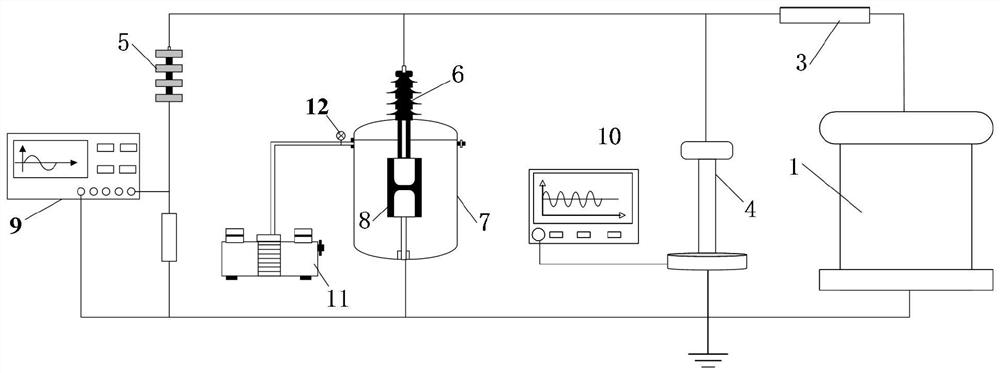

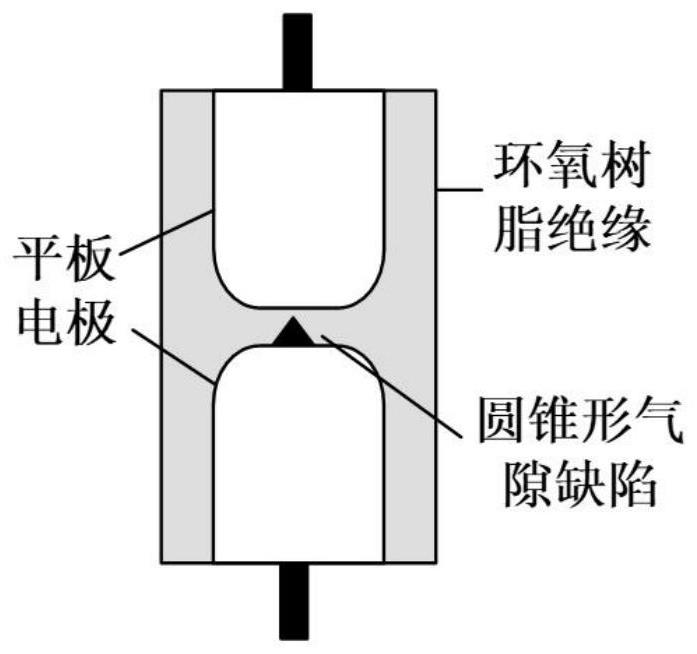

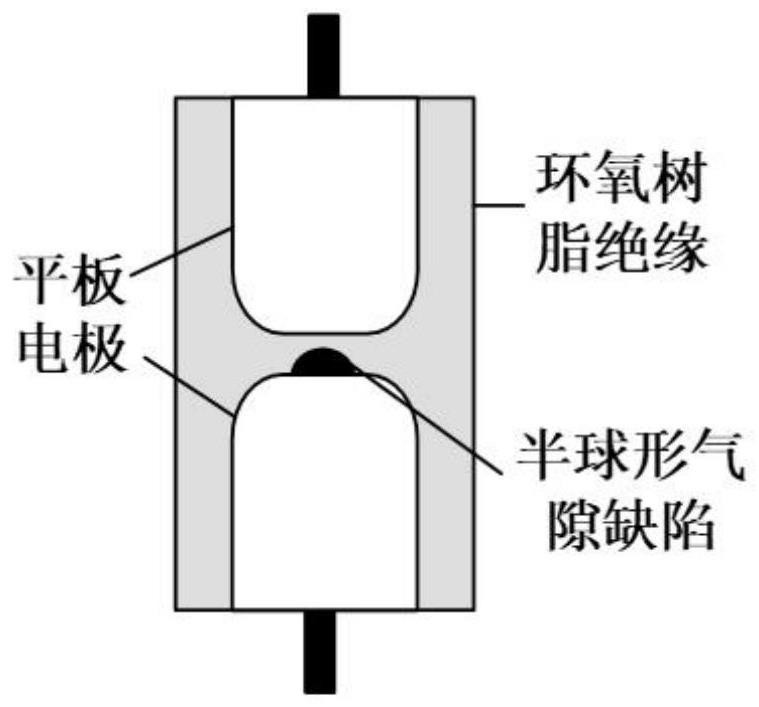

High-performance epoxy insulating part internal defect simulation system, method and application

A technology of epoxy insulation and internal defects, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve problems such as difficult to meet engineering requirements, single, poor on-site diagnosis, and achieve good accuracy and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the field of high-voltage insulation, such as fully enclosed equipment such as bushings, support insulators, contact boxes, insulating cylinders and poles made of epoxy resin on GIS, GIL and other switchgears, and filled with a large amount of SF6 gas, when there is When there is a fault, it is more complicated to repair, and the average power outage period after the accident is longer. For example, when applied to poles, it mainly refers to an independent component composed of a vacuum interrupter and / or conductive connection and its terminals encapsulated with solid insulating material. Since its solid insulating materials are mainly epoxy resin, power silicone rubber and adhesive, etc., the outer surface of the vacuum interrupter is sealed from bottom to top according to the solid sealing process, and the adhesive, power silicone rubber and epoxy resin are encapsulated in A pole is formed on the periphery of the main circuit. During the production process, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com