Reference block for alloy steel bar ultrasonic flaw detection and using method of reference block

A technology for comparing test blocks and alloy steel bars, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and analysis of materials, etc. and other problems, to achieve the effect of accurate inspection results, saving inspection costs, and accurate defect positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

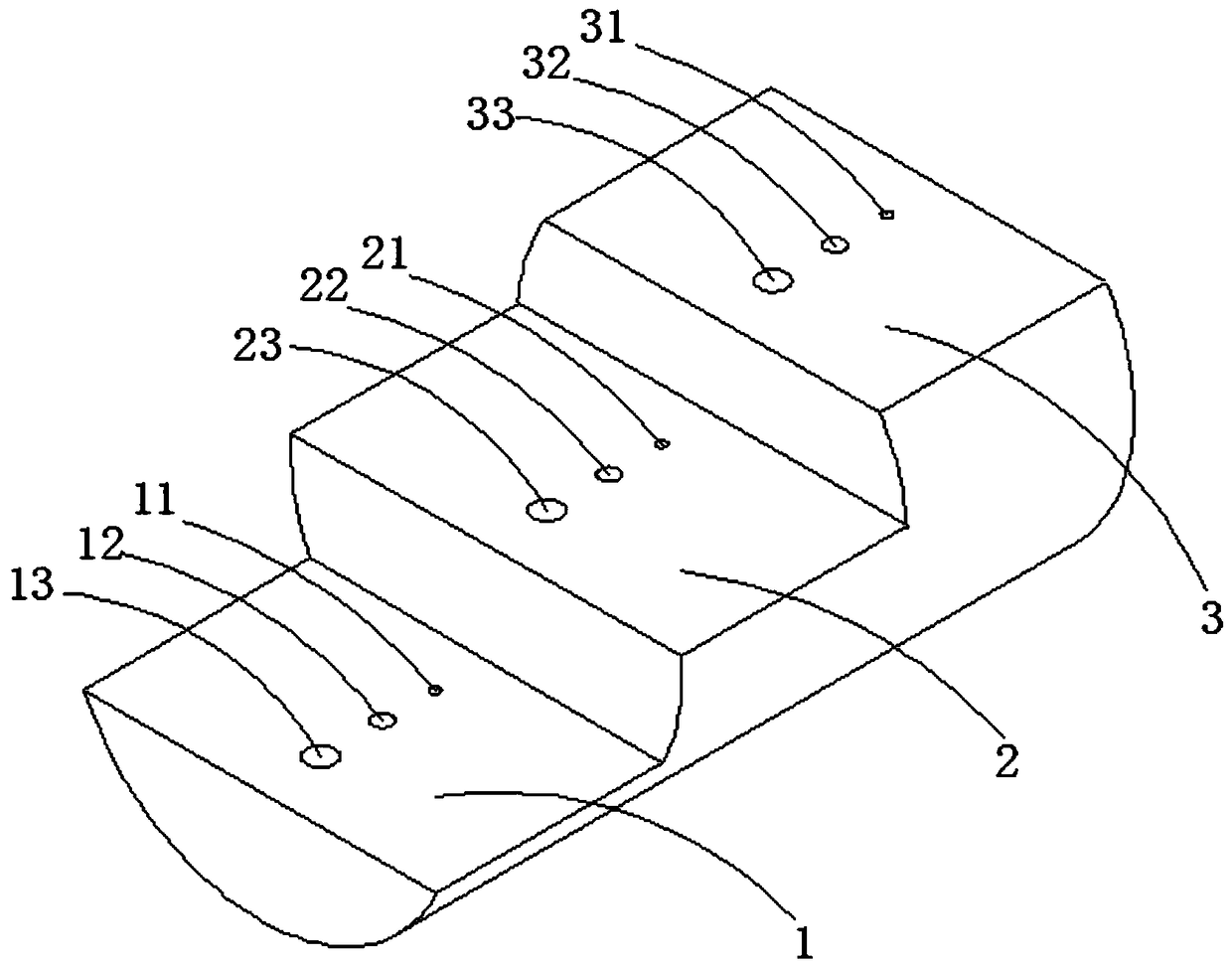

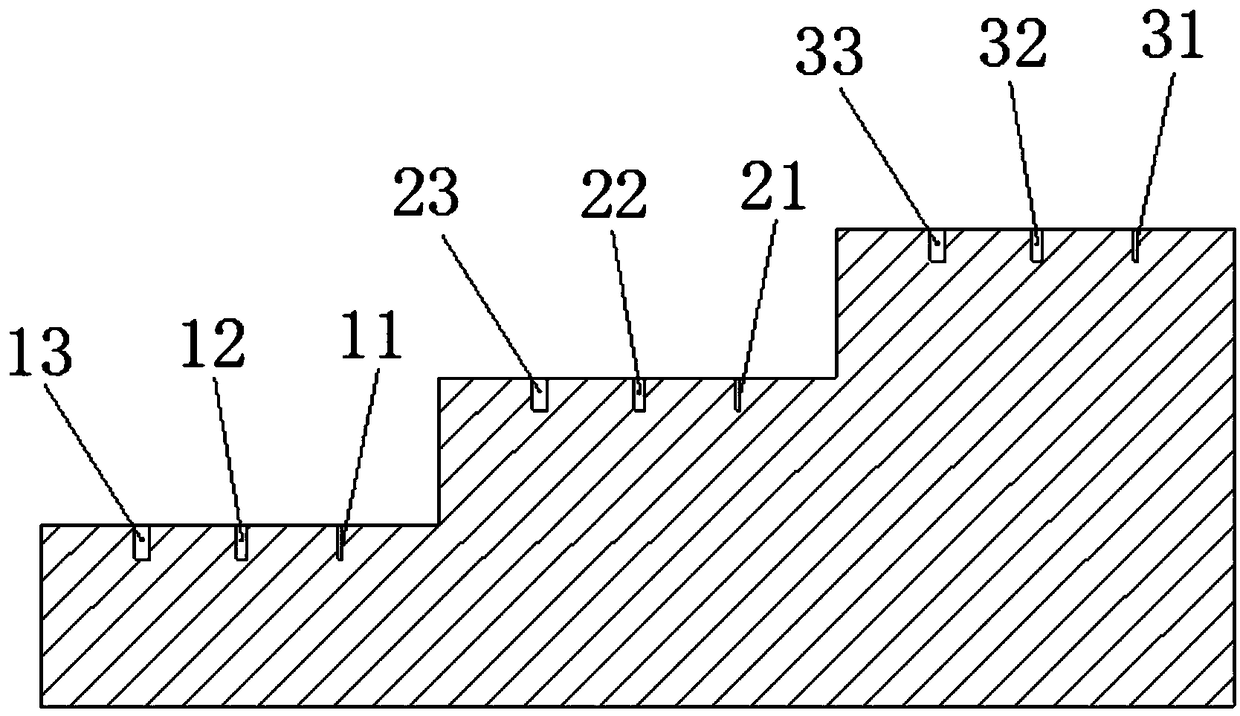

[0042] The steel grade of the bar to be inspected in this embodiment is 40Cr, the specification is Φ60mm, the alloy composition of the comparison test piece is similar or similar to 40Cr, and the flaw detection sensitivity is Φ3mm.

[0043] S1, select the comparison test block:

[0044] The diameter D of the comparison test block is 60mm, L 3 45mm, L 2 30mm, L 1 15mm. The drilling diameter of the flat-bottomed hole is accurate, and the axis of the hole coincides with the diameter line of the bar, and the surface of the flat-bottomed hole is perpendicular to the axis, and the inside of the hole is clean.

[0045] S2, adjust flaw detection sensitivity:

[0046] Couple the ultrasonic straight probe to the circumferential surface of the comparison test block, find out the C of the C comparison section 3 3 The maximum echo of the flat-bottomed hole 33, adjust the echo amplitude to 80% of the full scale, and then find the A of the comparison section A1 3 The maximum echo of th...

Embodiment 2

[0050] The steel grade of the inspected bar in this example is 35CrMo, the specification is Φ100mm, the alloy composition of the comparison test piece is similar or similar to that of 35CrMo, and the flaw detection sensitivity is Φ2mm.

[0051] S1, select the comparison test block:

