Patents

Literature

81results about How to "Improve detection efficiency and accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

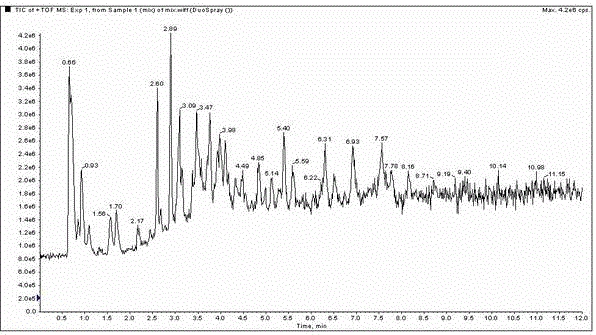

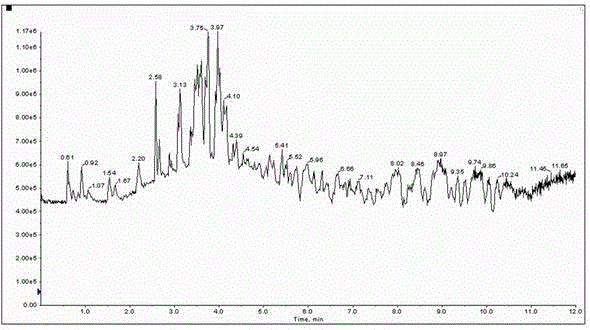

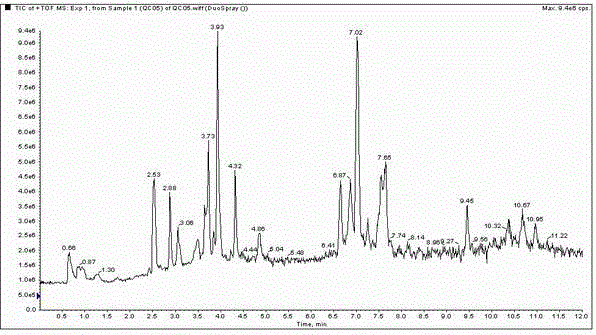

Combined liquid chromatography-mass spectroscopy method for high-flux detection of 113 lipids in blood sample of living body

InactiveCN106093227AImprove detection efficiency and accuracyHigh sensitivityComponent separationSolventChemistry

The invention provides a combined liquid chromatography-mass spectroscopy method for high-flux detection of 113 lipids in a blood sample of a living body, belonging to the field of bioanalytical chemistry. The method comprises the following steps: subjecting a to-be-detected sample to pretreatment; then adding a reaction solvent and an extraction agent for extraction; and then carrying out liquid chromatographic-mass spectroscopic detection. The method is simple to operate and high in selectivity and sensitivity, and can rapidly detect 113 lipids in blood, wherein the 113 lipids include 48 of phosphatidylcholines (PC), 21 lysophosphatidylcholines (Lyso-PC), 17 phosphatidylethanolamines (PE), 4 lysophosphatidylethanolamines (LPE), 6 lysophosphatidylinositols (PI), 9 sphingomyelins (SM) and 8 ceramides (Cer). The method has precision meeting requirements on analysis of serum samples, good stability and high detection sensitivity to most lipid metabolites, and is applicable to lipidomic analysis of serum samples.

Owner:LIAONING RUNSHENG KANGTAI BIOMEDICAL TECH CO LTD

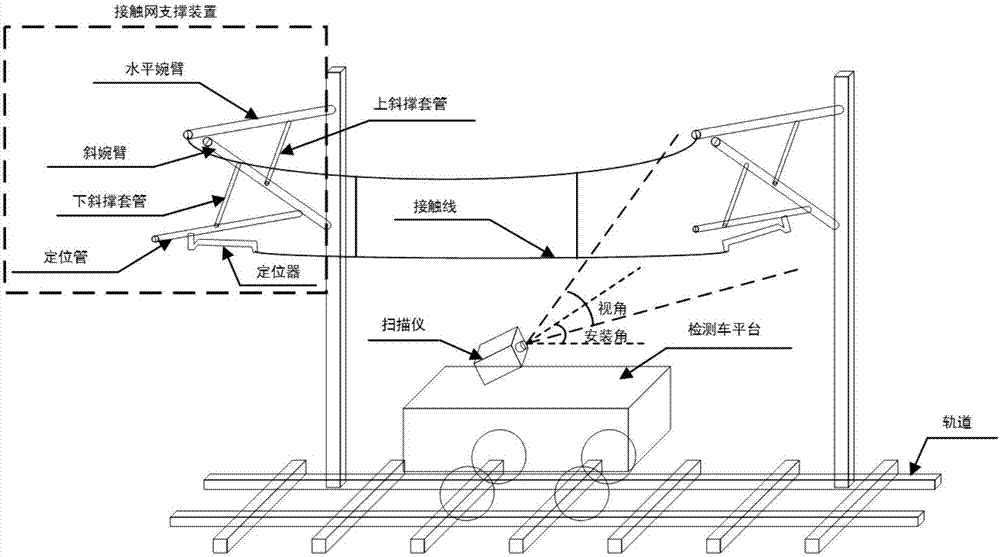

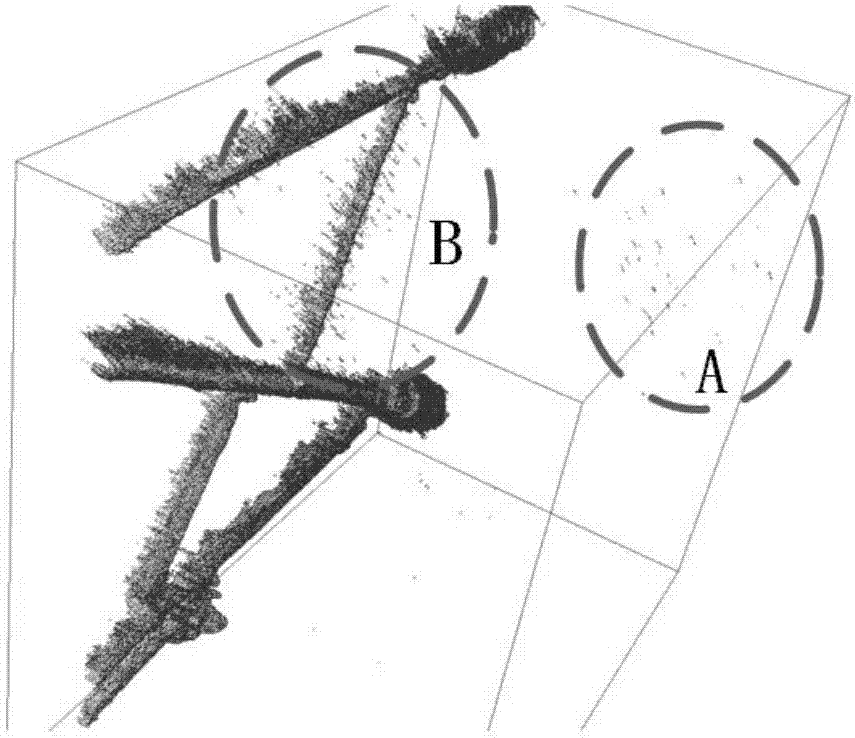

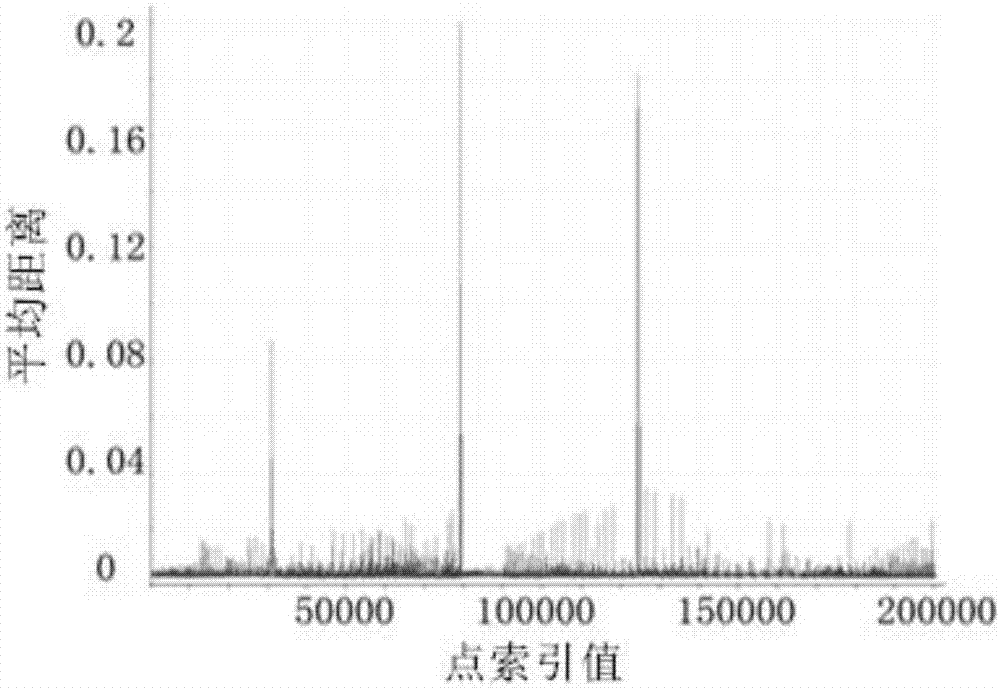

Overhead line device parameter detection method based on BIM and three-dimensional point cloud fusion

InactiveCN107578400AHigh precisionReduce total timeImage enhancementImage analysisReal time acquisitionDevice parameters

The present invention discloses an overhead line device parameter detection method based on BIM and three-dimensional point cloud fusion. The method includes acquiring the three-dimensional point cloud image of an overhead line support device in real time; preprocessing the point cloud data of overhead line support device to realize point cloud data de-noising and structure plane detection and correction; establishing an overhead line BIM model and performing the point cloud processing to generate the standard overhead line support device point cloud data; registering the preprocessed overheadline support device point cloud data and the standard overhead line support device point cloud data to realize the registration segmentation of the overhead line support device point cloud data; andperforming the column structural component extraction on the local areas after the overhead line support device point cloud data segmentation to calculate the geometric structur parameters of the overhead line support device. According to the method, the processing time of the system is effectively shortened, and the accuracy and the real-timeness of system detection are improved, and the requirements of online detection on the geometric structure parameters of the high-speed railway overhead line support device on real-timeness and precision are met.

Owner:SOUTHWEST JIAOTONG UNIV

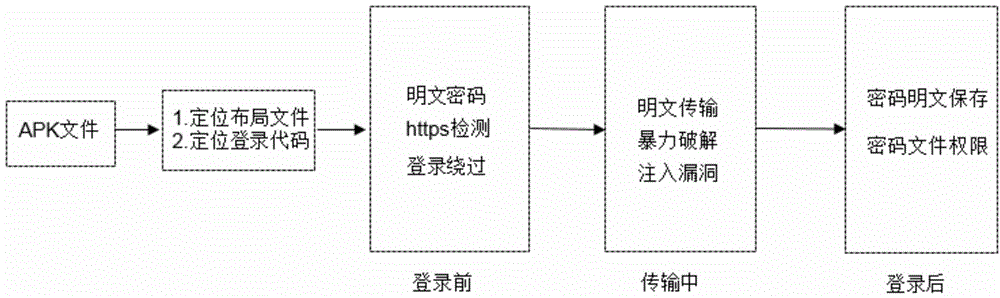

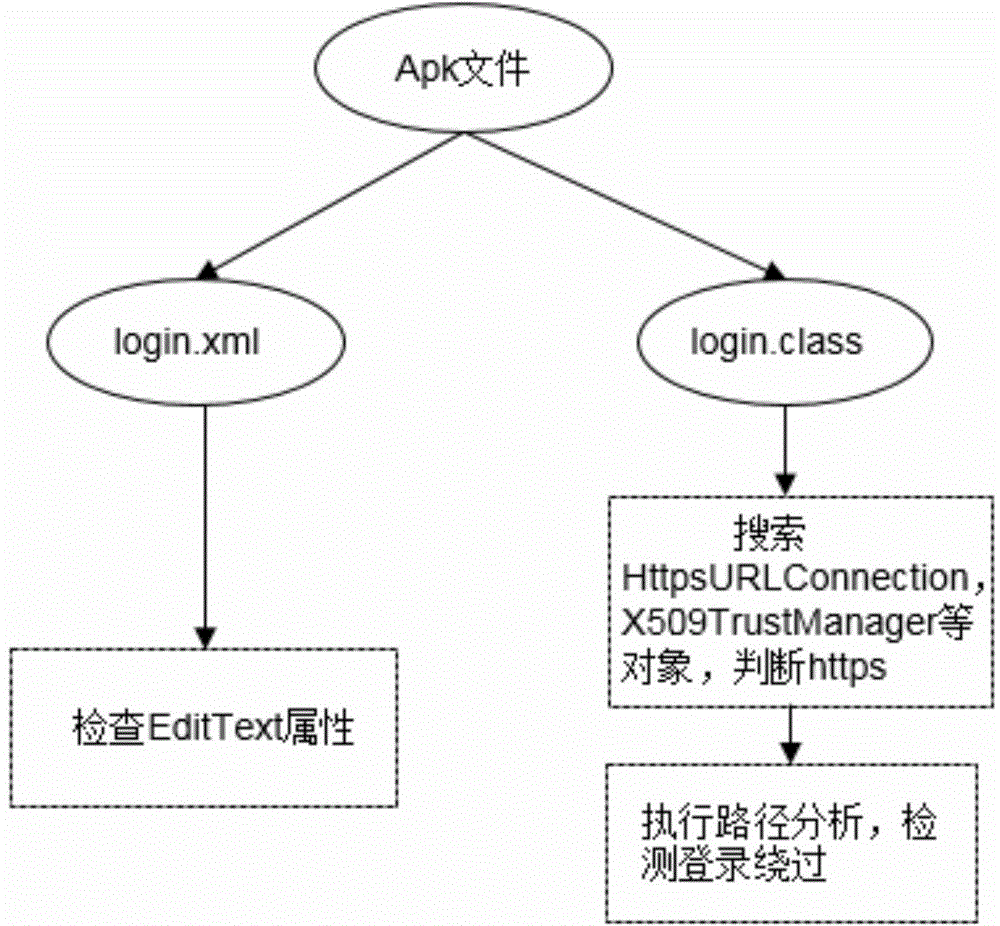

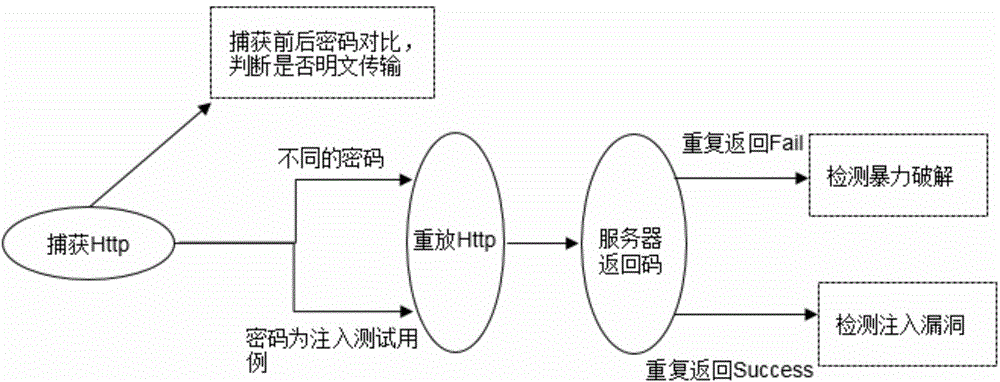

Method for detecting safety of user login interface of Android software

ActiveCN104683327AImprove detection efficiency and accuracyMany detection pointsTransmissionFeature matchingSafety testing

The invention relates to a method for detecting the safety of a user login interface of Android software. The method comprises the steps of firstly, analyzing an apk (Android Package) of the Android software, and locating related codes of a login page by using a feature matching method; then, abstracting a user login behavior into three stages of login pre-processing, data package transmission and login post-processing, establishing a detecting model, and carrying out safety testing on key nodes which easily cause a safety problem; finally, judging nodes having the safety problem according to an execution situation of the codes and a feedback situation of a server, carrying out safety evaluation, and analyzing the existing safety problem. According to the method disclosed by the invention, the detection is carried out aiming at the safety of the login page of the Android software, covered detection points are multiple, and the detection efficiency and the detection accuracy are high.

Owner:INST OF INFORMATION ENG CAS

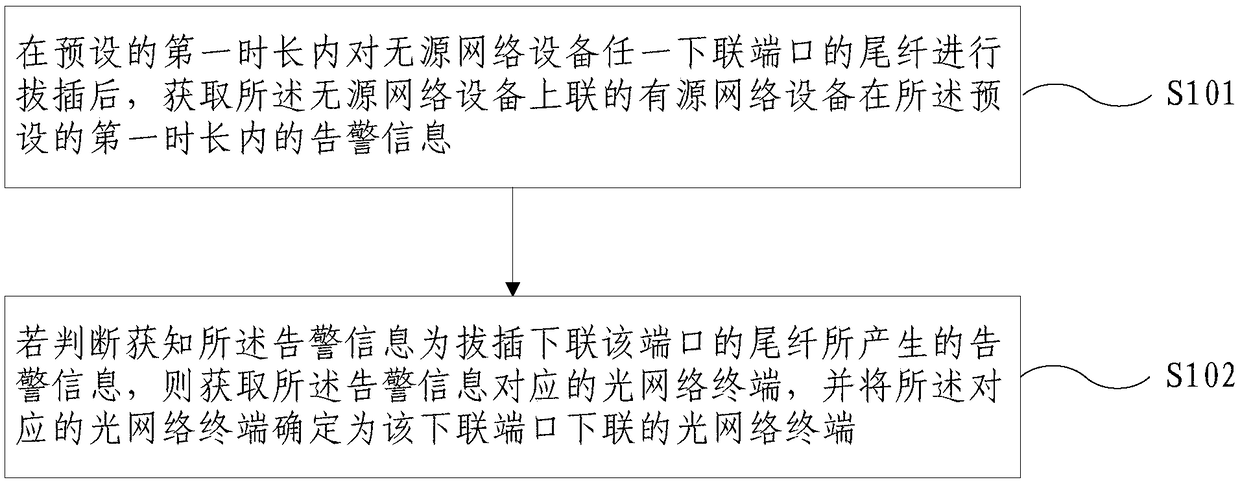

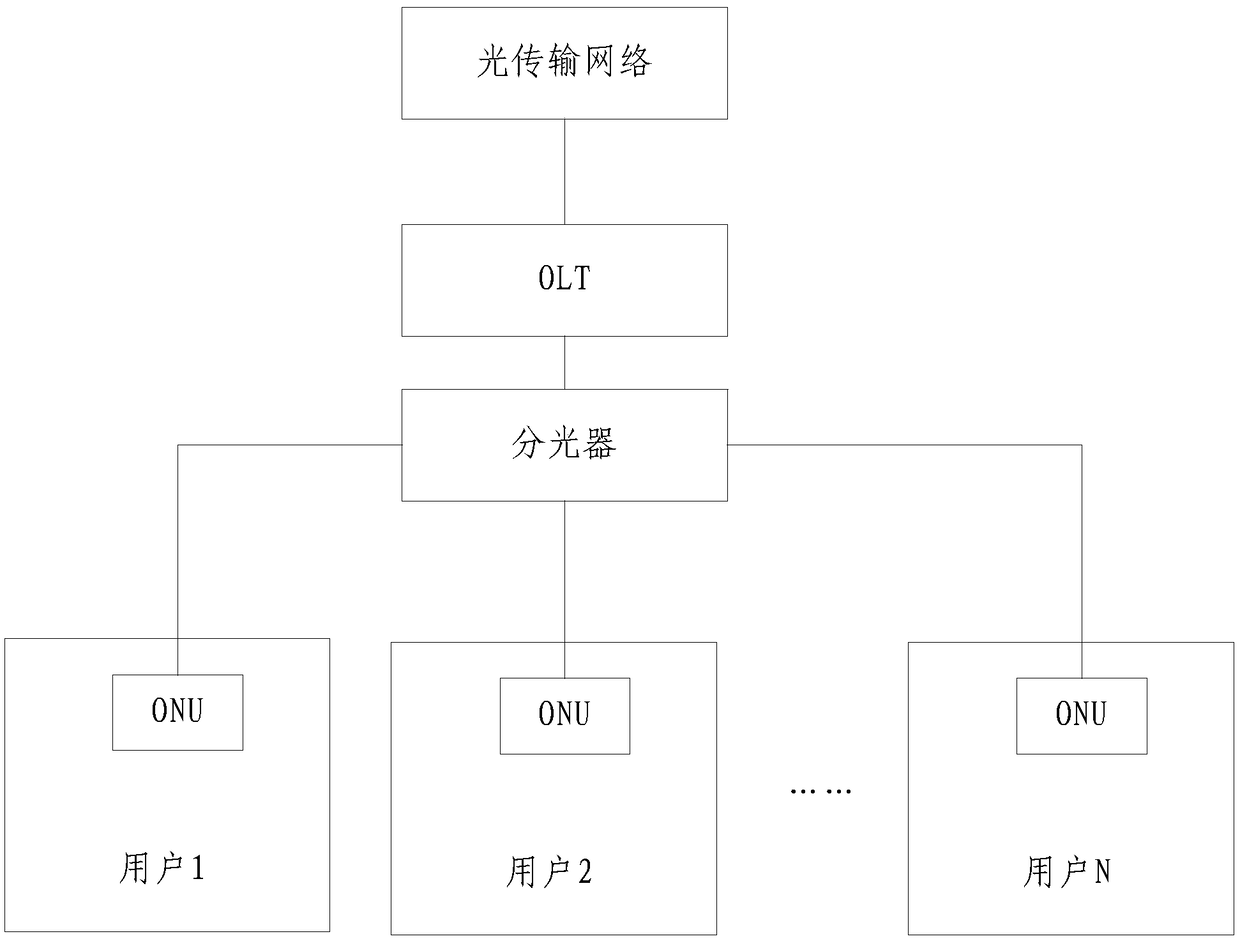

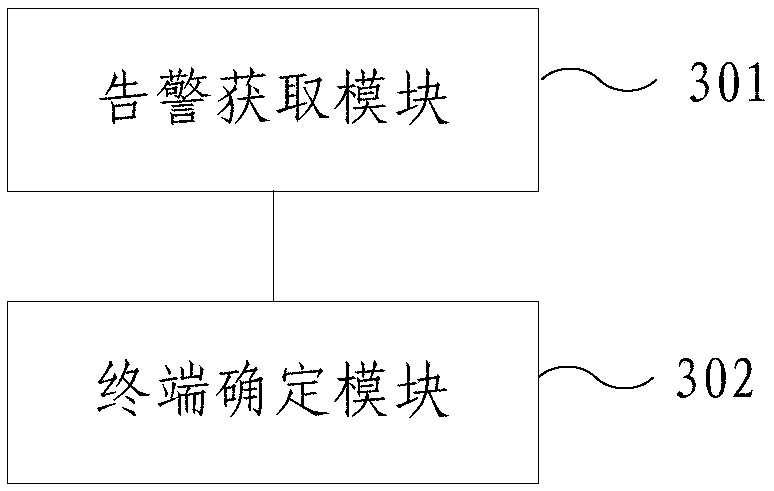

Method and system for detecting port state of network device

ActiveCN109218857AAvoid Resource InventoryImprove detection efficiency and accuracyMultiplex system selection arrangementsElectromagnetic transmissionOptical network terminalNetwork Access Device

The embodiment of the present invention provides a method and system for detecting the port state of a network device. The method includes: acquiring the alarm information of an active network deviceconnected to a passive network device within a preset first time period after the tail fiber of any downlink port of the passive network device is plugged in and out within the preset first time period; if it is determined that the alarm information is the alarm information generated by plugging in and out the tail fiber of the downlink port, acquiring an optical network terminal corresponding tothe alarm information and determining the corresponding optical network terminal as an optical network terminal connected to the downlink port. The method and system for detecting the port state of the network device provided by the embodiment of the present invention can quickly and accurately obtain a corresponding relationship between the downlink port of the passive network device and the optical network terminal, and improve the detection efficiency and accuracy of the port state of the network device.

