Surface treatment method of GIS/GIL epoxy resin insulator

A technology of epoxy resin and surface treatment, which is applied in the field of high-pressure equipment to achieve the effects of high processing efficiency, simple equipment, and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

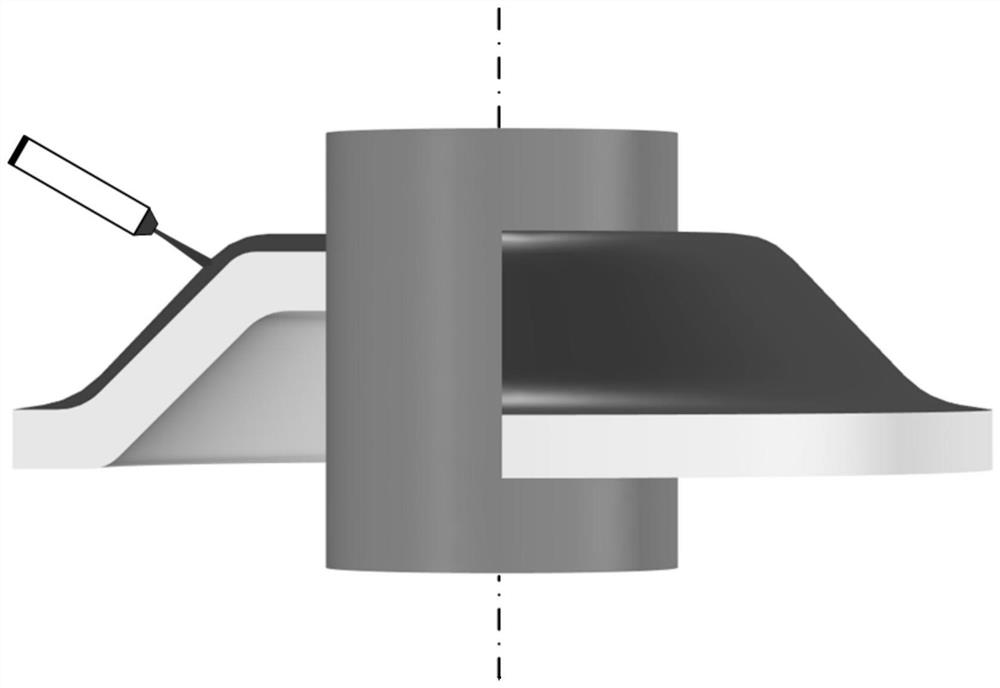

[0032] The present embodiment provides a surface treatment method for a GIS / GIL epoxy insulator, comprising the following steps:

[0033] (1) Place bisphenol A epoxy resin, acid anhydride curing agent and micro-alumina filler in a container, stir for 30 minutes at a rotating speed of 60 r / min, and mix evenly to obtain a mixture, wherein bisphenol A epoxy resin and acid anhydride are cured The mass ratio of the agent to the micro-alumina filler is bisphenol A epoxy resin: acid anhydride curing agent: micro-alumina filler = 100:85:330;

[0034] (2) the mixture is evacuated under the vacuum degree of -0.1MPa, and the time of the evacuation is 30min;

[0035] (3) preheating the mold at 100° C. for 2 hours, and slowly pouring the mixture obtained in step (2) into the mold with the release agent applied to the inner wall after the preheating treatment;

[0036] (4) Curing the mold obtained in step (3) at 100°C for 10h, then heating up to 140°C, performing secondary curing for 14h, ...

Embodiment 2

[0042] The present embodiment provides a surface treatment method for a GIS / GIL epoxy insulator, comprising the following steps:

[0043] (1) Place bisphenol A epoxy resin, acid anhydride curing agent and micro-alumina filler in a container, stir for 30 minutes at a rotating speed of 50 r / min, and mix evenly to obtain a mixture, wherein bisphenol A epoxy resin and acid anhydride are cured The mass ratio of the agent to the micro-alumina filler is bisphenol A epoxy resin: acid anhydride curing agent: micro-alumina filler = 100:85:330;

[0044] (2) the mixture is evacuated under the vacuum degree of -0.1MPa, and the time of the evacuation is 30min;

[0045] (3) preheating the mold at 100° C. for 1 h, and slowly pouring the mixture obtained in step (2) into the mold with the release agent applied to the inner wall after the preheating treatment;

[0046] (4) Curing the mold obtained in step (3) at 100°C for 10h, then heating up to 140°C, performing secondary curing for 14h, cool...

Embodiment 3

[0050] The present embodiment provides a surface treatment method for a GIS / GIL epoxy insulator, comprising the following steps:

[0051] (1) Place bisphenol A epoxy resin, acid anhydride curing agent and micro-alumina filler in a container, stir for 30 minutes at a rotating speed of 70 r / min, and mix evenly to obtain a mixture, wherein bisphenol A epoxy resin and acid anhydride are cured The mass ratio of the agent to the micro-alumina filler is bisphenol A epoxy resin: acid anhydride curing agent: micro-alumina filler = 100:85:330;

[0052] (2) the mixture is evacuated under the vacuum degree of -0.1MPa, and the time of the evacuation is 30min;

[0053] (3) preheating the mold at 100° C. for 3 hours, and slowly pouring the mixture obtained in step (2) into the mold with the release agent applied to the inner wall after the preheating treatment;

[0054] (4) Curing the mold obtained in step (3) at 100°C for 10h, then heating up to 140°C, performing secondary curing for 14h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com