Method for preparing anti-static and high-performance flue gas purification filter material

A flue gas purification and high-performance technology, which is used in the preparation of flue gas purification filter materials and the preparation of anti-static, temperature-resistant and wear-resistant flue gas purification filter materials, which can solve the problem of poor mechanical strength, low wear resistance and high temperature resistance. , poor conductivity and other problems, to achieve the effect of extending the service life, expanding the scope of application, and improving the speed of static dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 0.01g of graphene oxide and 0.25g of graphene to 50ml of dimethylformamide solution, ultrasonically disperse evenly, then add 5g of PVDF, heat in a 60°C water bath until dissolved evenly, and obtain a uniform solution. The solution was injected into the syringe, and the PVDF nanofiber membrane with graphene oxide and graphene attached was obtained by controlling the liquid inflow rate of the solution to be 13 μl / min and the spinning voltage to be 22 kv. The average diameter of the PVDF nanofibers is 750 nm, and the thickness of the film is 80 μm.

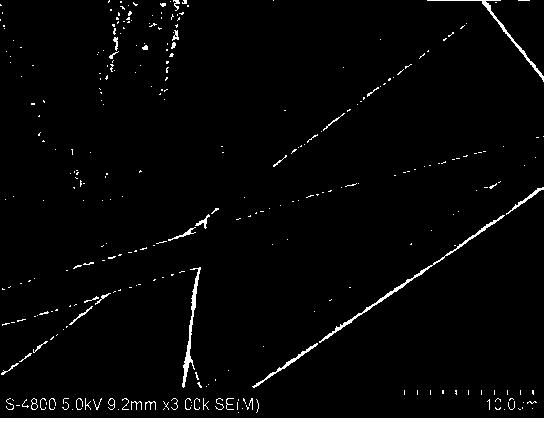

[0019] Heat-treat the PVDF nanofiber membrane in a vacuum oven at 200°C for 60 minutes to obtain an antistatic PVDF nanofiber membrane. The SEM image is as follows figure 1 shown. Evaluate the resistivity and wear resistance of the test film, and the surface resistivity of the antistatic PVDF nanofiber film can reach 2×10 3 Ω, the wear resistance is improved by more than 220% compared with the filter material of the sam...

Embodiment 2

[0021] Add 0.005g of graphene oxide and 0.05g of single-walled carbon nanotubes to 50ml of dimethylacetamide solution, ultrasonically disperse evenly, then add 5g of aramid fiber 1313, heat in a water bath at 50°C until uniformly dissolved, and obtain a uniform solution. The solution was injected into the syringe, and the aramid 1313 nanofiber filter membrane with graphene oxide and single-walled carbon nanotubes attached was obtained by controlling the liquid inflow rate of the solution to 13 μl / min and the control voltage to 25 kv. The average diameter of the aramid 1313 nanofiber is 850 nm, and the thickness of the film is 72 μm.

[0022] The aramid 1313 nanofiber filter membrane was heat-treated in a vacuum oven at 50° C. for 100 min to obtain an antistatic aramid 1313 nanofiber filter membrane. Evaluate the resistivity and wear resistance of the test membrane, and the surface resistivity of the antistatic aramid 1313 nanofiber filter membrane is less than 3.5×10 3 Ω, and...

Embodiment 3

[0024] Add 0.01 g of graphene oxide and 0.1 g of multi-walled carbon nanotubes to 50 ml of dimethyl sulfoxide solution, ultrasonically disperse evenly, then add 10 g of polyimide, and stir magnetically for 12 hours until it dissolves evenly to obtain a uniform solution. The solution was injected into the syringe, and the polyimide nanofiber filter membrane with graphene oxide and multi-walled carbon nanotubes attached was obtained by controlling the liquid inlet speed of the solution to 12 μl / min and the control voltage to 24 kv. The average diameter of the polyimide nanofibers was 680 nm, and the thickness of the film was 88 μm.

[0025] The polyimide nanofiber membrane was heat-treated in a vacuum oven at 300° C. for 60 minutes to obtain an antistatic polyimide nanofiber filter membrane. Evaluate the resistivity and wear resistance of the test membrane, and the surface resistivity of the antistatic polyimide nanofiber filter membrane is less than 1.2×10 3 Ω, the wear resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com