Owner:BEIJING MATARNET TECH

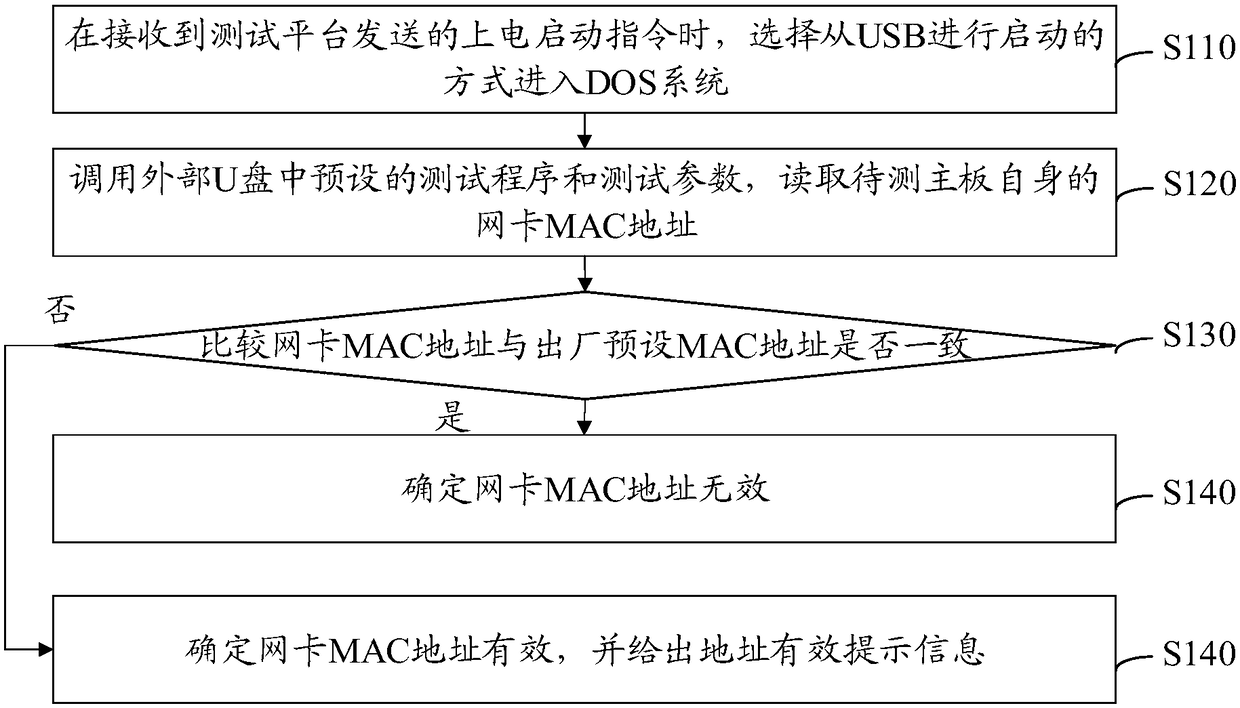

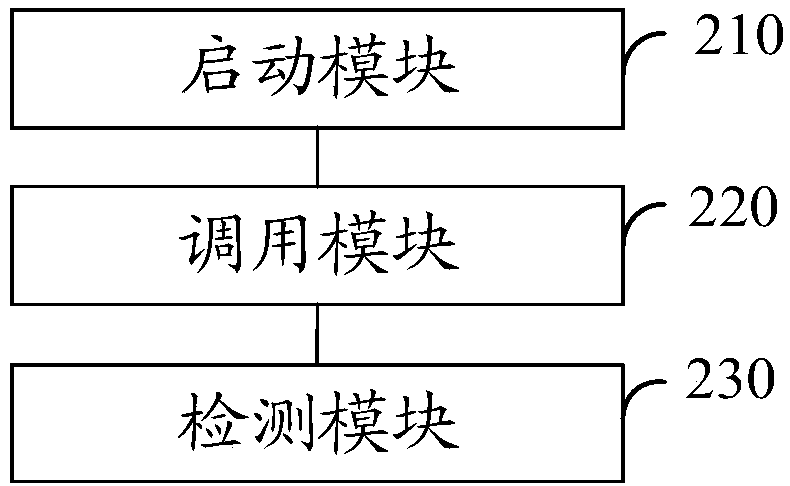

Network card MAC address detection method and device

InactiveCN108632107AAvoid mistakesImprove detection efficiency and accuracyData switching networksComputer hardwareMAC address

The invention relates to a network card MAC address detection method and a network card MAC address detection device. According to the network card MAC address detection method and the network card MAC address detection device, the startup of a mainboard to be detected is controlled by means of a test platform, that is, a method of booting from USB is selected to enter a DOS system when a power-onstartup instruction sent by the test platform is received, then a test program and test parameters preset in an external U disk can be called to read a network card MAC address of the mainboard to bedetected, the network card MAC address is compared with a factory default MAC address, and the network card MAC address is determined to be invalid when the network card MAC address is consistent with the factory default MAC address, thereby realizing the detection of the network card MAC address. During the detection process, the tedious operations of starting and checking the mainboard by a tester are not needed, the network card MAC address is read by calling the test program and is compared with the factory default MAC address, thus the detection of the network card MAC address can be realized, the problem that errors can be easily caused by the tester during the manual detection process due to subjective factors and the like can be avoided, and the detection efficiency and precisioncan be improved.

Owner:EVOC INTELLIGENT TECH

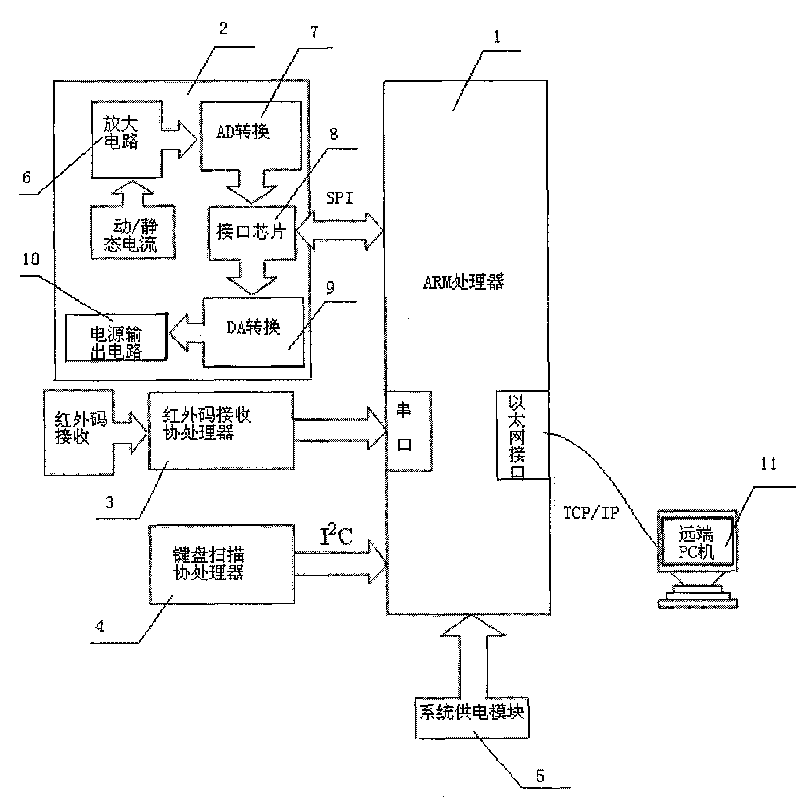

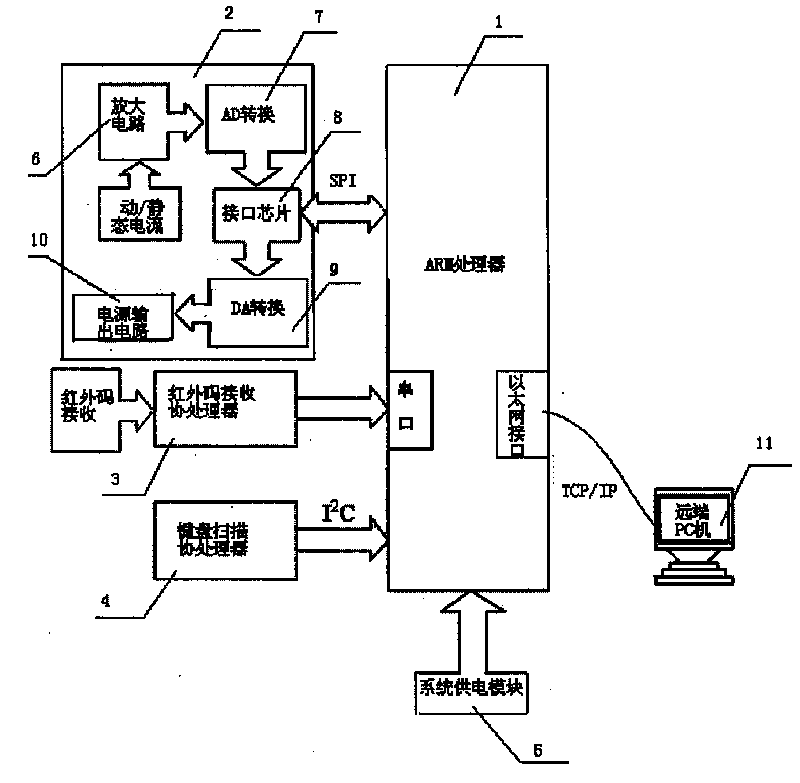

Device for real-time detecting product of production line of remote control

ActiveCN101692105AImprove detection efficiency and accuracyImplement automatic detectionNon-electrical signal transmission systemsElectrical testingEmbedded systemVoltage regulation

The invention discloses a device for real-time detecting a product of the production line of remote control, which can automatically detects parameters of the remote control such as dynamic current, quiescent current and the like, and improve detection efficiency and accuracy. The detection data can also be transmitted to an upper PC for database management, being convenient for real-time detecting product percent of pass. The invention comprises an embedded CPU module 1, a dynamic and quiescent current detecting and voltage regulating module 2, an infrared code receiving co-processor 3, a keyboard scanning co-processor 4, and a system power supplying module 5. The embedded CPU module is ARM 9 processor, is communicated with the dynamic and quiescent current detecting and voltage regulating module 2 via an SPI bus, is communicated with the infrared code receiving co-processor 3 via a serial port, and is communicated with the keyboard scanning co-processor 4 via an I2C bus. The system power supplying module 5 is connected with the embedded CPU module 1 and supplies power to the embedded CPU module 1.

Owner:JIANGSU HUITONG GRP

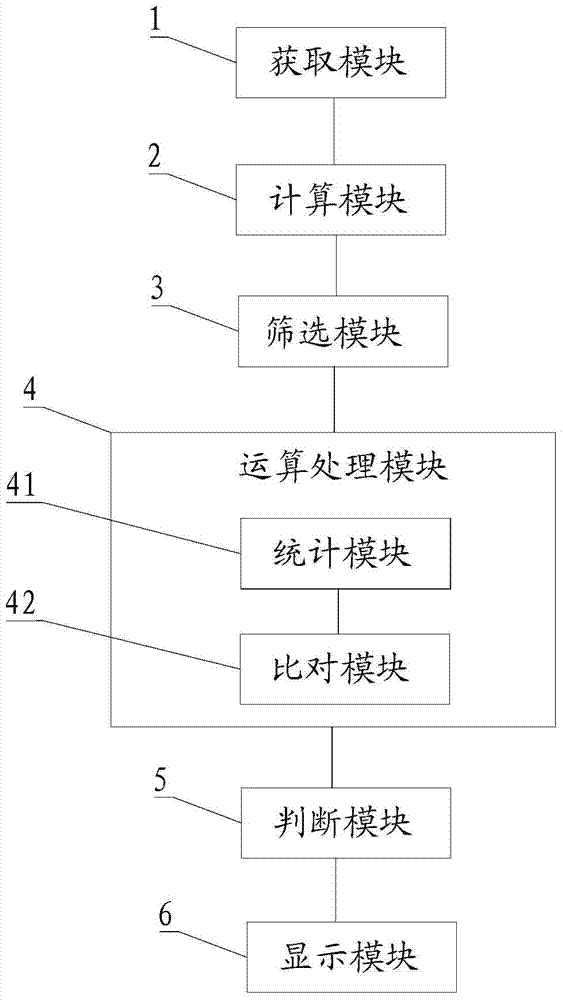

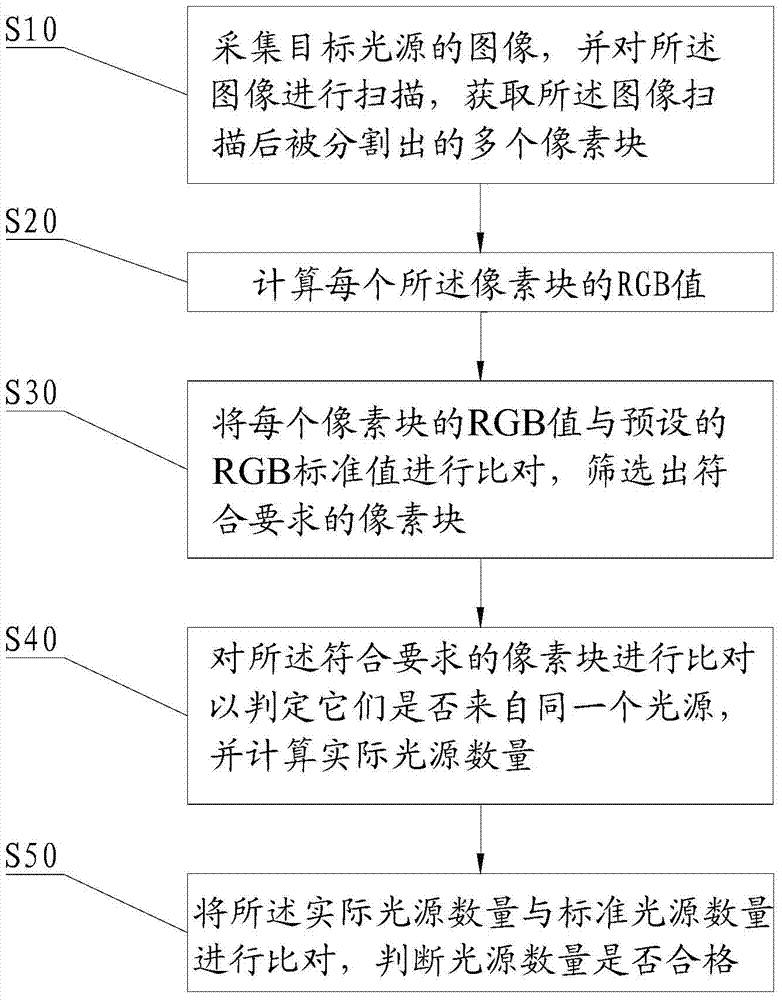

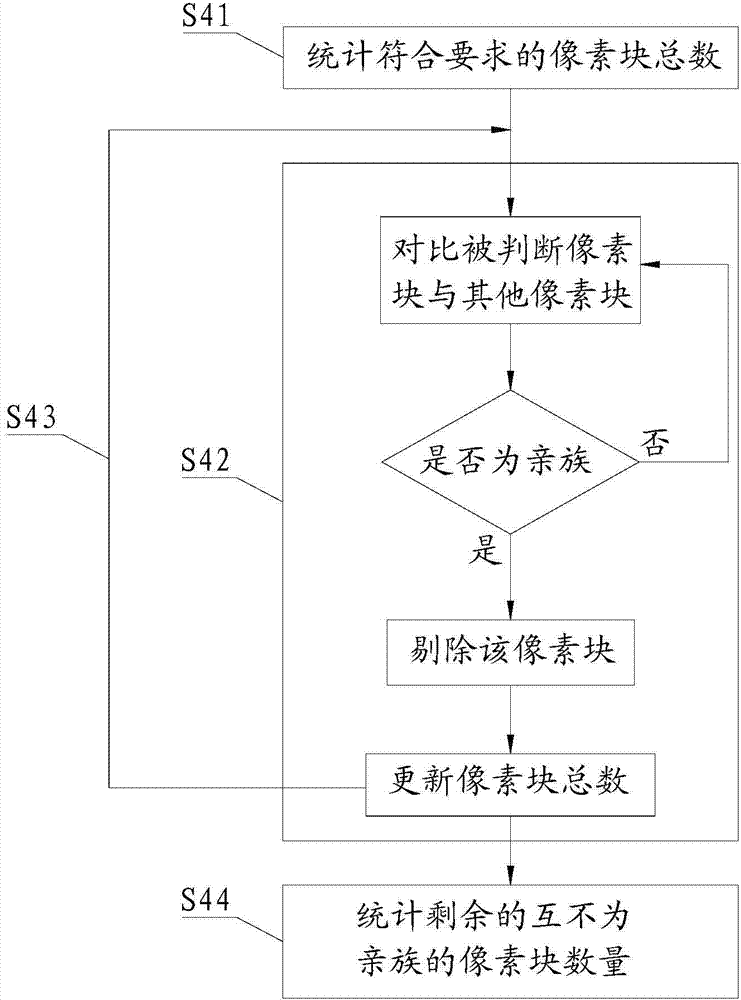

Light source detecting system and method

ActiveCN104766310AImprove detection efficiency and accuracyProtect eyesightImage analysisLight sourceStandard illuminant

The invention discloses a light source detecting method. The method comprises the steps that an image of a target light source is collected and scanned, and a plurality of pixel blocks formed by dividing the image after the image is scanned are obtained; an RGB value of each pixel block is calculated; the RGB value of each pixel block is compared with a preset RGB standard value so that the pixel blocks meeting the requirement can be screened out; the pixel blocks meeting the requirement are compared to judge whether the pixel blocks come from the same light source, and the number of actual light sources is calculated; the number of the actual light sources and the number of standard light sources are compared to judge whether the number of the light sources is qualified. The invention further discloses a light source detecting system. According to the detecting method, on the basis of finishing detecting the light source quality, the number of the light sources meeting the light emitting quality is calculated automatically, whether the number is qualified is judged, and therefore the detecting efficiency and the detecting accuracy are improved greatly.

