Mechanism for preventing parts from cracking by inlaying insert into epoxy insulator

An epoxy insulation and insert technology, applied in insulators, electrical components, substation/switch layout details, etc., can solve problems such as cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

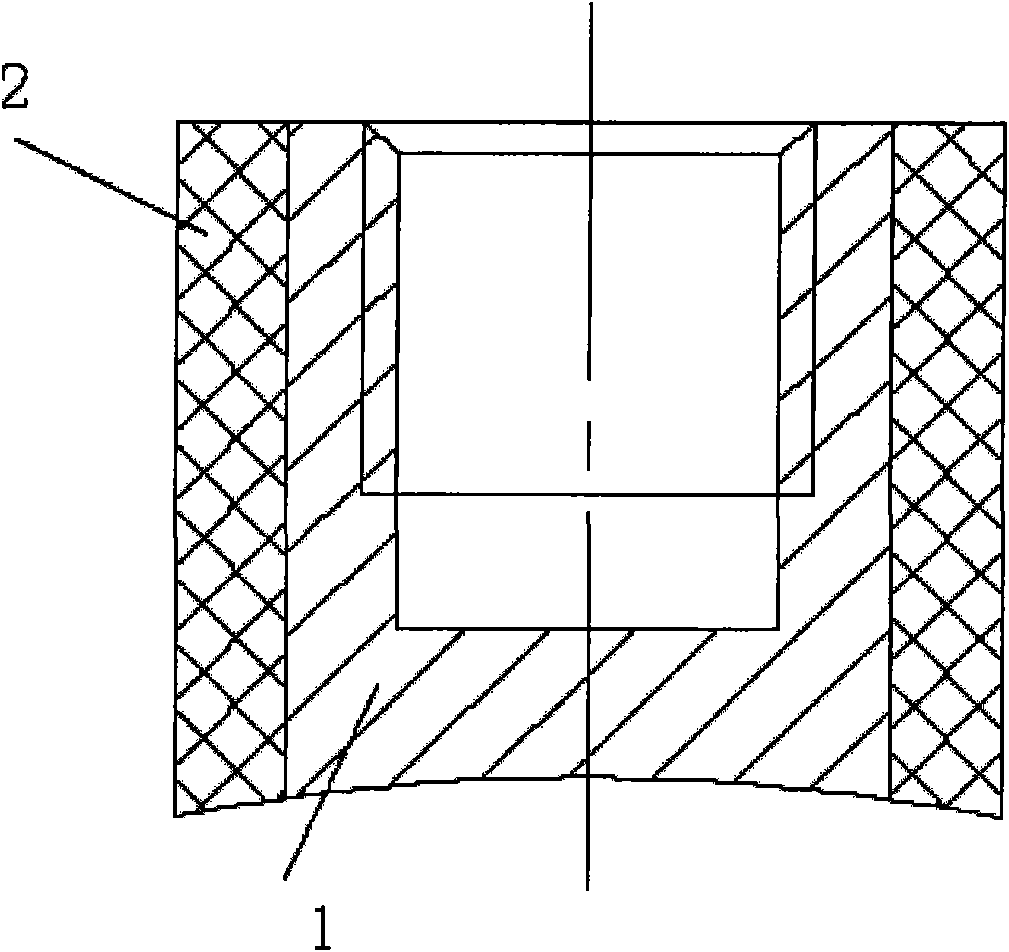

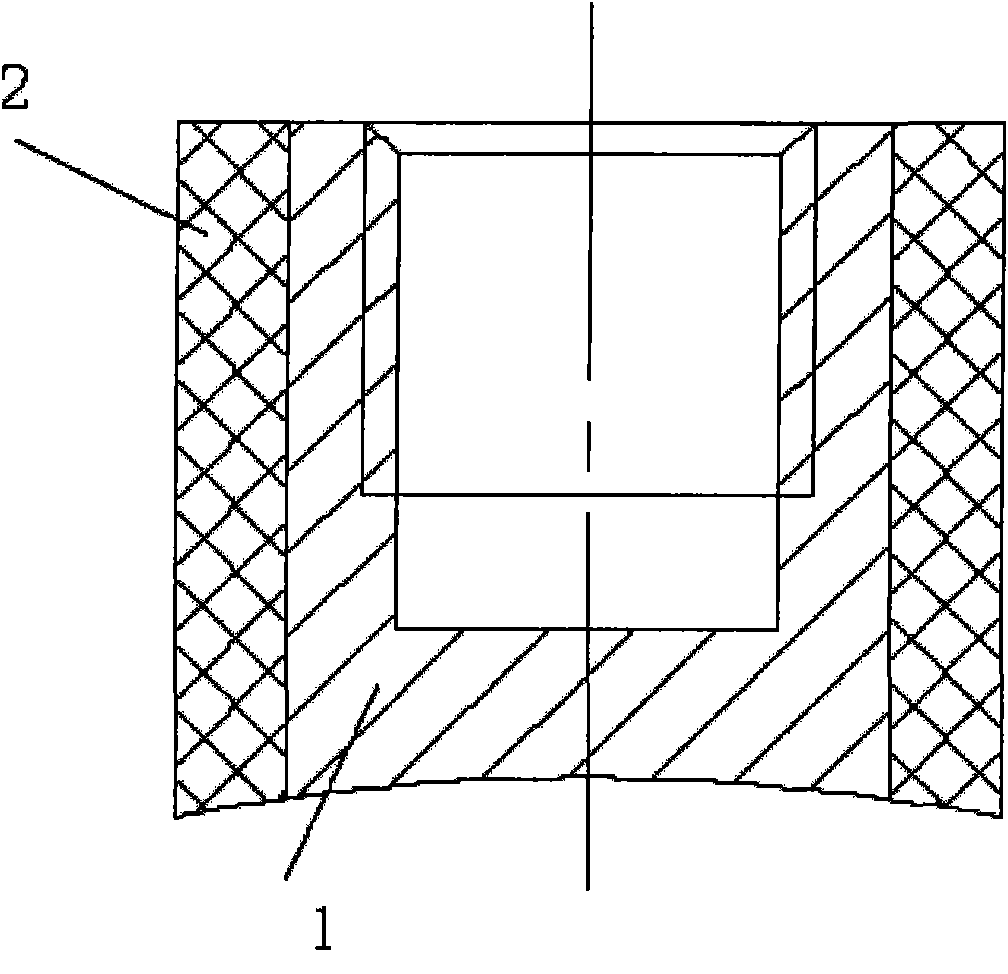

[0012] Depend on figure 1 It can be seen that the present invention includes: an insert 1 in epoxy resin; also includes: a buffer layer 2 between the epoxy resin and the insert 1;

[0013] The buffer layer 2 is semi-conductive nylon.

[0014] In the present invention, semi-conductive nylon is wrapped on the outer periphery of the metal insert, and the molding process is relatively easy; sandblasting is performed on the surface of the semi-conductive nylon before injection.

[0015] The basic principle of the present invention is: because the epoxy resin has contraction force when it is solidified in the mould, a large internal stress is generated between the metal insert and the epoxy resin. In order to relieve the stress, a buffer layer, such as semi-conductive nylon, is added between the metal insert and the epoxy resin.

[0016] Adopting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com