Preparation method of heat-resistant epoxy resin insulator

An epoxy resin, epoxy resin curing technology, applied in insulators, electrical components, circuits, etc., can solve the problems of the performance impact of epoxy insulators, reduce mismatch, increase bonding fastness, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

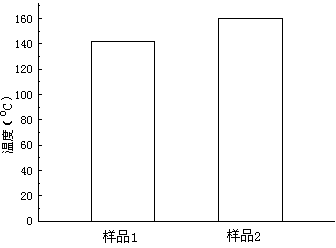

Embodiment 1

[0024] The γ-(2,3-glycidyloxypropoxy)propyltrimethoxysilane) and the curing agent diaminodiphenylmethane of E-44 bisphenol A type epoxy resin were prepared in a mass ratio of 1:10 After mixing, add a 2% ethanol solution of hydrochloric acid equal to γ-(2,3-glycidyloxypropyltrimethoxysilane) (among them, the concentration of hydrochloric acid used is 37%, and the ethanol used is Anhydrous ethanol, calculated according to the concentration of 2%), after being stirred evenly, it becomes a surface treatment agent, which is added to a container with silicon micropowder particles with a fineness of 1000 meshes for surface treatment. The ratio of differential and surface treatment agent is 1:0.2. After stirring for 20 minutes, heat the surface-treated microsilica powder at a temperature of about 40 degrees for 2 hours, and γ-(2,3-epoxypropoxy)propyltrimethyl Oxysilane) reacts with microsilica powder and curing agent, heats at 120 degrees for 1 hour to remove moisture on the surface o...

Embodiment 2

[0026] The curing agent methyltetrahydrophthalic anhydride of γ-(2,3-glycidyloxypropyltrimethoxysilane) and E-39-D type bisphenol A type epoxy resin is 1 in mass ratio: After mixing at a ratio of 30, add an ethanol solution with a hydrochloric acid content of 2% equal to that of γ-(2,3-glycidyloxypropyltrimethoxysilane) (wherein the concentration of hydrochloric acid used is 37%, The ethanol used is anhydrous ethanol, which is prepared according to the concentration of 2%). After stirring evenly, it becomes a surface treatment agent, which is added to a container with silicon micropowder particles with a fineness of 1000 meshes to treat the silicon micropowder. Surface treatment, wherein the ratio of silicon micropowder to surface treatment agent is 1:0.3. After stirring for 20 minutes, heat the surface treated silicon micropowder at a temperature of about 45 degrees for 1 hour to make γ-(2,3-epoxy Propoxy) Propyltrimethoxysilane) reacts with silicon micropowder and curing age...

Embodiment 3

[0028]The curing agent methyltetrahydrophthalic anhydride of γ-(2,3-glycidyloxypropyltrimethoxysilane) and E-39-D type bisphenol A type epoxy resin is 1 in mass ratio: After mixing at a ratio of 20, add an ethanol solution with a hydrochloric acid content of 2% equal to that of γ-(2,3-glycidyloxypropyltrimethoxysilane) (wherein, the concentration of hydrochloric acid used is 37%, The ethanol used is anhydrous ethanol, which is prepared according to the concentration of 2%). After stirring evenly, it becomes a surface treatment agent, which is added to a container with a fineness of 800 mesh silicon micropowder particles to treat the silicon micropowder. Surface treatment, wherein the ratio of silicon micropowder to surface treatment agent is 1:0.5. After stirring for 20 minutes, heat the surface treated silicon micropowder at a temperature of about 42 degrees for 1.5 hours to make γ-(2,3-epoxy Propoxy) Propyltrimethoxysilane) reacts with silicon micropowder and curing agent me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com