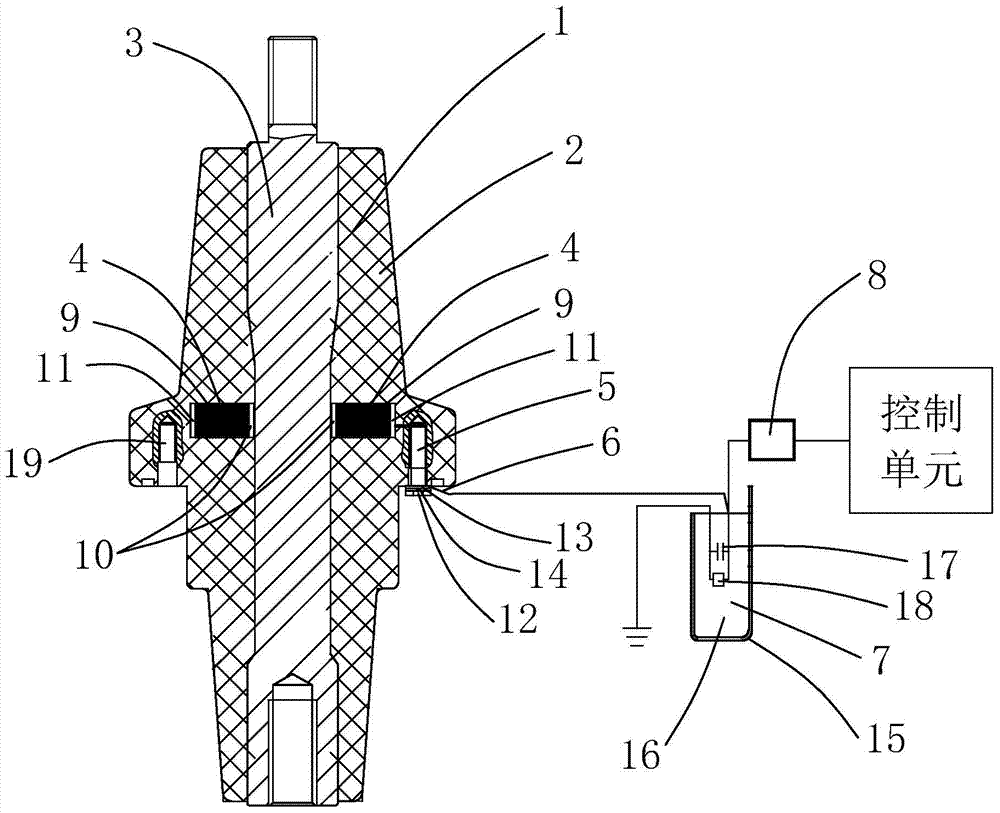

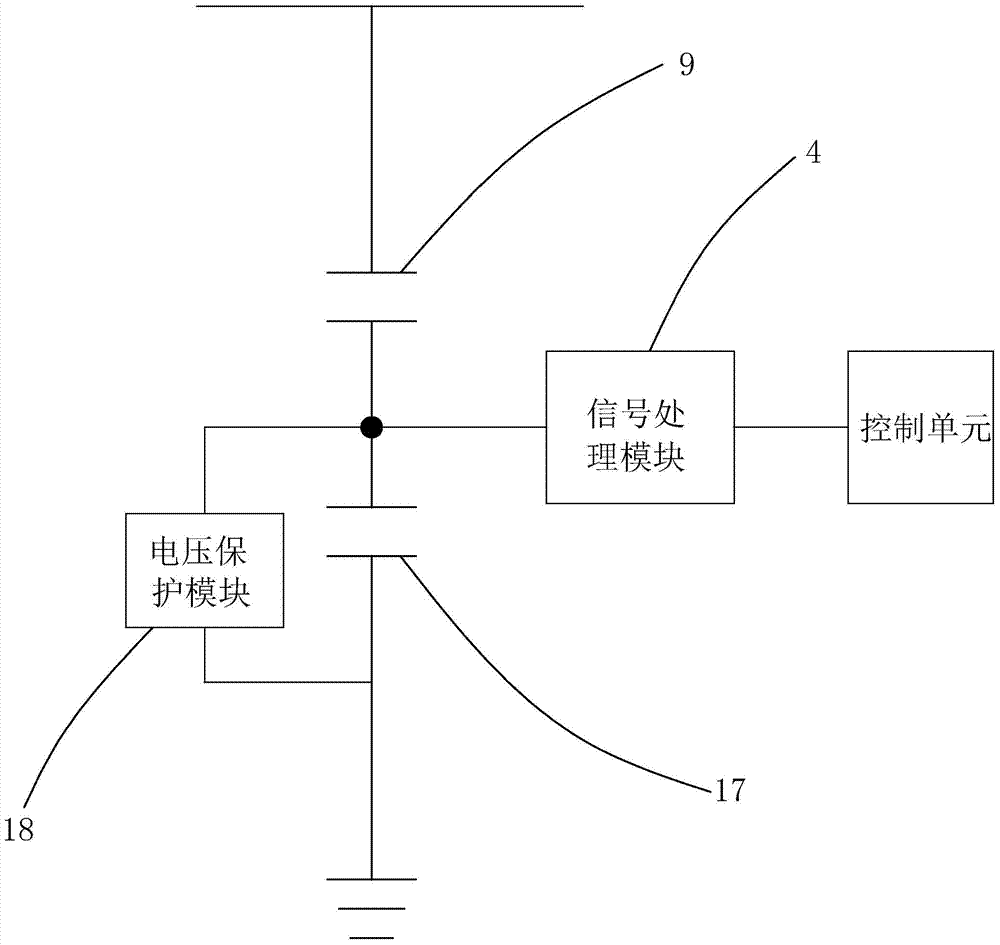

Hoop voltage sensing device

ActiveCN104267235ASmall footprintHigh measurement accuracyCurrent/voltage measurementVoltage dividersCapacitanceHigh voltage capacitors

The invention discloses a hoop voltage sensing device. The hoop voltage sensing device comprises an incoming and outgoing line casing pipe, the incoming and outgoing line casing pipe comprises an epoxy insulator, the epoxy insulator is of a hollow structure from top to bottom, a conducting rod is installed in the hollow structure, hoop high-voltage capacitors are installed at the solid portions on the two sides of the part, not the hollow structure, of the epoxy insulator, the hoop high-voltage capacitors are electrically connected with the conducting rod, the adjacent outer side of one of the hoop high-voltage capacitors is provided with a lead end installed in the solid portion of the epoxy insulator, the lead end is provided with an electric lead connected with the hoop high-voltage capacitors, the other end of the electric lead is connected with a low-voltage capacitor device, and the low-voltage capacitor device is connected with a signal processing module connected with a control unit of a switchgear. The hoop voltage sensing device is small in space occupation, influence on electric field distribution in an original environment of an electrical element is small, the measurement precision is high, the temperature and frequency features are good, and the cost is low.

