QFN packaging semiconductor device

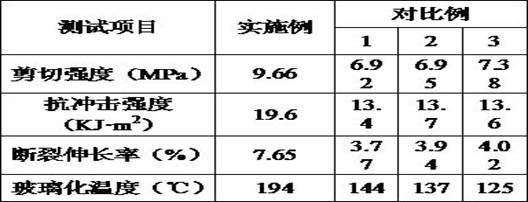

A semiconductor and device technology, which is applied in the field of QFN packaged semiconductor devices, can solve problems such as oversized pads and short circuits, and achieve the effects of controlling short circuits, improving cross-linking density, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

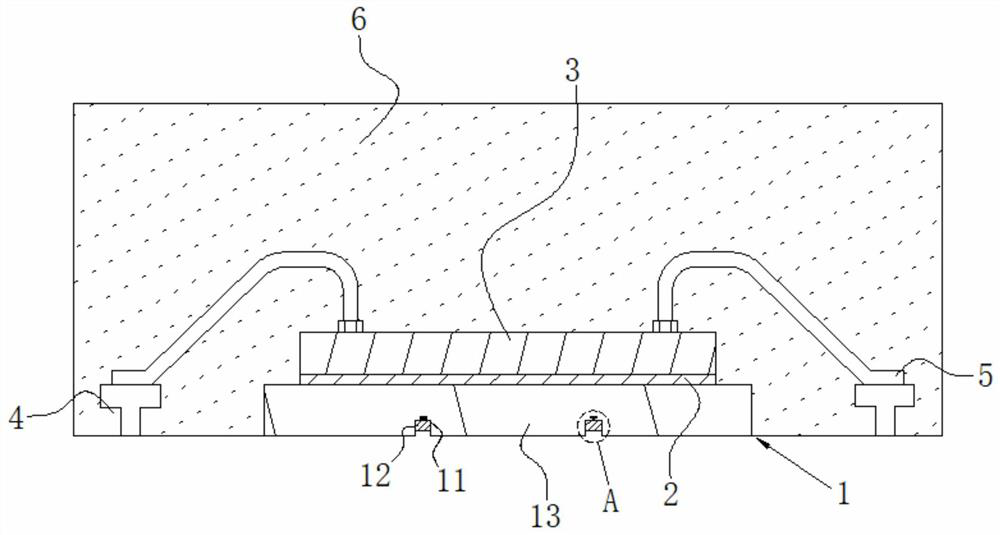

[0021] Embodiment: a kind of QFN encapsulation semiconductor device, comprise and be positioned at heat radiation pad 1, chip 3 and conductive pad 4 in epoxy insulator 6, described chip 3 is positioned on heat radiation pad 1, and described chip 3 and heat radiation welding A silver paste layer 2 is provided between the disks 1, and several conductive pads 4 are provided around the heat dissipation pad 1, and the conductive pads 4 and the chip 3 are connected by a lead 5;

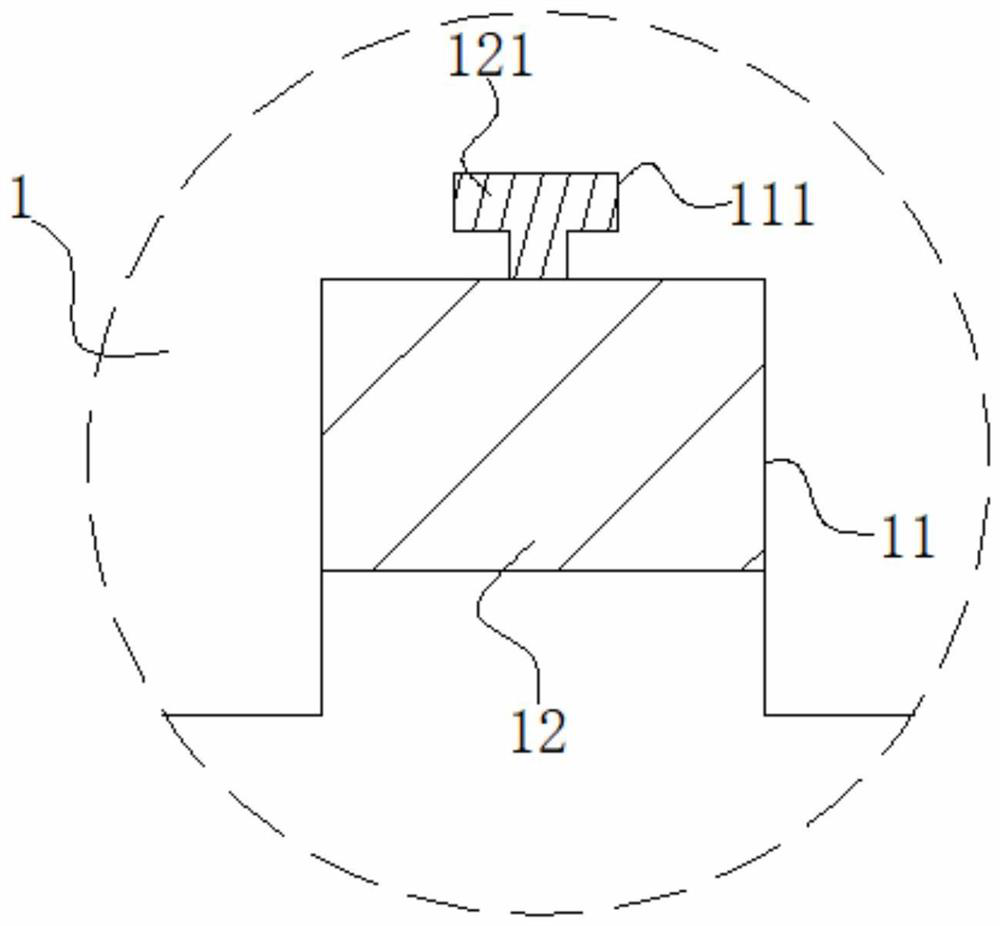

[0022] The side of the heat dissipation pad 1 away from the chip 3 is provided with a separation groove 11, the width of the separation groove 11 is 0.1-0.3 mm, and the separation groove 11 divides the side of the heat dissipation pad 1 away from the chip 3 into equal parts. At least two single pads 13, the separation grooves 11 are filled with heat-conducting insulating strips 12, the walls of the separation grooves 11 are provided with several T-shaped grooves 111 extending into the heat dissipation pads 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com