Method for removing difficultly degradable organic substance from packed bed in high voltage pulse electric field

A high-voltage pulsed electric field, refractory organic matter technology, applied in the field of water pollution treatment, can solve the problems of high energy consumption, difficult to achieve partial discharge of fillers, unfavorable mass transfer and diffusion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

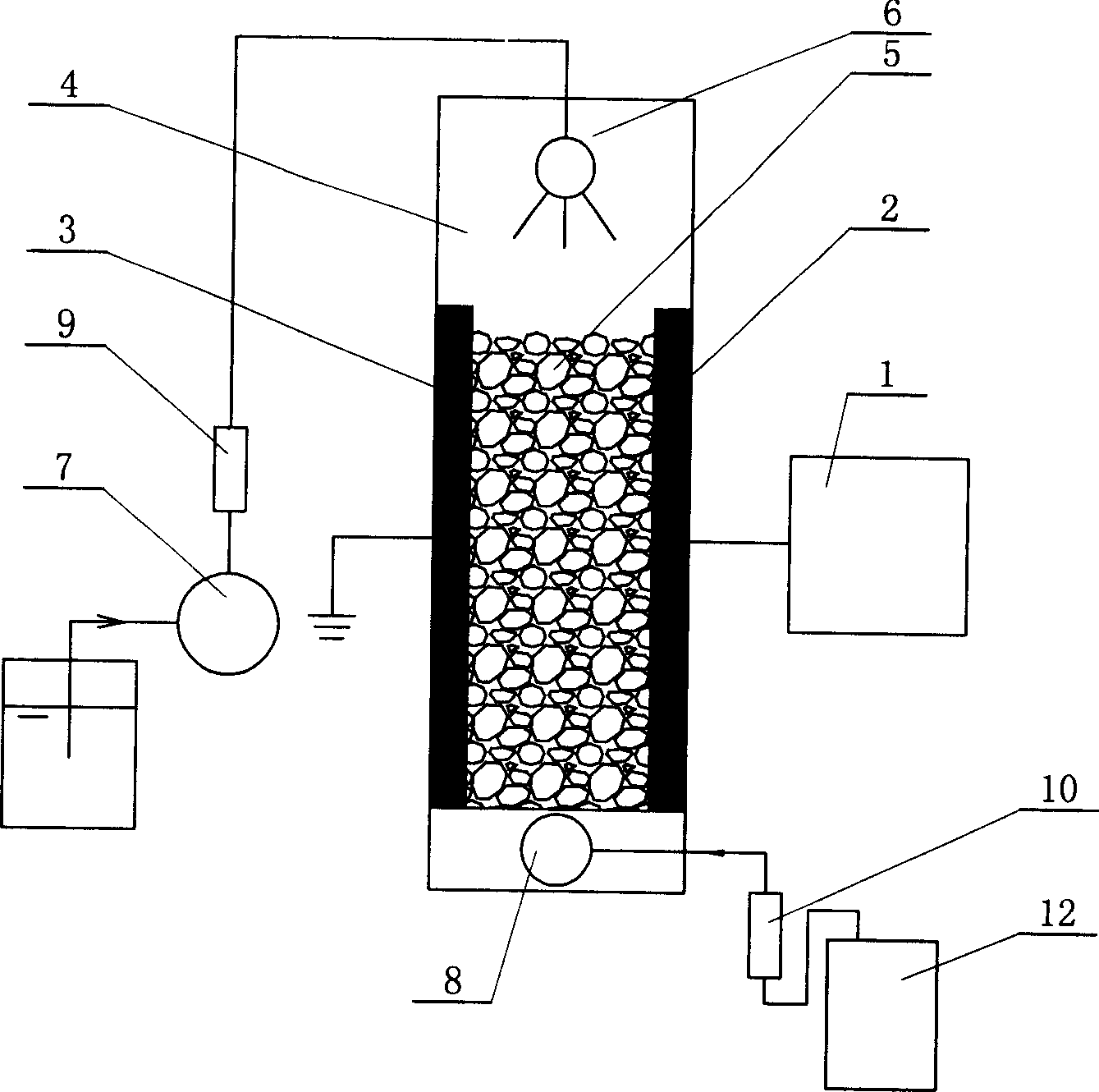

[0010] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. The technical solution of this embodiment is: apply pulse high voltage between the high voltage electrode 2 and the ground electrode 3 in the reaction vessel 4 filled with the particle filler 5 through the high voltage pulse power supply 1, and fill the gap between the high voltage electrode 2 and the ground electrode 3 The particle filler 5 is a high dielectric constant particle. When a pulsed high voltage is applied between the high voltage electrode 2 and the ground electrode 3, the aqueous solution to be treated passes through the spray tube arranged in the middle above the high voltage electrode and the ground electrode under the action of the water pump 7. Or the nozzle 6 sprays evenly into the reaction area in the form of mist droplets, and forms a thin layer of water film on the surface of the granular filler 5; the aeration tube 8 arranged in the...