Owner:ZHUHAI XJ ELECTRIC +1

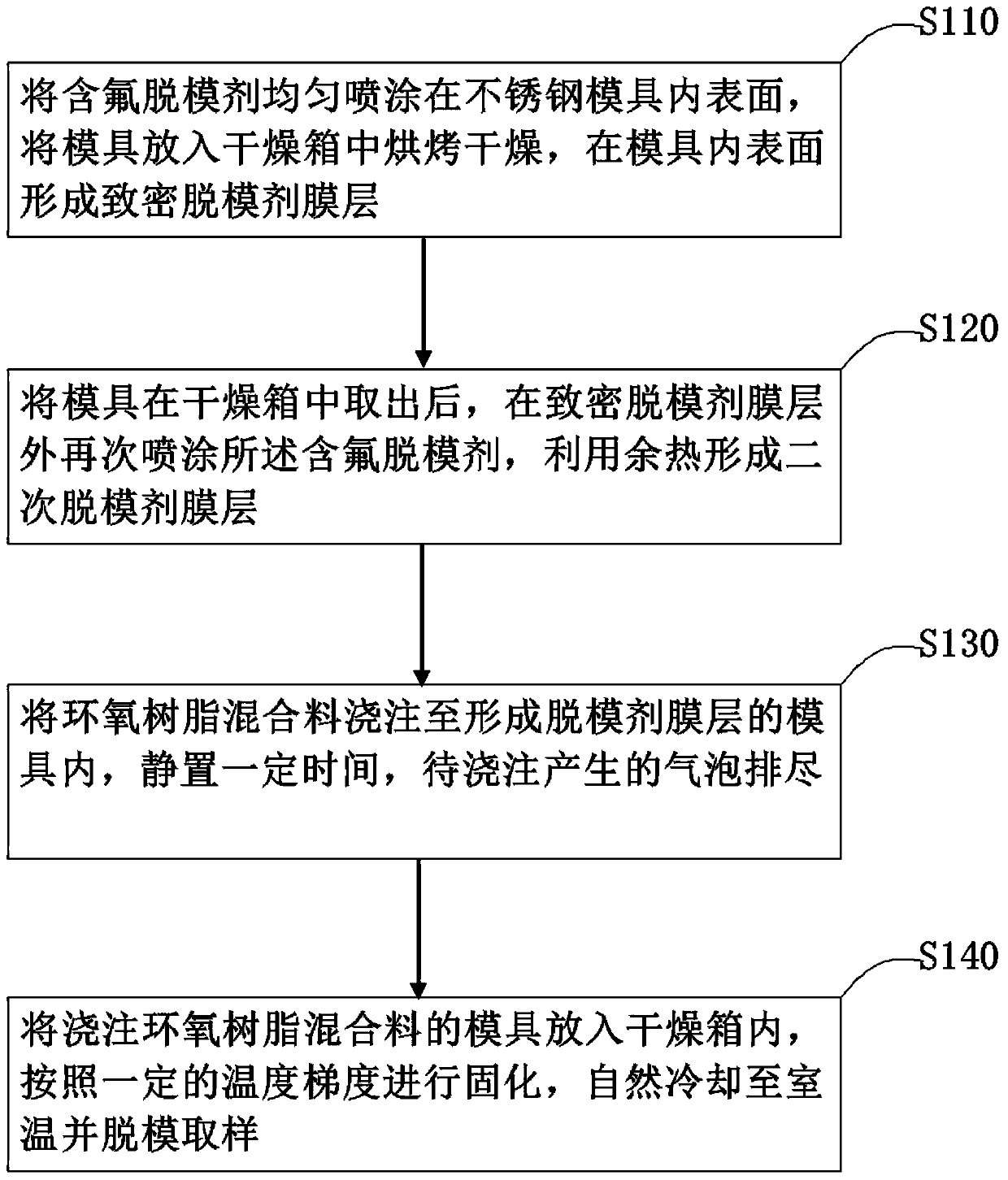

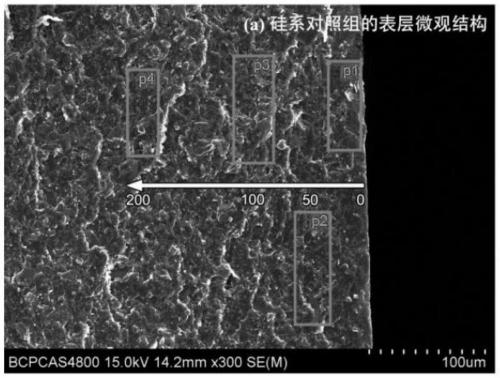

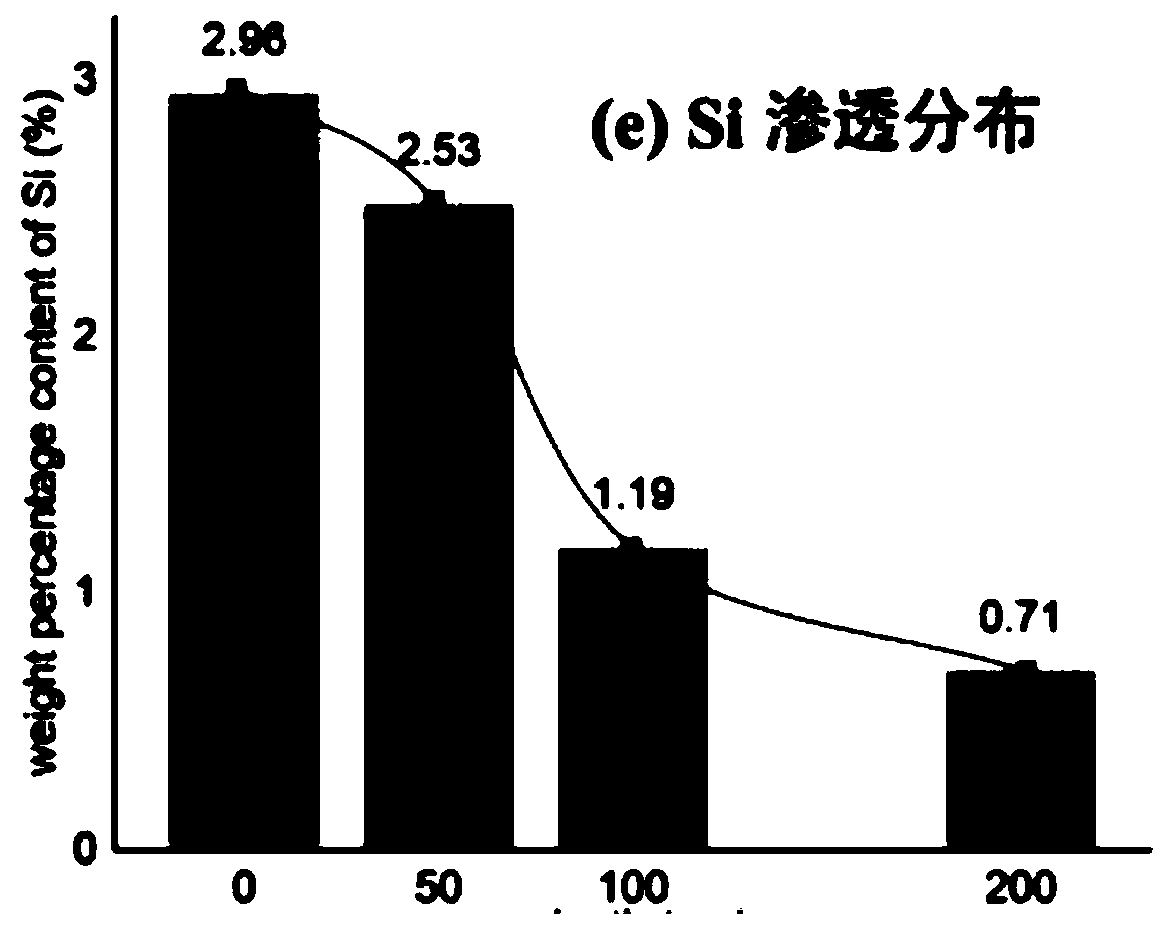

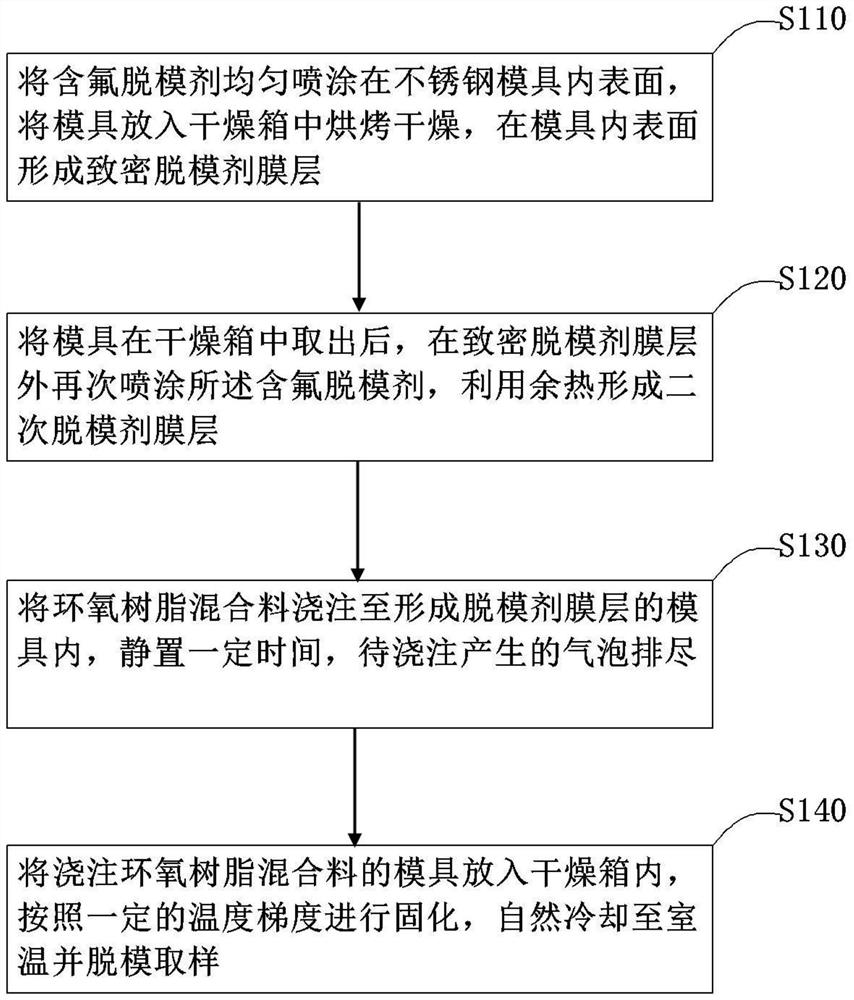

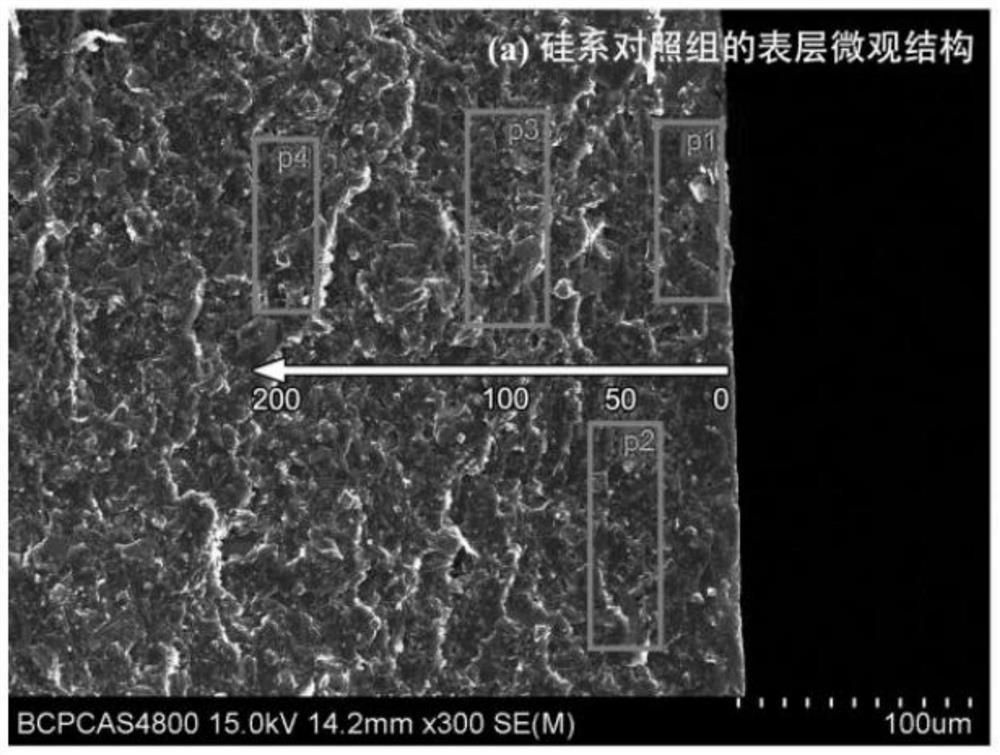

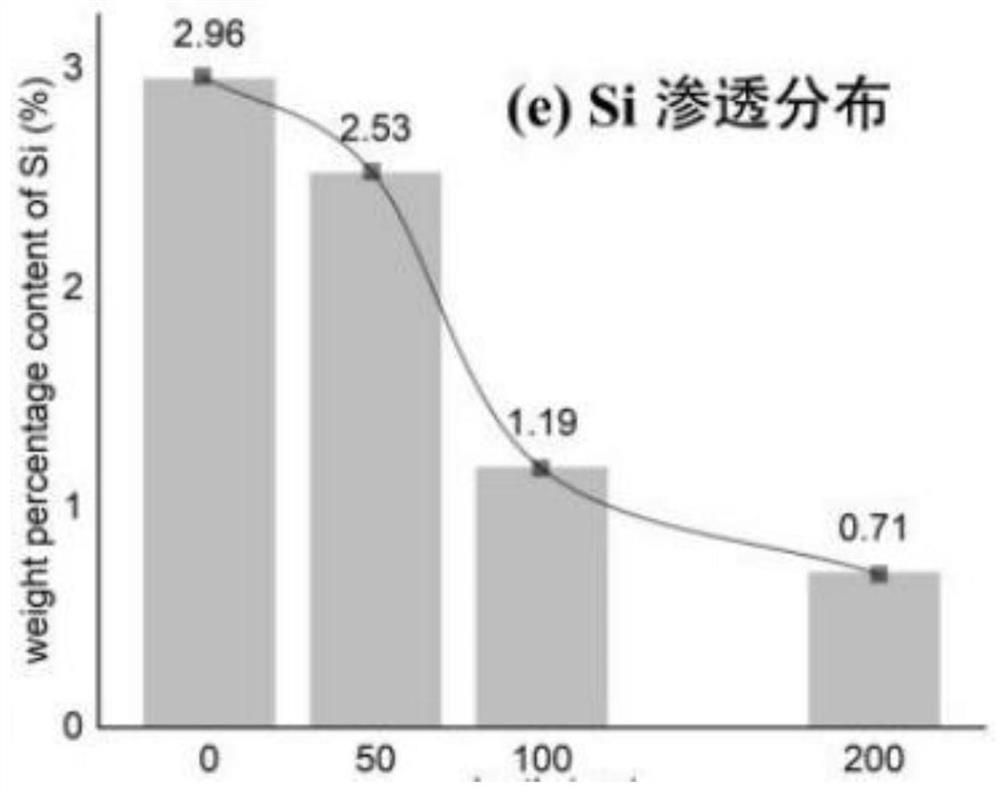

Preparation method of epoxy insulating composite material for improving electrostatic dissipation characteristics

ActiveCN111037819AReduce electrostatic charge build-upImprove static dissipation speedEpoxy insulatorsBis epoxide

The invention provides a preparation method of an epoxy insulating composite material for improving electrostatic dissipation characteristics, and belongs to the technical field of epoxy insulators. The method comprises the following steps: uniformly spraying a fluorine-containing mold release agent on the inner surface of a mold, and performing baking and drying in a drying oven to form a compactmold release agent film layer; after taking out the film layer, spraying the mold release agent again outside the compact mold release agent film layer to form a secondary mold release agent film layer; pouring an epoxy resin mixture into a mold for forming the mold release agent film layer, performing standing for a certain time, and completely discharging bubbles generated by pouring; and putting the mold into which the epoxy resin mixture is poured into a drying box, performing curing according to a temperature gradient, cooling the cured material to room temperature, and performing demolding and sampling to obtain an epoxy insulator with improved electrostatic dissipation performance. According to the invention, a fluorine-containing component is introduced into an epoxy composite system, and a fluorine-containing permeable layer is formed by adopting a pretreatment process of spraying the fluorine-containing release agent two times, so that electrostatic charge accumulation of epoxy resin is reduced, the electrostatic dissipation speed of the surface of the epoxy resin is increased, the operation is simple and convenient, and the cost is low.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

