Preparation method of epoxy insulating composite material for improving electrostatic dissipation characteristics

An epoxy insulation and electrostatic dissipation technology, applied in the field of epoxy insulators, can solve problems such as difficult industrial applications, achieve the effects of reducing electrostatic charge accumulation, strong industrial applicability, and improving static electricity dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

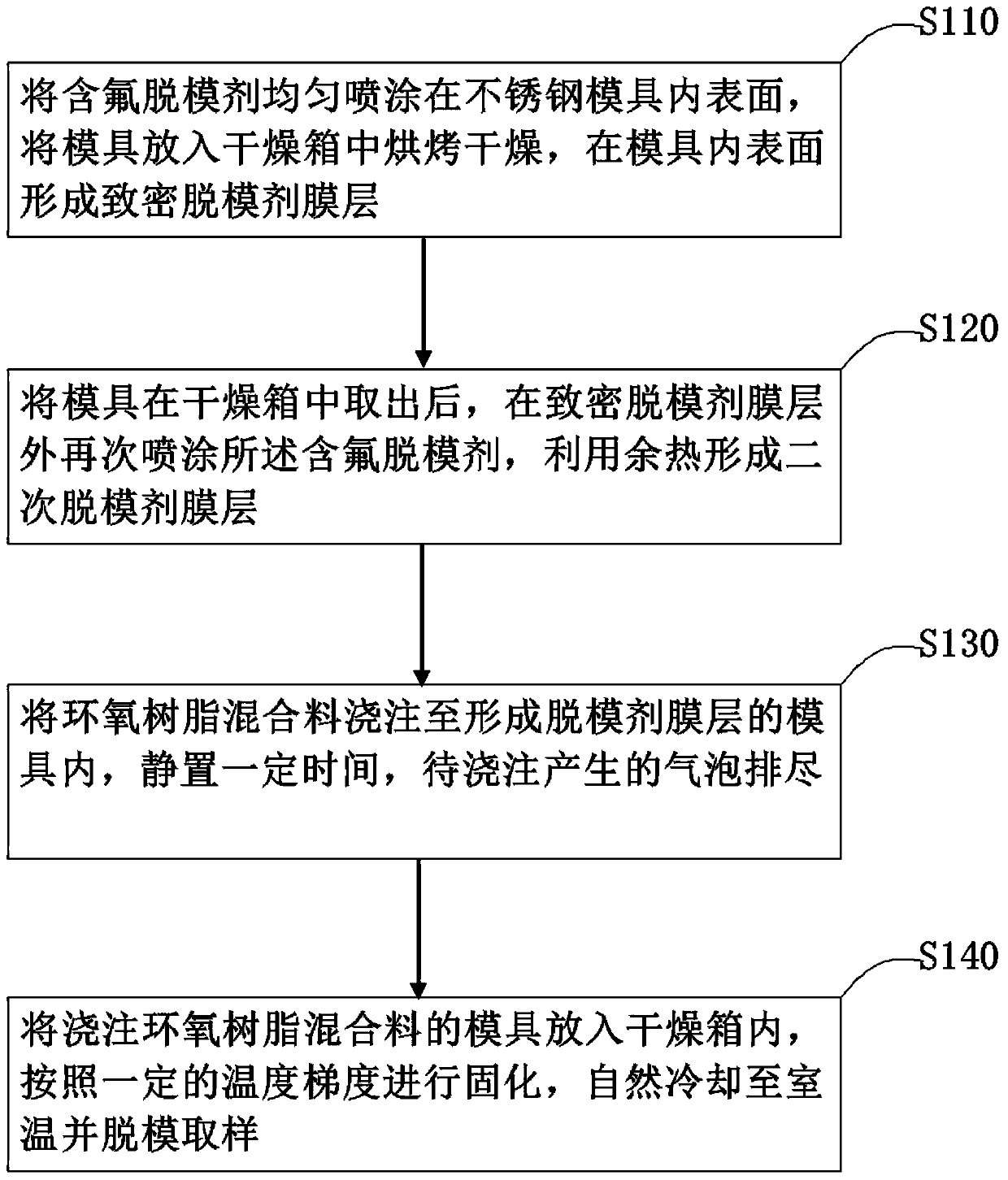

[0040] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing an epoxy insulating composite material with improved static dissipative properties, including the following process steps:

[0041] Step S110: cleaning the inner and outer surfaces of the mold, spraying a fluorine-containing mold release agent evenly on the inner surface of the stainless steel mold, putting the mold into a drying oven to bake and dry, and forming a dense mold release agent film layer on the inner surface of the mold;

[0042] Step S120: After taking the mold out of the drying oven, spray the fluorine-containing mold release agent again outside the dense mold release agent film layer, and form a secondary mold release agent film layer by using residual heat;

[0043] Step S130: pour the epoxy resin mixture into the mold forming the release agent film layer, and let it stand for a certain period of time until the air bubbles generated by pouring are exhauste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com