Owner:XIAMEN TOPSTAR LIGHTING

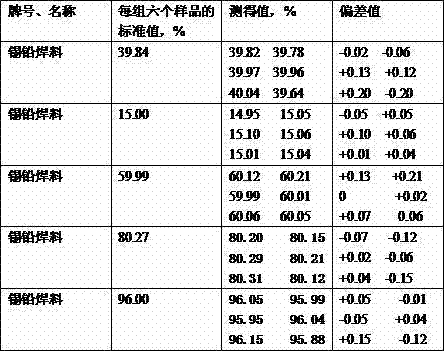

Method for determination of tin content in tin-lead solder by complexometric titration method

InactiveCN104515826ASimple and efficient operationImprove detection efficiency and accuracyChemical analysis using titrationStandard solutionComplexometric titration

The invention relates to the field of tin-lead solder detection, and in particular relates to a method for the determination of tin content in tin-lead solder by complexometric titration method. The steps are as follows: a tin-lead solder specimen is weighed and placed in a triangular beaker; 8ml hydrochloric acid and 1-2ml nitric acid are added, the tin-lead solder specimen is heated and dissolved at low temperature, EDTA and water are added, the triangular beaker is placed on an electric furnace for heating to boil for 1 to 2 minutes to dissolve salts, the triangular beaker is taken down and cooled to room temperature; extensive ph indicator paper is added, hexamethylenetetramine solution is added for about six times until the extensive ph indicator paper just turns yellow, then excess 5 ml of the hexamethylenetetramine solution is added, two drops of xylenol orange indicator is added, a zinc standard solution is added for titration until the solution just turns red and does not fade; solid sodium trifluoride is added, the solution is shaken evenly and stood still for 5 minutes; and the zinc standard solution is added for titration until the solution just turns red and does not fade to reach the terminal point; the tin percent content can be calculated by the result analysis, the method for the determination of tin content in tin-lead solder by complexometric titration method is simple in operation, a tin reduction device is not needed, and the detection efficiency and accuracy can be improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

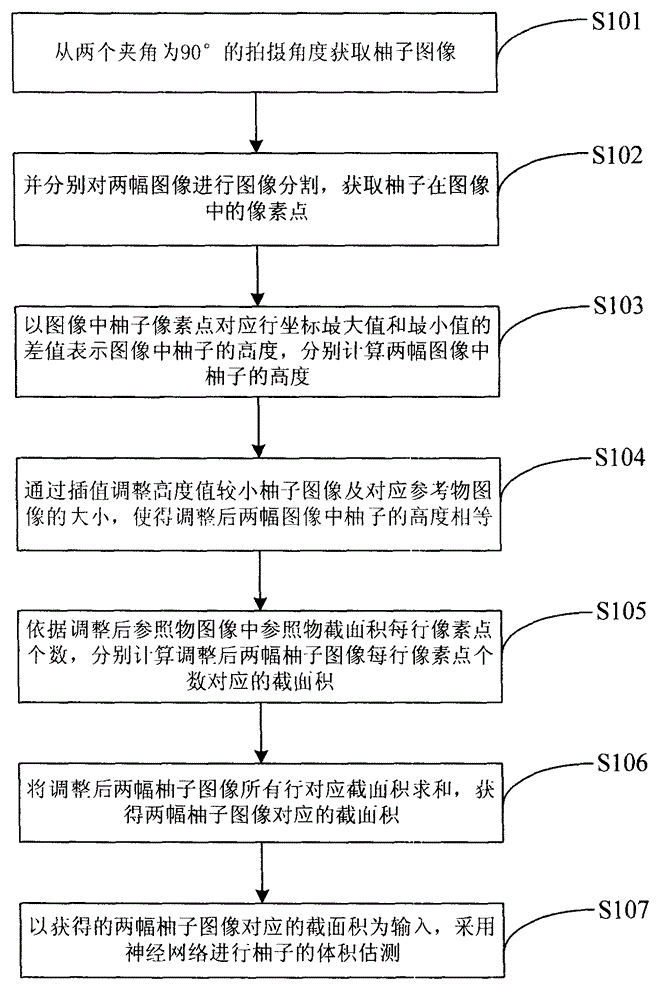

Grapefruit size estimating method based on binocular vision

InactiveCN103148781AImprove collection conditionsImprove detection efficiency and accuracyImage analysisUsing optical meansImage capturePattern recognition

The invention discloses a grapefruit size estimating method based on binocular vision. Grapefruit images are obtained by using two shooting angles, wherein included angles of the two shooting angles are ninety degrees. The grapefruit images are segmented and pixel points in the images are obtained. Corresponding cross section areas of the grapefruit images are obtained. Grapefruit image capture conditions are improved and accurate estimation to grapefruit sizes are achieved by utilizing a neural network. Detecting efficiency and accuracy are high. Former problems are well solved. The grapefruit size estimating method based on the binocular vision is strong in practicability, convenient to operate and capable of having good values of popularization and application.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

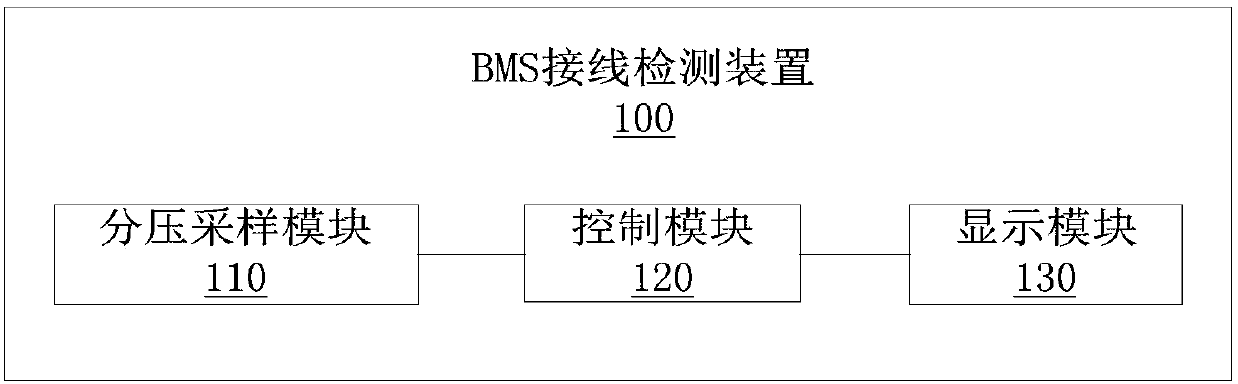

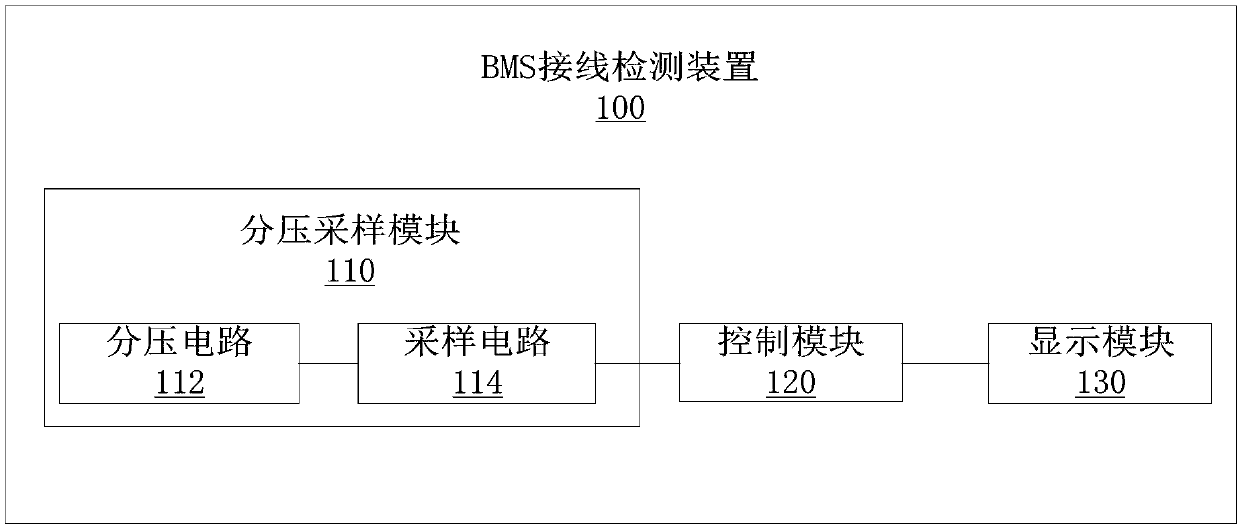

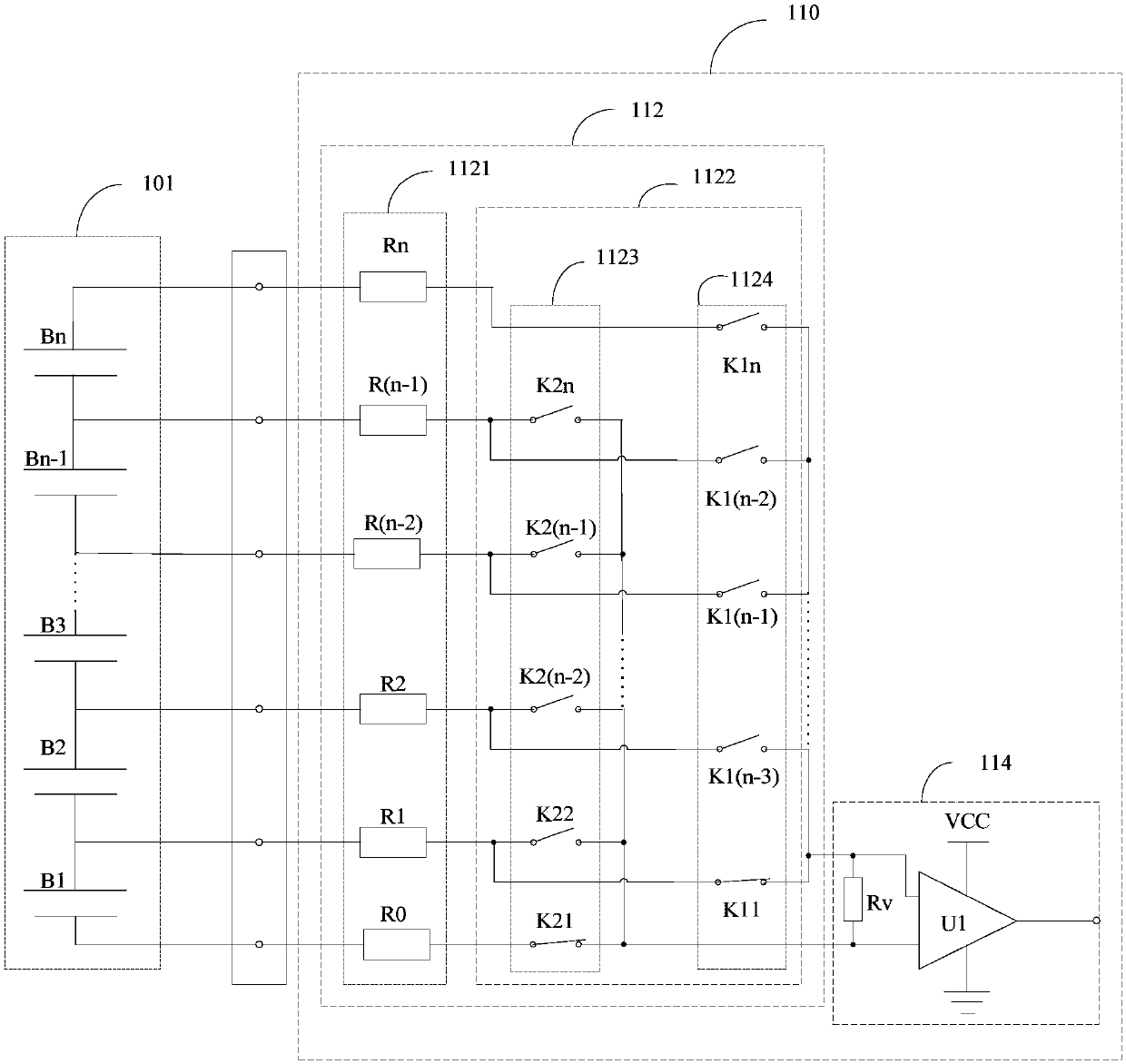

BMS (battery management system) wiring detection device and method

InactiveCN107870283AImprove detection efficiency and accuracyImprove securityElectric connection testingEngineeringBattery management systems

The invention provides a BMS (battery management system) wiring detection device and method and belongs to battery application technology. The BMS wiring detection device comprises a voltage-dividingsampling module, a control module and a display module; the voltage-dividing sampling module performs voltage-dividing sampling on voltage of two adjacent sampling wires of a wring harness to acquirethe voltage of the two adjacent sampling lines of the wiring harness, and the control module judges whether line sequence of the wiring harness is correct or not according to the voltage of the two adjacent sampling lines of the wiring harness and controls to display module to display a corresponding judging result, so that artificial intervention is not needed for wiring detection of a BMS, detection results are displayed directly through the display module, detection efficiency and accuracy are improved, and safety of BMS is improved.

Owner:山东谦恒电子科技有限公司

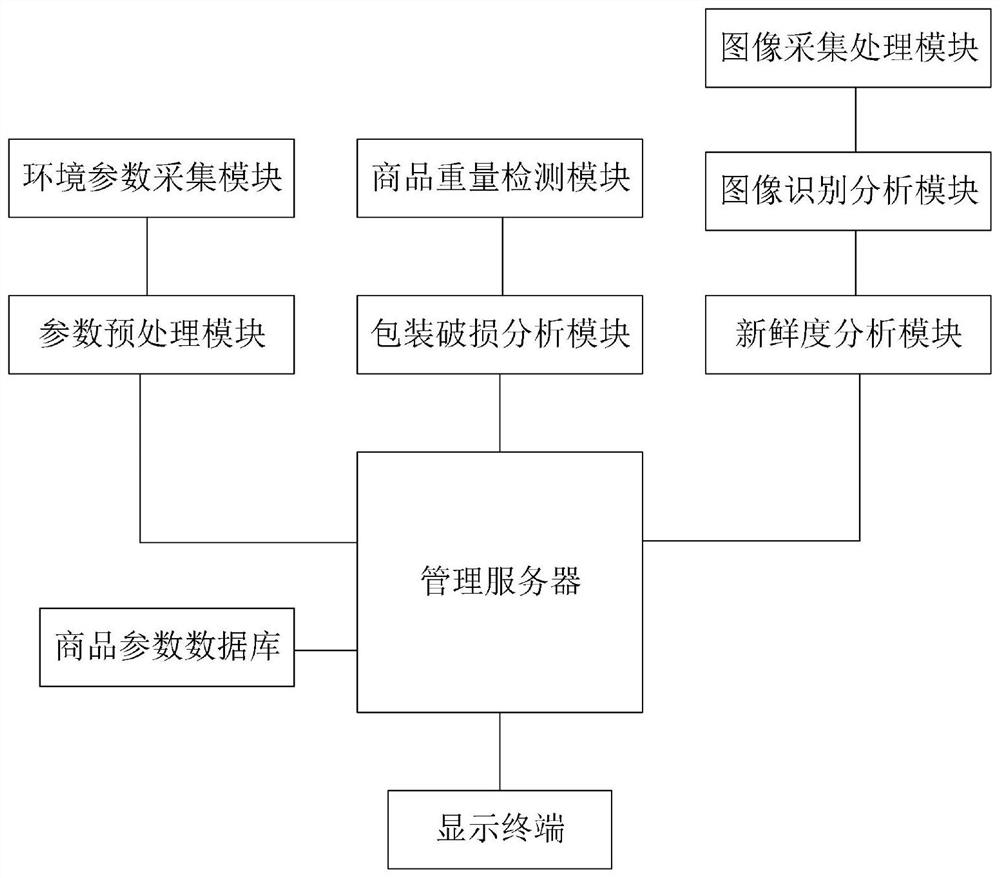

Fresh commodity safety intelligent detection management system based on big data

ActiveCN111721719AImprove detection efficiency and accuracyImprove detection efficiencyCharacter and pattern recognitionOptically investigating flaws/contaminationProcess engineeringManagement system

The invention discloses a fresh commodity safety intelligent detection management system based on big data. The system comprises a commodity weight detection module, a package damage analysis module,an environmental parameter acquisition module, a parameter preprocessing module, an image acquisition and processing module, an image recognition and analysis module, a commodity parameter database, afreshness analysis module, a management server and a display terminal. According to the invention, a commodity comprehensive eating safety coefficient is evaluated by considering factors such as weight change, temperature change, humidity change, peculiar smell concentration, commodity color, volume and existence of scratches and mildew spots on the surface of the commodity, and analyzing a commodity package breakage coefficient, a temperature safety influence coefficient, a humidity safety influence coefficient, a peculiar smell influence coefficient and commodity freshness, reference is provided for later commodity storage, the commodity eating safety detection efficiency and accuracy are improved, a lot of manpower cost is reduced, and commodity safety is guaranteed.

Owner:罗嗣扬

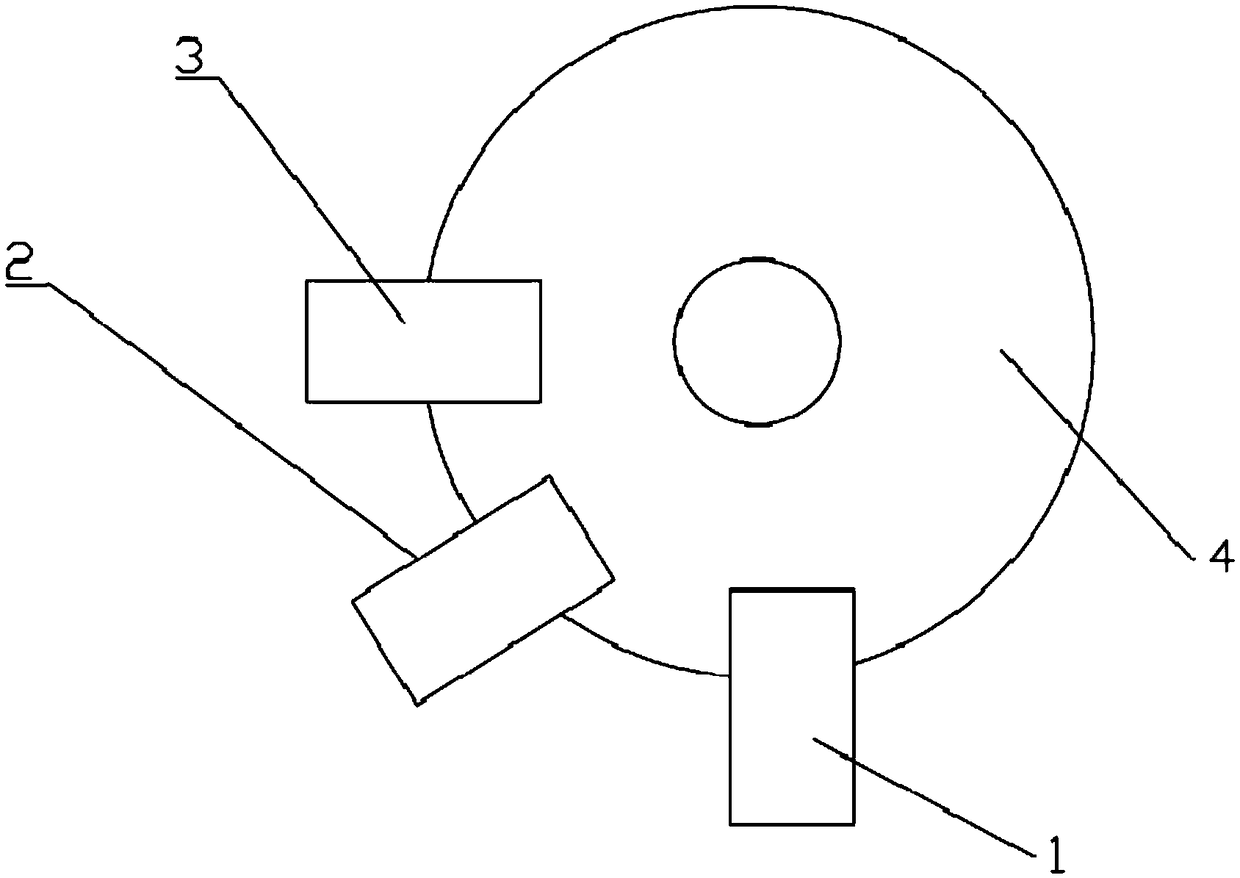

Visual inspection system and method for temperature controller casing

PendingCN108844961AImprove detection efficiency and accuracyImprove detection efficiencyOptically investigating flaws/contaminationUsing optical meansImage analysisEngineering

The invention discloses a visual inspection system and method for a temperature controller casing. The system comprises a glass turntable, a first position, a second position and a third position, wherein the first position, the second position and the third position are arranged along the edge of the glass turntable; a camera of the first position is used for shooting bottom outer ring images ofa measured temperature controller casing; a camera of the second position is used for shooting bottom inner ring images of the measured temperature controller casing; a camera of the third position isused for shooting top images of the measured temperature controller casing. Surface defect conditions of different areas of the temperature controller casing can be automatically detected, the imagesof the surface defect conditions can be automatically collected, the defect problems of the top and the bottom of the casing are found out by image analysis, and detection efficiency and accuracy areimproved; the system and method can be applied to the field of machine vision measurement systems.

