Post insulator flaw inspection device and usage method thereof

A technology of pillar insulator and flaw detection device, which is applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. The effect of accurate defect location and fatigue reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

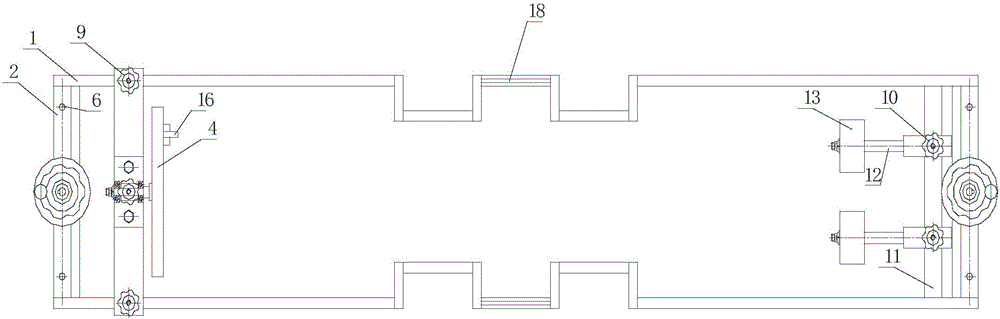

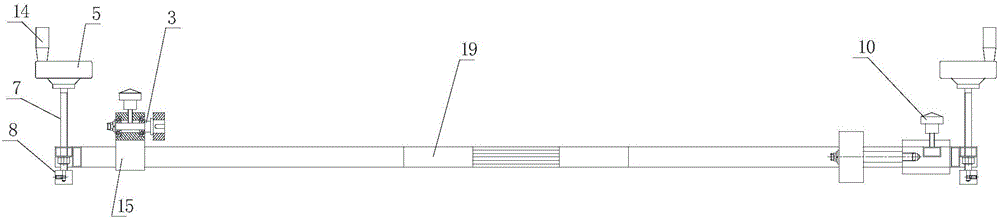

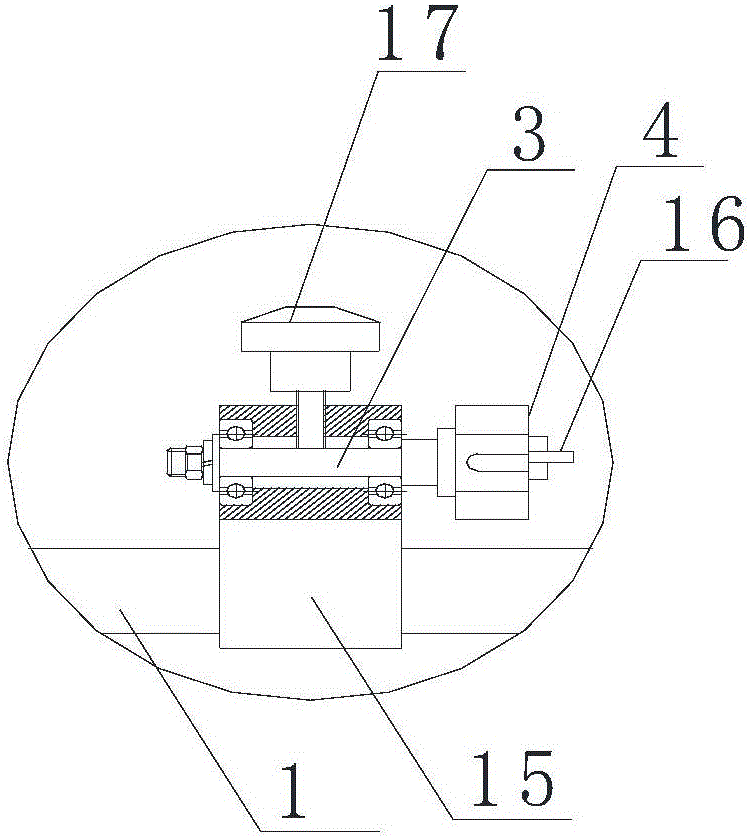

[0036] Such as figure 1 , figure 2 A post insulator flaw detection device is shown, which includes three functional parts: a load-bearing structure, a lifting structure, and a rotating structure. In order to improve the overall strength, all structures are made of titanium alloy, so that the overall weight of the present invention is only 9KG, and the lifting weight can reach 150KG, and it has good rigidity and no deformation. Wherein the load-bearing structure is a frame surrounded by the underframe crosspiece 2 and the underframe longitudinal piece 1 . Under normal circumstances, two base frame cross members 2 and two base frame longitudinal members 1 can form a frame. However, for the case where heavy post insulators need to be detected, additional underframe crosspieces 2 may also be provided. The number of additionally provided underframe crosspieces 2 is not limited, but the rotating structure cannot be affected. The lifting mechanism is installed on two underframe c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com