Method for inhibiting accumulation of surface charge of epoxy resin and composite materials thereof

A composite material and epoxy resin technology, applied in the field of electrical insulating materials, can solve the problems of distorted electric field, equipment accident, and the drop of flashover voltage along the surface, and achieve the effect of simple process and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

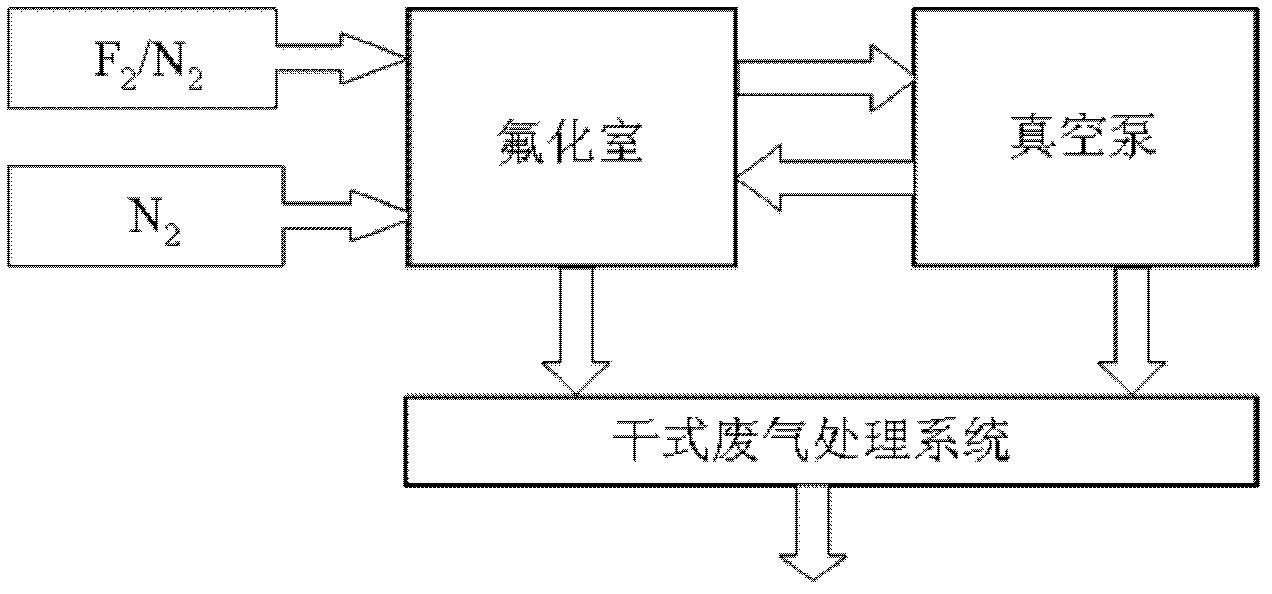

Method used

Image

Examples

Embodiment 1

[0029] Epoxy resin samples were subjected to gas-phase fluorination in a closed reaction chamber.

[0030] Gas-phase fluoridation treatment conditions: the temperature is 50° C., the volume concentration of fluorine gas in the fluorine / nitrogen gas mixture is 12.5%, the pressure of the reaction gas is 1 bar, and the fluorination treatment time is 30 minutes.

