Surge protection device

A surge protection device, lead technology, applied in the direction of electric solid device, semiconductor device, semiconductor/solid state device parts, etc. Reliability, the effect of enhancing the anti-surge capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

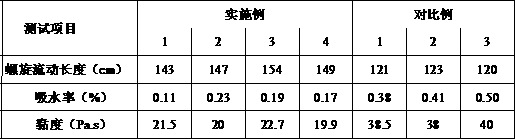

Embodiment 1~4

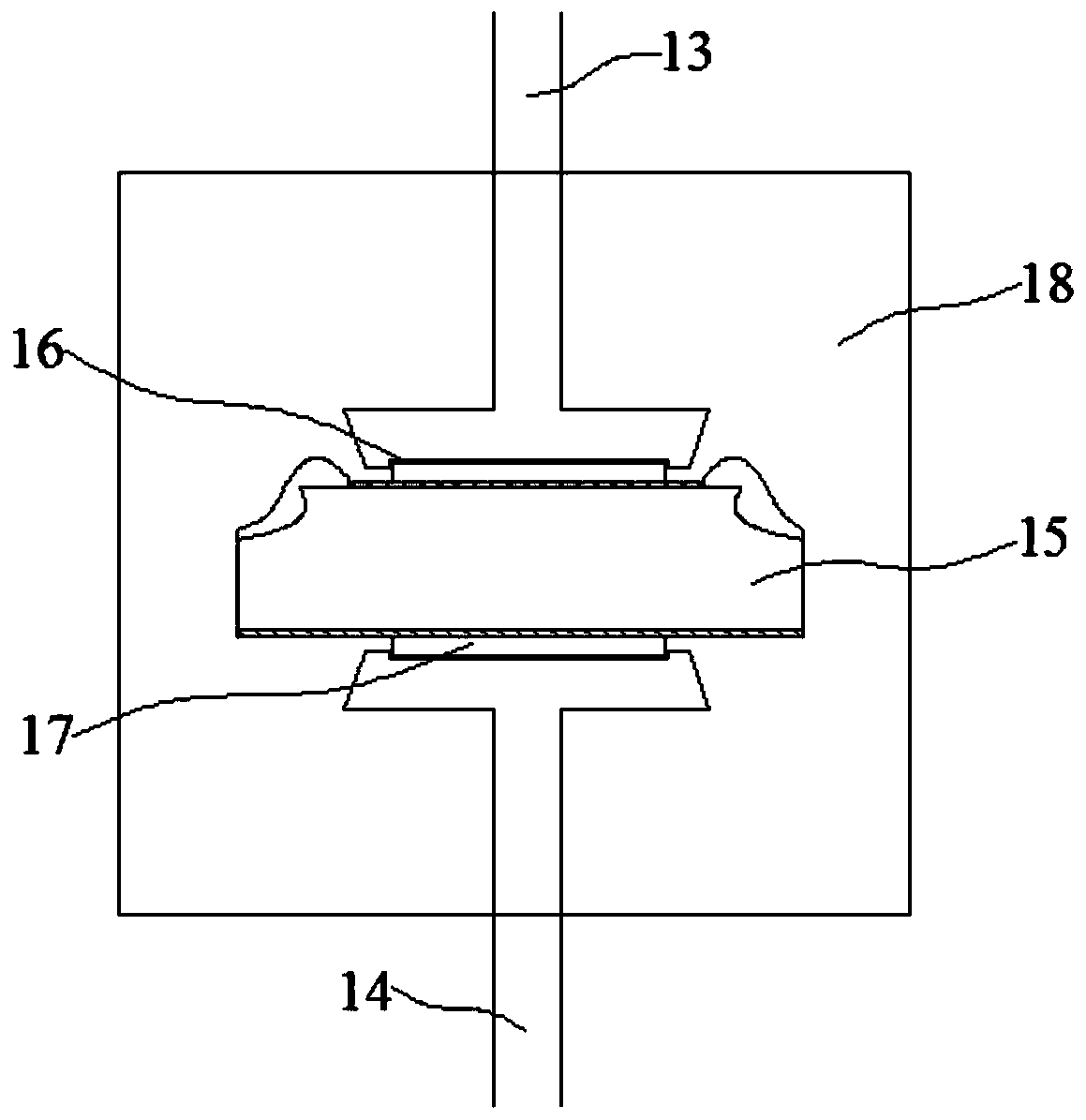

[0034] Embodiments 1 to 4: A surge protection device, comprising a first lead 13, a second lead 14 and a chip 15, the respective ends of the first lead 13, the second lead 14 and the chip are located in an epoxy insulator 18 , the respective ends of the first leads 13 and the second leads 14 have a groove 16, and the respective ends of the first leads 13 and the second leads 14 are connected with the first metal layer 6 and the second metal layer of the chip 15 respectively. 7 are electrically connected by a solder piece 17, which is embedded in the groove 16 at the end of the lead and the thickness of the solder piece 17 is greater than the depth of the groove 16;

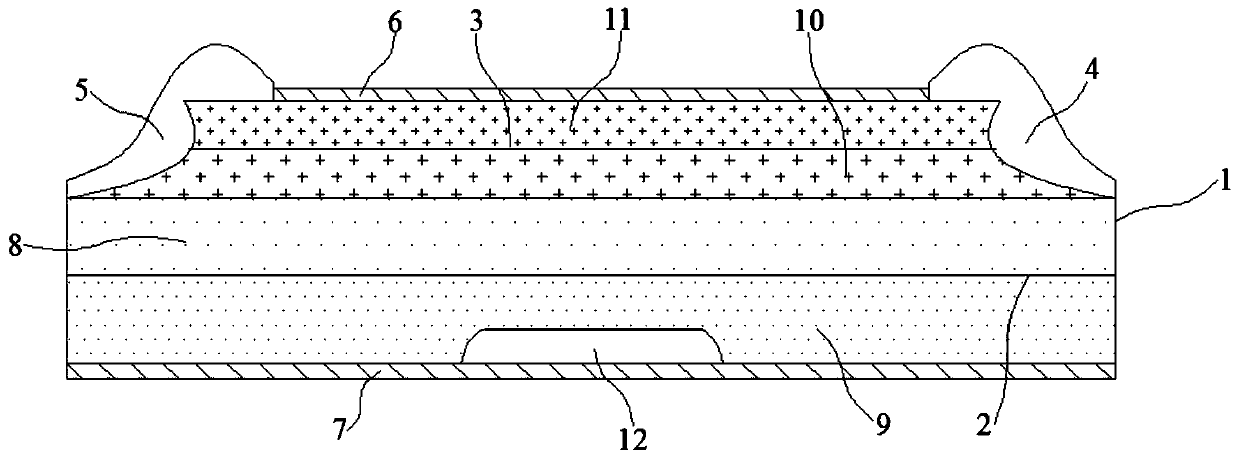

[0035] The chip 15 further includes a silicon substrate 1, and this silicon substrate 1 includes an N-type doped region 2 and a P-type doped region 3 adjacent in the vertical direction, and the P-type doped region 3 is surrounded by a trench 4 , the surface of the groove 4 is covered with an insulating passivation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com