Metal defect eddy current detection device and probe thereof

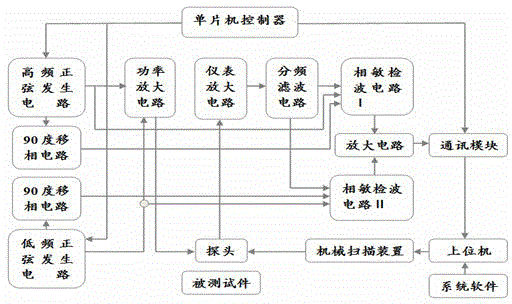

An eddy current detection and metal defect technology, which is applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, can solve problems such as difficult to accurately determine the location of defects, limited skin effect, etc., to increase the defect measurement range, Improving circuit performance, the effect of lasting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

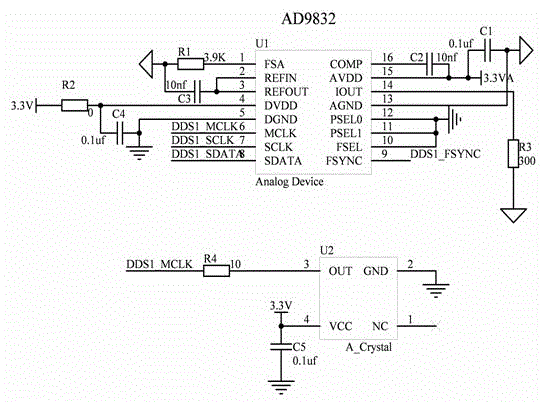

[0029] The integrated chip AD9832 in the high-frequency sinusoidal signal generating circuit and the low-frequency sinusoidal signal generating circuit is controlled by the microcontroller controller to generate high-frequency and low-frequency two-way sine waves. A 90-degree phase shift circuit is added to the circuit to generate high and low frequency signals orthogonal to the excitation signal?

[0030] like Figure 4 As shown, the 90-degree phase-shifting circuit connected to the high-frequency sinusoidal signal generating circuit is composed of the chip OP37 as the core. The first pin of the OP37 chip is connected to the second pin, and the first pin and the second pin of the OP37 chip are connected. Connect to one end of the first resistor R7 and the second resistor R8, the other end of the first resistor R7 is connected to the 6th pin of the OP37 chip, the other end of the second resistor R8 is connected to the 5th pin of the OP37 chip, and the OP37 The 5th pin of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com