A method for improving the discharge resistance performance of epoxy insulation in gas insulation system

A gas insulation system, epoxy insulation technology, applied in the direction of insulators, circuits, electrical components, etc., can solve the problems of polymer insulation surface degradation or carbonization, indirect economic losses, loss of insulation performance, etc., to achieve good practicability and scope of application Wide, improve the effect of discharge resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

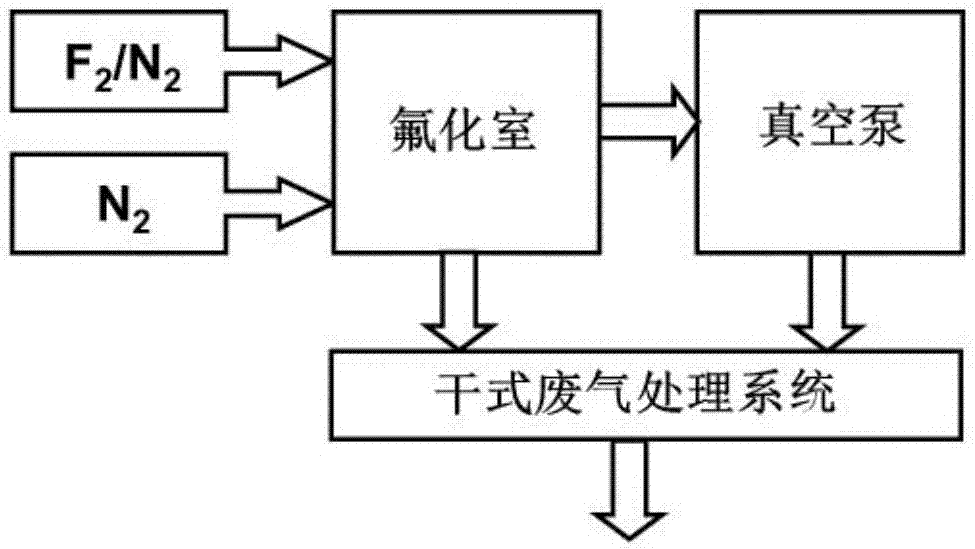

Method used

Image

Examples

Embodiment 1

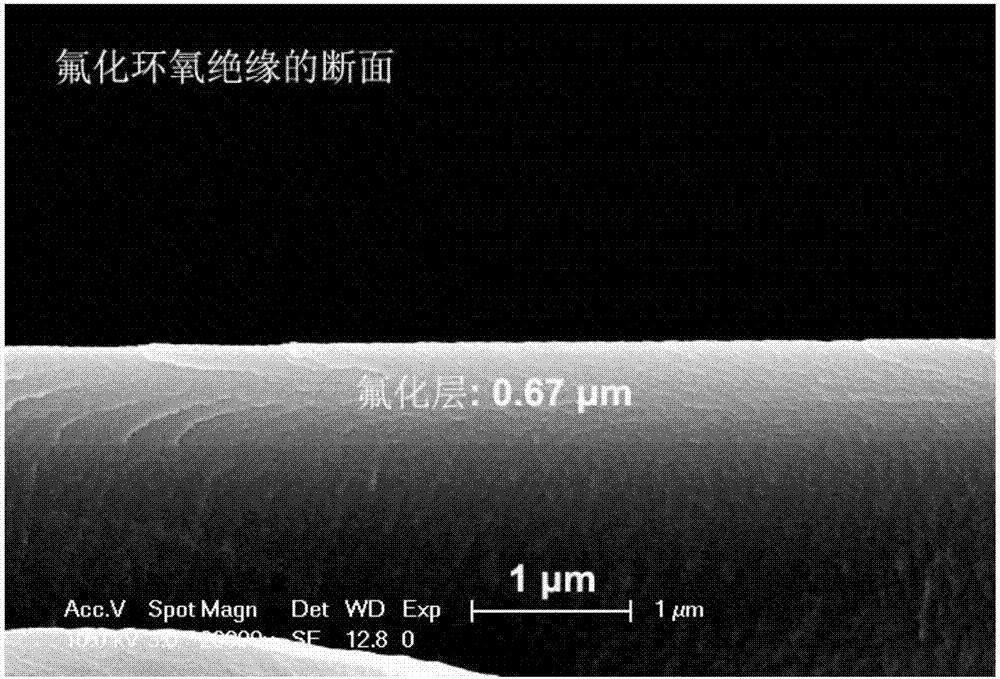

[0033] Fluorination treatment conditions for epoxy insulation: the temperature of the closed reaction chamber is 55°C, and the pressure is 1 bar. The fluorine gas accounts for 12.5% by volume of the reactive mixed gas, and the fluorination treatment time is 30 minutes.

[0034] Resistance to discharge ablation: the specific results are shown in Table 1. The epoxy insulation modified by the fluorination of the surface layer is 2 The average discharge ablation resistance (number of times) in the gas has increased by 11.3 times compared with the non-fluorinated epoxy insulation, and the average DC flashover voltage has increased by 14.1%. 6 The average discharge ablation resistance (number of times) in air is 2.0 times higher than that of non-fluorinated epoxy insulation, while the average AC flashover voltage has no significant change.

Embodiment 2

[0036] Fluorination treatment conditions for epoxy insulation: the temperature of the closed reaction chamber is 25°C, and the pressure is 0.1 bar. The fluorine gas accounts for 50% by volume of the reactive mixed gas, and the fluorination treatment time is 4 hours.

[0037] Resistance to discharge ablation: the specific results are shown in Table 1. The epoxy insulation modified by the fluorination of the surface layer is 2 The average discharge ablation resistance (number of times) in the gas has increased by 10.8 times compared with the non-fluorinated epoxy insulation, and the average DC flashover voltage has increased by 5.0%. 6 Compared with the non-fluorinated epoxy insulation, the average discharge ablation resistance (number) in the gas is increased by 1.5 times, while the average AC flashover voltage has no obvious change.

Embodiment 3

[0039] Fluorination treatment conditions for epoxy insulation: the temperature of the closed reaction chamber is 85°C, and the pressure is 1bar. The fluorine gas accounts for 12.5% by volume of the reactive mixed gas, and the fluorination treatment time is 30 minutes.

[0040] Resistance to discharge ablation: the specific results are shown in Table 1. The epoxy insulation modified by the fluorination of the surface layer is 2 The average discharge ablation resistance (number of times) in the gas has increased by 12.0 times compared with the non-fluorinated epoxy insulation, and the average DC flashover voltage has increased by 19.8%. 6 The average discharge ablation resistance (number of times) in air is 2.2 times higher than that of non-fluorinated epoxy insulation, while the average AC flashover voltage has no significant change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com