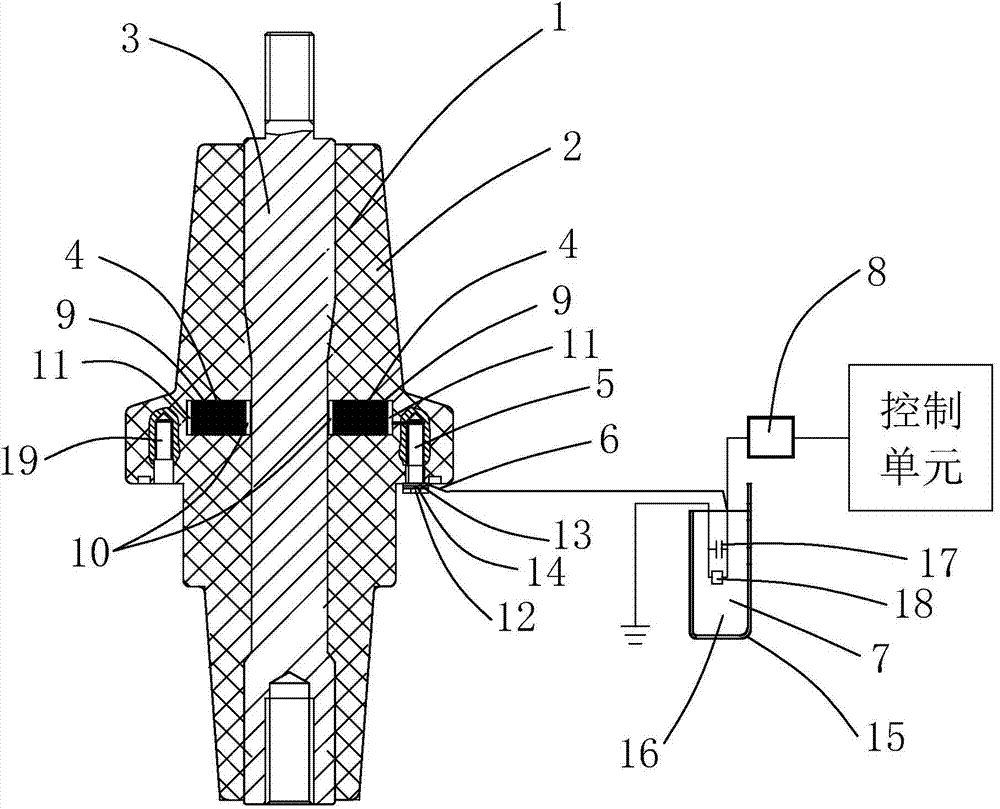

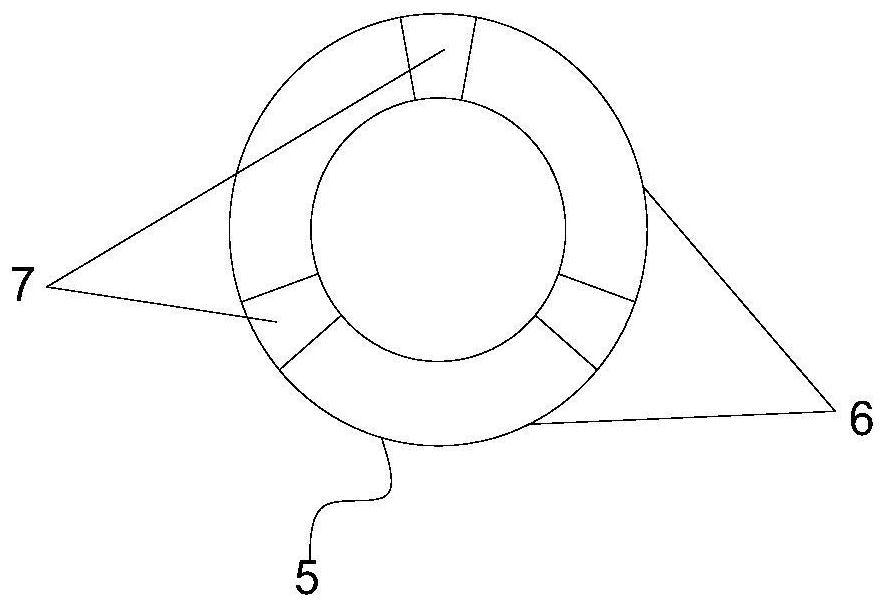

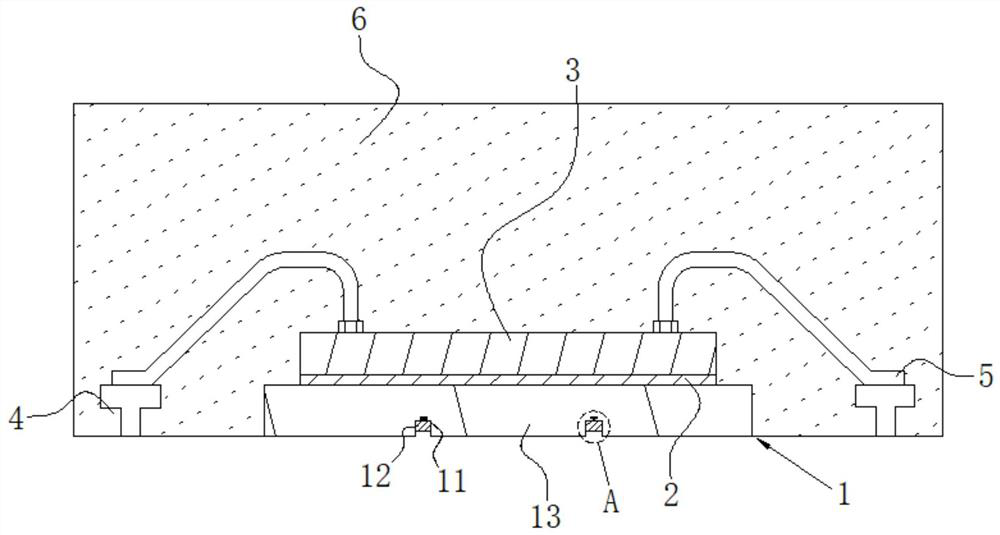

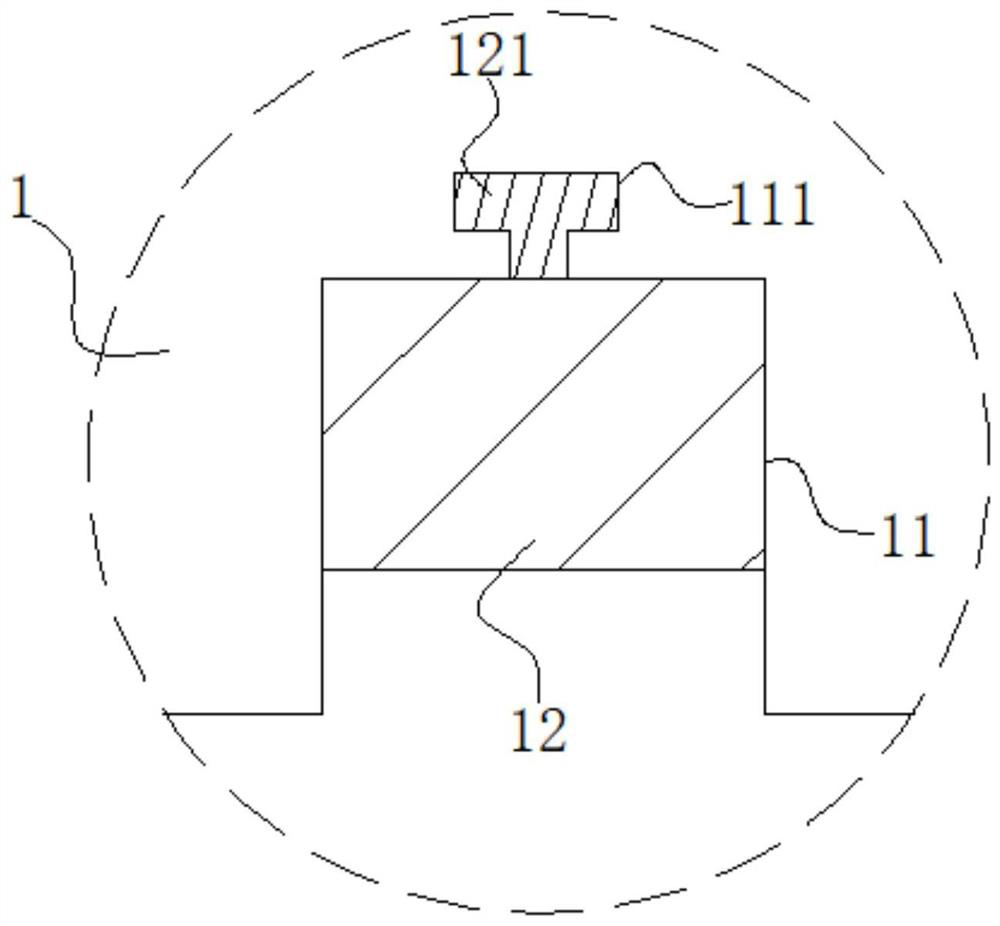

Electrostatic probe-based GIL insulator surface charge on-line monitoring system

ActiveCN111766457AReal-time monitoring of accumulationSmall distortionElectrical measurementsCopper electrodeElectrical connection

The invention discloses an electrostatic probe-based GIL insulator surface charge on-line monitoring system, which comprises an electrostatic probe; the electrostatic probe comprises three fan-ring-shaped red copper electrodes uniformly distributed along the circumferential direction of the electrostatic probe, fan-ring-shaped epoxy insulators are fixed between the fan-ring-shaped red copper electrodes, and the epoxy insulators are fixedly connected with an insulator; the fan-ring-shaped red copper electrodes are connected with resistance voltage dividing arms, the resistance voltage dividingarms are electrically connected with operational amplifiers, and the operational amplifiers are electrically connected with induction potential data acquisition devices used for detecting the fan-ring-shaped red copper electrodes. The electrostatic probe is pre-installed near a ground electrode of a GIL insulator, probe induction voltage is stored in real time through the data acquisition system,and the surface charge accumulation condition can be monitored in real time; the electrostatic probe measures surface charges in a non-contact manner, the original surface charge distribution is not damaged, and the probe adopts a circular ring design, so that the distortion of the probe to an original electric field can be effectively reduced.

Owner:HUNAN UNIV

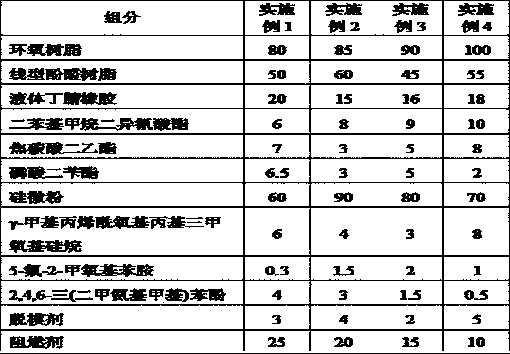

High-stability DFN packaging device

ActiveCN109904131AImprove cooling effectIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesNitrile rubberPolyethylene glycol

The invention discloses a high-stability DFN packaging device. An epoxy insulator of the high-stability DFN packaging device comprises the following raw materials in parts by weight: 80-100 parts of epoxy resin, 50-70 parts of linear phenolic resin, 12-18 parts of liquid nitrile rubber, 3-8 parts of diethyl pyrocarbonate, 65-90 parts of silica powder, 0.1-1.5 parts of octylphenylpolyethylene glycol, 2-5 parts of 3-aminopropyltriethoxysilane, 2-6 parts of cellulose acetate butyrate, 0.3-2 parts of 5-fluoro-2-methoxyaniline, 0.5-5 parts of 2,4,6-tri(dimethylamiomethyl)phenol, 1-5 parts of a release agent and 10-25 parts of a flame retardant. The high-stability DFN packaging device is excellent in heat dissipation effect and mechanical property and is stable and reliable in packaging structure, thereby having a wide application prospect.

Owner:西安航思半导体有限公司

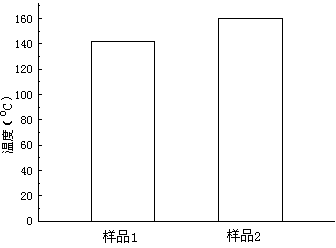

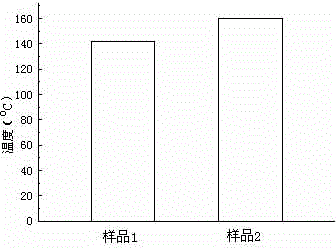

Preparation method of heat-resistant epoxy resin insulator

The invention discloses a preparation method of a heat-resistant epoxy resin insulator, which comprises the following steps: performing surface treatment on silicon micropowder with epoxy resin curing agent and gamma-(2,3-epoxy propoxy)propyltrimethoxysilicane; heating the silicon micropowder subjected to surface treatment at 40-50 DEG C for 1-2 hours, and drying for 1-2 hours under the condition of heating to 105-120 DEG C; and then, naturally cooling, mechanically separating bonded silicon micropowder particles, compounding with epoxy resin, and curing to obtain the heat-resistant epoxy resin insulator, wherein the glass transition temperature of the heat-resistant epoxy resin insulator is increased by more than 10 DEG C in comparison with the common epoxy insulator. The invention has the advantages of simple process and mild reaction conditions, and can effectively improve the heat resistance of the epoxy resin insulator. Compared with the conventional silicon micropowder filled epoxy resin composite material, the glass transition temperature of the epoxy resin insulator prepared by the invention is increased by more than 15 DEG C when the silicon micropowder particle content is 30%.

