Synchronous control system for digital rays of circular welding seam on pipe

A digital ray and synchronous control technology, applied in the field of digital ray technology and pipeline systems, can solve the problems of poor positioning accuracy, unfavorable pipeline promotion and application, etc., and achieve the effects of real-time imaging and electronic storage, high imaging resolution, and accurate defect positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

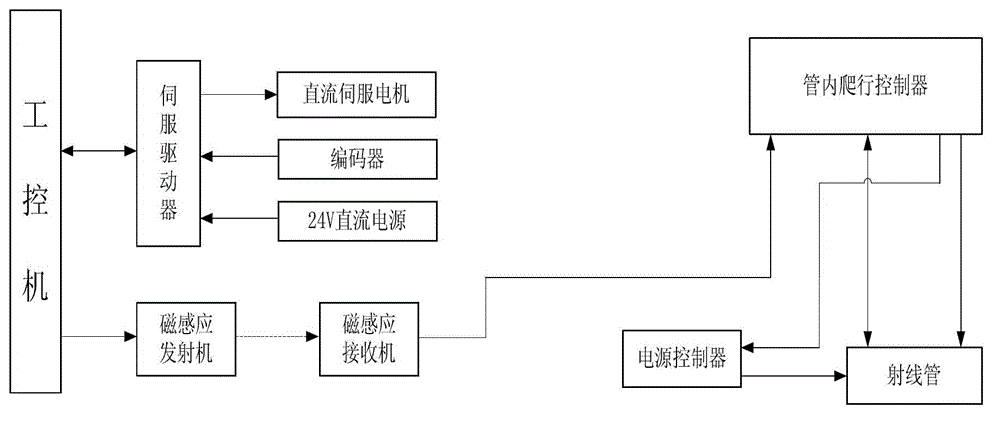

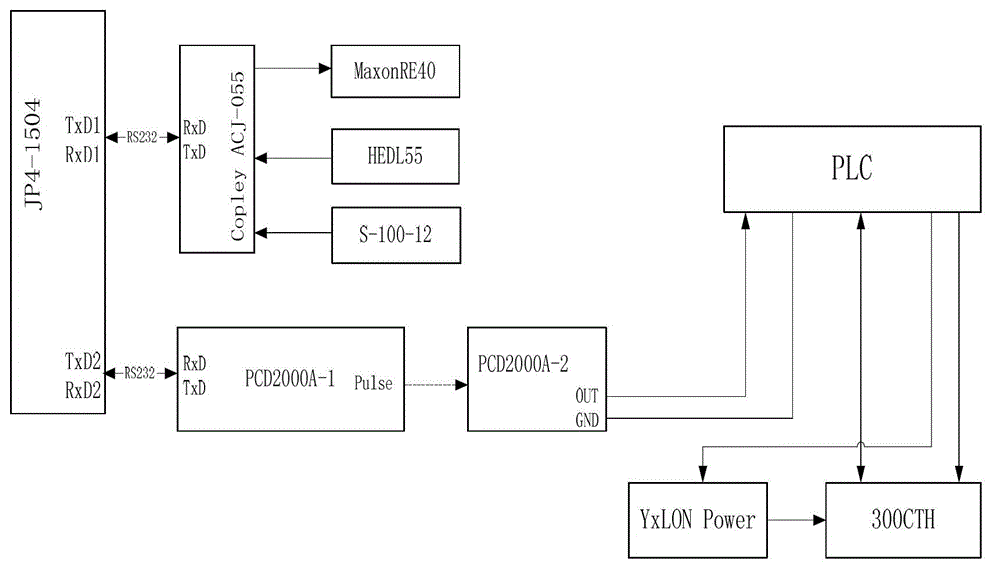

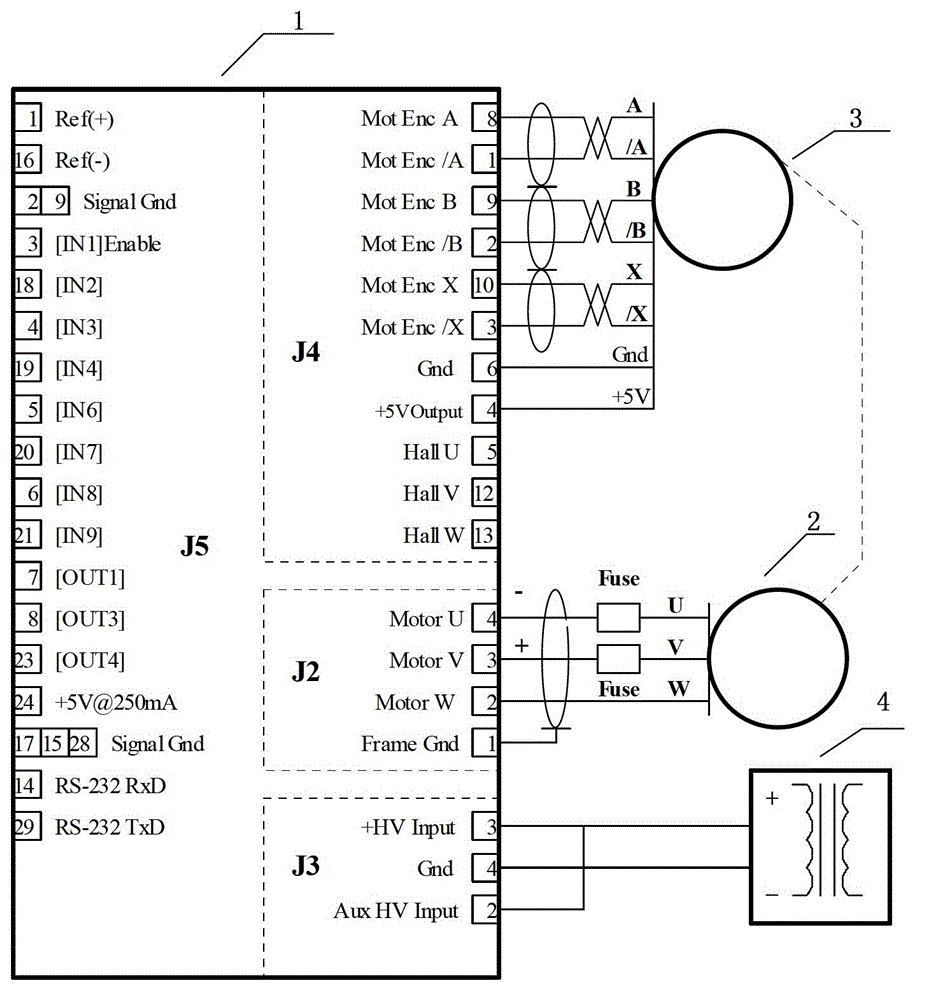

[0018] Embodiment. Illustrate the specific embodiment of the present invention with this example, and the present invention is described further. This example is an industrial test prototype, its composition is as follows: figure 1 As shown, the circuit and wiring are as Figure 2-Figure 4 shown.

[0019] The industrial computer is connected with the magnetic induction transmitter by RS232, and the magnetic induction transmitter is connected with the magnetic induction receiver by emitting electromagnetic field signals, and sends exposure start and exposure stop commands to the crawling controller PLC in the tube; the crawling controller PLC in the tube is connected to the ray tube through a control cable ; The industrial computer is also connected to the servo driver through the RS232 communication line, the servo driver with the encoder is connected to the DC servo motor, and the DC power supply is connected to the servo driver, DC servo motor and encoder to supply power to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com