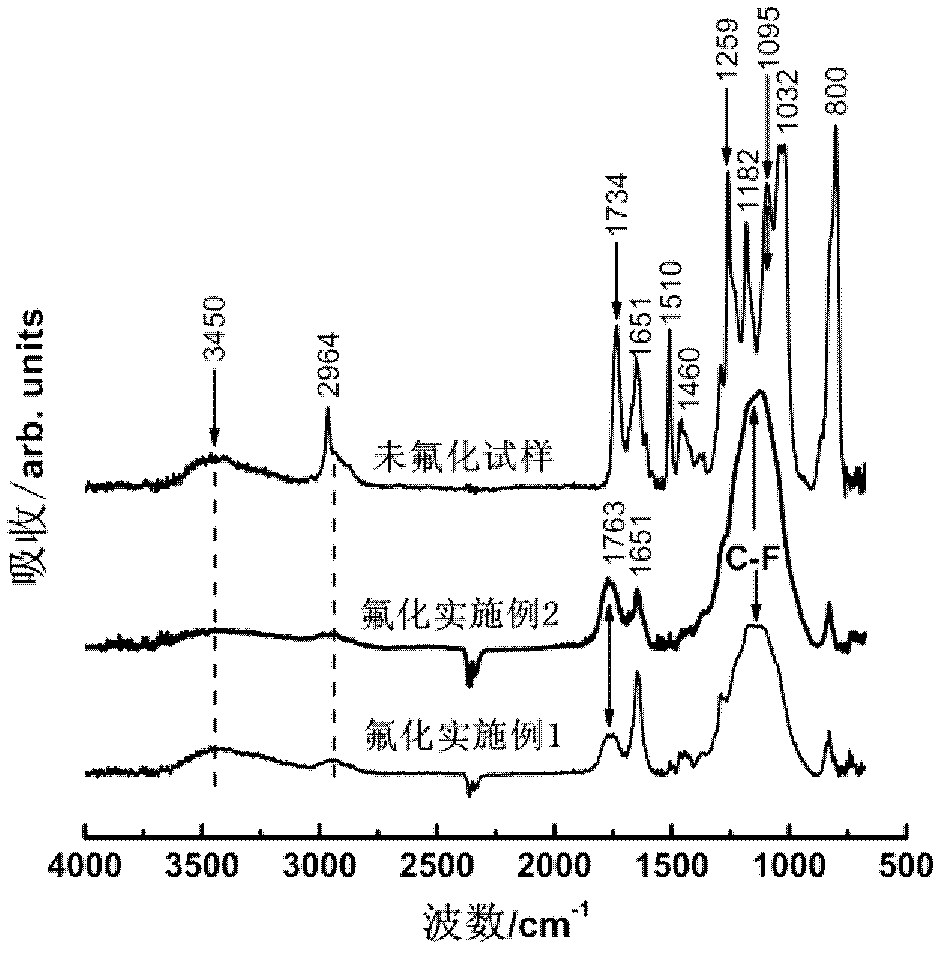

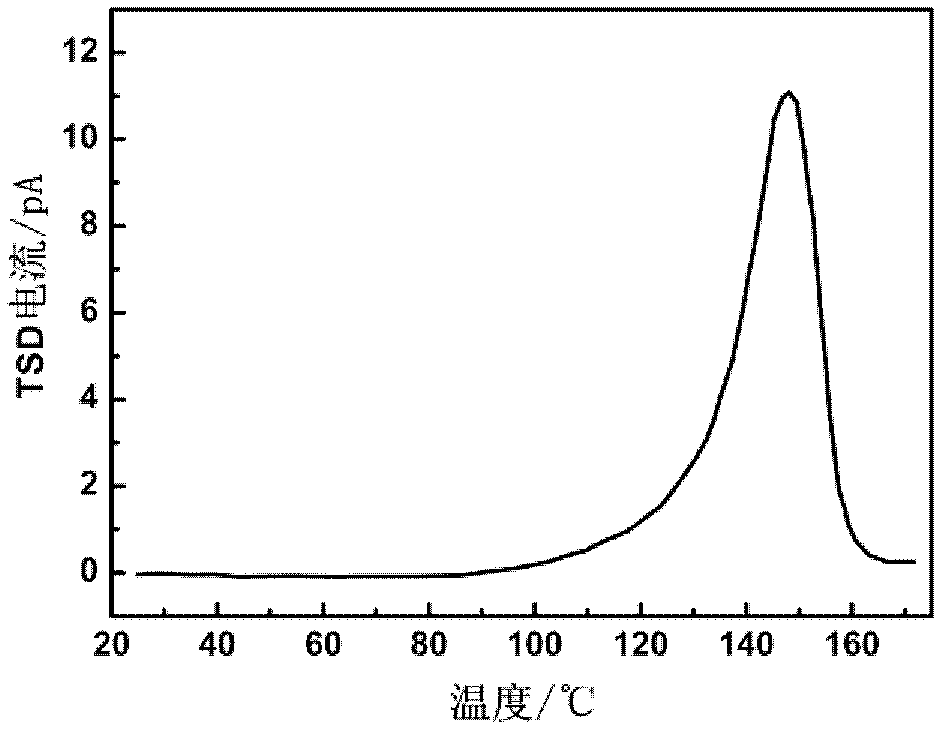

[0031] The surface potential of embodiment 1 sample or the measurement result of surface charge decay and surface conductivity: with the sample (former sample) corona charging without fluorination treatment, have the stable voltage that is almost equal to charging grid voltage (-2kV) Compared with the initial surface potential of the sample, the initial surface potential of the sample in Example 1 after charging is much lower than this charging grid voltage value (-2kV), and the surface potential or surface charge rapidly decays to zero at room temperature (see Figure 4 Example 1 curve in). This and the surface conduct...

Embodiment 2

[0033] Epoxy resin samples were subjected to gas-phase fluorination in a closed reaction chamber.

[0034] Gas-phase fluoridation treatment conditions: the temperature is 55° C., the volume concentration of fluorine gas in the fluorine / nitrogen gas mixture is 20%, the pressure of the reaction gas is 0.2 bar, and the fluorination treatment time is 60 minutes.

[0035] The measurement result of surface potential or surface charge decay and surface conductivity of embodiment 2 sample, please refer to Figure 4 Curve and table 1 in embodiment 2. Similar to the results of the sample in Example 1, the initial surface potential of the sample in Example 2 after charging is also far below the charging grid voltage value (-2kV), and the surface potential or surface charge also rapidly decays to zero at room temperature, The surface conductivity of the sample of Example 2 is also significantly greater than that of the original sample.

Embodiment 3

[0037] Epoxy resin samples were subjected to gas-phase fluorination in a closed reaction chamber.

[0038] Gas-phase fluorination treatment conditions: the temperature is 120° C., the volume concentration of fluorine gas in the fluorine / nitrogen gas mixture is 1%, the pressure of the reaction gas is 2 bar, and the fluorination treatment time is 30 minutes.

[0039] The measurement result of surface potential or surface charge decay and surface conductivity of embodiment 3 sample, please refer to Figure 4 Curve and table 1 in embodiment 3. Similar to the results of the samples of Examples 1 and 2, but its surface potential or surface charge decays faster than the first two, due to its higher surface conductivity (2.6 × 10 -13 [S]).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com