Owner:ZHEJIANG SCI-TECH UNIV +1

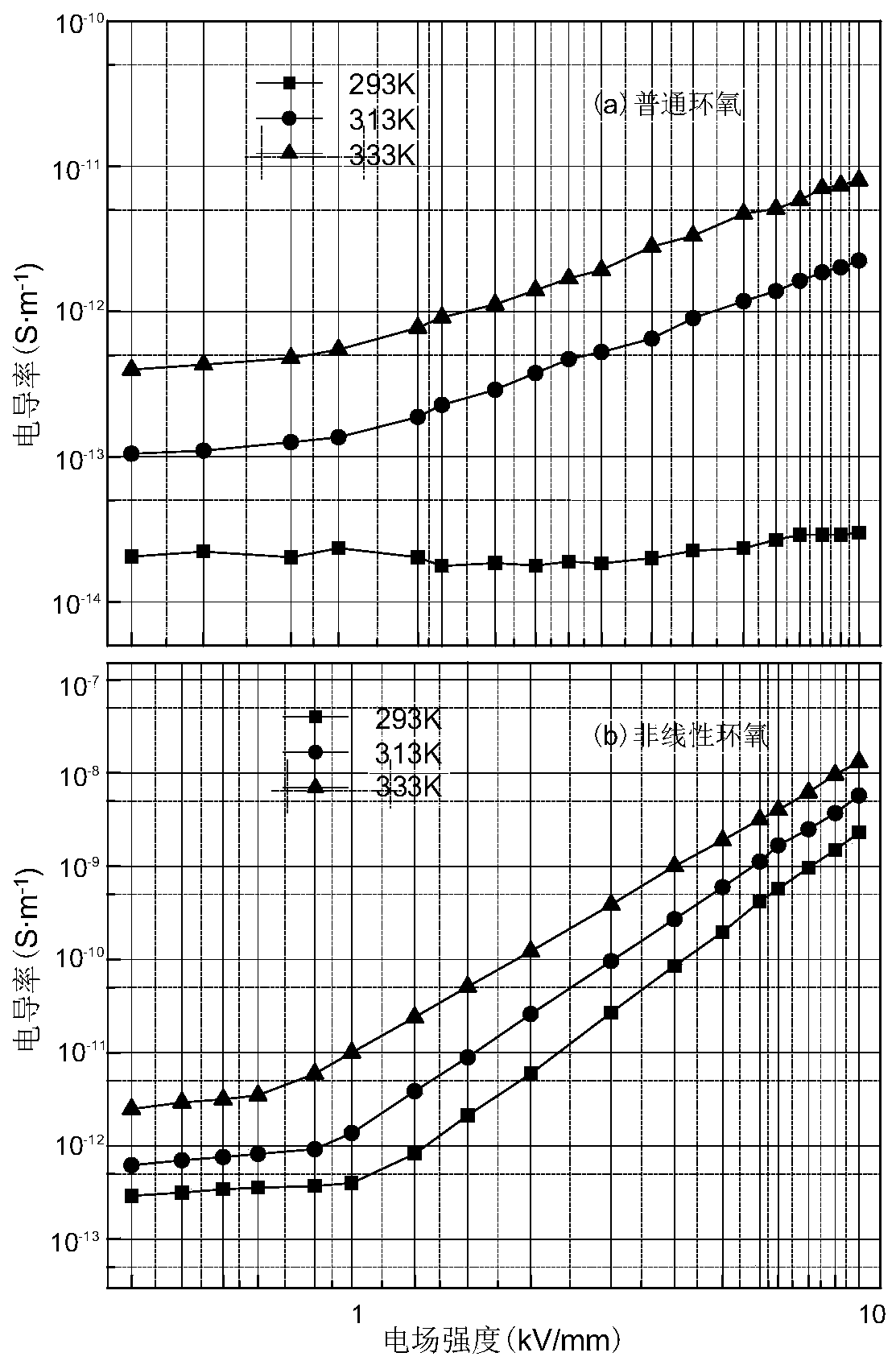

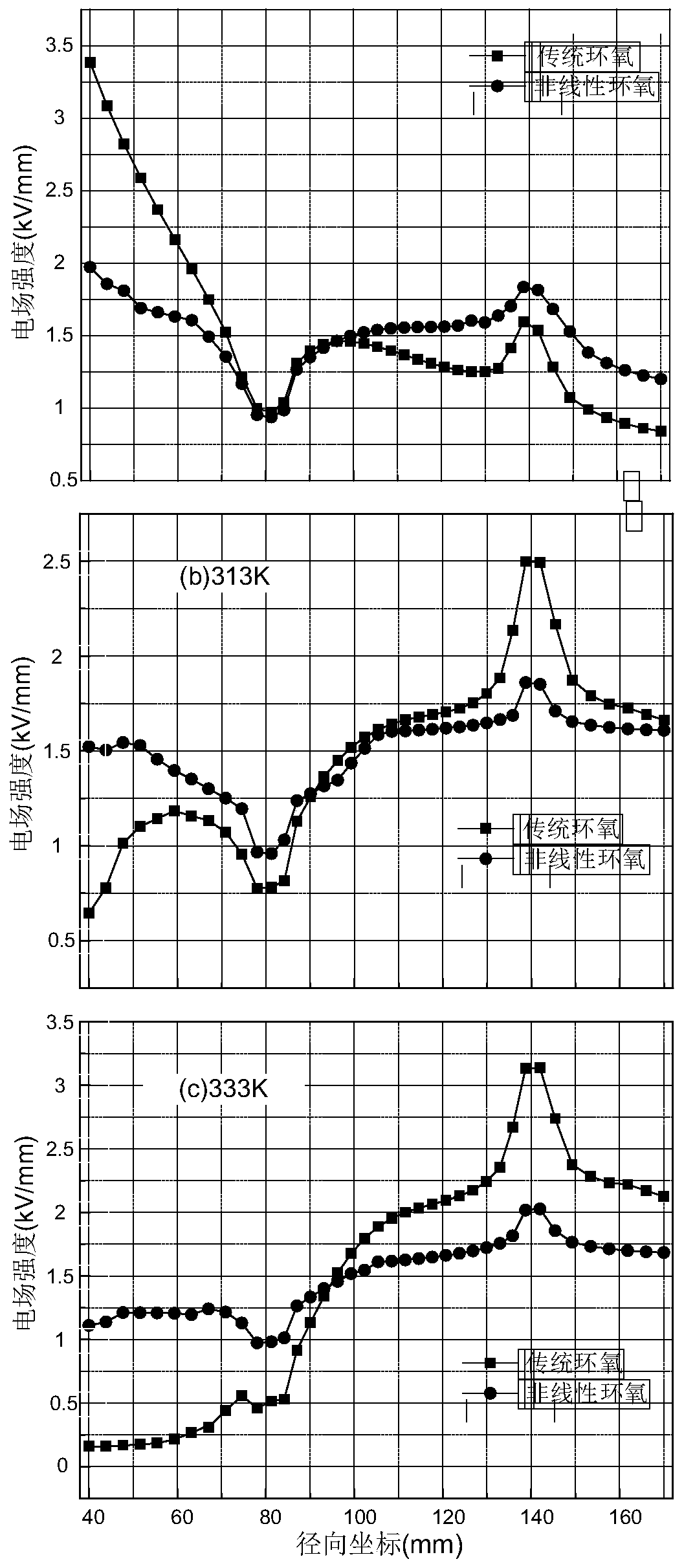

220kVGIL insulator voltage-sharing method based on non-linear conductive epoxy resin

InactiveCN109858141AThe maximum value of the surface electric field strength decreasesImprove uniformitySpecial data processing applicationsElement modelElectrical field strength

The invention discloses a 220kV GIL insulator voltage-sharing method based on non-linear conductive epoxy resin. The method comprises the following steps: 1) establishing a simplified GIL model; 2) setting various electrical, thermal and basic parameters of different materials of the GIL: setting the normal temperature pressure of SF6 to be 0.4 Mpa; and 3) establishing a finite element model of the direct current GIL, and performing mesh generation on the model. After the non-linear conductive epoxy resin is adopted to replace a common epoxy resin insulator, the surface electric field distortion degree of the insulator is greatly improved compared with that of the common epoxy insulator. The uniformity of electric field intensity distribution of the upper and lower surfaces is obviously improved, and the maximum value of the electric field intensity of the upper surface of the insulator is obviously reduced.

Owner:TIANJIN UNIV

Preparation method of high temperature resistant qfn packaging structure

ActiveCN109904125BGuaranteed stabilityImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesMeth-Engineering

