Device and method for detecting carbon fiber composite material truss bonding defects by ultrasonic phased array

A technology of ultrasonic phased array and composite materials, which is applied in the directions of measuring devices, analyzing materials, and analyzing solids by using sound waves/ultrasonic waves/infrasonic waves, etc. It can solve the problems that the efficiency cannot meet the progress of satellite verification, the payload cabin is bulky and difficult to realize, etc. , to achieve intuitive defect display, improve detection efficiency, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

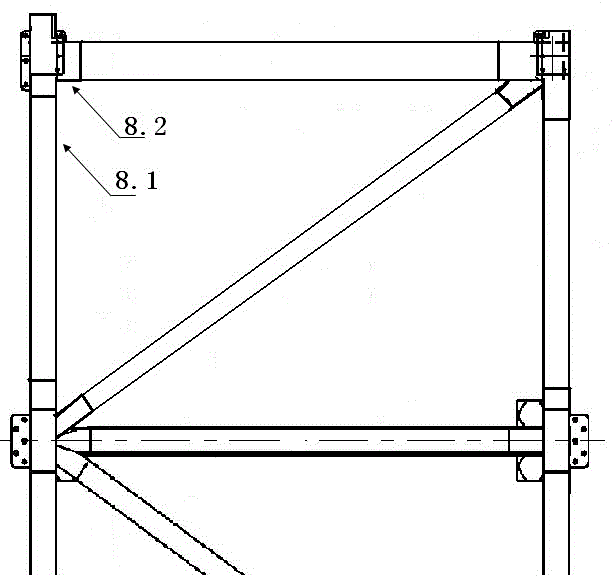

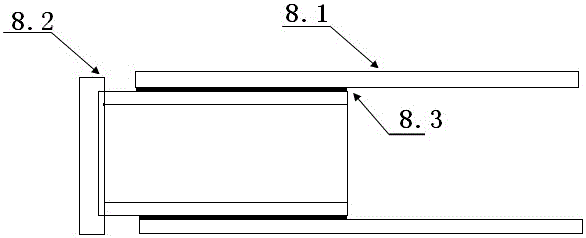

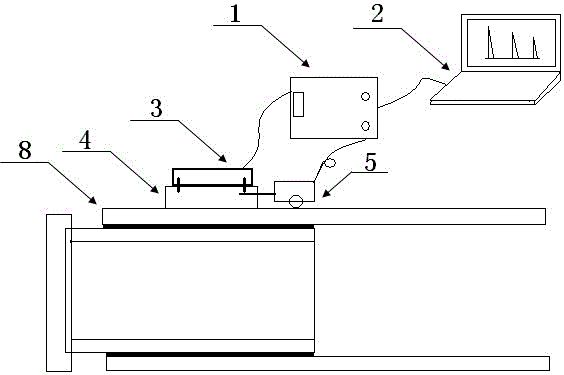

[0036] The following will combine Figure 1 to Figure 5 The ultrasonic phased array detection device and method for carbon fiber composite material truss bonding defects of the present invention will be further described in detail.

[0037] image 3 Shown is a schematic diagram of an ultrasonic phased array detection device for carbon fiber composite material truss bonding defects according to a preferred embodiment of the present invention. like image 3 As shown, the ultrasonic phased array detection device for carbon fiber composite truss bonding defects includes an ultrasonic phased array detector 1, a control computer 2, an ultrasonic phased array probe 3, a coupling wedge 4, a displacement encoder 5, and a coupling agent and comparison test block;

[0038] The ultrasonic echo signal output end of the ultrasonic phased array detector 1 is connected to the signal input end of the control computer 2 through a USB interface, and the control computer 2 is loaded with detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com