A preparation method of epoxy insulating composite material with improved static dissipative properties

A technology of epoxy insulation and static dissipation, applied in the field of epoxy insulators, can solve problems such as difficult industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

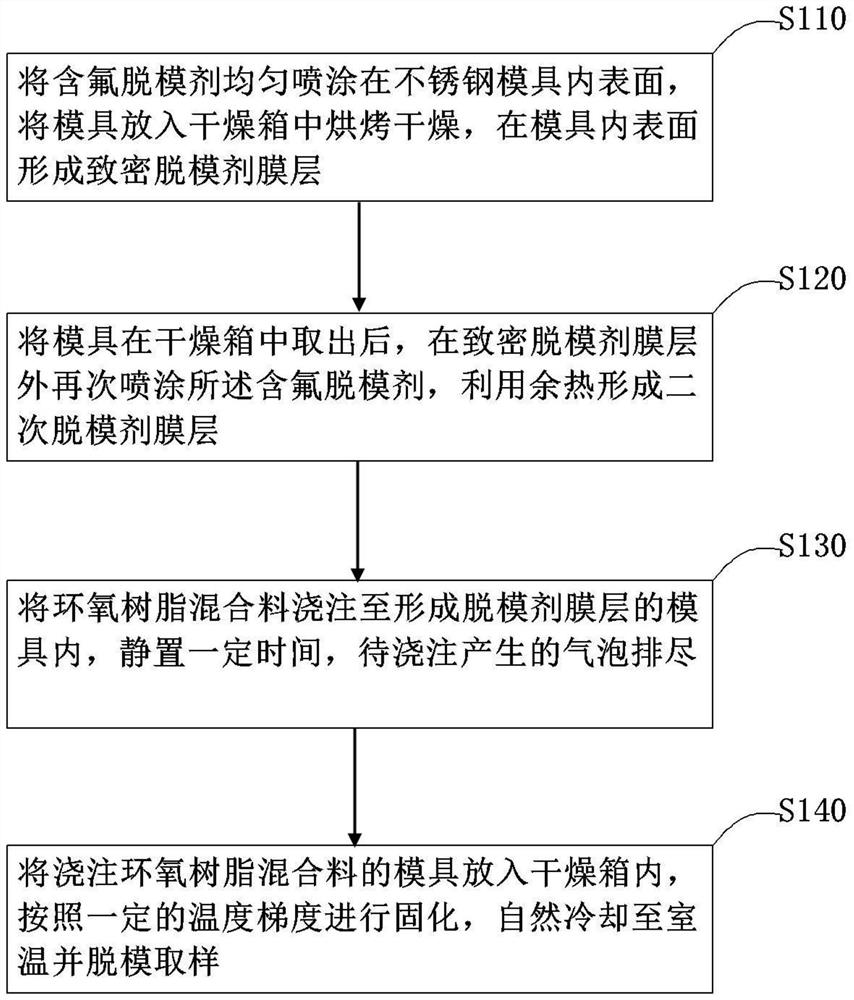

[0039] like figure 1 As shown, the embodiment of the present invention provides a method for preparing an epoxy insulating composite material with improved static dissipative properties, including the following process steps:

[0040] Step S110: cleaning the inner and outer surfaces of the mold, spraying a fluorine-containing mold release agent evenly on the inner surface of the stainless steel mold, putting the mold into a drying oven to bake and dry, and forming a dense mold release agent film layer on the inner surface of the mold;

[0041] Step S120: After taking the mold out of the drying oven, spray the fluorine-containing mold release agent again outside the dense mold release agent film layer, and form a secondary mold release agent film layer by using residual heat;

[0042] Step S130: pour the epoxy resin mixture into the mold forming the release agent film layer, and let it stand for a certain period of time until the air bubbles generated by pouring are exhausted; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com