Owner:西安航思半导体有限公司

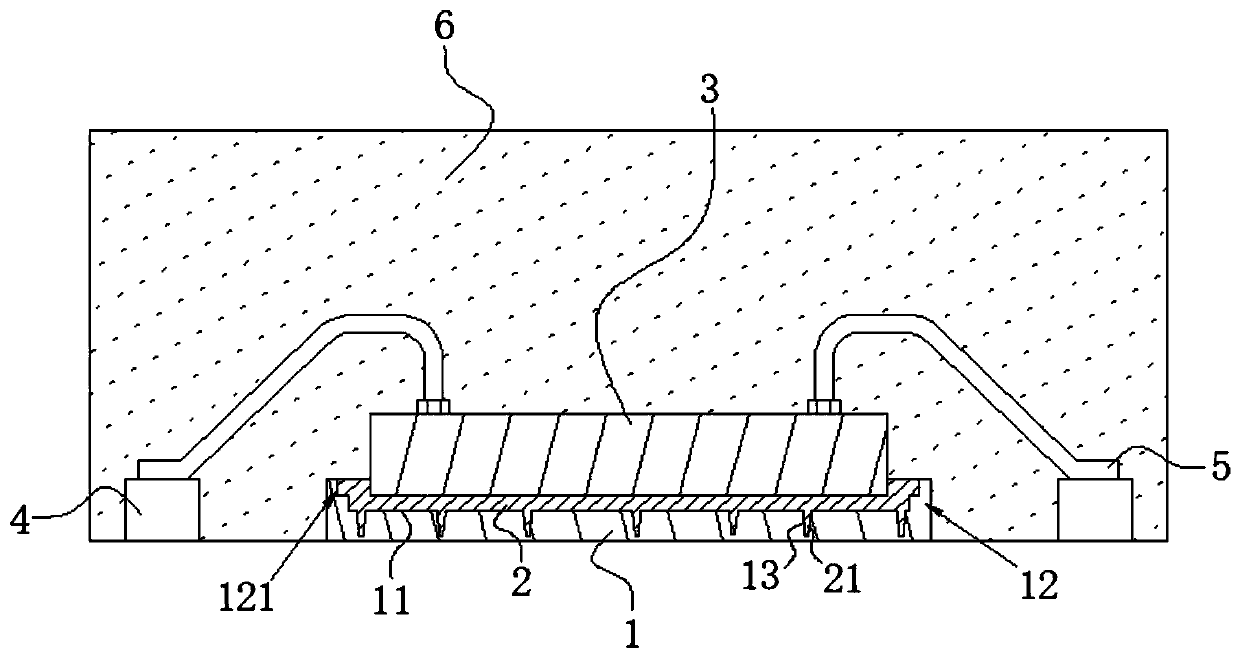

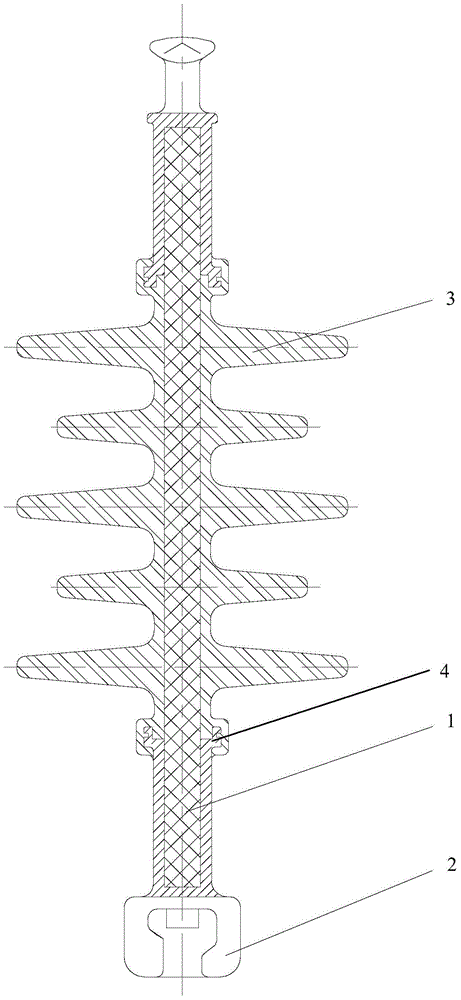

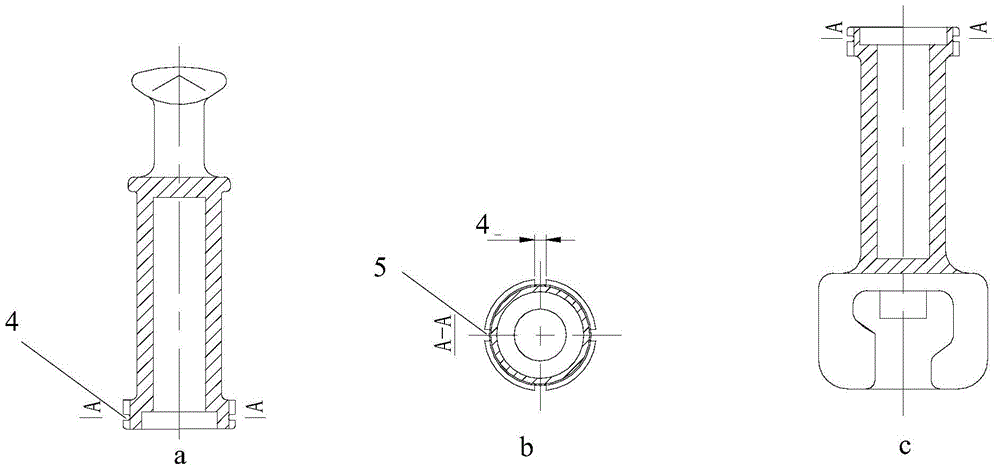

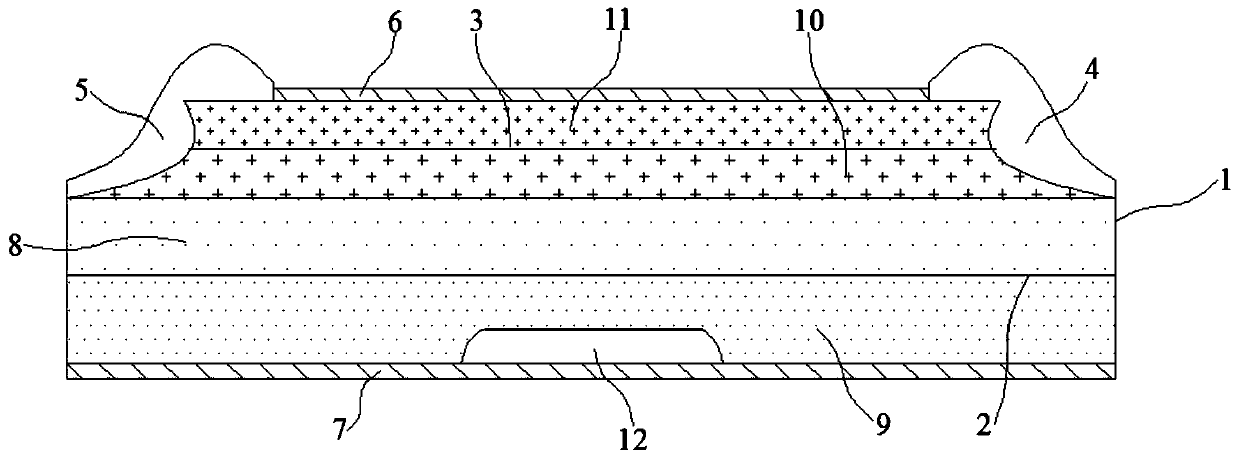

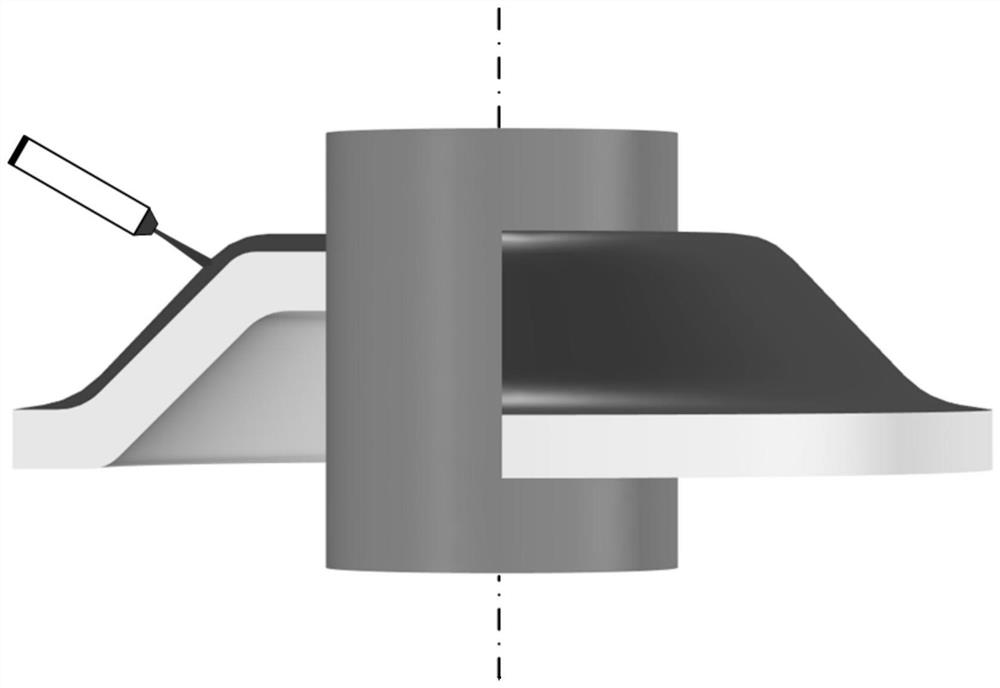

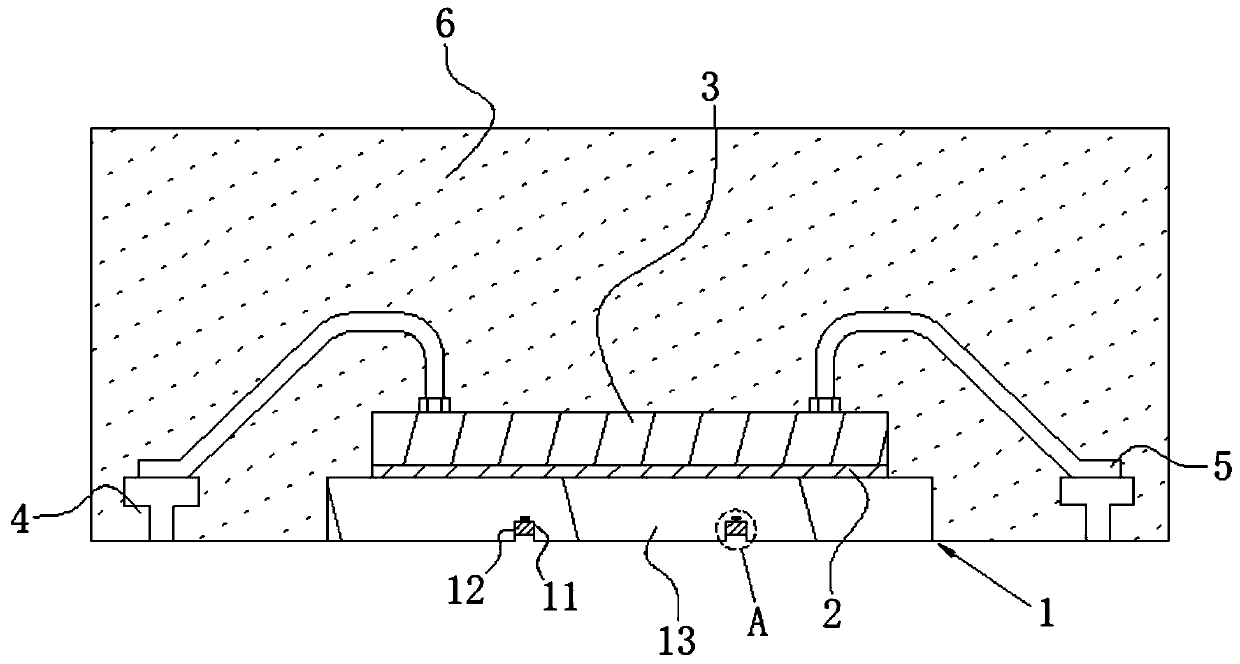

a suspension insulator

ActiveCN103617845BImprove electrical strengthIncrease stiffnessSuspension/strain insulatorsFiberGlass fiber

The invention belongs to the technical field of high-voltage power transmission and transformation, and in particular relates to a suspension insulator. The invention discloses a suspension insulator, which comprises a mandrel 1 and fittings 2 at both ends thereof and an umbrella shed 3. The mandrel is made of epoxy resin and / or alkali-free glass fiber, and the shed 3 is made of flexible epoxy resin. APG equipment molding. The suspended insulator provided by the invention has simple structure, reasonable design and high molding efficiency. After molding, the overall rigidity of the insulator has been greatly improved. Compared with silicon rubber insulators, epoxy resin insulators have the advantages of easy maintenance and bird-proof pecking.

Owner:赛思迈(上海)新材料科技有限公司

Surge protection device

InactiveCN110098161AImprove anti-surge performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringEpoxy insulators

The invention discloses a surge protection device, which comprises a first lead, a second lead and a chip. The ends of the first lead and the second lead and the chip are located in an epoxy insulator. The first lead and the second lead have grooves at the ends thereof. The ends of the first lead and the second lead are respectively and electrically connected with a first metal layer and a secondmetal layer of the chip through soldering lugs. The soldering lugs are embedded into the grooves at the ends of the leads, and the thickness of the soldering lugs is greater than the depth of the grooves. The epoxy insulator includes the following raw materials by weight: 80-100 parts of epoxy resin, 40-60 parts of phenol resin, 75-90 parts of silica micro-powder, 5-15 parts of flame retardant, 2-6 parts of gamma-aminopropyl triethoxysilane, 0.3-2 parts of nano-silica particles, 0.1-1.5 parts of azabicyclo, 0.5-1.5 parts of isooctyl phenyl polyoxyethylene ether, 0.2-1.5 parts of tris-(dimethylaminomethyl)phenol and 3-8 parts of mold release agent. Bad phenomena such as wire tapping, layering and blowhole can be greatly reduced during packaging of the surge protection device, and the packaging yield of the device can be improved.

Owner:苏州达晶微电子有限公司

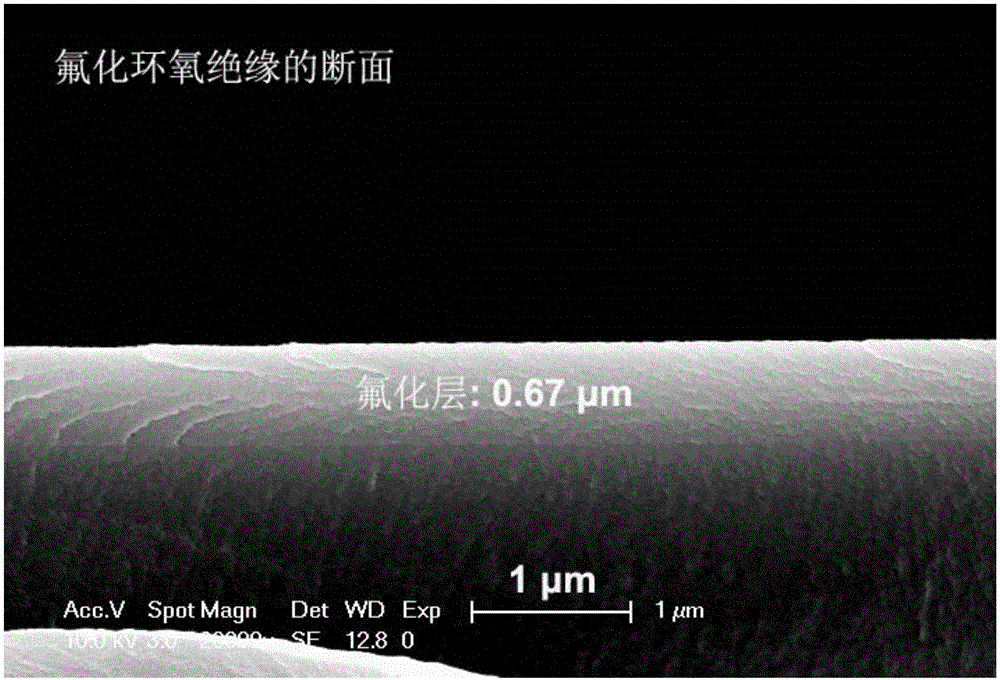

Fluorinated 110kV basin-type insulator

PendingCN111081435AIncreased DC flashover voltageImprove DC flashover performanceInsulatorsSulfur hexafluoridePhysical chemistry

The invention relates to a fluorinated 110kV basin-type insulator, which comprises an insulator body, wherein a fluorinated layer is generated on the outer surface of the insulator body through a fluorination device, and the insulator body is made of an epoxy resin mixture; the thickness of the fluorinated layer is 0.3-2[mu]m; and the epoxy resin mixture comprises epoxy resin and aluminum oxide. According to the invention, the surface layer of the epoxy insulator is fluorinated by using a direct fluorination technology, the cost is low, the formula and the production process do not need to beadjusted, the direct current flashover voltage of the fluorinated 110kV basin-type insulator is increased to average 290kV from average 250kV before fluorination in a sulfur hexafluoride gas environment of two atmospheric pressures, and the direct current flashover performance of the fluorinated 110kV basin-type insulator is improved by 10%-20%; the conductivity of the surface of the insulator body is improved from 1*10<-19> to 1*10<-13> and reaches 6 orders of magnitudes or above, surface charge accumulation of the insulator body can be effectively inhibited, and the service life of the insulator body is greatly prolonged.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

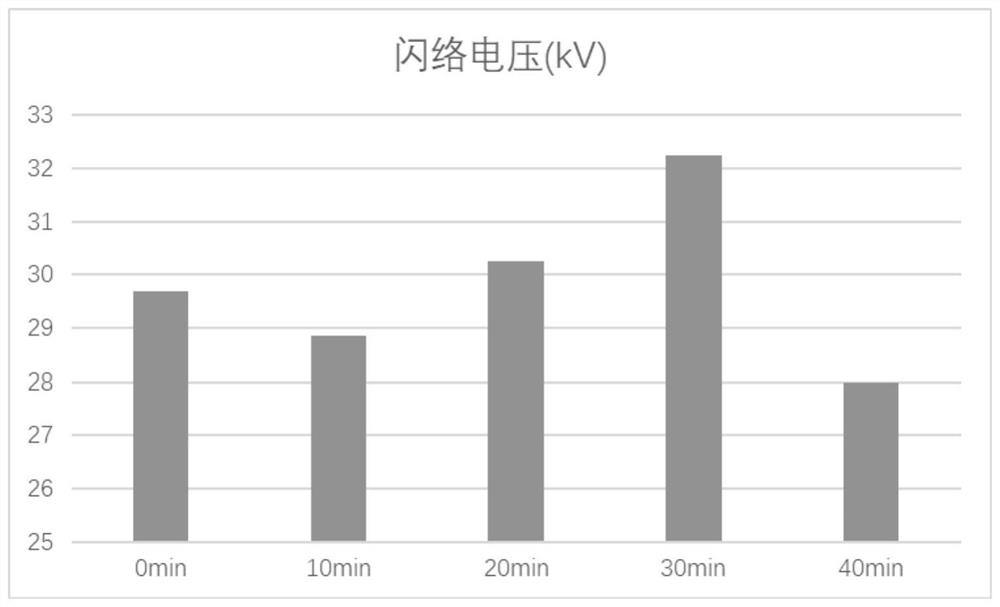

Surface treatment method of GIS/GIL epoxy resin insulator

PendingCN114188111AImprove cleanlinessImprove electrical resistanceInsulatorsPhysical chemistryEpoxy insulators

The invention discloses a surface treatment method of a GIS / GIL epoxy resin insulator, and belongs to the field of high-voltage equipment. The method comprises the following steps that a laser beam with the power density being 10-20 W / cm < 2 > is used for uniformly scanning a GIS / GIL epoxy resin insulator sample, and the scanning time is 20-30 min. According to the method, laser treatment is carried out on the surface of the GIS / GIL epoxy insulator, the surface flashover voltage of the GIS / GIL epoxy insulator is improved by changing laser parameters, and a brand new method is provided for manufacturing the high-performance GIS / GIL epoxy resin insulator.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

