High-energy photon deodorization device

A light quantum and high-energy technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, can solve problems such as insufficient ultraviolet light intensity, and achieve the effect of improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

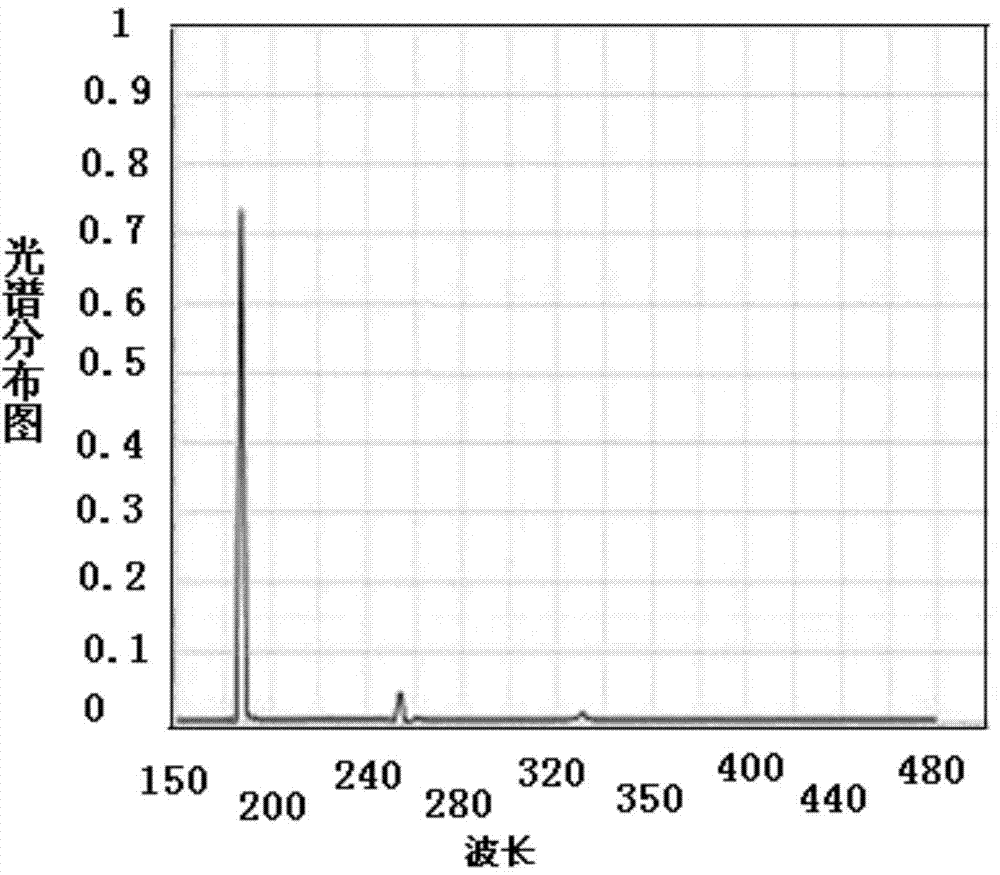

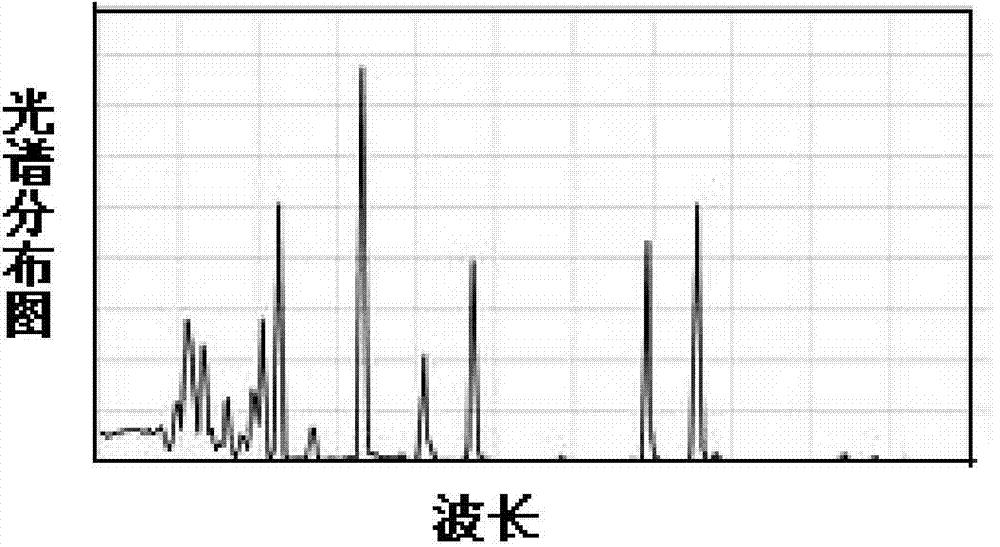

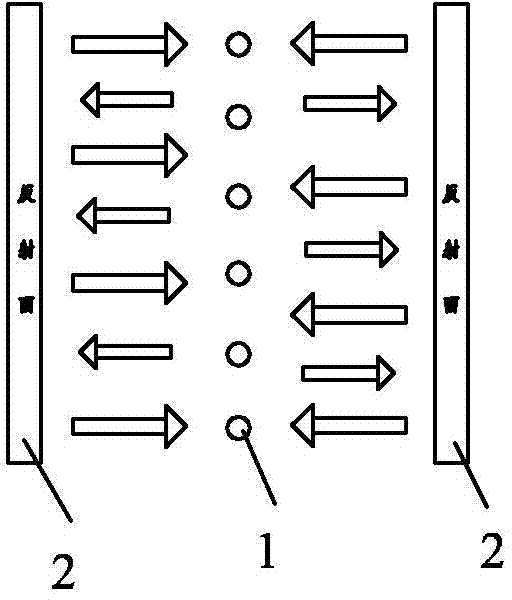

[0008] Specific implementation mode one: the following combination Figure 4 , Figure 5 This embodiment will be specifically described. This embodiment includes a cylinder body 6, an air inlet port 7 and an air outlet port 8, and the air inlet port 7 and the air outlet port 8 are respectively arranged at both ends of the cylinder body 6, and it also includes N groups of narrow-wave excitation light sources 1 and N+1 groups of light reflection plates 2, each group of narrow-wave excitation light source 1 is composed of a power conversion circuit 1-1 and a plurality of luminous tubes 1-2, and a plurality of luminous tubes 1-2 are arranged in parallel with each other In the plane, the power conversion circuit 1-1 supplies power to a plurality of light-emitting tubes 1-2; N+1 groups of light reflecting plates 2 are arranged in parallel and at equal intervals, and any two light reflecting plates of N+1 groups of light reflecting plates 2 A group of narrow-wave excitation light s...

specific Embodiment approach 2

[0012] Specific implementation mode two: the following combination Figure 4 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes a front-end filter 9 and a rear-end filter 10. The front-end filter 9 is arranged in the cylinder body 6 adjacent to the air inlet port 7 and separates the cylinder body. The end of the cylinder 6 is filled; the rear filter 10 is arranged in the cylinder 6 adjacent to the air outlet 8 of the exhaust end and fills the end of the cylinder 6 . Such setting increases the filter equipment and improves the purity of the treated gas.

specific Embodiment approach 3

[0013] Specific implementation mode three: the following combination Figure 4 This embodiment will be specifically described. The difference between this embodiment and the second embodiment is that each group of narrow-wave excitation light sources 1, each group of light reflection plates 2, front-end filter 9 and rear-end filter 10 are respectively installed in a drawer body, and each drawer body is viewed from the side. The side is inserted into the cylinder body 6 and fixed. With such arrangement, it is convenient to disassemble, replace and maintain. Figure 8 It is a structural schematic diagram of the third embodiment of high-energy light quantum equipment, which is composed of two 5000m 3 / h air volume high-energy photon deodorization equipment series module combination form, the series module combination form is conducive to the treatment of high-concentration malodorous gases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com