[0052] The diameter D of the comparison test block is 100mm, L 3 75mm, L 2 50mm, L 1 is 25mm. The drilling diameter of the flat-bottomed hole is accurate, and the axis of the hole coincides with the diameter line of the bar, and the surface of the flat-bottomed hole is perpendicular to the axis, and the inside of the hole is clean.

[0053] S2, adjust flaw detection sensitivity:

[0054] Couple the ultrasonic straight probe to the circumferential surface of the comparison test block, find out the C of the C comparison section 3 2 The maximum echo of the flat-bottomed hole 32, adjust the echo amplitude to 80% of the full scale, and then find out A vs. A of section 1 2 The maximum echo of the ...

Embodiment 3

[0058] The steel grade of the inspected bar in this example is 12Cr1MoV, the specification is Φ130mm, the alloy composition of the comparison test piece is similar or similar to that of 12Cr1MoV, and the flaw detection sensitivity is Φ1mm

[0059] S1, select the comparison test block:

[0060] The comparison test block specification D is 128mm, L 3 96mm, L 2 64mm, L 1 is 32mm. The drilling diameter of the flat-bottomed hole is accurate, and the axis of the hole coincides with the diameter line of the bar, and the surface of the flat-bottomed hole is perpendicular to the axis, and the inside of the hole is clean.

[0061] S2, adjust flaw detection sensitivity:

[0062] Couple the ultrasonic straight probe to the circumferential surface of the comparison test block, find out the C of the C comparison section 3 1 For the maximum echo of the flat-bottomed hole, adjust the echo amplitude to 80% of the full scale, and then find out A and compare the A of section 1 1 The maximu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com