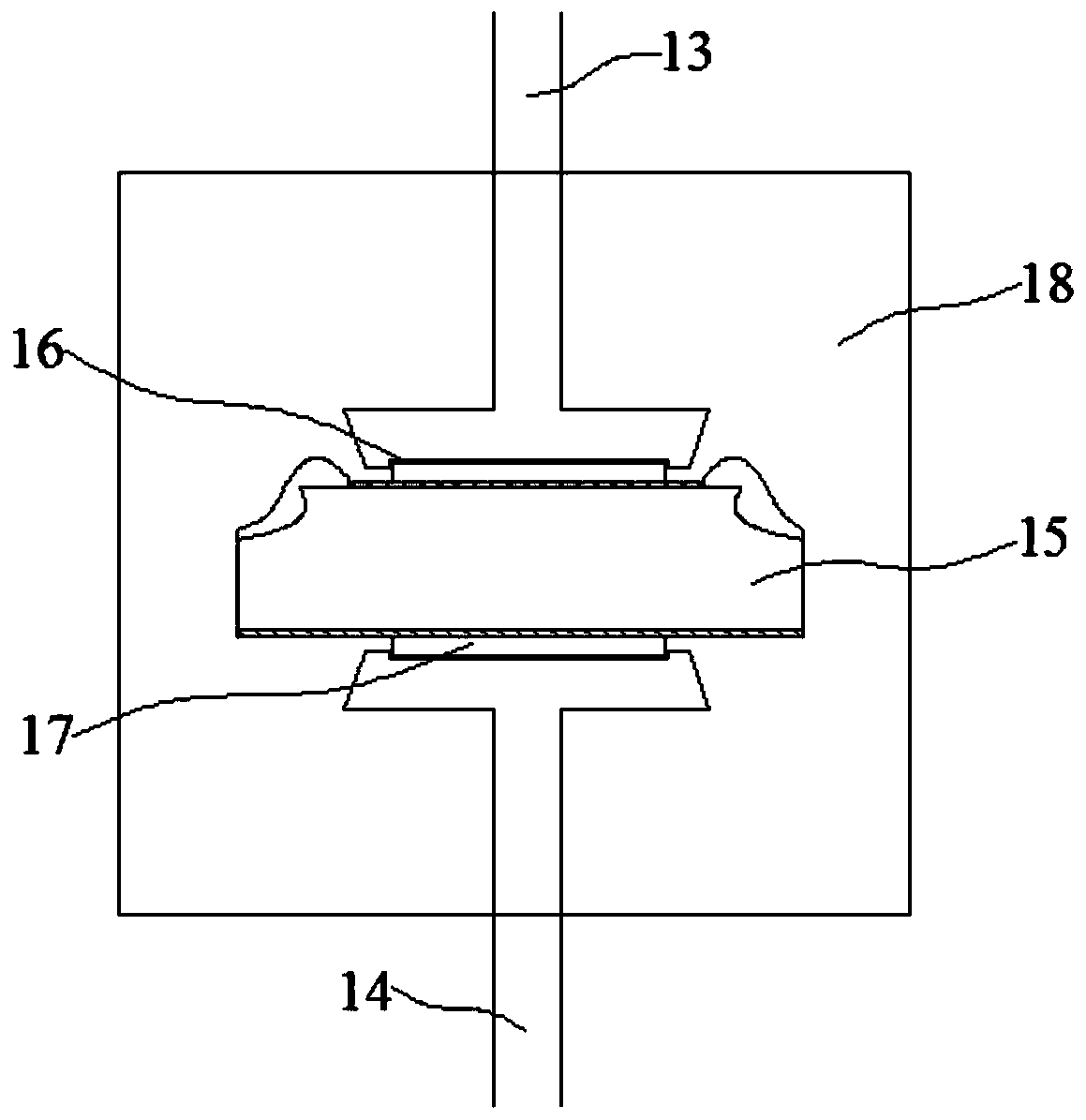

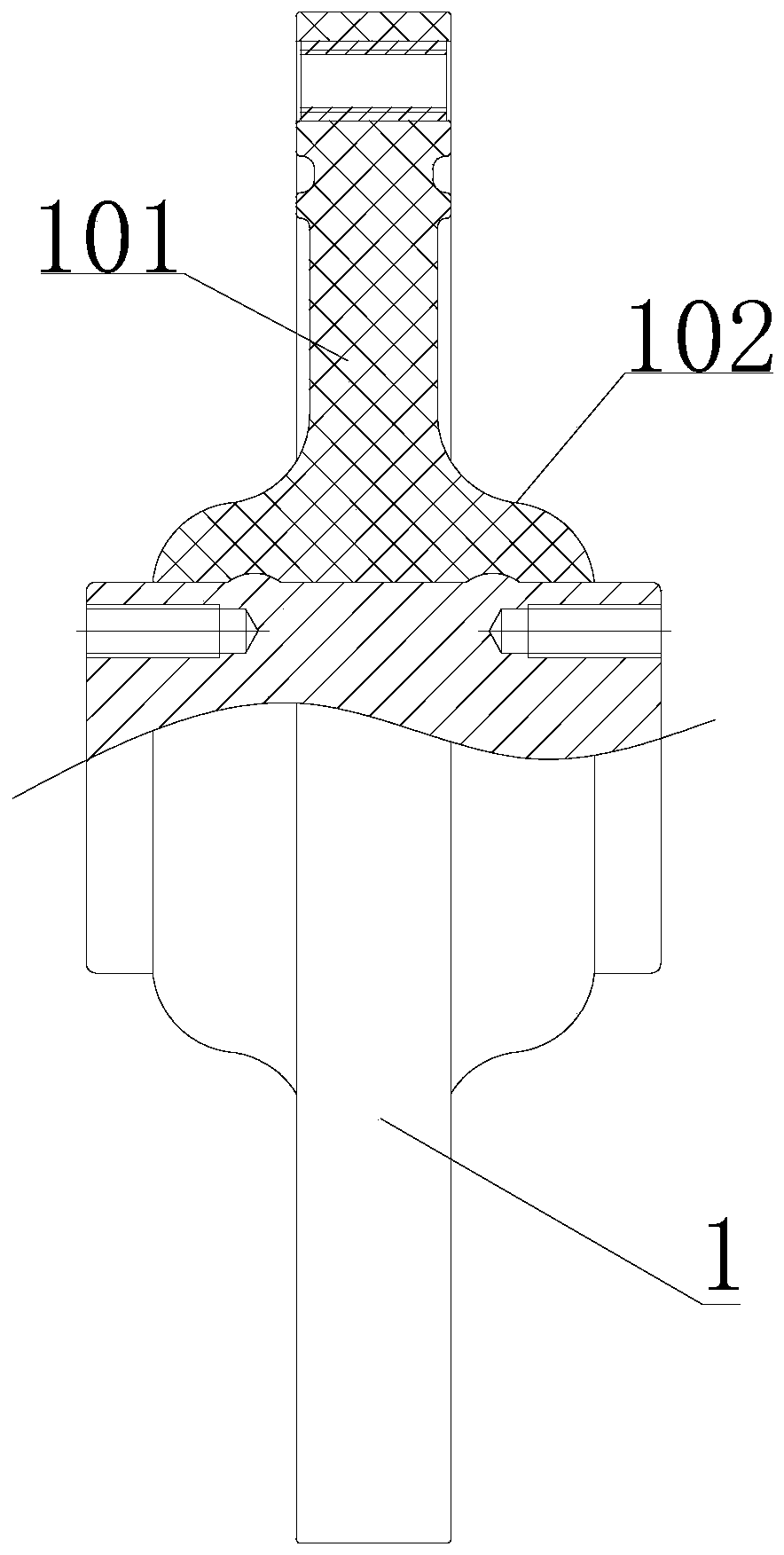

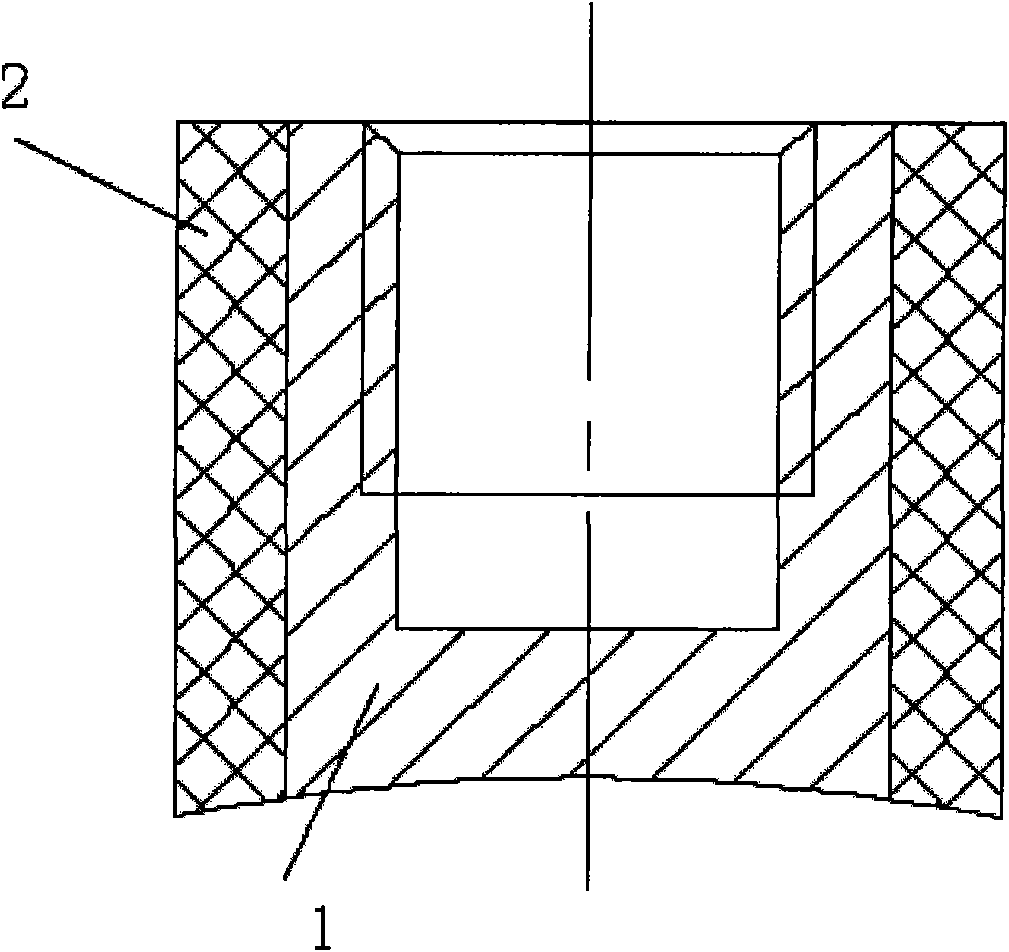

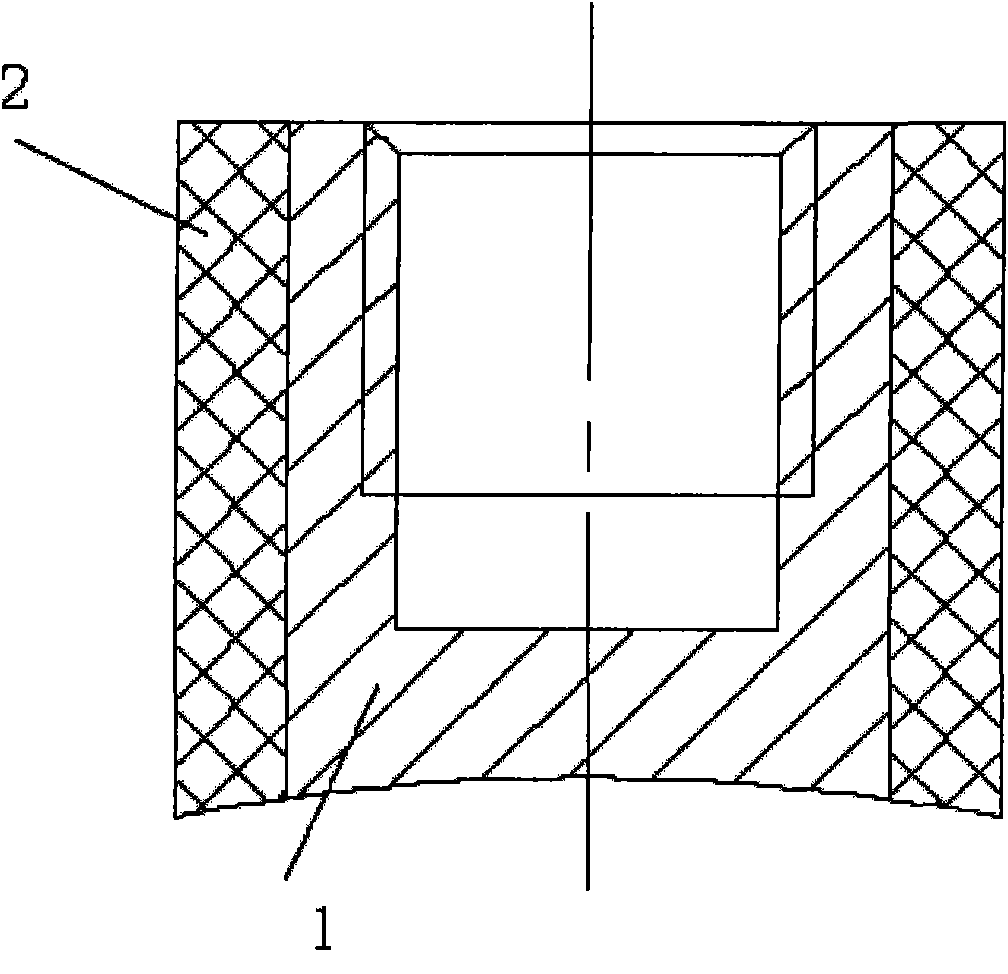

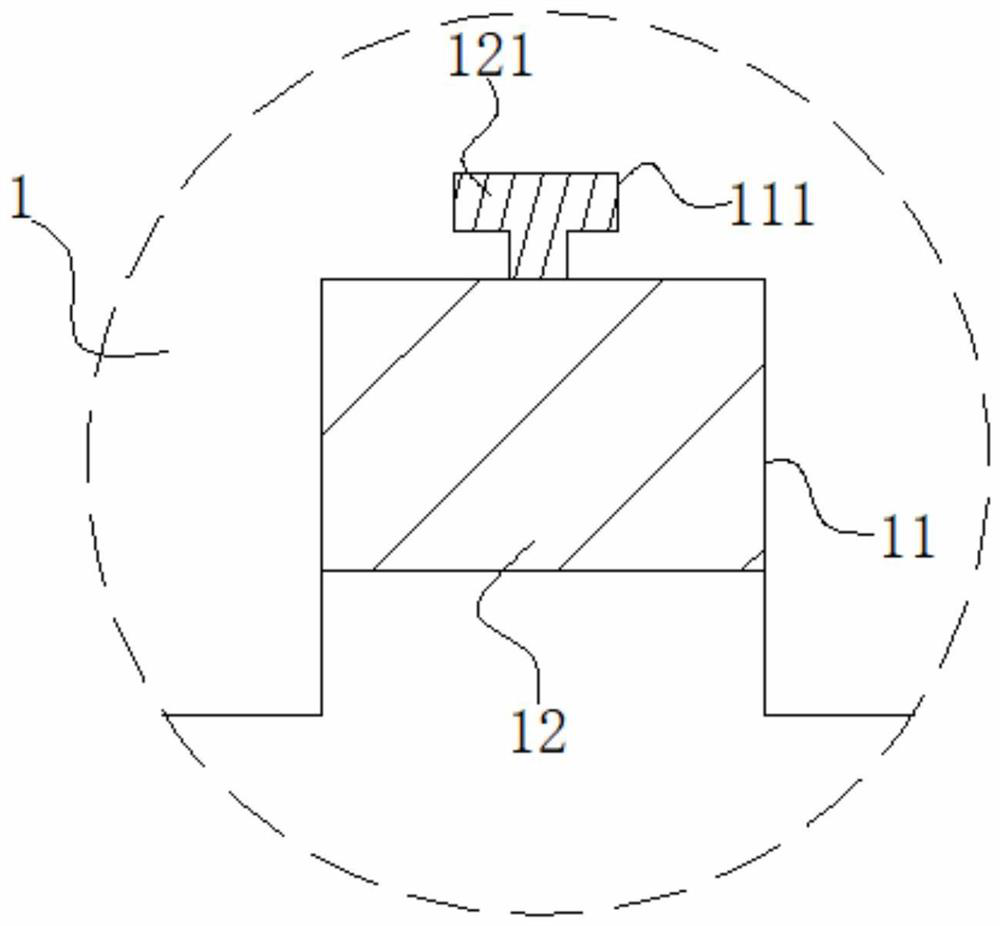

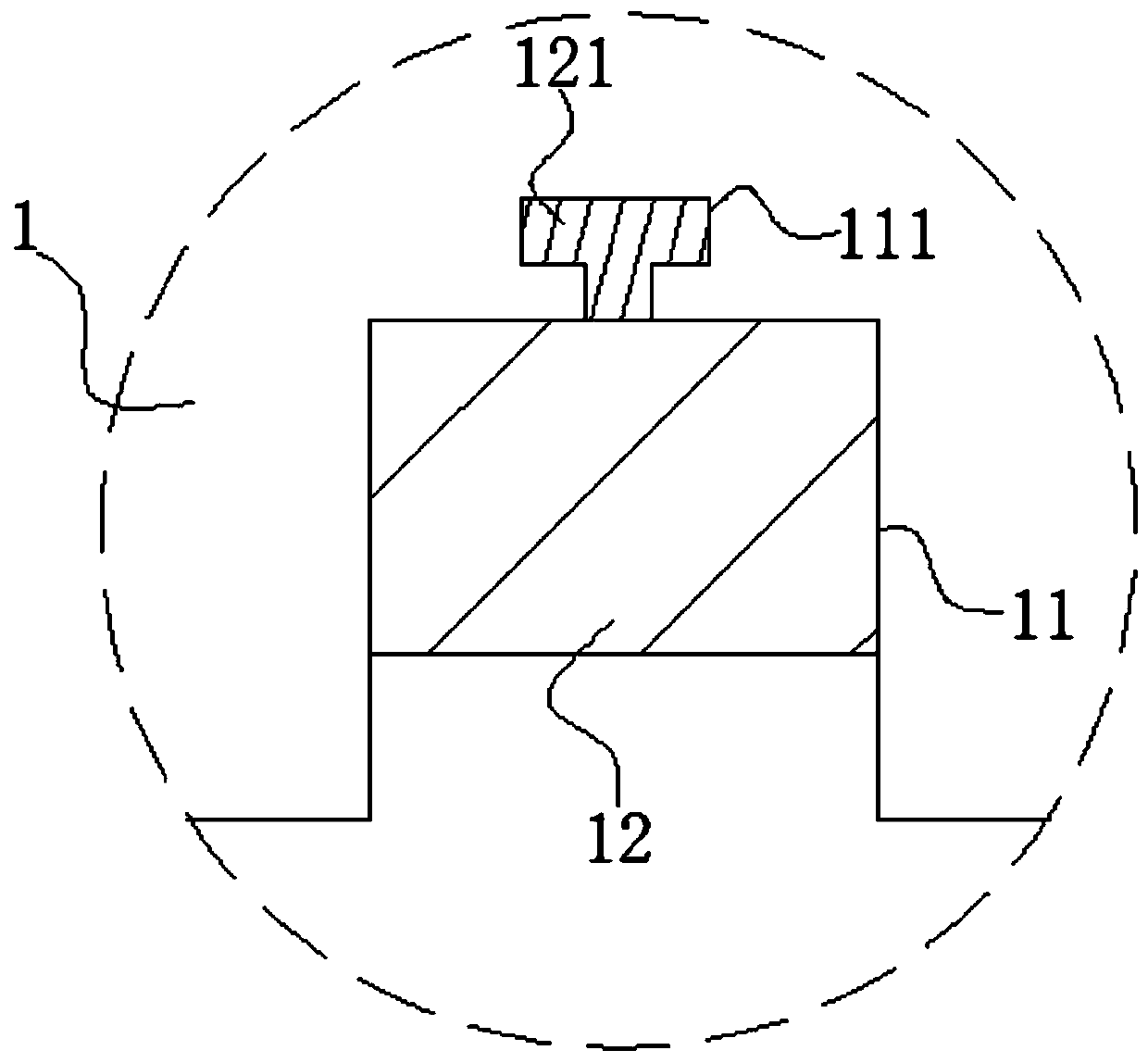

Mechanism for preventing parts from cracking by inlaying insert into epoxy insulator

InactiveCN101866728AIncrease internal stressNo crackingSubstation/switching arrangement detailsInsulatorsEngineeringEpoxy insulators

The invention relates to a mechanism for preventing parts from cracking by inlaying an insert into an epoxy insulator, comprising the insert (1) in an epoxy resin and a buffer layer (2) arranged between the epoxy resin and the insert (1). The mechanism has the following beneficial effect: the buffer layer is added, thus great internal stress is generated between the metal insert and the epoxy resin so that the parts are free from cracking.

Owner:SHANGHAI ROX ELECTRIC

A preparation method of epoxy insulating composite material with improved static dissipative properties

ActiveCN111037819BReduce electrostatic charge build-upImprove static dissipation speedPolymer scienceEpoxy insulators

The invention provides a method for preparing an epoxy insulating composite material with improved electrostatic dissipation characteristics, belonging to the technical field of epoxy insulators, comprising spraying a fluorine-containing mold release agent evenly on the inner surface of a mold, putting it into a drying oven to bake and dry, and forming Dense release agent film layer; after taking it out, spray the release agent again outside the dense release agent film layer to form a secondary release agent film layer; pour the epoxy resin mixture into the mold that forms the release agent film layer , let it stand for a certain period of time, until the air bubbles generated by pouring are exhausted; put the mold of pouring epoxy resin mixture into the drying box, solidify according to the temperature gradient, cool to room temperature, demould and sample, and obtain epoxy resin with improved electrostatic dissipation performance. insulator. The present invention introduces fluorine-containing components into the epoxy composite system, and adopts the pretreatment process of secondary spraying of fluorine-containing release agent to form a fluorine-containing permeable layer, which reduces the electrostatic charge accumulation of epoxy resin and improves the surface of epoxy resin. Excellent static dissipation speed, simple and convenient operation, and low cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

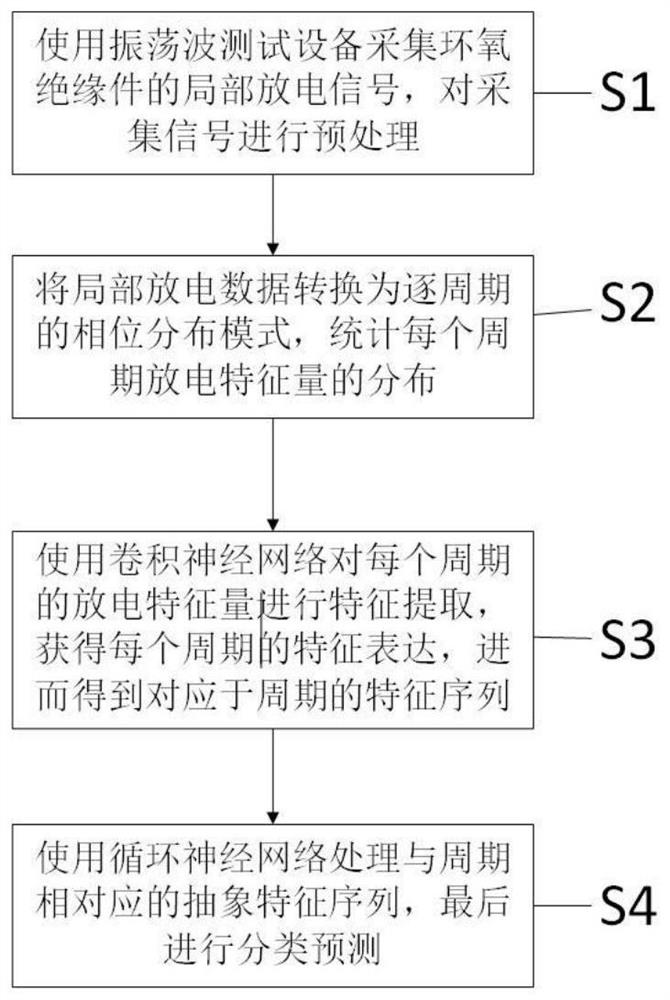

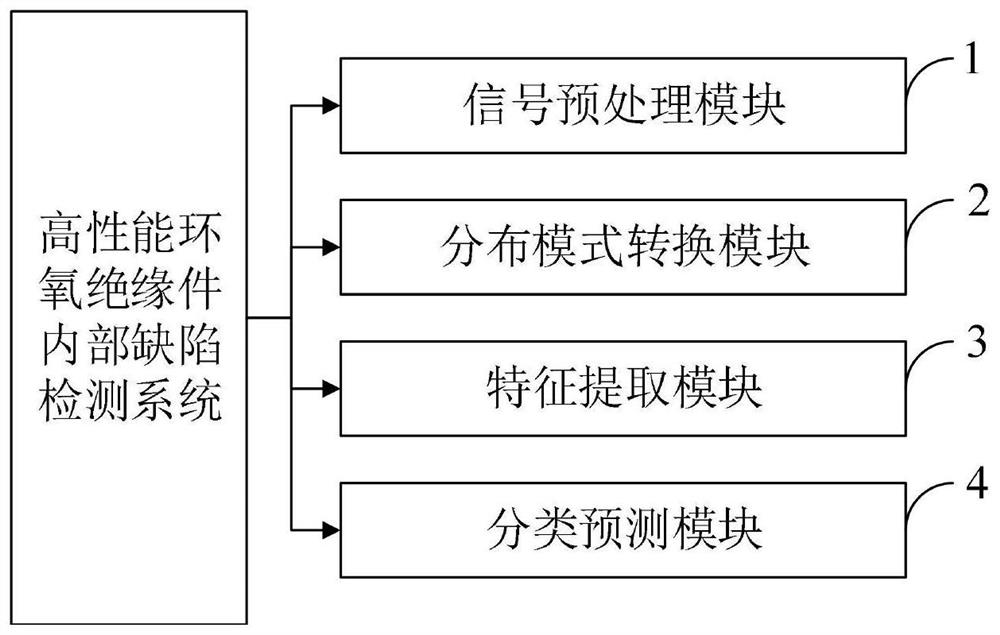

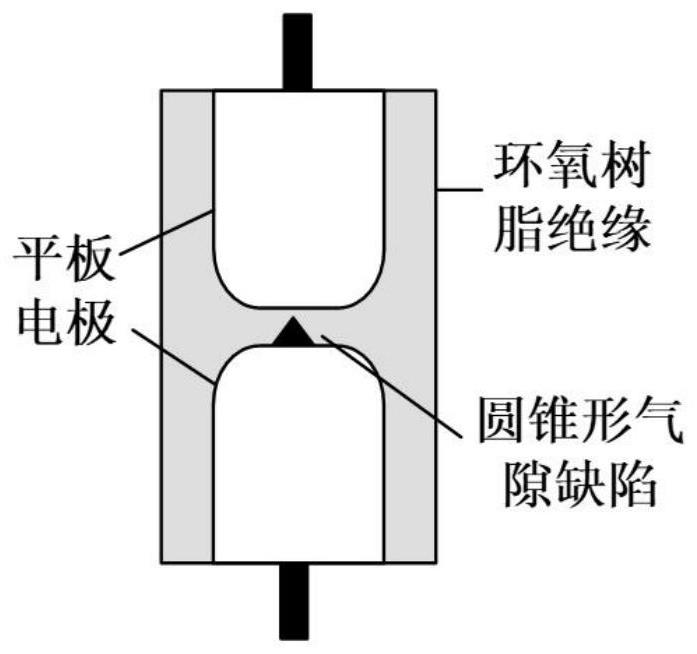

Method, system and equipment for detecting internal defects of high-performance epoxy insulating part and medium

PendingCN113985222AAccurate identificationRealize identificationTesting dielectric strengthNeural architecturesFeature extractionAlgorithm