Owner:FOSHAN UNIVERSITY

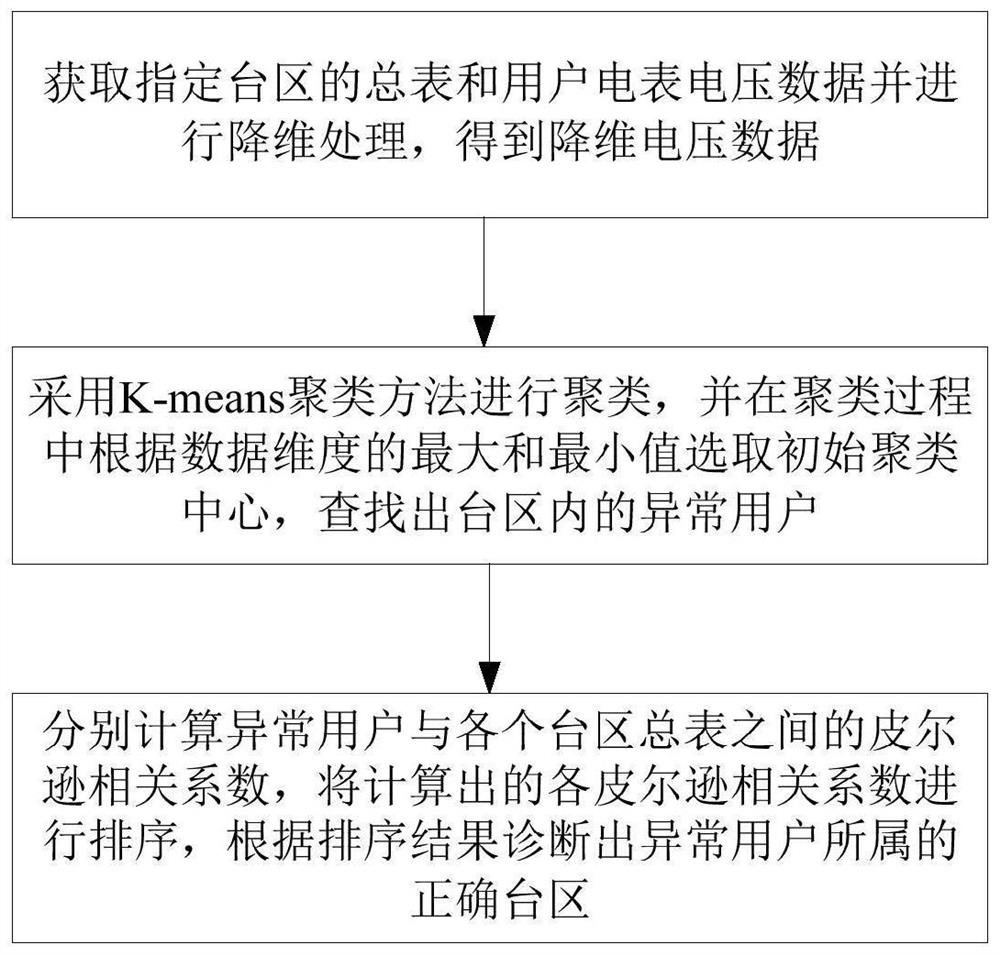

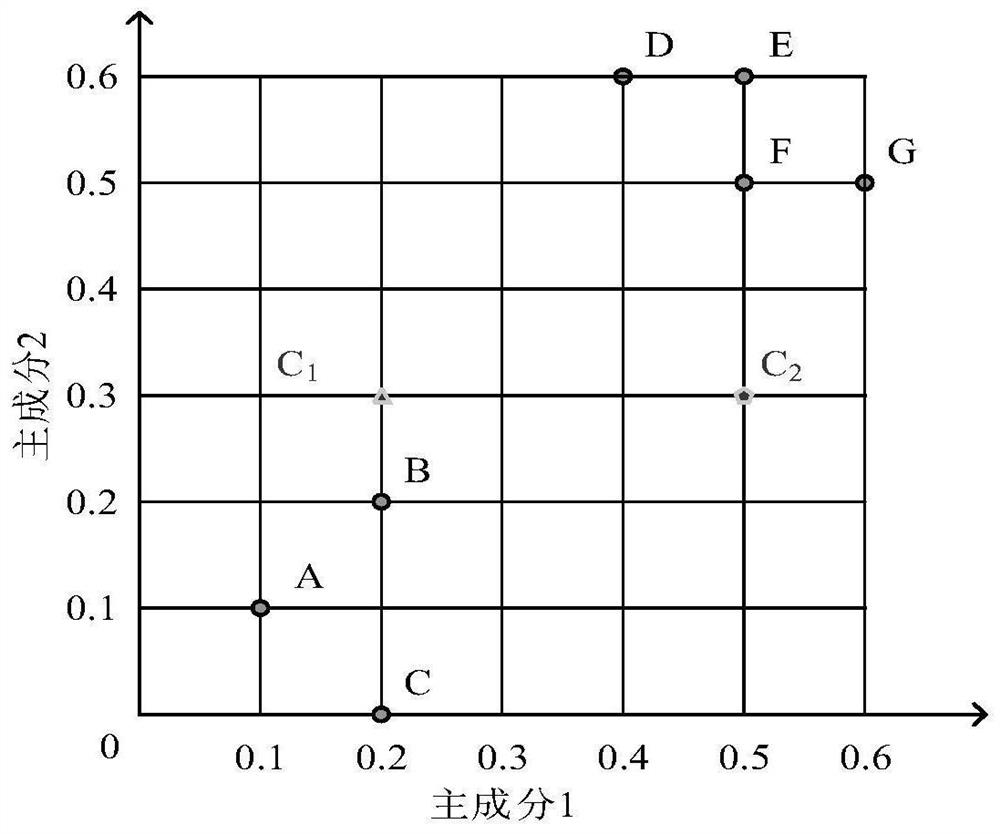

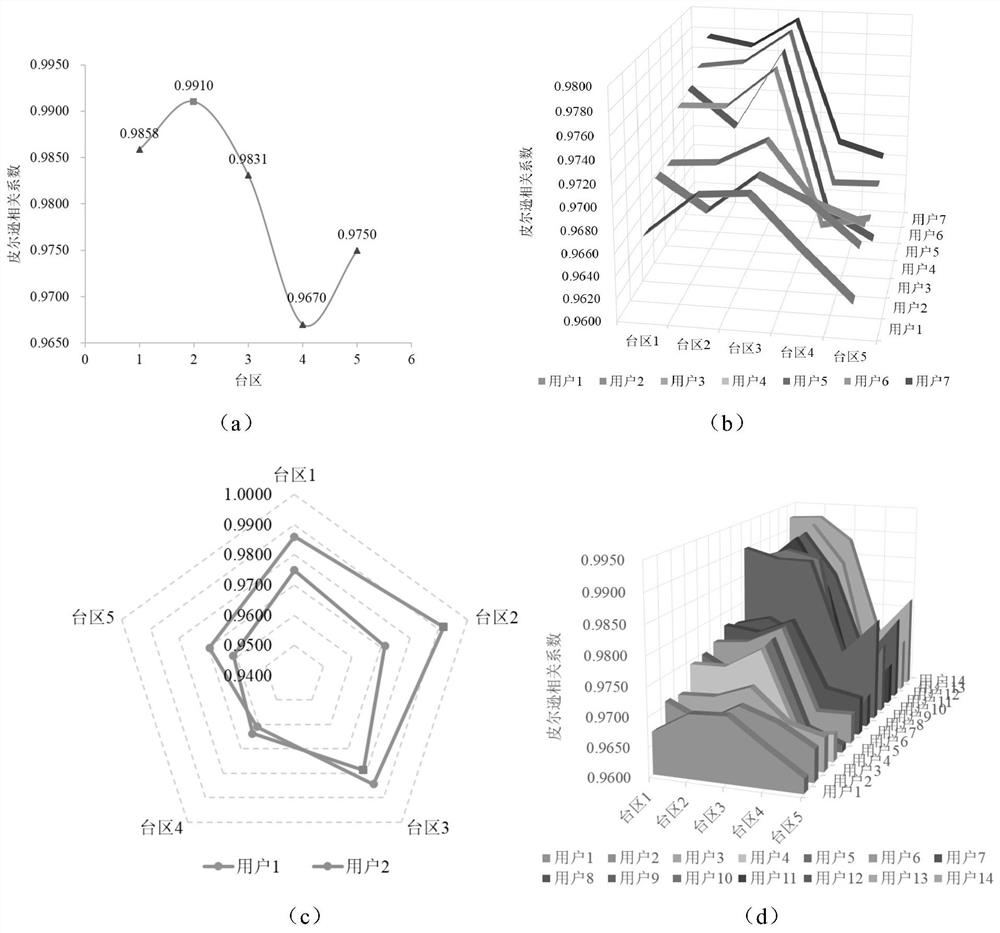

Transformer area user-transformer relation abnormity diagnosis method and device

PendingCN112699913AEfficiently implement feature information miningImprove detection efficiency and accuracyCharacter and pattern recognitionElectrical measurementsData scienceTransformer

The invention discloses a transformer area user-transformer relation abnormity diagnosis method and device, and the method comprises the steps: S01, obtaining a total meter and user ammeter voltage data of a specified transformer area, and carrying out the dimension reduction processing, and obtaining dimension-reduced voltage data; S02, clustering the dimension-reduced voltage data by adopting a Kmeans clustering method, selecting an initial clustering center according to the maximum value and the minimum value of the data dimension in the clustering process, and finding out abnormal users with abnormal user-transformer relationships in a specified transformer area; S03, respectively calculating Pearson correlation coefficients between the abnormal user and each transformer area general table, sorting the calculated Pearson correlation coefficients, and diagnosing a correct transformer area to which the abnormal user belongs according to a sorting result. The method can realize diagnosis of one or more abnormal users in the same transformer area and multiple abnormal users in different transformer areas, and has the advantages of simple realization method, high diagnosis efficiency and precision and the like.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

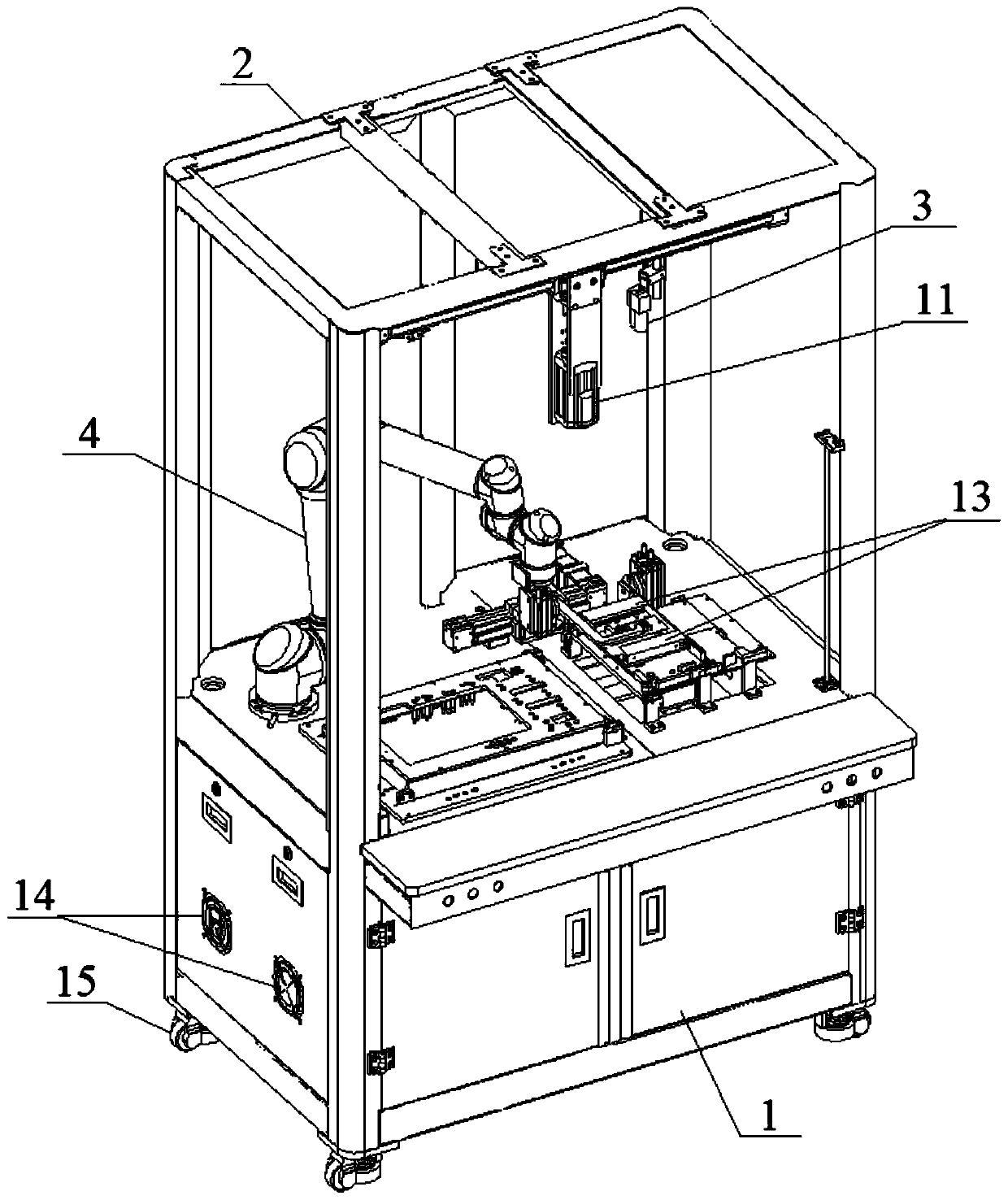

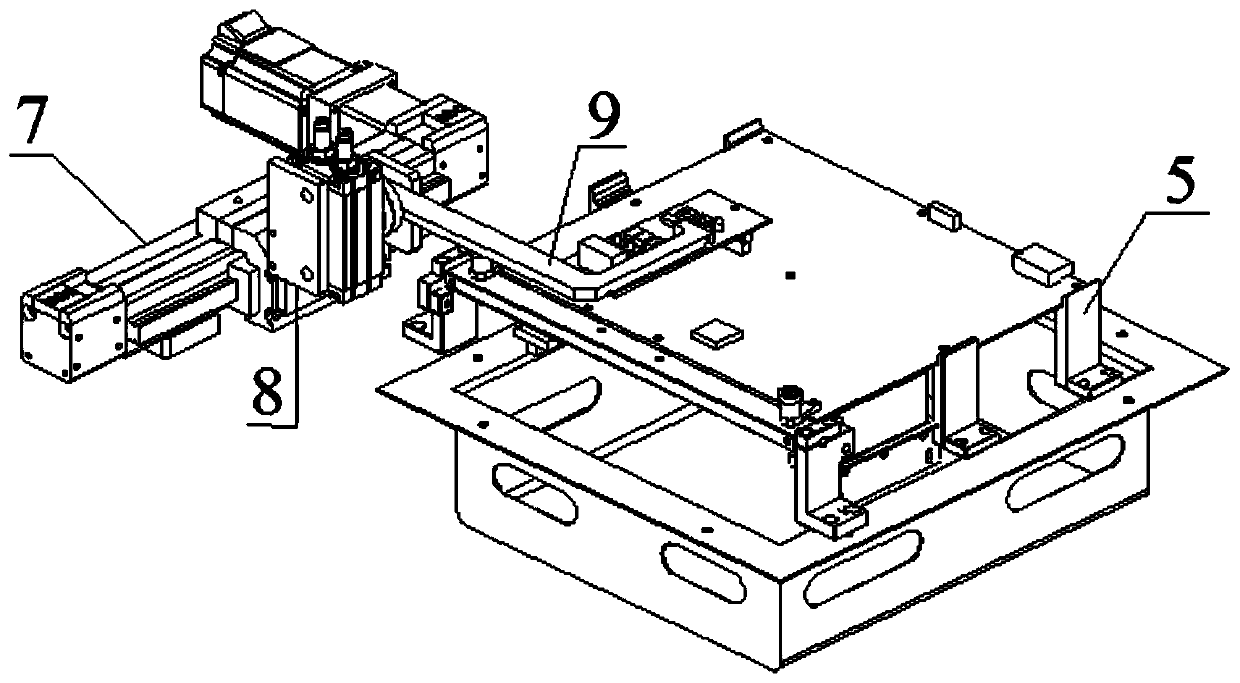

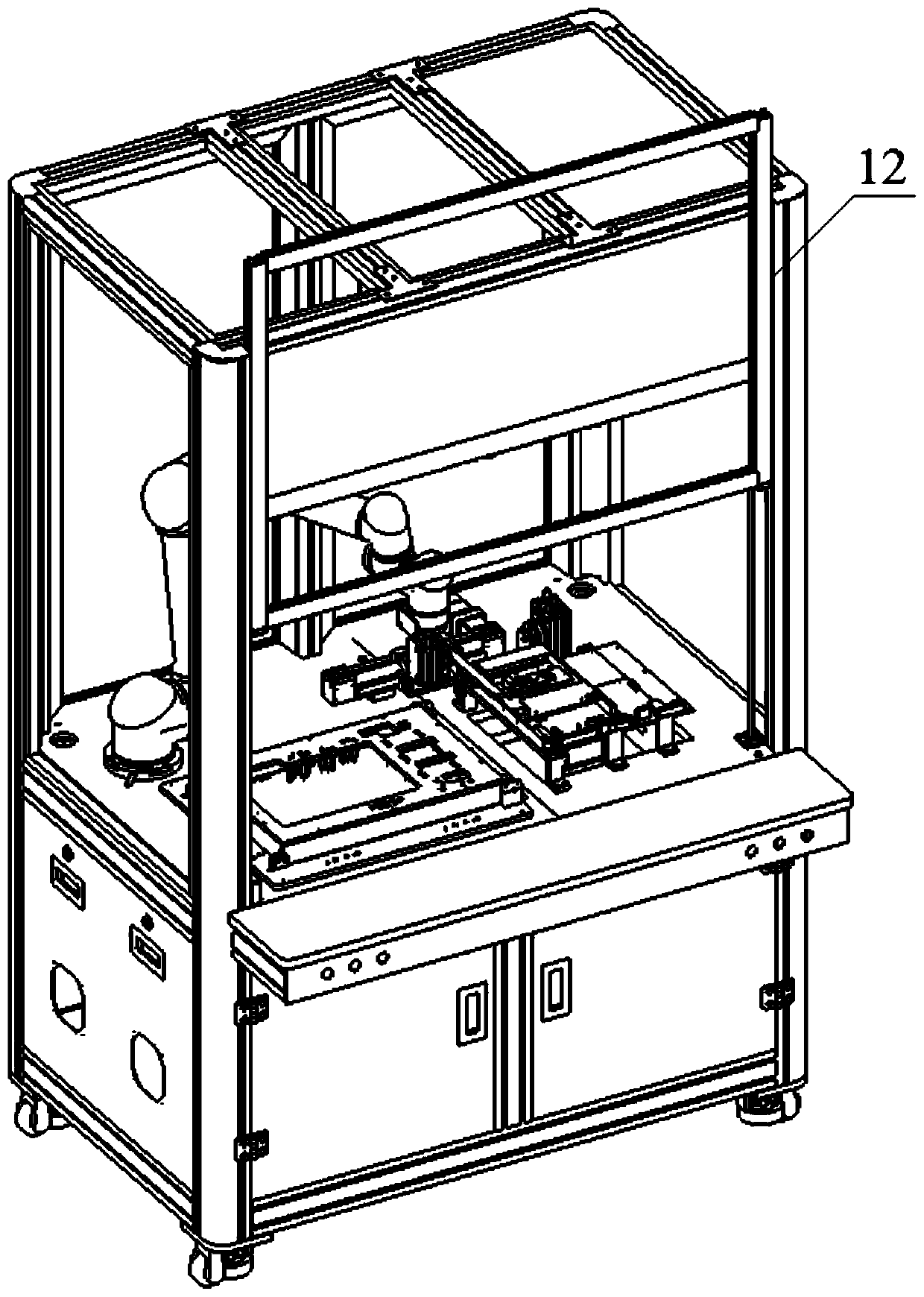

Automatic detecting device and method for PCB board

PendingCN110456254AImprove detection efficiency and accuracyEasy to managePrinted circuit testingAutomated test systemsManipulatorElectrical and Electronics engineering

The invention relates to the technical field of automatic detection, in particular to an automatic detecting device for a PCB board. The automatic detecting device for the PCB board comprises an electric cabinet, a rack, a camera, a manipulator, a positioning detecting device and an upper computer; the rack, the manipulator and the positioning detecting device are mounted on the electric cabinet;the camera is mounted on the top of the rack; the camera, the manipulator and the positioning detecting device are located in the rack; the camera is located above the positioning detecting device; the upper computer is electrically connected to the camera and the manipulator separately; the positioning detecting device is used for fixing the PCB board; the camera is used for obtaining the position and angle information of a rotary dial switch on the PCB board and the digital tube numerical value information on the PCB board; and the manipulator is used for performing dial adjustment on the rotary dial switch on the PCB board. The invention does not require manual adjustment, has high degree of automation, and improves the detection efficiency.

