High-strength epoxy insulator material and preparation method thereof

An epoxy insulation and high-strength technology, applied in the field of insulator materials, can solve the problems of high brittleness and poor toughness, and achieve the effects of improved toughness, good thermal stability and excellent electrical insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

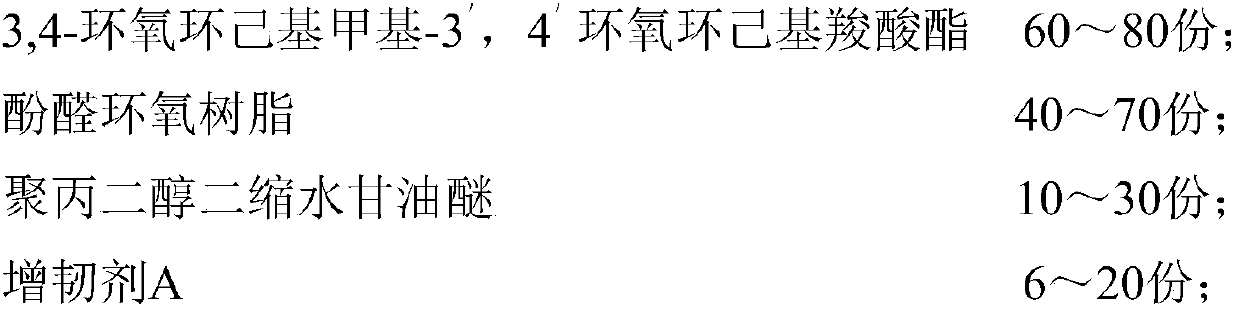

[0030] A high-strength epoxy insulator material is obtained by reacting a modified resin composition and a curing agent composition, and the modified resin composition includes the following raw materials in parts by weight:

[0031]

[0032] The curing agent composition comprises the following raw materials in parts by weight:

[0033] 82 parts of methyl hexahydrophthalic anhydride;

[0034] 36 parts of maleic anhydride;

[0035] Toughening agent hyperbranched polyether 12 parts.

[0036] The preparation method comprises the following steps:

[0037] (1) Preparation of modified resin composition: add 3,4-epoxycyclohexylmethyl-3', 4'epoxycyclohexyl carboxylate into the reaction kettle, preheat to 55°C; add novolac epoxy Resin, heat up to 72°C; add polypropylene glycol diglycidyl ether and toughening agent hyperbranched polyether in sequence, stir and mix at a speed of 300r / min, heat up to 90°C, continue stirring for 40min, and vacuum defoam to obtain a resin composition;...

Embodiment 2

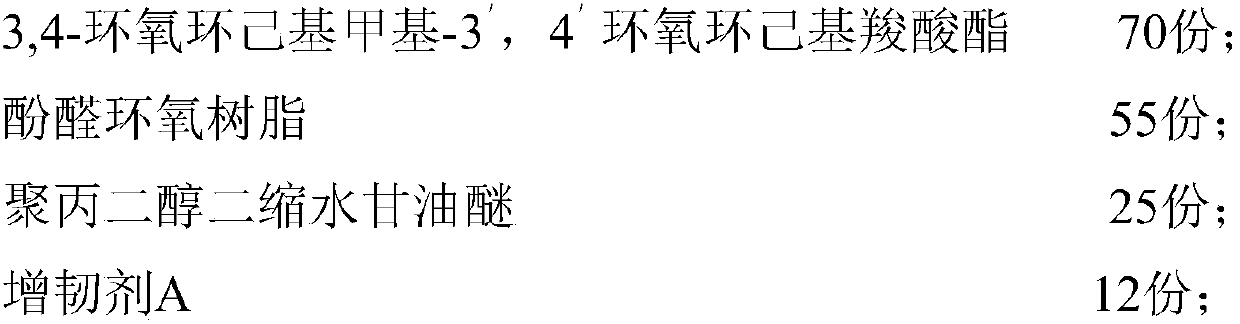

[0041] A high-strength epoxy insulator material is obtained by reacting a modified resin composition and a curing agent composition, and the modified resin composition includes the following raw materials in parts by weight:

[0042]

[0043] The curing agent composition comprises the following raw materials in parts by weight:

[0044] 80 parts of methyl hexahydrophthalic anhydride;

[0045] 25 parts of maleic anhydride;

[0046] 9 parts of toughening agent oligomer glycol.

[0047] The preparation method comprises the following steps:

[0048] (1) Preparation of modified resin composition: add 3,4-epoxycyclohexylmethyl-3', 4'epoxycyclohexyl carboxylate into the reaction kettle, preheat to 52°C; add novolac epoxy Resin, heat up to 76°C; add polypropylene glycol diglycidyl ether and toughening agent nano-zinc oxide in sequence, stir and mix at a speed of 280r / min, heat up to 88°C, continue stirring for 42min, and vacuum defoam to obtain a resin composition;

[0049] (2)...

Embodiment 3

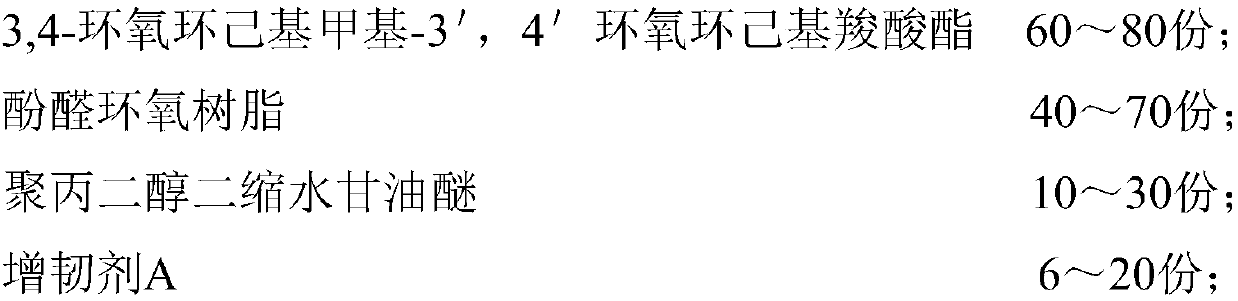

[0052] A high-strength epoxy insulator material is obtained by reacting a modified resin composition and a curing agent composition, and the modified resin composition includes the following raw materials in parts by weight:

[0053]

[0054] The curing agent composition comprises the following raw materials in parts by weight:

[0055] 82 parts of methyl hexahydrophthalic anhydride;

[0056] 35 parts of maleic anhydride;

[0057] Toughening agent aromatic polycarboxylic acid 13 parts.

[0058] The preparation method comprises the following steps:

[0059] (1) Preparation of modified resin composition: add 3,4-epoxycyclohexylmethyl-3', 4'epoxycyclohexyl carboxylate into the reaction kettle, preheat to 60°C; add novolac epoxy Resin, heat up to 80°C; add polypropylene glycol diglycidyl ether and toughening agent nano-silica in sequence, stir and mix at 400r / min, heat up to 90°C, continue stirring for 50min, and vacuum defoam to obtain a resin composition;

[0060] (2) Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com