The invention belongs to the technical field of high-voltage insulation and fault diagnosis and discloses a high-performance epoxy insulator internal defect detection method, system and device and a medium. The high-performance epoxy insulator internal defect detection method comprises steps of carrying out preprocessing of a partial discharge signal of an epoxy insulator collected by an oscillatory wave test device; converting the time-distributed partial discharge signal into a cycle-by-cycle phase distribution mode, and counting the distribution of the discharge characteristic quantity of each cycle; performing feature extraction on the discharge feature quantity of each period by using a convolutional neural network to obtain abstract feature expression of each period so as to obtain an abstract feature sequence corresponding to the period; and processing the abstract feature sequence corresponding to the period by using a recurrent neural network, and then carrying out classification prediction. According to the method, effective information in periodic change is fully excavated and utilized, identification of the defect type of the epoxy insulating part under the oscillatory wave voltage is realized, and the defect type of the epoxy insulating part can be effectively identified with relatively high accuracy.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Surface mounted TVS device

InactiveCN110085680AImprove anti-surge performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPorosityEngineering

The invention discloses a surface mounted TVS device, which comprises an upper lead frame, a lower lead frame and a chip, wherein respective welding parts of the upper lead frame and the lower lead frame and the chip are located in an epoxy insulator, the welding part at one end of the upper lead frame is provided with a groove, the welding parts of the upper lead frame and the lower lead frame are electrically connected with a first metal layer and a second metal layer of the chip respectively through welding strips, and the raw materials of the epoxy insulator include the following components in parts by weight: 80-100 parts of epoxy resin, 40-60 parts of phenol resin, 75-90 parts of silicon micropowder, 5-15 parts of a flame retardant, 2-6 parts of gamma-aminopropyl triethoxysilane, 0.3-2 parts of nano silicon dioxide particles, 0.1-1.5 parts of azabicyclo, 2-8 parts of carboxylated acrylonitrile butadiene rubber, 0.3-2 parts of 2-amino-4-fluoro-1- methoxyphenyl, 0.2-1.5 parts of tri-(dimethylaminomethyl)phenol and 3-8 parts of a demoulding agent. The surface mounted TVS device can greatly reduce the bad phenomena such as punching, layering and porosity when being packaged, alsoenhances the overall mechanical properties of epoxy and effectively ensures the stability of the packaging structure.