Owner:南京优倍自动化系统有限公司

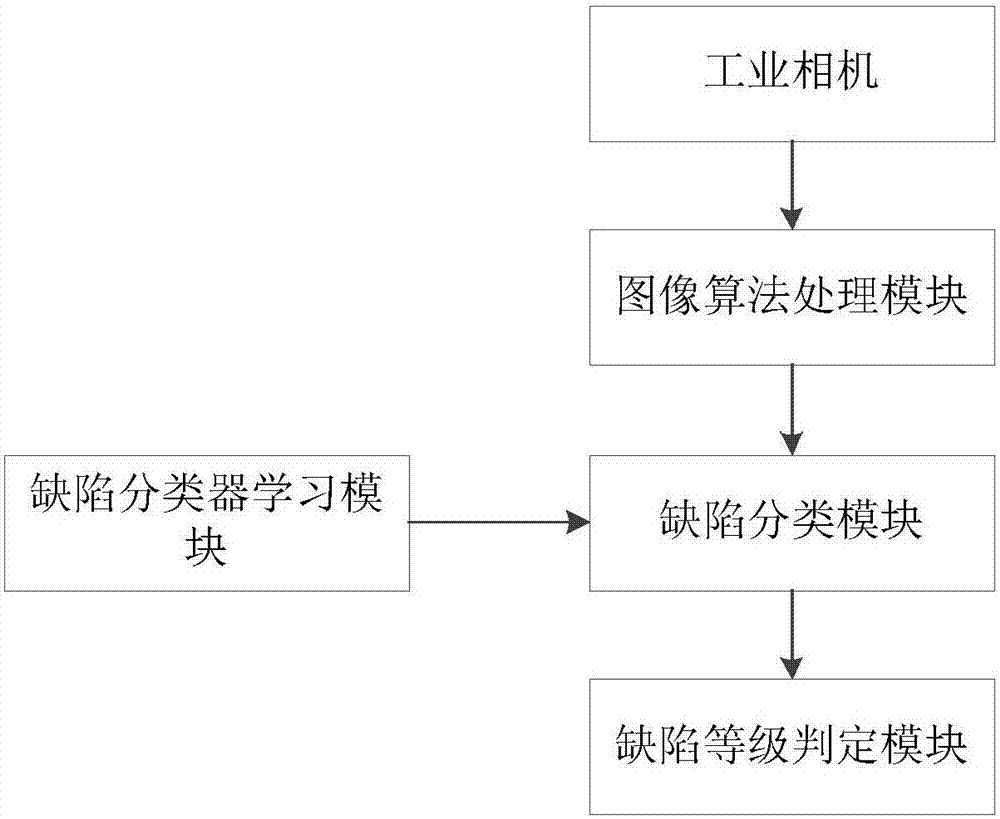

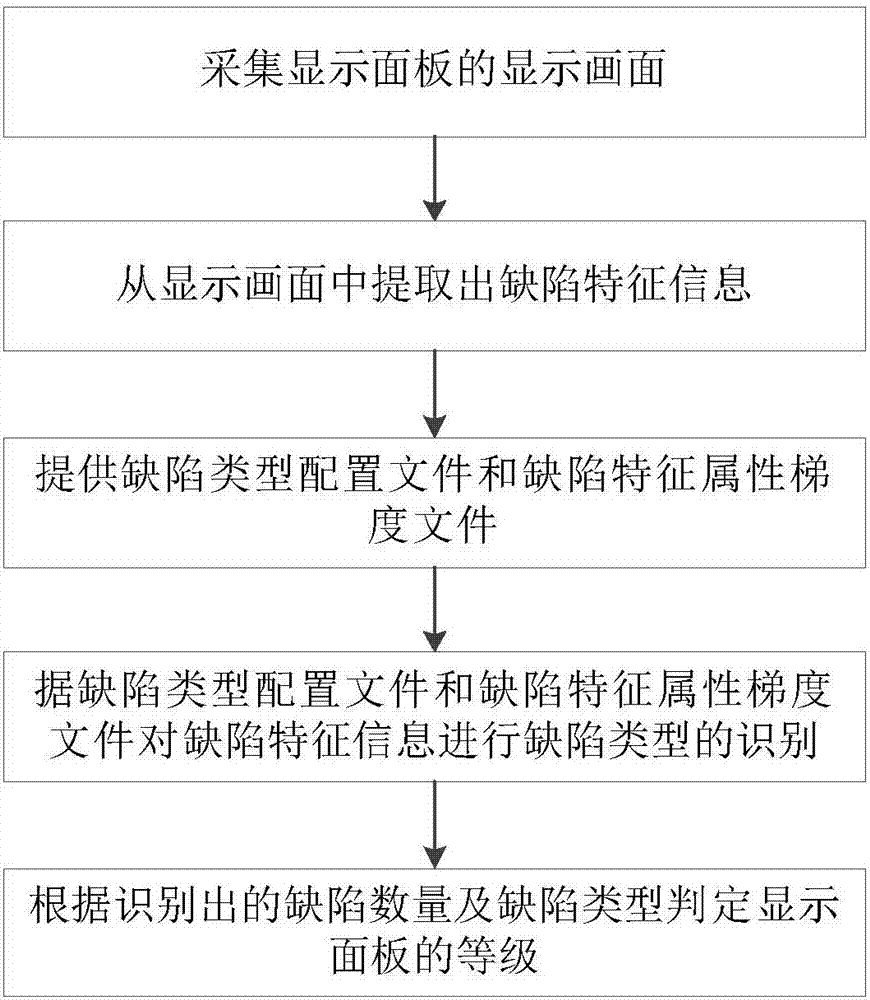

AOI (Automated Optical Inspection)-based display panel defect classification method and device

ActiveCN107290345AImprove detection efficiency and accuracyRealize the degree of automationOptically investigating flaws/contaminationConvolutionAutomated optical inspection

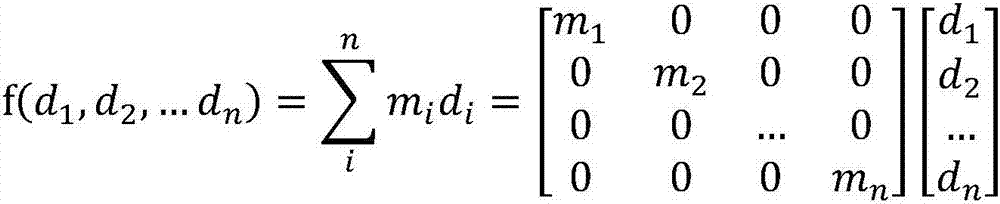

The invention discloses an AOI (Automated Optical Inspection)-based display panel defect classification method and device. The method comprises the following steps: 1) acquiring a display picture of a display panel, and extracting a defect feature attribute vector d of the display picture; and 2) providing a defect feature attribute descriptive set M, wherein the defect feature attribute descriptive set M comprises feature attribute description vectors m of multiple defect types; respectively performing convolution on the defect feature attribute vector d and the feature attribute description vector m of each defect type, and generating a group of convolution values, wherein the defect type corresponding to the maximum convolution value is the defect type of the defect feature attribute vector d. According to the method disclosed by the invention, the automation degree of defect recognition and grade determination of the display panel can be realized by automatically extracting the defect feature information of the display panel and automatically recognizing the quantities and types of the display defects, and the detection efficiency and accuracy of the defect recognition and grade determination of the display panel can be greatly improved.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

Method for detecting position and type of workpiece on subway vehicle side inspection image

PendingCN112418155AReduce labor intensityImprove detection efficiency and accuracyCharacter and pattern recognitionNeural architecturesComputer visionEngineering

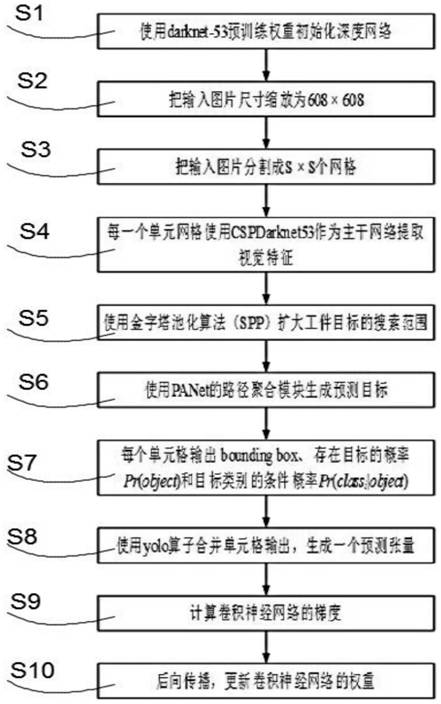

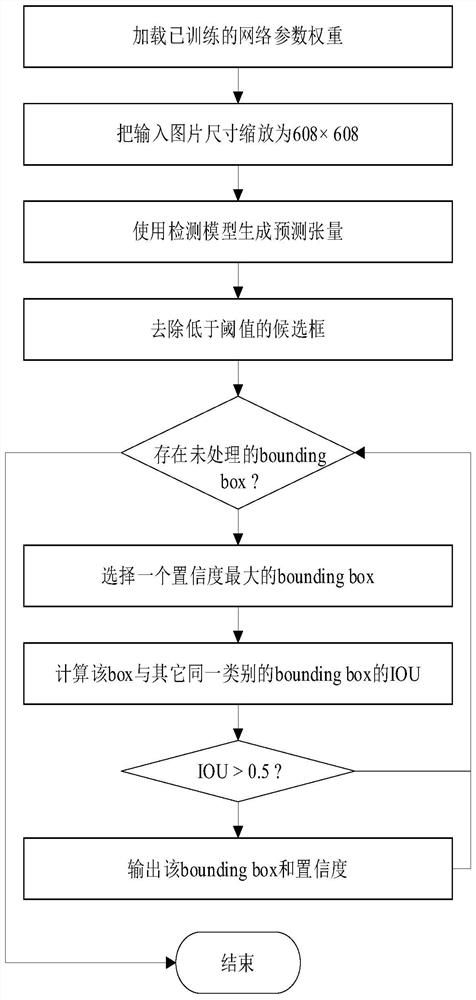

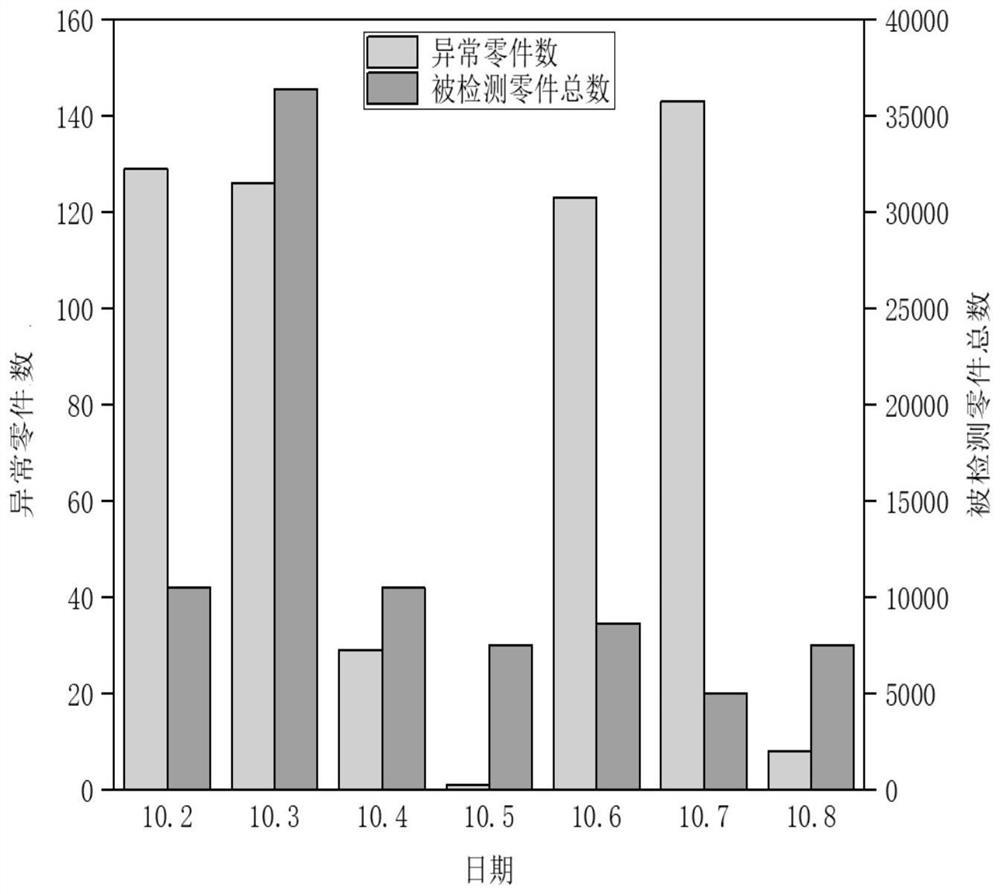

The invention discloses a method for detecting the position and type of a workpiece on a subway train side inspection image. The method employs a software algorithm to replace manual operation, employs a subway train side workpiece detection and recognition model, can be used for the development of an intelligent subway inspection system, and replaces a manual observation detection mode. Accordingto the method, the YOLOv4 is used as a basis to construct the subway train side workpiece positioning and recognition model, the YOLOv4 has a very good effect in target detection application, and thecapability is migrated to subway inspection application, so that the accuracy of train side workpiece positioning can be effectively improved; and powerful support is provided for subsequent defect analysis, by using the detection model provided by the invention, a workpiece can be quickly and accurately positioned from a subway vehicle body scanning picture, a sub-picture area can be segmented,and the output picture only comprises a workpiece with a known model, so that the subsequent analysis on the state of the workpiece is greatly facilitated, and the difficulty of subsequent analysis isreduced.

Owner:成都川哈工机器人及智能装备产业技术研究院有限公司 +1

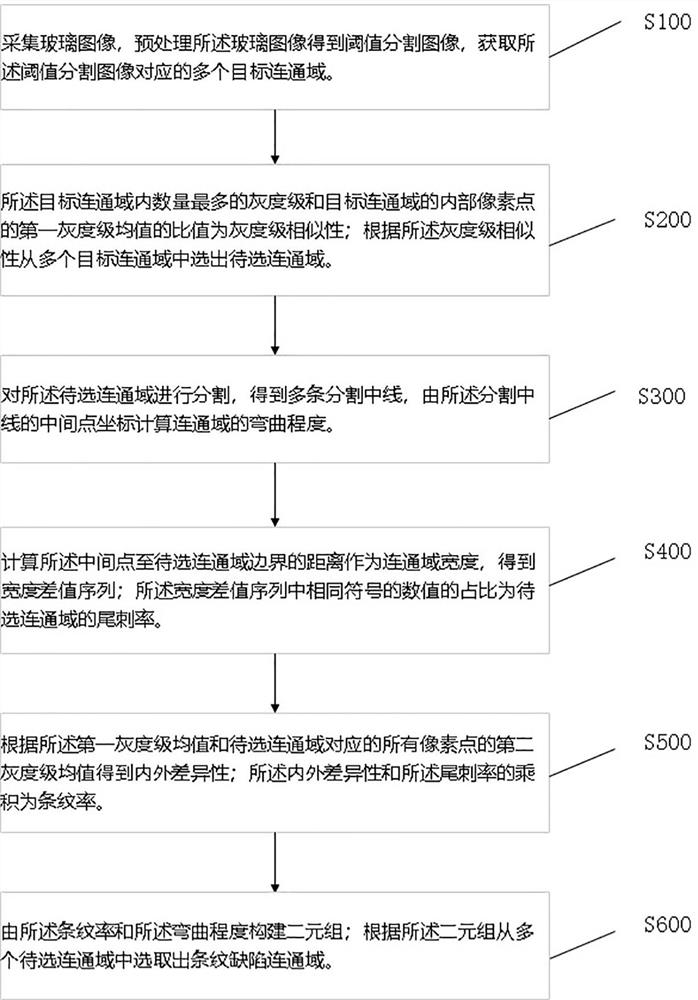

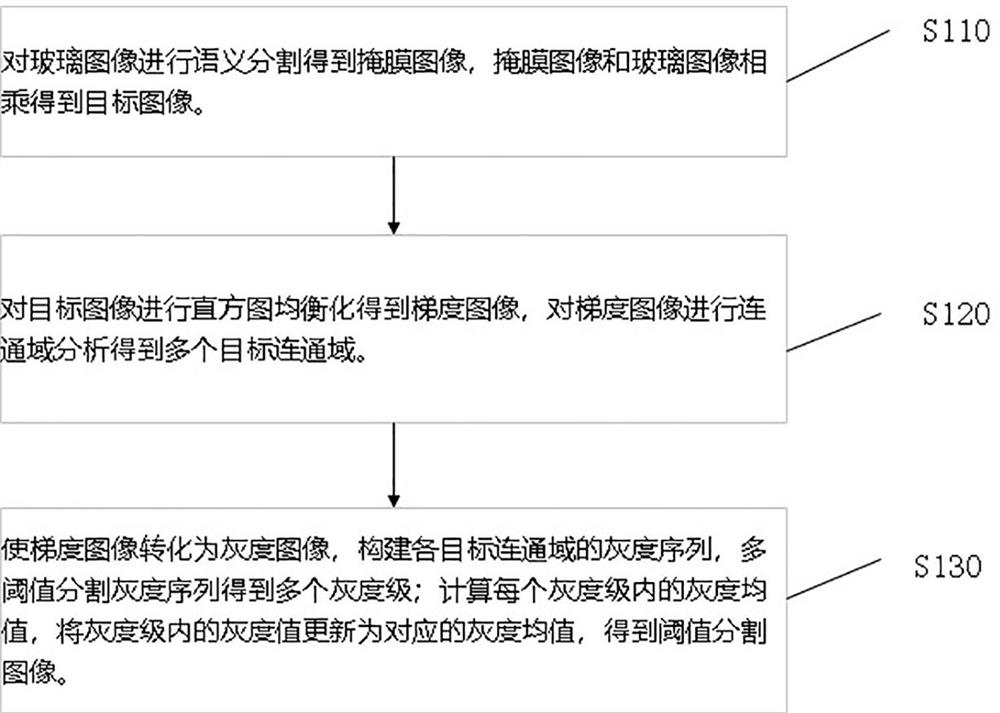

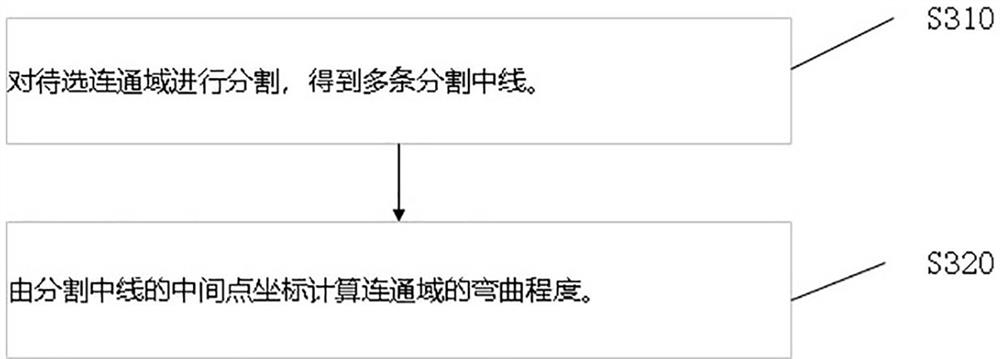

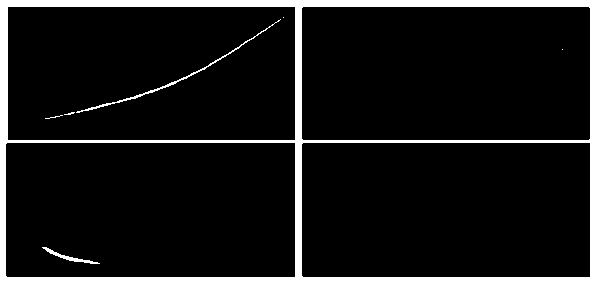

Glass defect intelligent detection method

ActiveCN114219805AImprove detection efficiency and accuracyImprove accuracyImage enhancementImage analysisGray levelEngineering

The invention relates to the technical field of image processing, in particular to a glass defect intelligent detection method, which comprises the following steps of: firstly, preprocessing an acquired glass image to obtain a threshold segmentation image and a corresponding target connected domain; and calculating the gray level similarity of the target connected domain according to the gray level corresponding to each pixel point in the target connected domain, and screening the target connected domain according to the gray level similarity to obtain a to-be-selected connected domain. The connected domain width of the to-be-selected connected domain is calculated, a width difference value sequence is obtained, and the proportion of the values of the same symbols in the width difference value sequence is the tail thorn rate. And calculating internal and external differences of the to-be-selected connected domain according to the gray level of the to-be-selected connected domain, wherein the product of the internal and external differences and the tail thorn rate is the fringe rate. And constructing a two-tuple by the fringe rate and the bending degree, and selecting a fringe defect connected domain from the to-be-selected connected domain according to the two-tuple. According to the embodiment of the invention, defect detection is carried out on the collected glass image, so that the accuracy and efficiency of glass defect detection are improved.