specific Embodiment approach 2

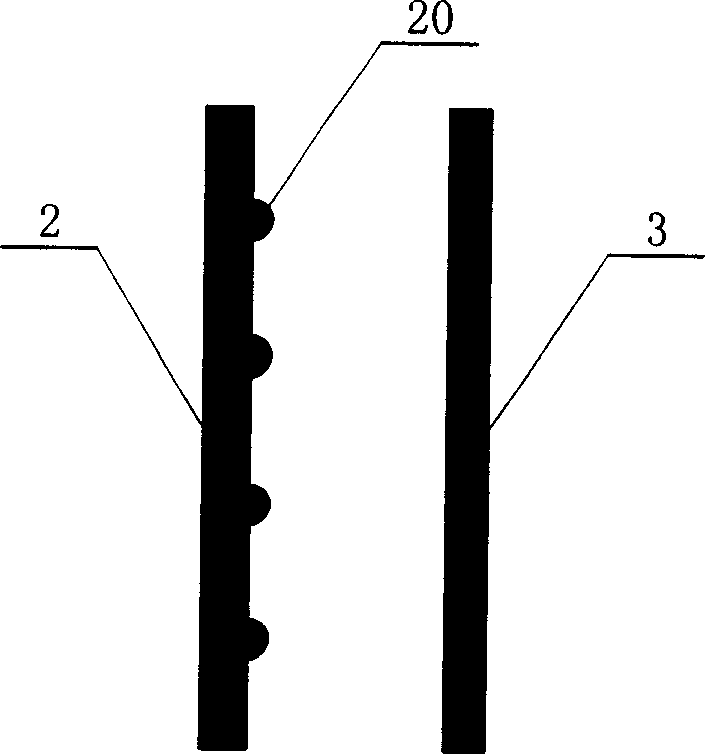

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the surface of the particle filler 5 supports metals, metal oxides or nano-scale semiconductor catalysts; the supported metals include: cobalt, copper, nickel, chromium, vanadium, platinum , palladium, ruthenium, rhodium, lead, cerium, iron or silver; the supported metal oxides include iron oxides such as iron oxyhydroxide and ferric oxide, manganese oxides, copper oxides or vanadium oxides, and the supported nanoscale The semiconductor catalyst includes nano-scale titanium dioxide or nano-scale silicon dioxide, and the surface of the particle filler 5 can also support the above-mentioned metal compound or the above-mentioned metal oxide compound. Other composition and connection modes are the same as those in Embodiment 1.

specific Embodiment approach 3

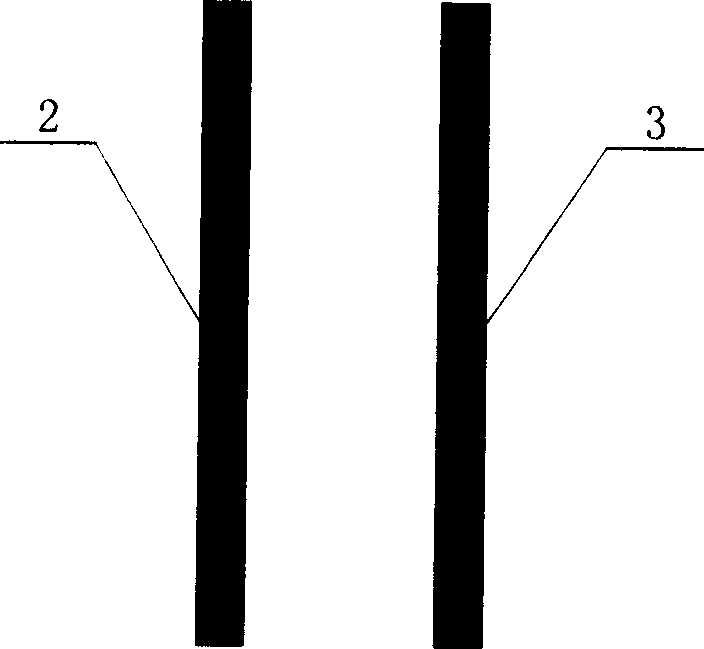

[0012] Specific implementation mode three: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is: the high voltage electrode 2 and the ground electrode 3 are both metal plates, the high voltage electrode 2 and the ground electrode 3 are arranged in parallel and opposite each other, and the distance between the high voltage electrode 2 and the ground electrode 3 is 1 to 5 cm; other The composition and connection method are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com