A method for dual-frequency ultrasonic detection of inclusions in bearing steel

A technology of inclusions and ultrasonic waves, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, the improvement of process efficiency, instruments, etc., can solve the problems such as the inability to overall reflect the purity of molten steel smelting, pollution discharge in the detection process, and complex sample processing. To achieve the effect of stable scanning and detection process, accurate defect positioning, and efficient and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

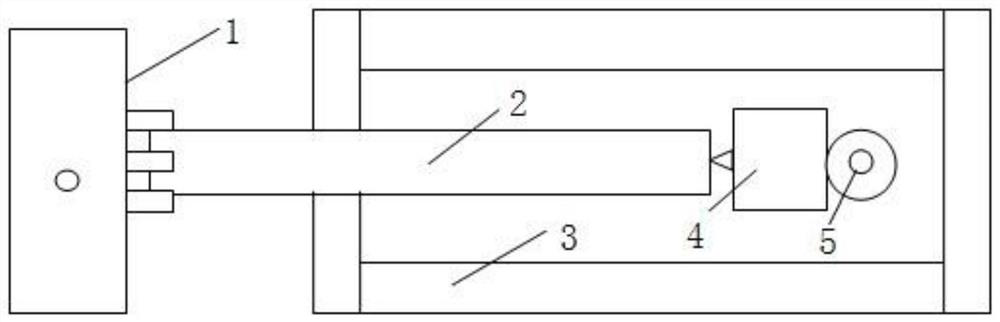

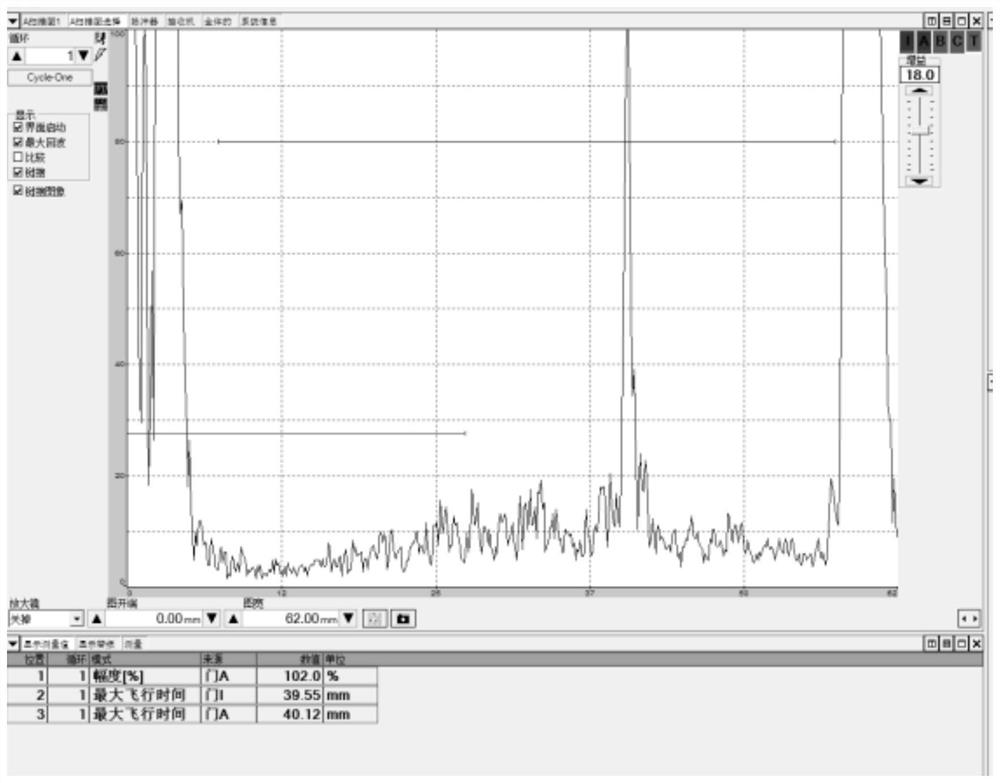

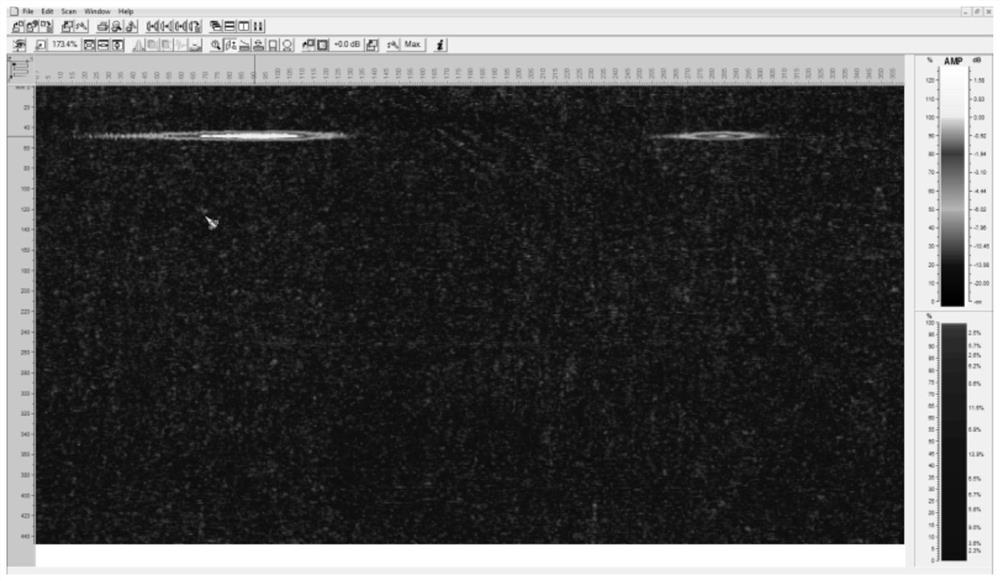

[0035] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0036] This embodiment relates to a method for ultrasonically detecting inclusions in bearing steel, and the detection object is medium carbon bearing steel. Specific steps are as follows

[0037](1) Take a cylindrical bearing steel sample with a diameter of 50mm and a length of 500mm as the analysis sample;

[0038] (2) Heat treatment of the sample: quenching and tempering, the quenching heating temperature of bearing steel is 800-900 ℃, after the temperature reaches 25-45min, the temperature is kept for 25-45 minutes, and it is cooled in water when it is released from the furnace. The water is cooled for the second time, and after the water is discharged, it is air-cooled to room temperature; the tempering heating temperature of the tempering is 400-700 ° C, and the air-cooling is carried out after holding for 20-40 minutes.

[0039] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com