Owner:苏州达晶微电子有限公司

QFN packaging semiconductor device

ActiveCN113451235AImprove mechanical propertiesIncrease crosslink densitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

The invention discloses a QFN packaging semiconductor device, which comprises a heat dissipation bonding pad, a chip and a conductive bonding pad positioned in an epoxy insulator. One side, far away from the chip, of the heat dissipation bonding pad is provided with a separation groove, the width of the separation groove is 0.1-0.3 mm, and the separation groove equally divides the side, far away from the chip, of the heat dissipation bonding pad into at least two bonding pad monomers; the epoxy insulator is prepared from the following raw material components in parts by weight: epoxy resin, linear phenolic resin, liquid nitrile rubber, diphenylmethane diisocyanate, diethyl pyrocarbonate, dibenzyl phosphate, silica powder, gamma-methacryloxypropyltrimethoxysilane, 5-fluoro-2-methoxyaniline, 2, 4, 6-tri (dimethylaminomethyl) phenol, a release agent and a flame retardant. According to the QFN packaging semiconductor device, the overall mechanical property of the epoxy insulator is enhanced, and the stability of a packaging structure is effectively guaranteed.

Owner:XIAN HANGSI SEMICON CO LTD

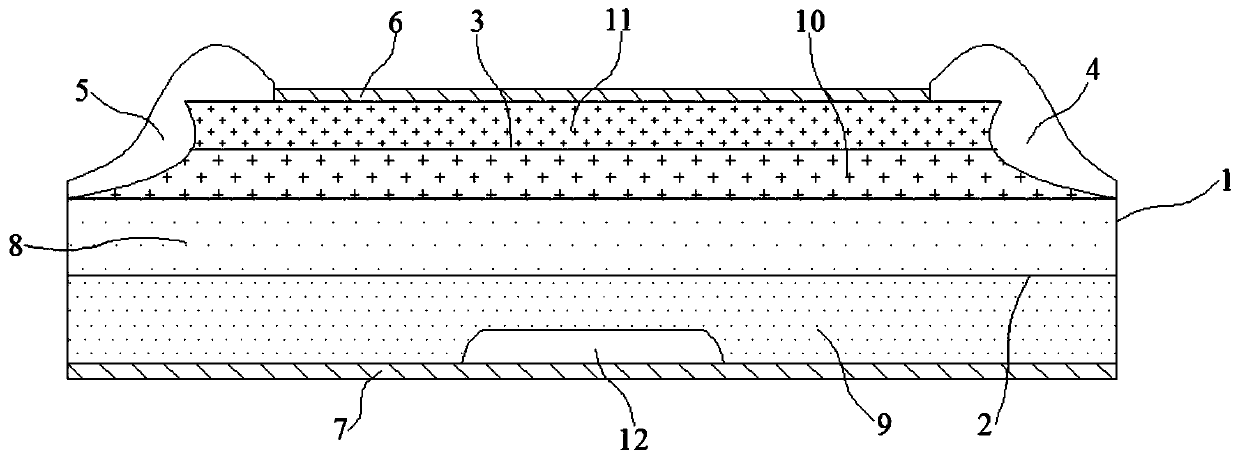

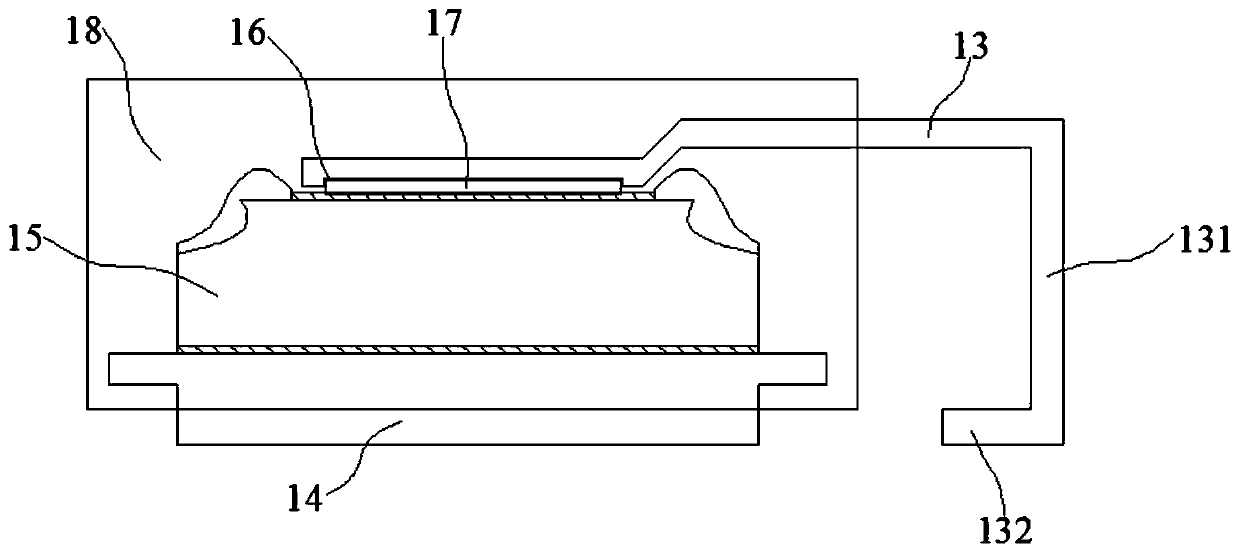

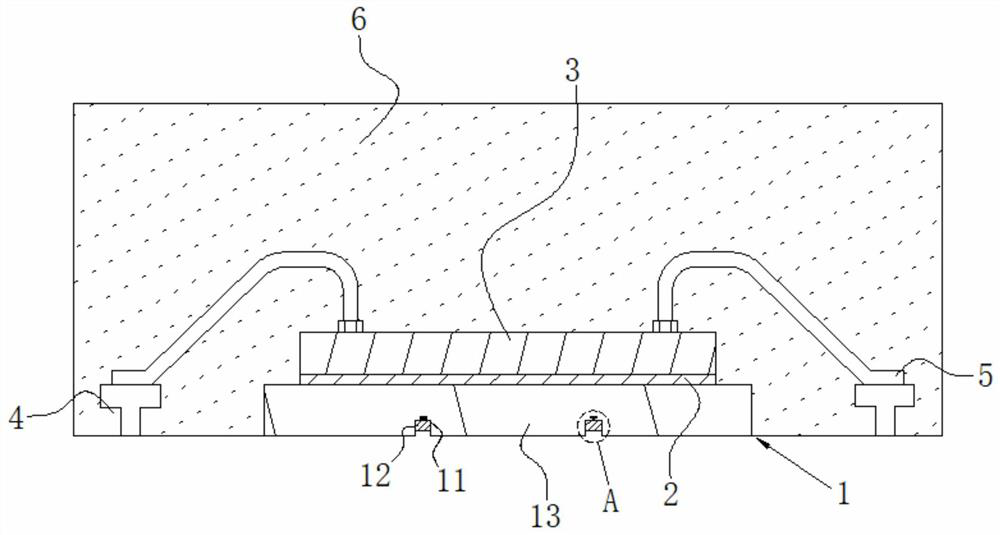

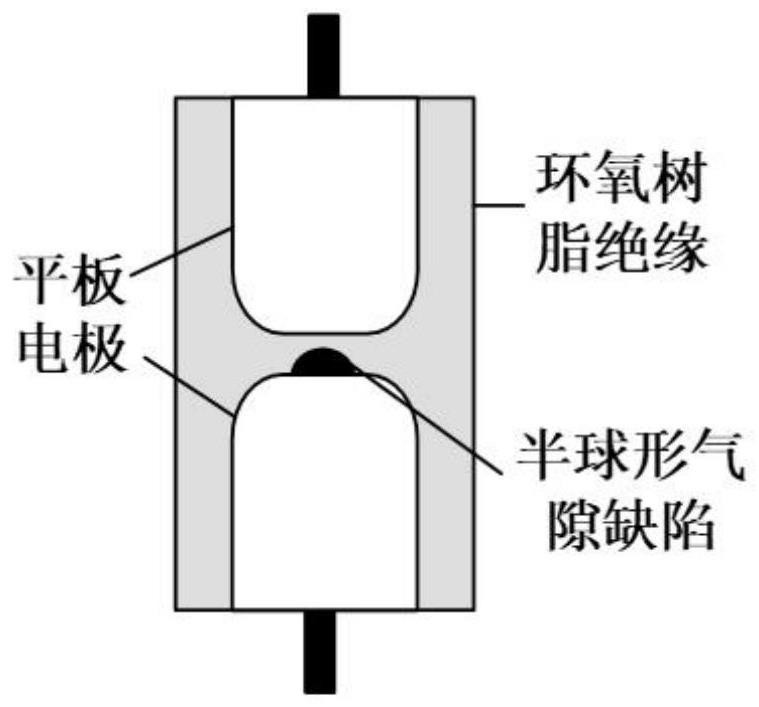

High-performance epoxy insulating part internal defect simulation system, method and application

PendingCN113985220ARich Defect DataGood response speed and accuracyTesting dielectric strengthPartial dischargeEpoxy insulators

The invention belongs to the technical field of high-voltage tests and discloses a high-performance epoxy insulator internal defect simulation system and method and application. The system comprises a power frequency AC power supply module, a discharge chamber module, a detection module and a defect model, wherein the AC power supply module is connected with the discharge chamber module and is used for providing and controlling high voltage in the discharge chamber module through a non-partial discharge test transformer; the discharge chamber module comprises a discharge cavity, the discharge cavity is used for providing a high voltage and a discharge environment required by an experimenter for a defect model, the defect model is arranged in the discharge cavity, and the discharge cavity is connected with a high voltage end of the non-partial discharge test transformer; and the detection module is used for detecting a discharge signal when the defect model discharges. According to the system, different defect models are set to simulate the types of defects possibly appearing in the epoxy insulating part in the actual production and operation process, the system has the characteristic of being closer to actual faults, and meanwhile, the system has good accuracy and response speed.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Preparation method of heat-resistant epoxy resin insulator

The invention discloses a preparation method of a heat-resistant epoxy resin insulator, which comprises the following steps: performing surface treatment on silicon micropowder with epoxy resin curing agent and gamma-(2,3-epoxy propoxy)propyltrimethoxysilicane; heating the silicon micropowder subjected to surface treatment at 40-50 DEG C for 1-2 hours, and drying for 1-2 hours under the condition of heating to 105-120 DEG C; and then, naturally cooling, mechanically separating bonded silicon micropowder particles, compounding with epoxy resin, and curing to obtain the heat-resistant epoxy resin insulator, wherein the glass transition temperature of the heat-resistant epoxy resin insulator is increased by more than 10 DEG C in comparison with the common epoxy insulator. The invention has the advantages of simple process and mild reaction conditions, and can effectively improve the heat resistance of the epoxy resin insulator. Compared with the conventional silicon micropowder filled epoxy resin composite material, the glass transition temperature of the epoxy resin insulator prepared by the invention is increased by more than 15 DEG C when the silicon micropowder particle content is 30%.

Owner:ZHEJIANG SCI-TECH UNIV +1

A method for improving the discharge resistance performance of epoxy insulation in gas insulation system

ActiveCN106782941BChange physical and chemical characteristicsSimple processInsulatorsState of artProduct gas

The invention relates to a method for improving the discharge resistance of an epoxy insulator in a gas insulation system. According to the method, fluoridation is carried out on the epoxy insulator by using a gas mixture of fluorine gas and nitrogen gas or a gas mixture of fluorine gas and inert gas under the conditions of appropriate temperature and pressure in a closed reaction chamber, a fluoridation layer containing C-F bonds is formed on the surface of the epoxy insulator, so that the method is used for improving the discharge resistance of the epoxy insulator. Compared with the prior art, the method disclosed by the invention is simple in processing steps, good in controllability and low in economic cost, the epoxy insulators with arbitrary shapes and dimensions can be uniformly modified in batches, and the method is specially applicable for commercial application.

Owner:TONGJI UNIV

Preparation method of high temperature resistant QFN package structure

ActiveCN109904125AGuaranteed stabilityImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesPhosphateEngineering

The invention discloses a preparation method of a high temperature resistant QFN package structure. The QFN package structure comprises a heat dissipation pad, a chip and conductive pads which are located in an epoxy insulator, wherein the chip is located on the heat dissipation pad, a plurality of conductive pads are disposed around the heat dissipation pad, and the conductive pads and the chip are connected by a lead. The method comprises the following steps of S1, firstly uniformly mixing the silicon micropowder and the flame retardant with gamma-methacryloxypropyltrimethoxysilane for surface treatment; S2, adding epoxy resin, novolac resin, liquid nitrile rubber, diphenylmethane diisocyanate, diethyl pyrocarbonate, dibenzyl phosphate, 5-fluoro-2-methoxyaniline, 2,4,6-tris(dimethylaminomethyl)phenol and a release agent. The preparation method has excellent heat resistance under the premise of ensuring good mechanical properties, and the glass transition temperature reaches 190-230 DEG C, which can meet the requirements of the packaging of high power and high heating chips.

Owner:西安航思半导体有限公司

A Ring Voltage Sensing Device

ActiveCN104267235BSmall footprintHigh measurement accuracyCurrent/voltage measurementVoltage dividersCapacitanceLow voltage

The invention discloses a hoop voltage sensing device. The hoop voltage sensing device comprises an incoming and outgoing line casing pipe, the incoming and outgoing line casing pipe comprises an epoxy insulator, the epoxy insulator is of a hollow structure from top to bottom, a conducting rod is installed in the hollow structure, hoop high-voltage capacitors are installed at the solid portions on the two sides of the part, not the hollow structure, of the epoxy insulator, the hoop high-voltage capacitors are electrically connected with the conducting rod, the adjacent outer side of one of the hoop high-voltage capacitors is provided with a lead end installed in the solid portion of the epoxy insulator, the lead end is provided with an electric lead connected with the hoop high-voltage capacitors, the other end of the electric lead is connected with a low-voltage capacitor device, and the low-voltage capacitor device is connected with a signal processing module connected with a control unit of a switchgear. The hoop voltage sensing device is small in space occupation, influence on electric field distribution in an original environment of an electrical element is small, the measurement precision is high, the temperature and frequency features are good, and the cost is low.

Owner:ZHUHAI XJ ELECTRIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com