Surface mounted TVS device

A surface mount and device technology, applied in the field of surface mount TVS devices, can solve the problems of short circuit of gold wire, affecting diode performance, reducing yield, etc., to prevent short circuit, enhance anti-surge ability, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

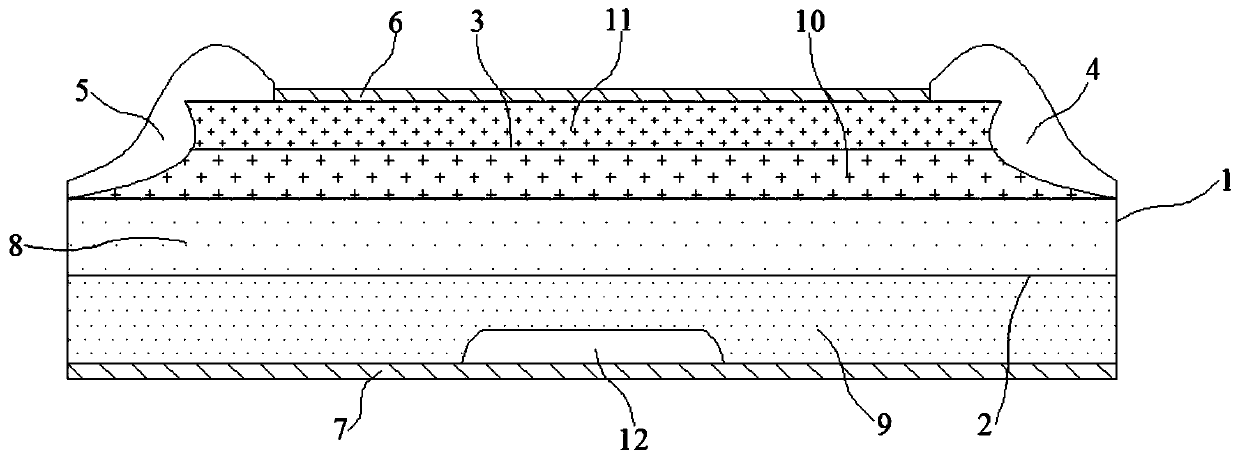

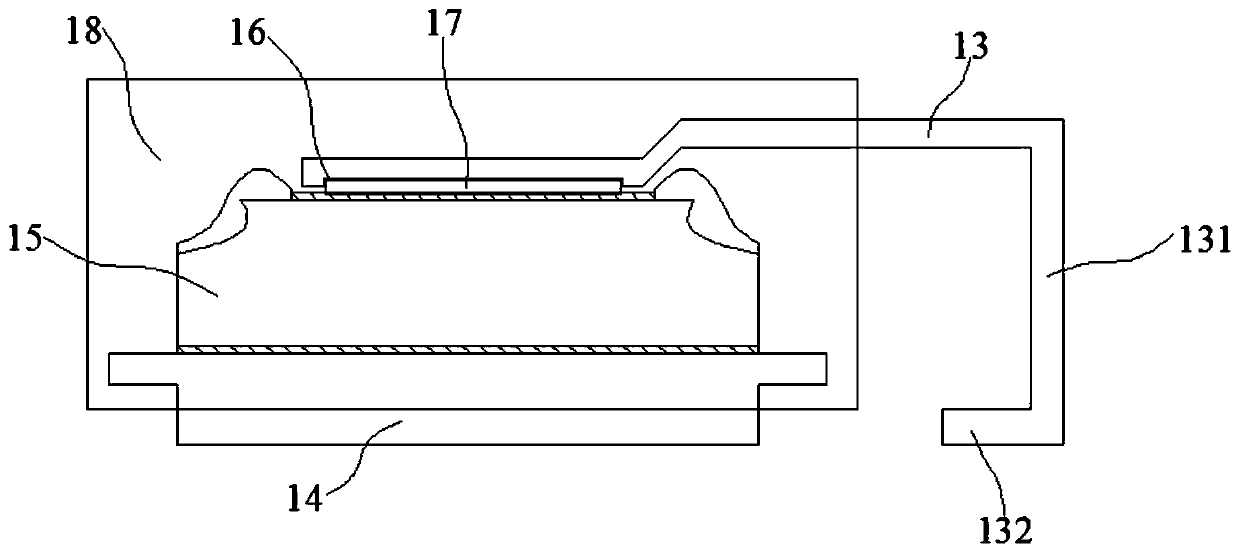

[0035] Embodiment 1~4: a kind of surface mount type TVS device, comprise upper lead frame 13, lower lead frame 14 and chip 15, described upper lead frame 13, lower lead frame 14 welding part and chip are respectively positioned at epoxy insulator 18, the welding portion located at one end of the upper lead frame 13 has a groove 16, and the respective welding portions of the upper lead frame 13 and the lower lead frame 14 are respectively connected to the first metal layer 6 and the second metal layer 7 of the chip 15. The soldering piece 17 is electrically connected between them. The welding piece 17 is embedded in the groove 16 of the upper lead frame 13 and the thickness of the welding piece 17 is greater than the depth of the groove 16. The other end of the upper lead frame 13 is a bending area 131. This bending The end of the bending area 131 is a pin portion 132, and the pin portion 132 of the upper lead frame 13 and the lower part of the lower lead frame 14 are located on...

Embodiment 1

[0045]The release agent in Example 1 is silicone oil, and the flame retardant is a phosphorus-nitrogen series flame retardant; the release agent in Example 2 is an organosilicon polymer, and the flame retardant is a crystal water salt flame retardant; Embodiment The release agent in 3 is fluorine-containing silicone oil, and the flame retardant is crystal water salt flame retardant; the release agent in embodiment 4 is isooctyl ester, and the flame retardant is phosphorus nitrogen series flame retardant and crystal water Mixture of salt flame retardants.

[0046] The raw material preparation method of above-mentioned epoxy insulator 18 comprises the following steps:

[0047] S1. Mix 80-100 parts of epoxy resin and 40-60 parts of phenol resin in a reactor at 70-110 degrees Celsius for hot-melt mixing, stir evenly, and then pulverize into powder after cooling;

[0048] S2. Mix 75-90 parts of silicon micropowder, 5-15 parts of flame retardant and 2-6 parts of γ-aminopropyltrieth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com