Owner:武汉旺佳玻璃制品有限公司

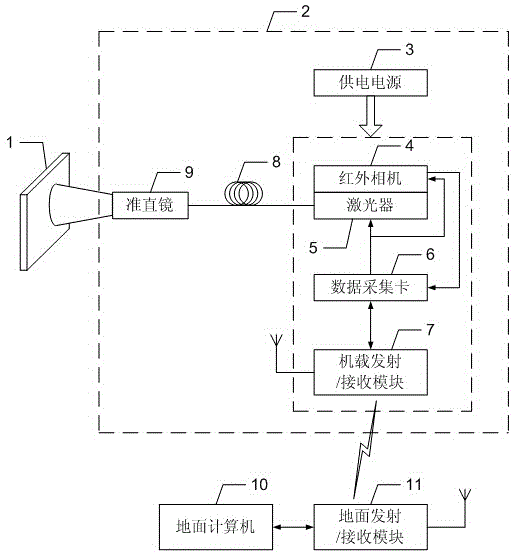

Active infrared nondestructive test unmanned plane system

InactiveCN105486716AEnsure stable operationImprove detection efficiency and accuracyMaterial flaws investigationTest objectPhase locking

The invention discloses an active infrared nondestructive test unmanned plane system and belongs to the field of a nondestructive test on a large complex member such as an aerospace structural component. The system solves the problem that the aerospace structural component has a large volume and a complex structure so that manual climbing checking efficiency is low and potential safety hazard exists. The system comprises an unmanned plane main body, an unmanned plane mounted monitoring module is arranged on the unmanned plane main body, a ground-based computer transmits a position instruction in a wireless way to control the unmanned plane main body so that the unmanned plane main body is moved to a certain position on the outer surface of a tested object, a data acquisition card controls a modulating signal and power of a laser according to an acquisition instruction, light beams transmitted through the laser go through optical fibers, are collimated through a collimating lens and irradiate the outer surface of the tested object, an infrared camera acquires an image sequence and the ground-based computer carries out phase locking operation on the acquired image sequence and a reference signal so that a thermal radiation signal amplitude image and a phase image of the tested object are obtained and defect types and positions are obtained.

Owner:HARBIN INST OF TECH

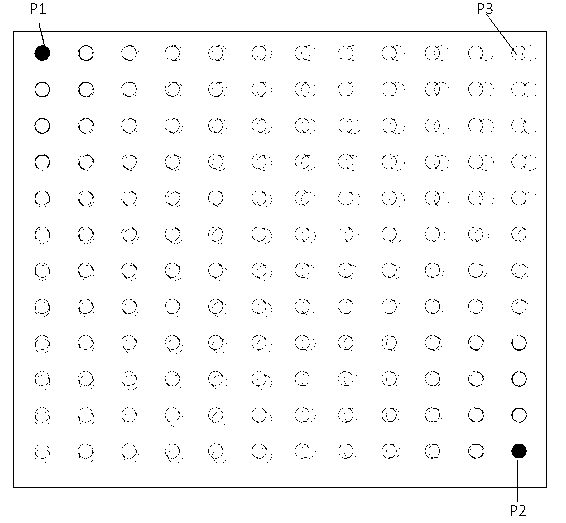

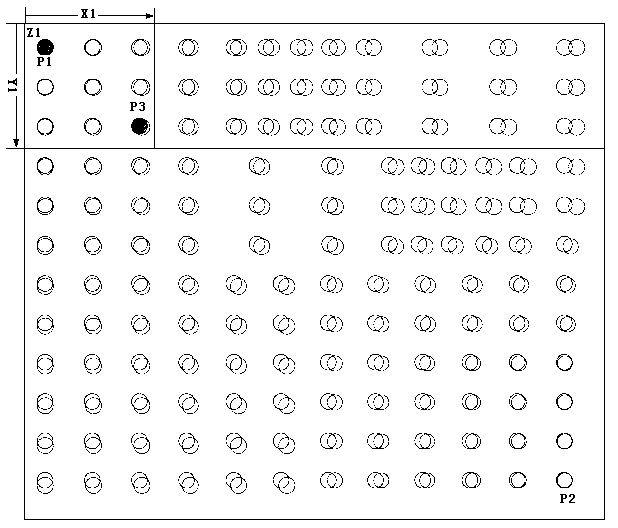

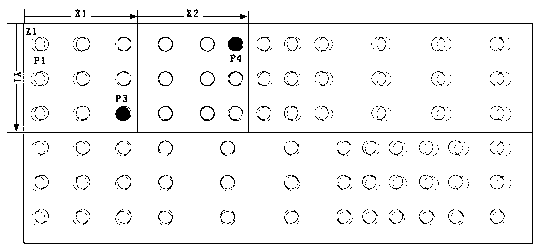

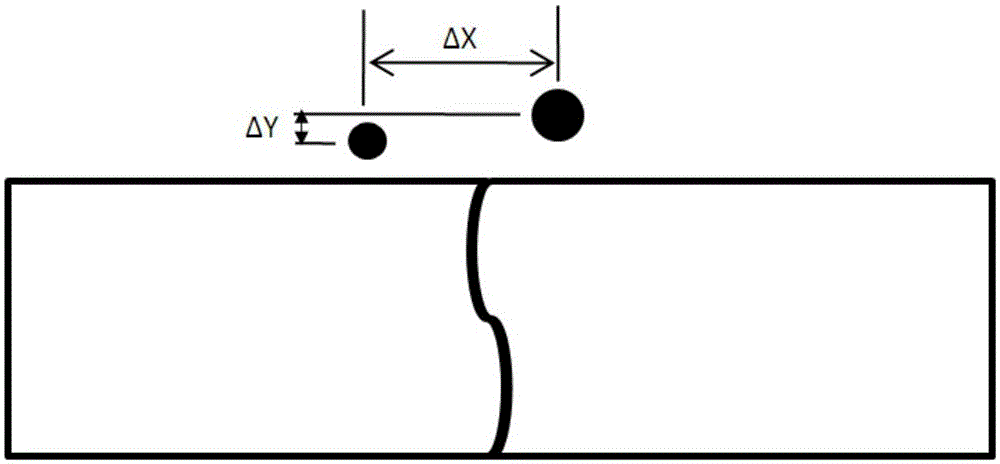

Soft board detection partition position-alignment correction method

ActiveCN103217421AImprove detection efficiency and accuracyEliminate accumulated errorsMaterial analysis by optical meansIntegrated systemsCorrection method

The invention relates to a soft board detection partition position-alignment correction method. The soft board detection partition position-alignment correction method solves the problem that based on the prior art, in soft board detection, correct identification is failed because of deformation offset. The soft board detection partition position-alignment correction method comprises the following steps of acquiring a soft board image, transforming openings and lines in the soft board image into figures, arranging P1 and P2 figure markers at two diagonal line vertexes of the soft board, carrying out two-point primary position-alignment by the P1 and P2 figure markers, setting an upper limit value N of the partition figure number, partition Y-direction height Y1 and a X-direction stepping value X' distance, determining a first partition range Z1, selecting two diagonal points P1 and P3 in the range Z1, carrying out two-point positioning, comparing design figures and the recognized figures, and carrying out continuous area scanning until the whole scanning is finished so that partition position-alignment detection of the soft board is finished. The soft board detection partition position-alignment correction method solves the above problem well, and can be used for a SMT template cutting and detection integrated system and especially in a SMT laser template cutting and detection device system.

Owner:KUNSHAN THETA MICRO

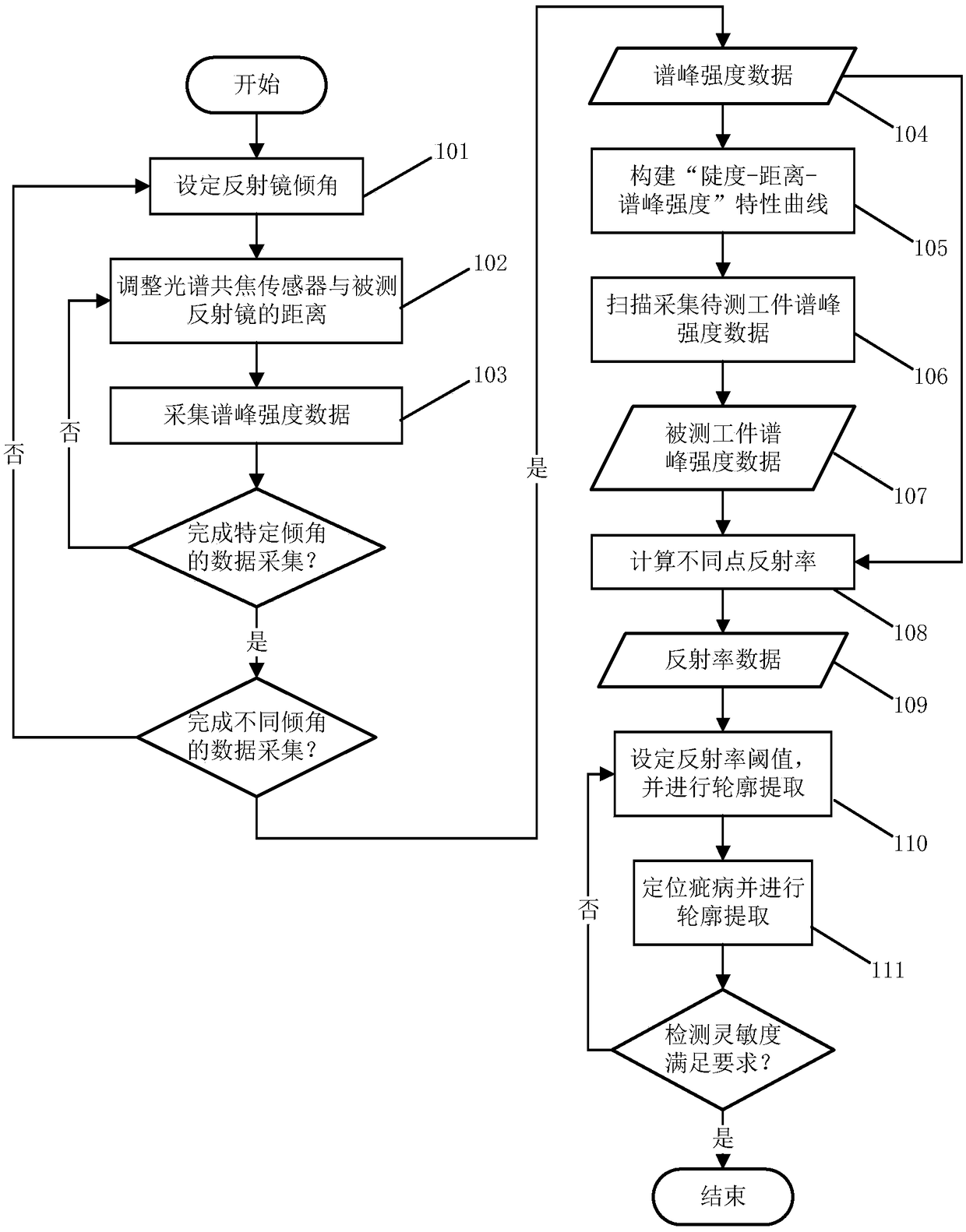

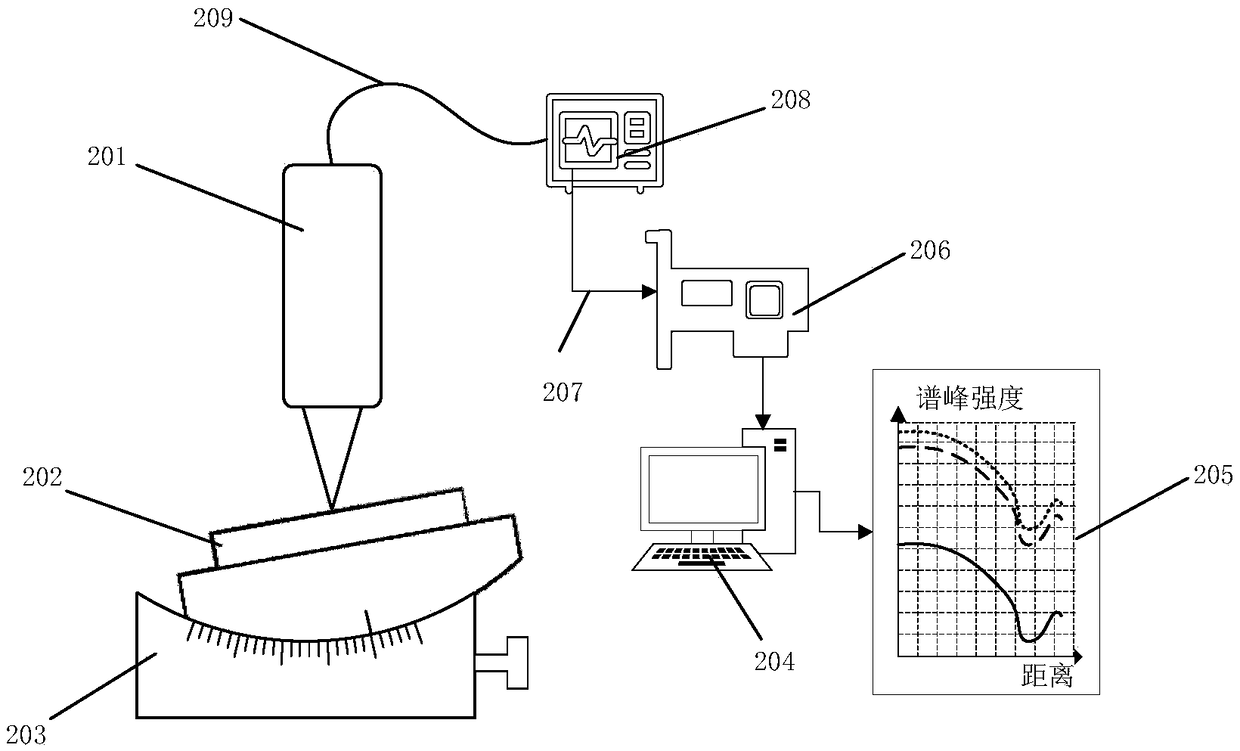

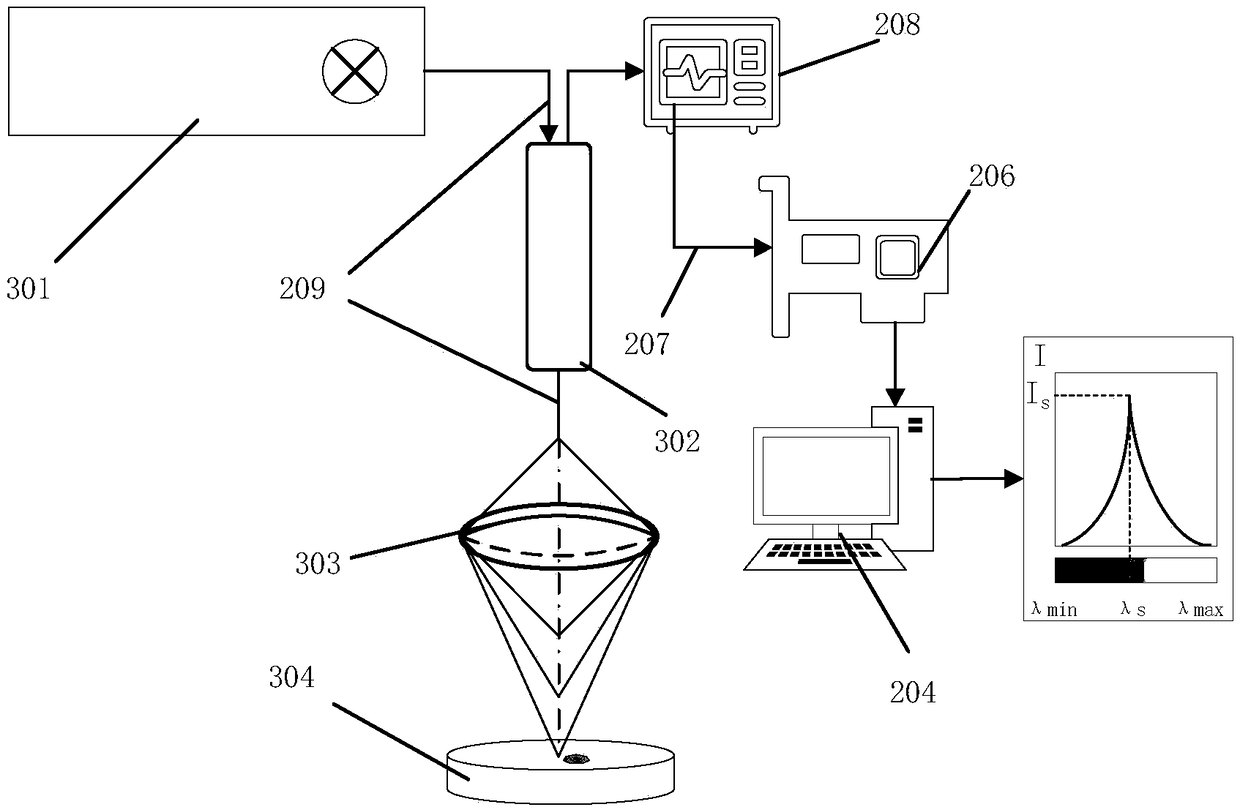

Method for measuring surface defects based on spectral confocal sensor

InactiveCN109283184AAvoid human errors or secondary clamping errorsImprove detection efficiency and accuracyOptically investigating flaws/contaminationPhysicsReflectivity

The invention discloses a method for measuring surface defects based on a spectral confocal sensor. A plane reflector is installed on an angular displacement table, the distance between a spectral sensor and a to-be-measured workpiece is adjusted, the acquisition of spectral peak intensity data at a set inclination angle is finished, the angular displacement table is adjusted to be at different inclination angles, until the acquisition of the spectral peak intensity data at all specified inclination angles is finished; a "steepness-distance-spectral peak intensity" characteristic curve is established; scanning measurement is performed on the to-be-measured workpiece, spectral peak intensity data of return light on the surface of the workpiece is acquired, and a reflectivity matrix of the surface of the to-be-measured workpiece is calculated; and a reflectivity threshold value is set, and a reflectivity sudden change region is identified by setting a reflectivity threshold value region,so that a defect region and a normal region are distinguished, and defect positioning and contour extraction are completed. A mathematical model between the spectral peak intensity and the surface reflectivity is built by an experiment method, and the surface defects are positioned by the reflectivity, so that a novel method is provided for the detection of the surface defects of optical elements.

Owner:ZHEJIANG UNIV

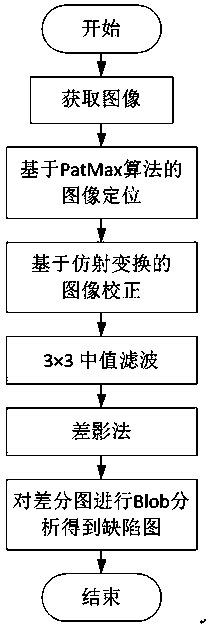

Mobile phone screen detection method

ActiveCN110111330AEliminate noise effectsImprove detection efficiency and accuracyImage enhancementImage analysisComputer visionBlob analysis

The invention provides a mobile phone screen detection method. The method comprises the following steps of firstly, carrying out image positioning on an obtained mobile phone screen image by using a template positioning technology of a PatMax algorithm, correcting the mobile phone screen image by using an image correction technology based on affine transformation, and carrying out image filteringby using 3 * 3 median filtering to eliminate the noise influence and protect the edge information of a test image, and then training a template image, subtracting the template image from the test image to obtain a difference image, and finally detecting and positioning the defect features in the image by utilizing a Blob analysis method. The method provided by the invention can effectively identify various defects of the mobile phone screen, and has the higher detection efficiency and precision.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

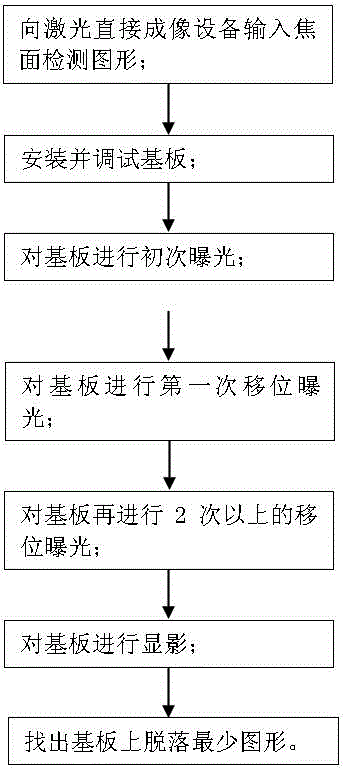

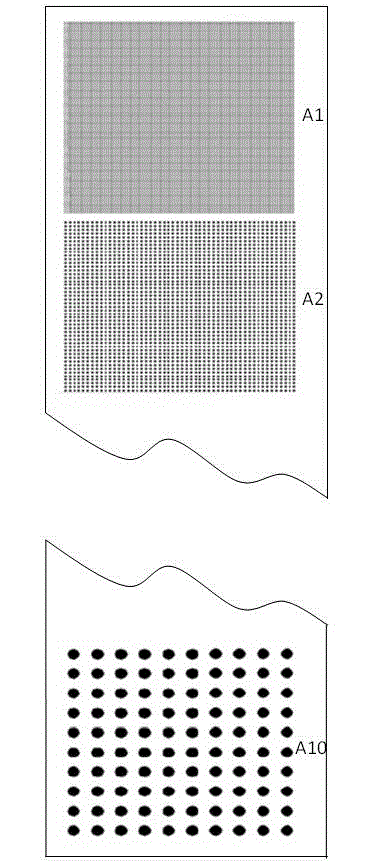

Method for acquiring optimal focal plane distance of laser direct imaging equipment

InactiveCN105549346AImprove detection efficiency and accuracyReduce the risk of obsolescencePhotomechanical exposure apparatusMicrolithography exposure apparatusLine widthExposure

In the prior art, the exposure focal plane of laser direct imaging equipment is difficult to rapidly acquire. Based on the difficult problem in the prior art, the present invention provides a method for acquiring the optimal focal plane distance of laser direct imaging equipment. The method comprises: inputting a focal plane detection pattern into laser direct imaging equipment; installing and debugging a substrate; carrying out primary exposure on the substrate; carrying out primary displacement exposure on the substrate; repeatedly performing the displacement exposure on the substrate; developing the substrate; and finding the least shedding pattern on the substrate. According to the present invention, the necessarily-used detection step for measuring the line width by using a microscope in the traditional method is eliminated, the optimal expose focal plane can be quickly, intuitively and accurately found, the detection efficieny and the accuracy of the focal plane are improved, and the PCB reject risk caused by the insufficient exposure is reduced.

