Spin exchange coupling based uniform distribution device for flue gas, equipment equipped with device and working method

A cyclone and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of large deviation of catalyst flue gas flow rate, catalyst blockage, low denitration efficiency, etc., and reduce ammonia escape and reduction. agent consumption, ease of processing and installation, and the effect of improving denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] Example.

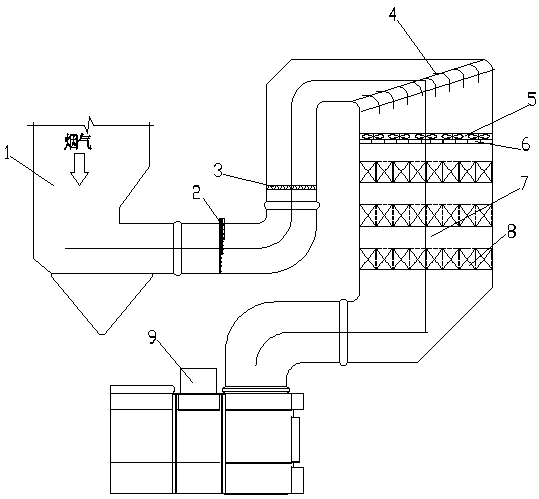

[0024] see Figure 1-4 .

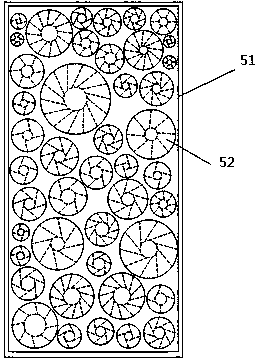

[0025] This embodiment is a smoke swirl sink coupling uniform distribution device 5 , which includes a flat plate 51 and a plurality of circular flow holes 52 , and all the circular flow holes 52 are arranged on the flat plate 51 .

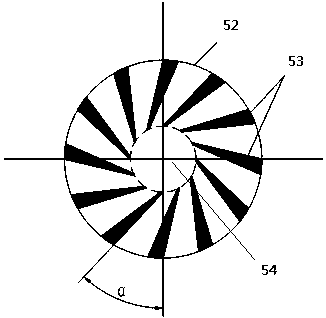

[0026] Each circular flow hole 52 is provided with a guide vane group, and the guide vane group includes a plurality of guide vanes 53, and the guide vanes 53 on the same circular flow hole 52 move clockwise or counterclockwise. Swirl arrangement. In this embodiment, the flat plate 51 has a circular flow hole 52 equipped with a clockwise swirling guide vane 53 and a circular flow hole 52 equipped with a counterclockwise swirling guide vane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com