Corrected full-focus imaging method for anisotropy weld seam defect array detection

An anisotropy and imaging method technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids and other directions, can solve problems such as weld seam anisotropy and non-uniformity, and achieve inaccurate and accurate defect positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

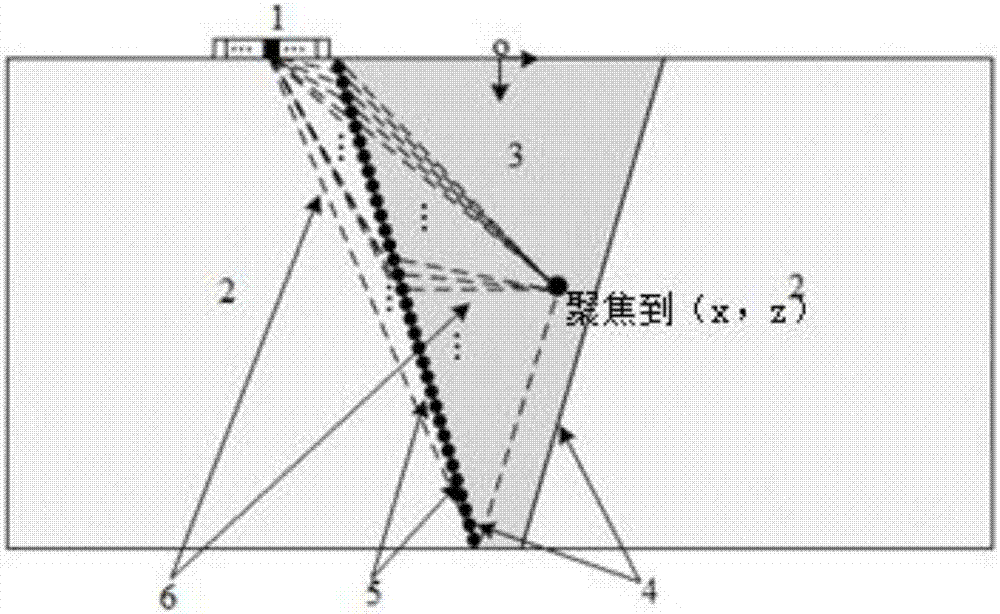

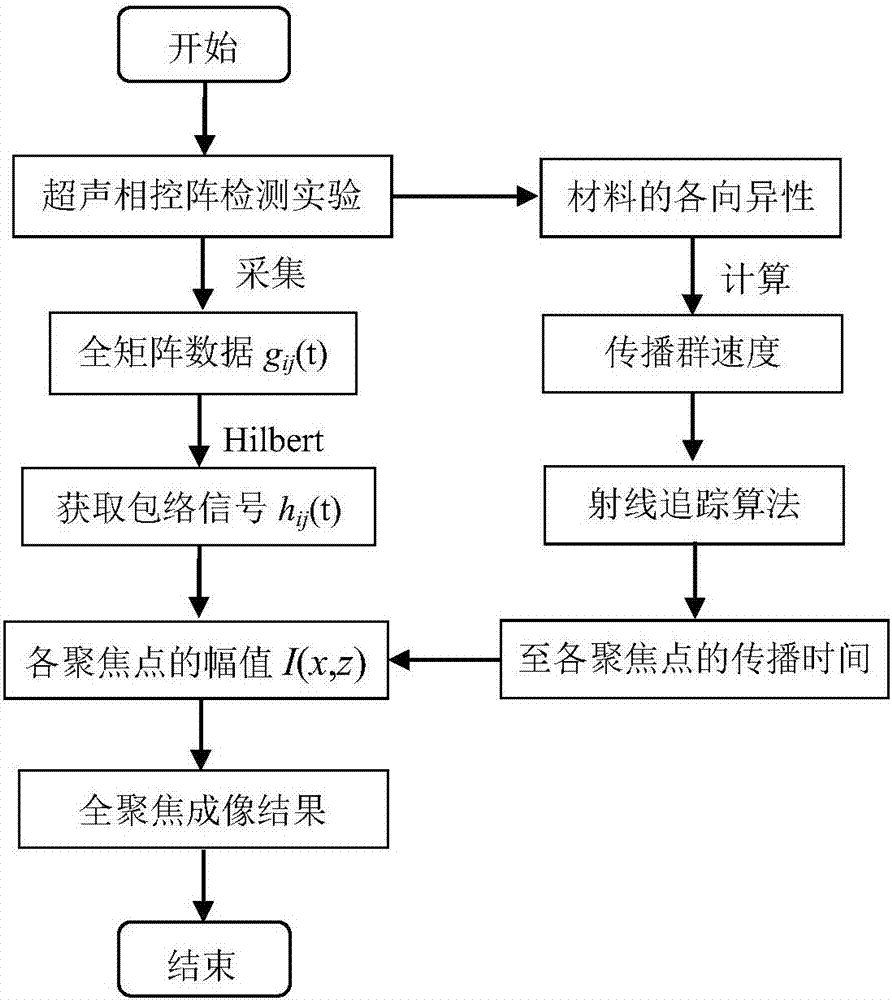

[0050] It is also possible to partition the weld model according to the grain orientation, that is, divide the weld into multi-layer grain orientation structures; see Figure 5 ; First calculate the time from the initial point excitation array element to the discrete point on the boundary of each layer; then calculate the time between the discrete point on the boundary line of the layer where the target point is located and the previous layer to the target point; since the incident direction of the wave is unknown , so the speed cannot be directly calculated. The propagation direction of the wave can be obtained according to the connection line between the discrete point on the boundary line of the layer where the target point is located and the previous layer and the target point, and the incident direction of the wave can be deduced according to the propagation direction of the wave; the incident direction of the wave and The group velocity can be calculated from the grain d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com