Owner:HEFEI ADVANTOOLS SEMICON

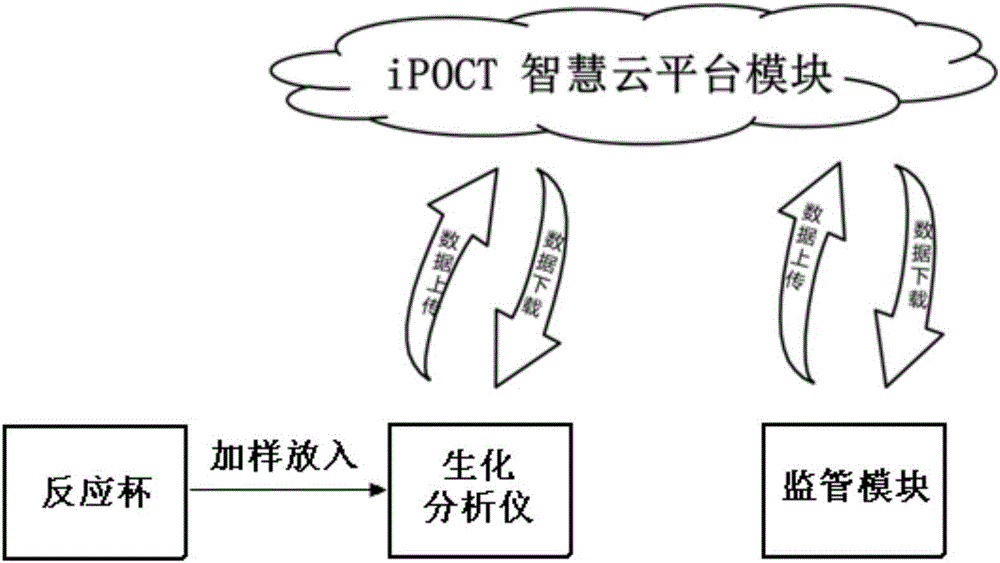

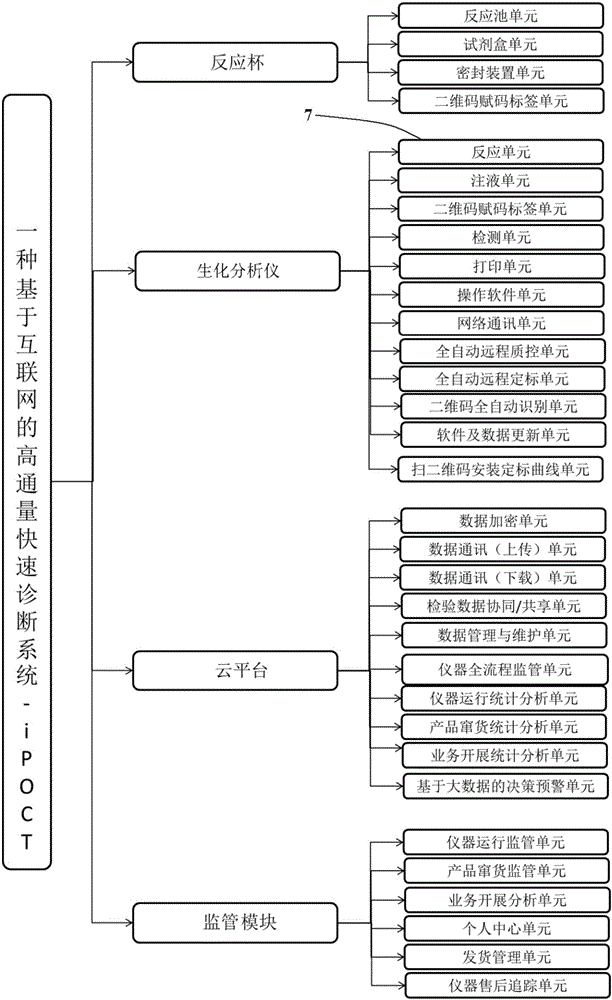

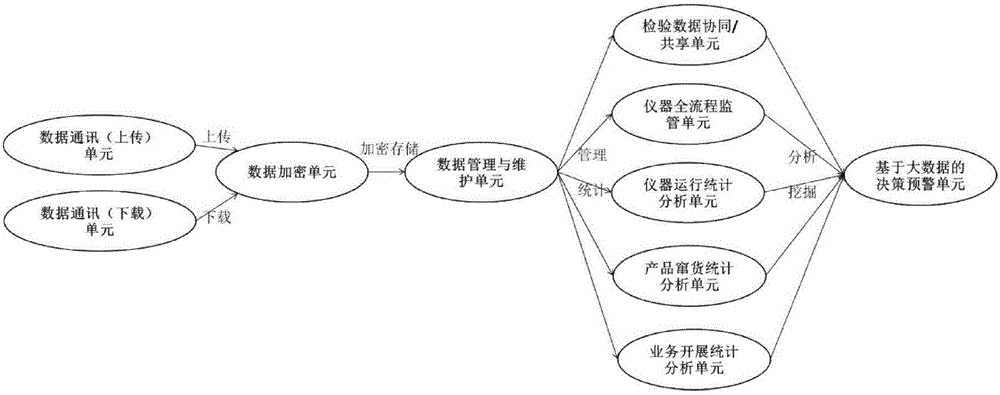

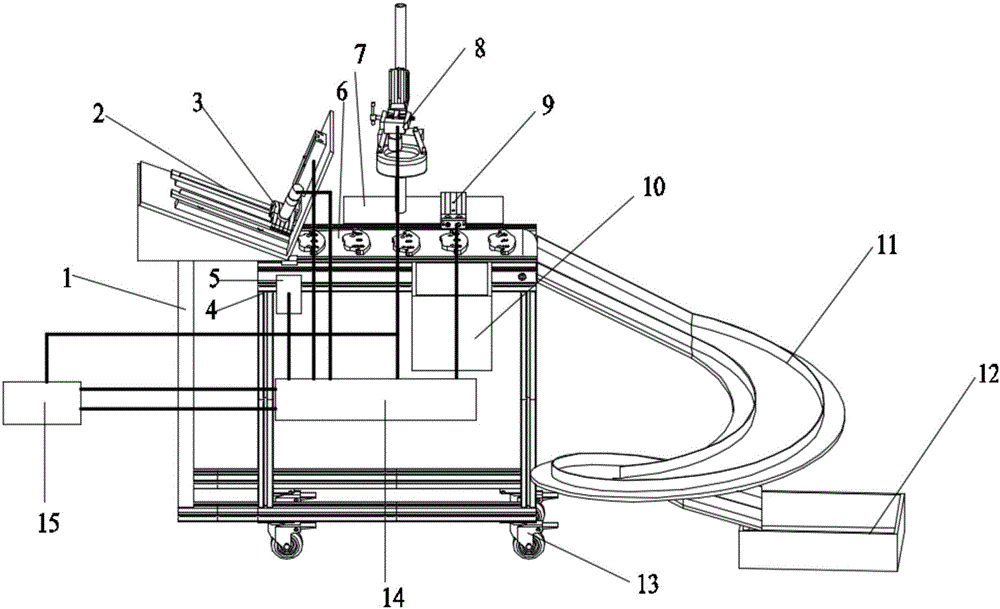

Internet-based high-throughput quick diagnosis system and method

ActiveCN106226510AAvoid instrument and reagent silosImprove detection efficiency and accuracyBiological testingTransmissionChemistryService information

Owner:TZONE (HUNAN) BIOTECHNOLOGY LLC

Automatic detecting device for product quality of brake pads

PendingCN106733728AGuarantee product qualityImprove detection efficiency and accuracyOptically investigating flaws/contaminationSortingPersonal computerImage processing

The invention relates to an automatic detecting device for product quality of brake pads. The automatic detecting device comprises a rack, a discharging device supporting frame fixed to the front end of the rack, a fixing plate fixed to the side of the rack and a rotary sliding way arranged at the rear end of the rack. A conveyor belt is arranged above the rack, a discharging device is arranged above the discharging device supporting frame, and a machine vision device and a removing air cylinder are fixed to the upper portion of the fixing plate. The discharging device is used for stably discharging the brake pads onto the conveyor belt one by one in order, the conveyor belt conveys the brake pads to the lower portion of the machine vision device so that image collection can be carried out, then, collected images are transmitted to an industrial personal computer to be processed so that whether the brake pads are qualified or not can be judged, the qualified brake pads are conveyed into the rotary sliding way through the conveyor belt and finally fall into a qualified product box, the unqualified brake pads are removed by the removing air cylinder and fall into a waste box, and the whole detection process is completed through cooperated control of a PLC control system and the industrial personal computer.

Owner:CHINA JILIANG UNIV

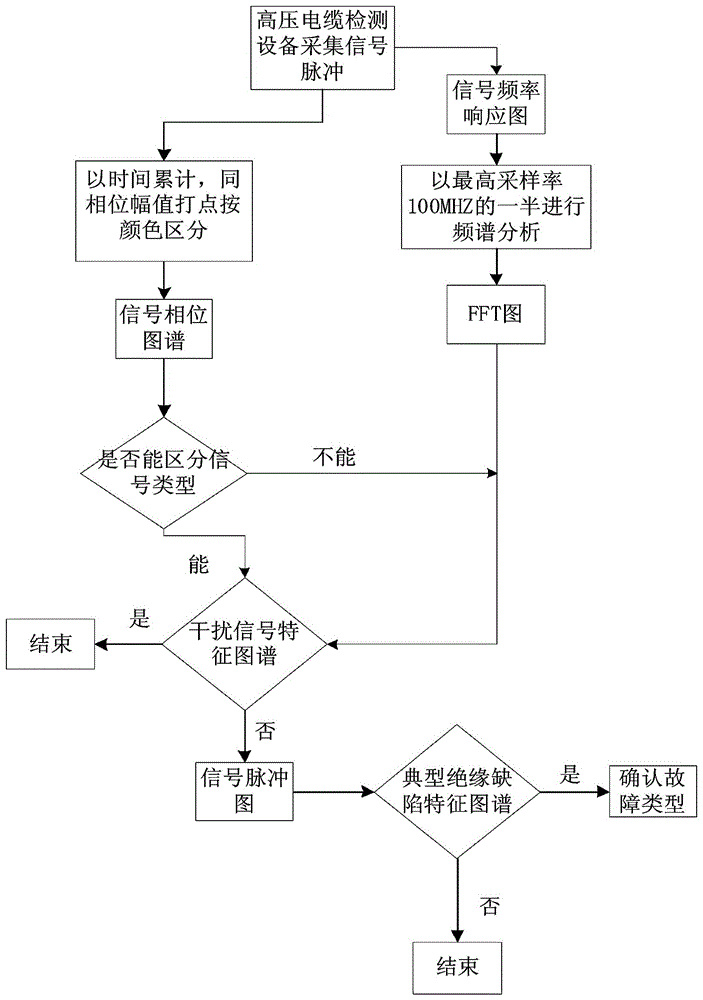

Method of identifying high voltage cable inner insulation defect type based on specific chromatograms

ActiveCN106019042AEliminate Interfering SignalsImprove detection efficiency and accuracyElectrical testingPhase correlationSignal frequency

The invention relates to a method of identifying a high voltage cable inner insulation defect type, belonging to the electric power system power transmission equipment fault diagnosis technical field, and especially relates to a method of identifying a high voltage cable inner insulation defect type based on specific chromatograms. The method employs a signal phase spectrogram, a signal frequency response diagram and a signal pulse diagram to identify a high voltage cable inner insulation defect type based on specific chromatograms, and comprises the steps of: according to the time accumulation effect of the phase spectrogram, finding a phase related plotting graph with high repetition frequency, and performing preliminary discrimination on interference signals and insulation defect signals; selecting signal center frequency and bandwidth through an FFT graph, performing full spectrum band range scanning, meanwhile observing the plotting conditions of the phase spectrogram, and eliminating interference signals; and performing comparison identification on the pulse diagram and a special function atlas, and accurately performing insulation defect type identification. The method can rapidly identify a high voltage cable fault type without later calculation, and improve cable detection efficiency and accuracy.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +2

