Combustion type heater device used in fume desulfurization and denitrification system

A technology of desulfurization, denitrification and heater, applied in the field of air pollutant control, can solve problems such as poisoning of catalysts with high denitration activity, and achieve the effects of avoiding high local temperature, efficient operation, and avoiding deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

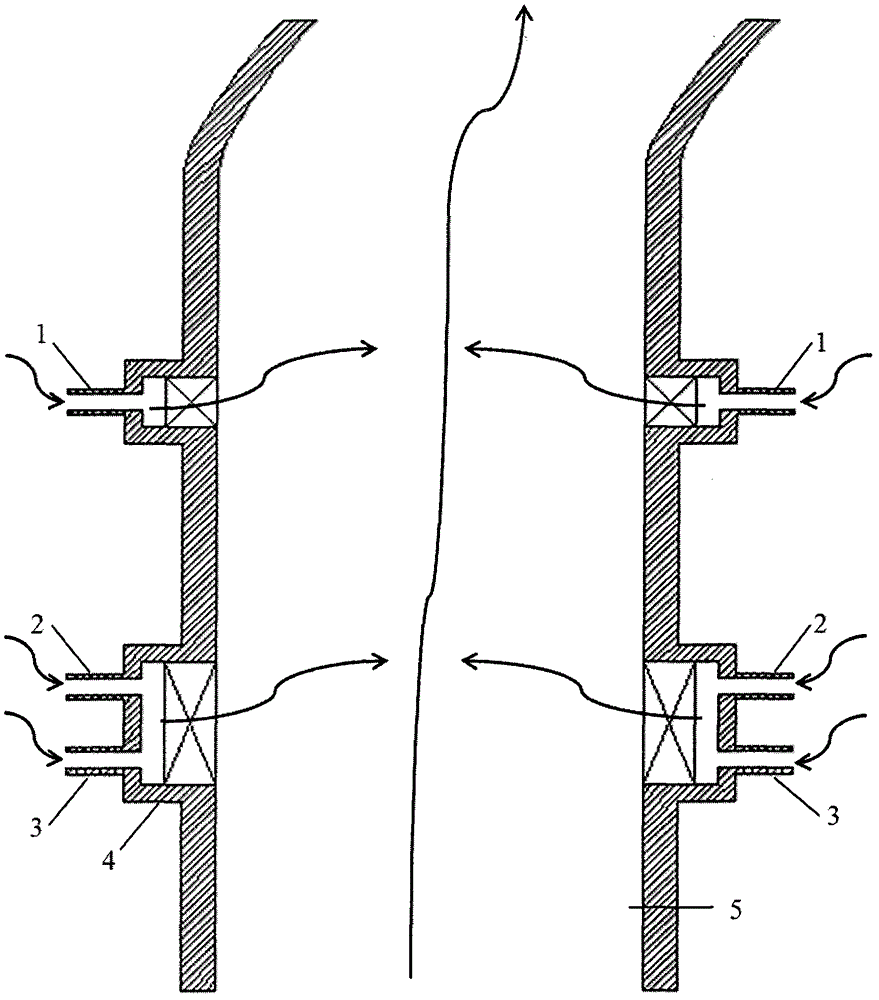

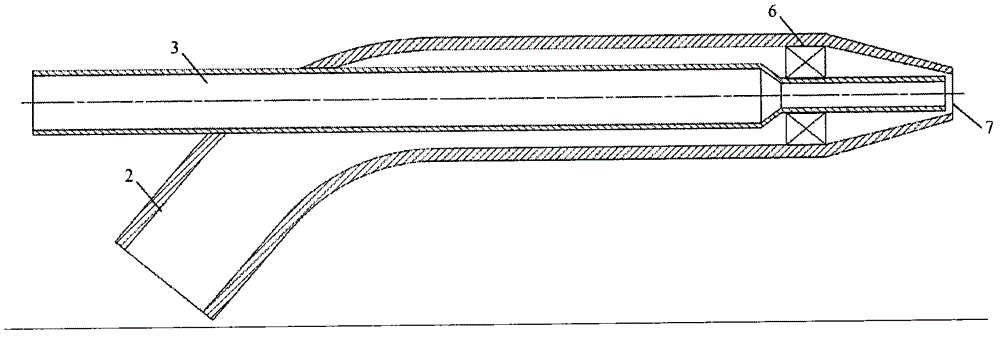

[0028] See figure 1 and figure 2 , The first embodiment provides a combustion heater device for flue gas desulfurization and denitrification system, including a blender 1 , a combustion air channel 2 , a fuel channel 3 , a combustion nozzle 4 and a flue 5 . The combustion nozzle 4 includes a swirl vane 6 and a jet swirl combustion nozzle 7 . Combustion air passage 2, fuel passage 3 and combustion nozzle 4 jointly constitute a burner. The size and model of each component are selected according to the composition, temperature, target temperature, fuel type and other requirements of the treated flue gas.

[0029] In this embodiment, the combustion-supporting air passes through the combustion-supporting air channel 2 and the swirl vane 6 and then enters the jet swirl combustion nozzle 7 to be mixed with the fuel passing through the fuel channel 3 for combustion. The high-temperature gas after combustion is sprayed into the flue through the jet swirl combustion nozzle 7 to heat...

Embodiment 2

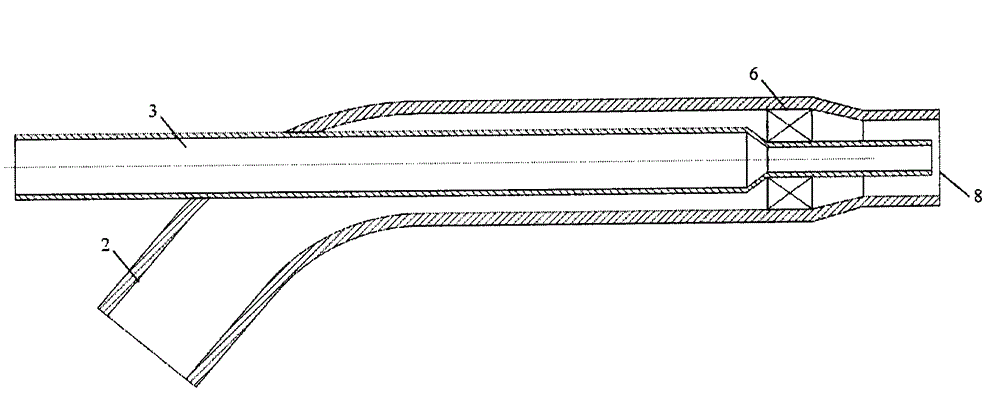

[0034] See figure 1 and image 3 , the first embodiment provides a combustion heater device used in a flue gas desulfurization and denitrification system. The combustion nozzle 4 includes a swirl vane 6 and a lobe swirl combustion nozzle 8 . Other structures and principles of the second embodiment are the same as those of the first embodiment, and will not be repeated here.

Embodiment 3

[0036] See figure 1 and Figure 4 , the first embodiment provides a combustion heater device used in a flue gas desulfurization and denitrification system. The combustion nozzle 4 includes swirl vanes 6 and sawtooth swirl combustion nozzles 9 . Other structures and principles of the third embodiment are the same as those of the first embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com