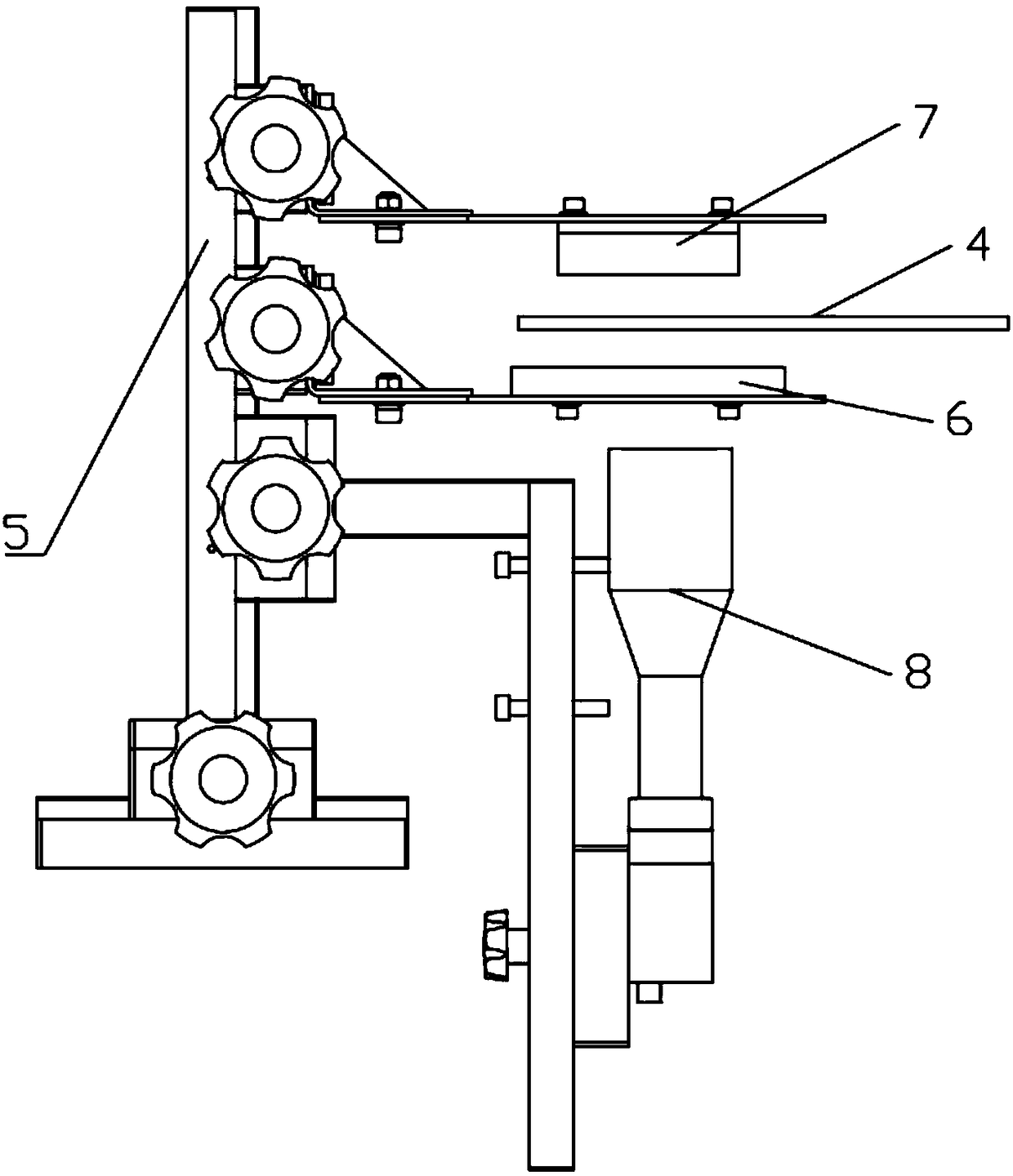

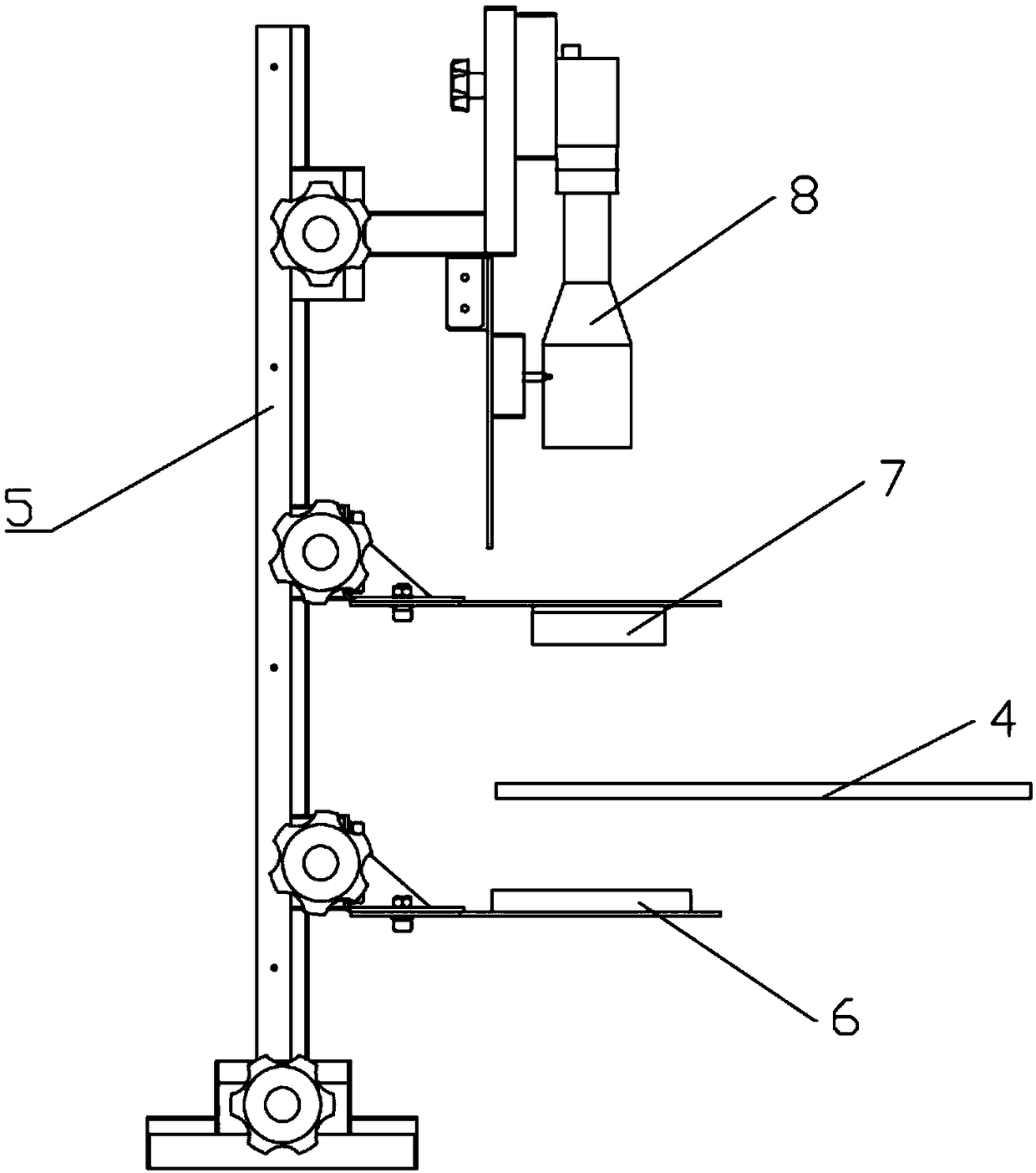

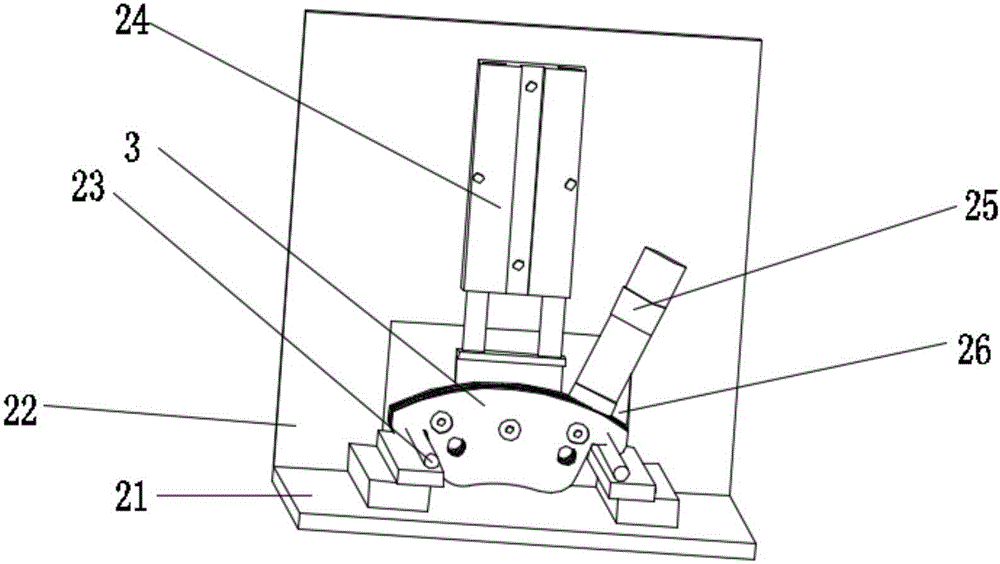

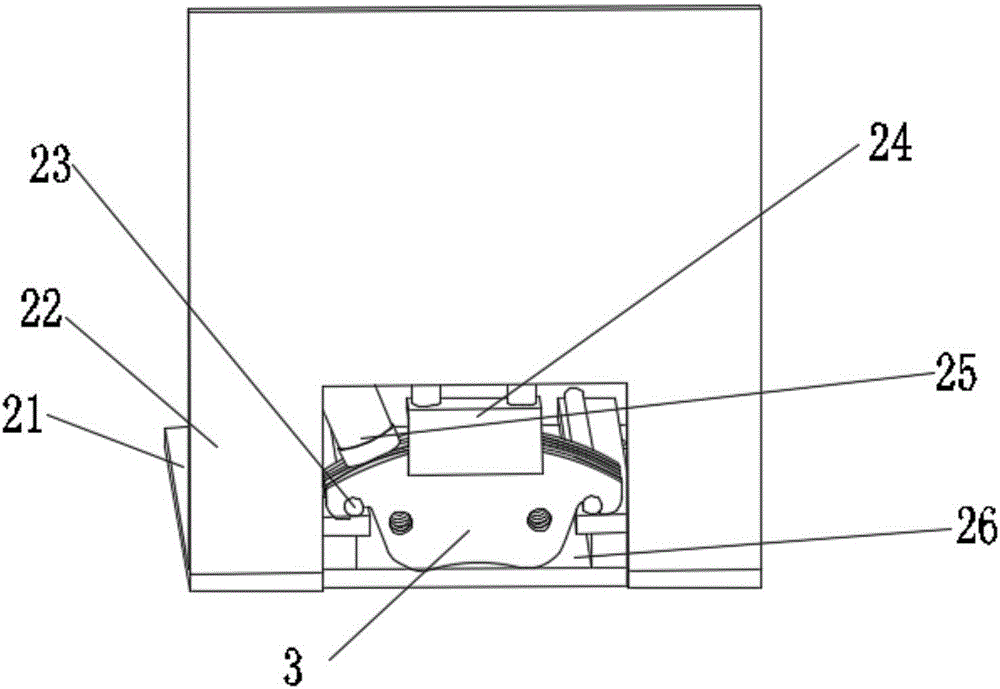

Full-automatic spinning machine steel collar surface size and accuracy detecting device

ActiveCN107185853AEasy to detect on the back sideImprove detection efficiency and accuracySortingElectric machineryTransfer mechanism

The invention relates to a full-automatic spinning machine steel collar surface size and accuracy detecting device. The detecting device comprises a working table and further comprises a feeding mechanism, a first detecting mechanism, a transferring mechanism, an overturning mechanism, a second detecting mechanism, a screening mechanism and a control system which are arranged on the working table; the first detecting mechanism is arranged at the discharging end of the feeding mechanism and comprises a first material disc, a rotating device, a first upper detecting camera and a linear scanning camera, the first material disc is arranged on the rotating device and is located at the discharging end of the feeding mechanism, the first upper detecting camera is located over the first material disc, and the linear scanning camera is located on one side of the first material disc; the transferring mechanism is in butt joint with the first detecting mechanism and the overturning mechanism, the overturning mechanism is provided with an overturning motor and clamping jaws, and the clamping jaws are connected with the overturning motor and are located on the two sides of a steel collar to clamp the steel collar during overturning; and the second detecting mechanism comprises a second upper detecting camera, the second upper detecting camera is located above the overturned steel collar, and the screening mechanism is located on one side of the second detecting mechanism. By means of the full-automatic detecting device, qualified and unqualified steel collars are conveniently distinguished.

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

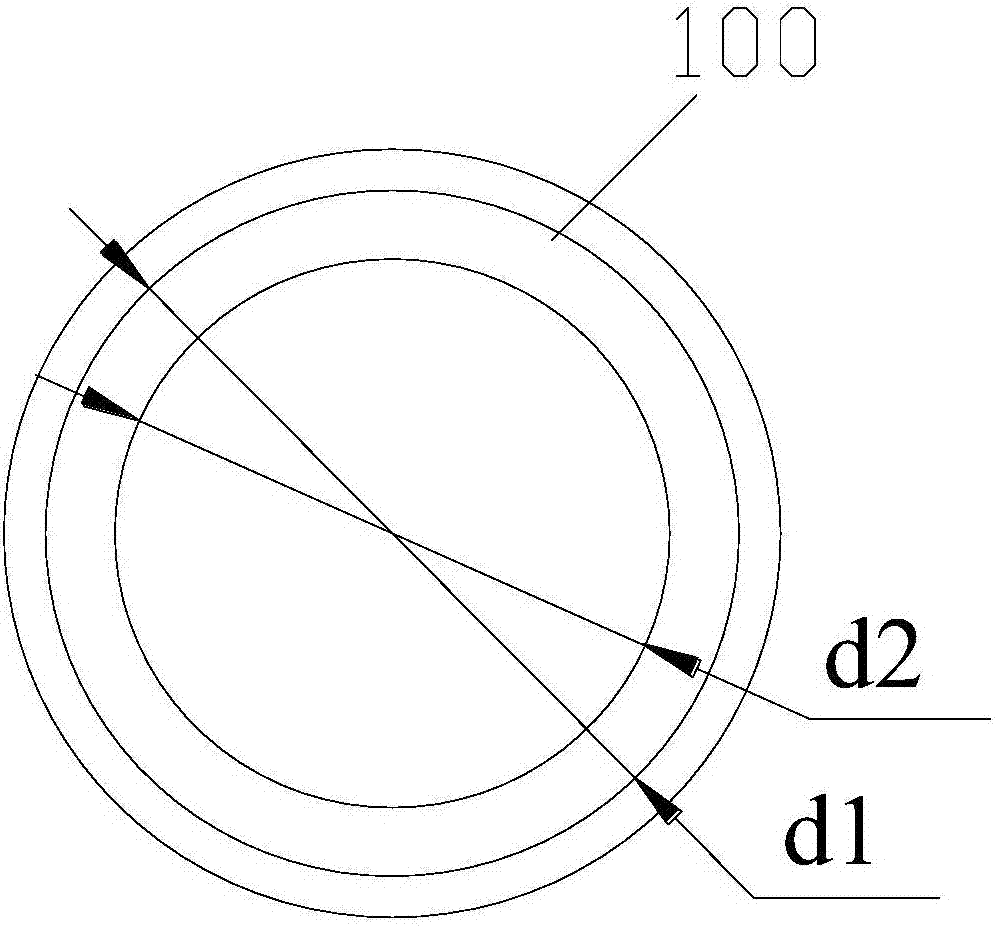

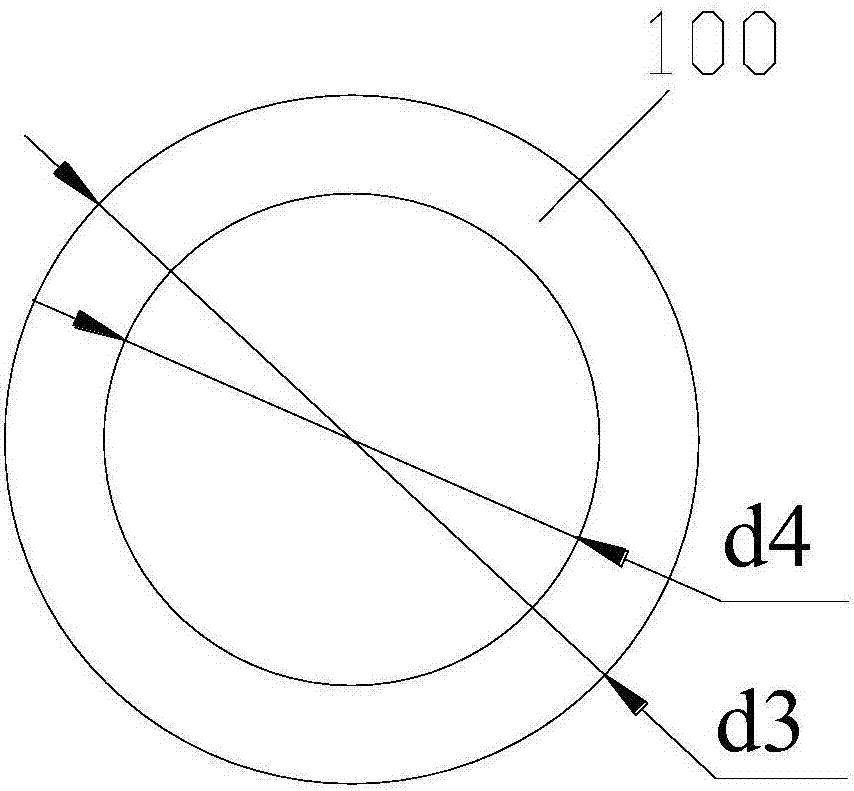

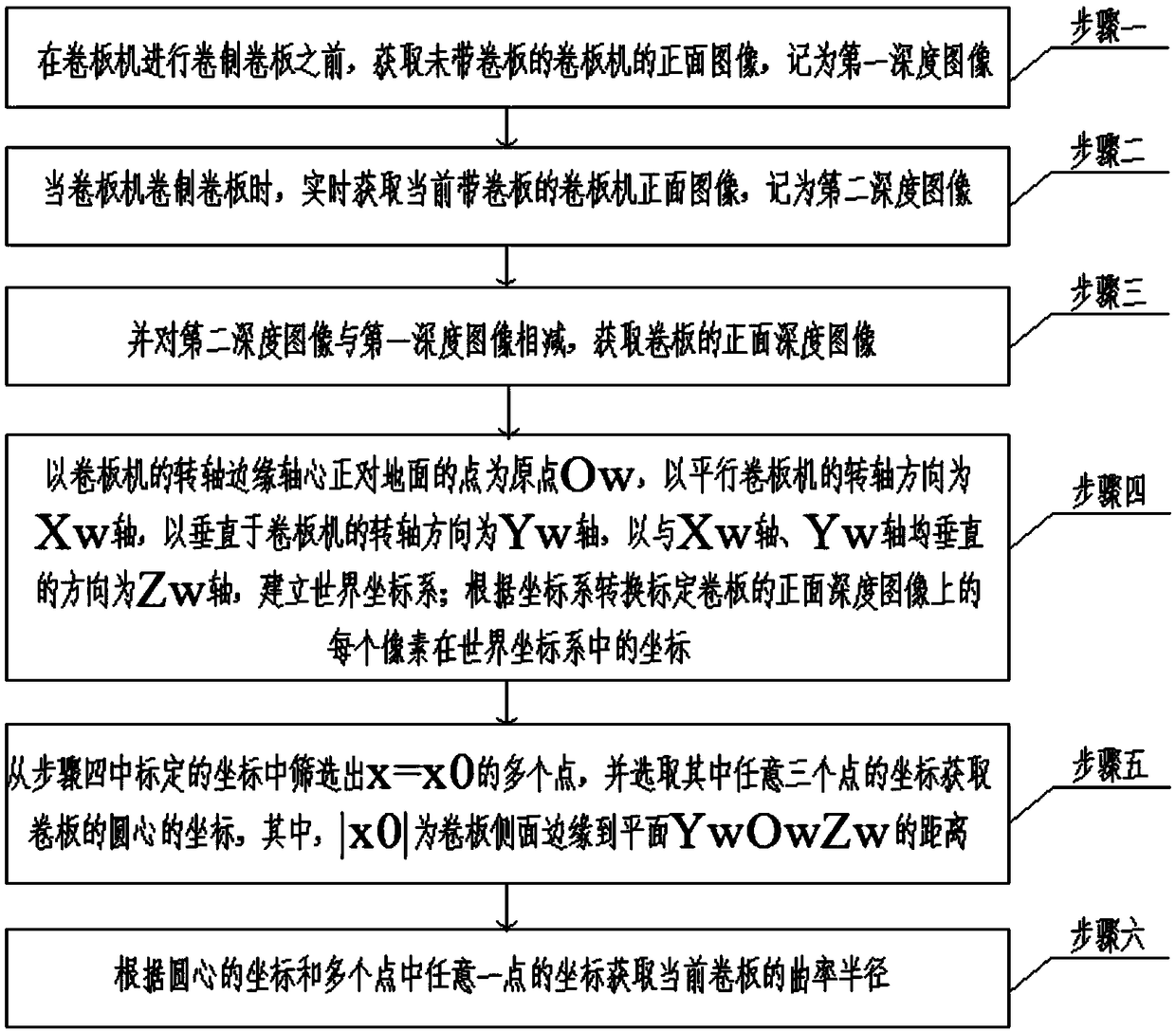

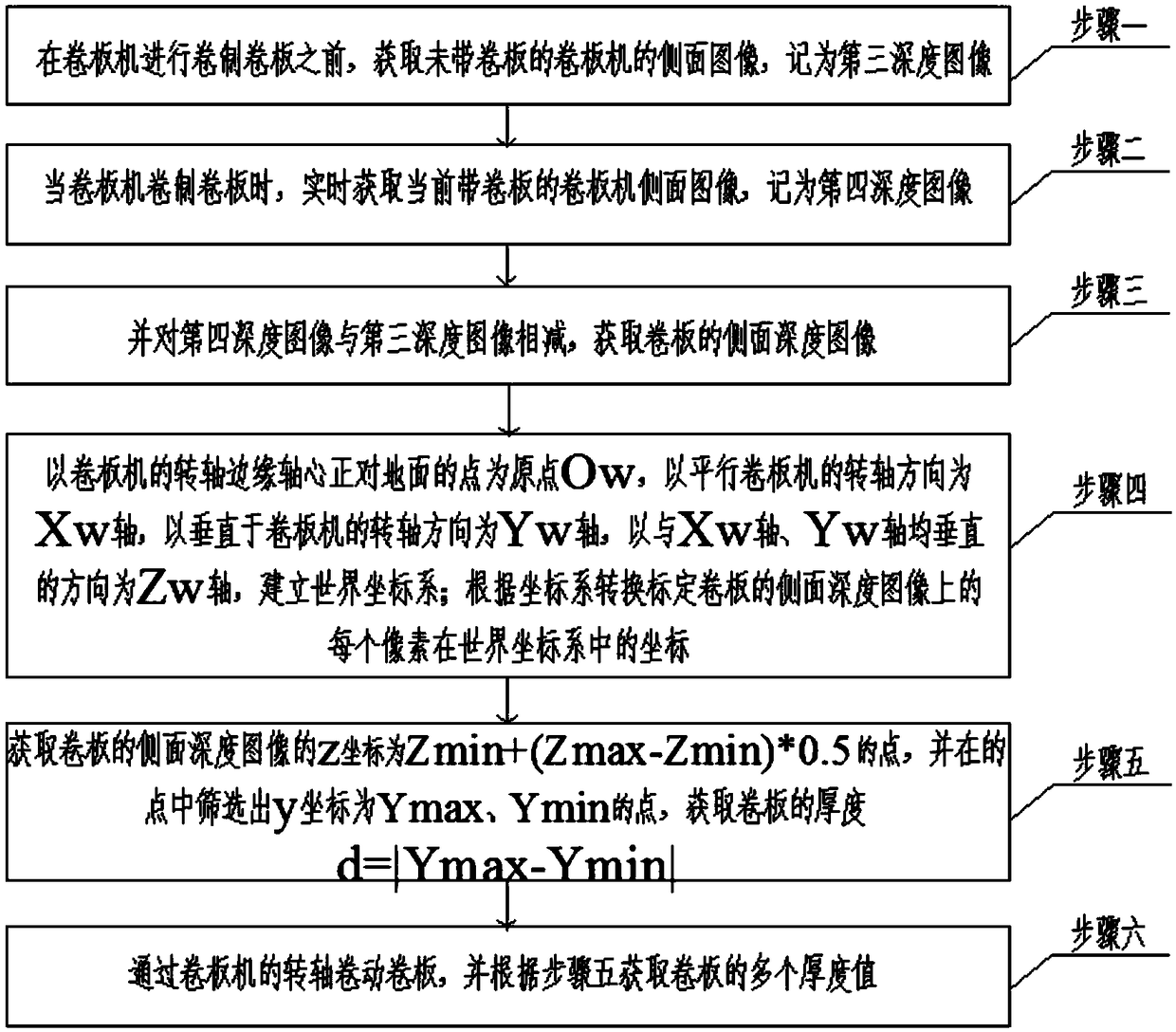

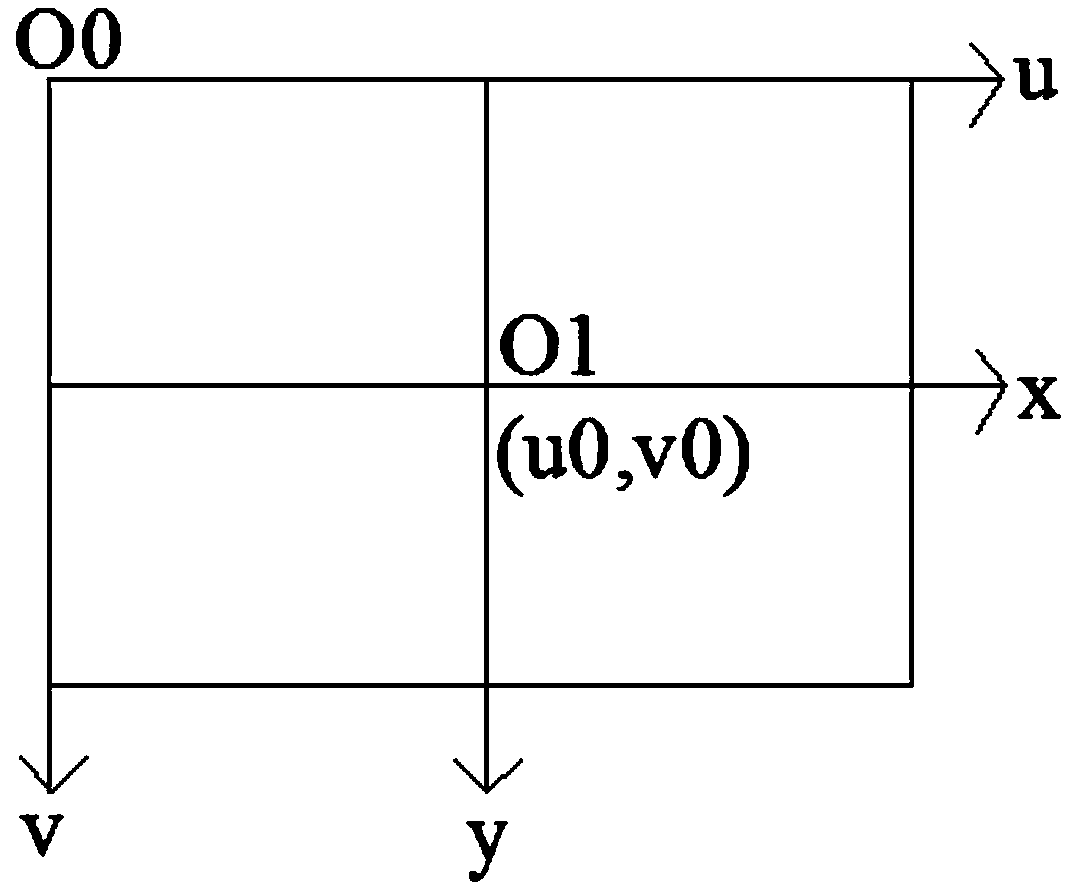

Method for measuring radius of curvature and thickness of coiling machine based on depth camera

ActiveCN109357637AImprove detection efficiency and accuracyImprove precisionUsing optical meansPhysicsEngineering

The invention discloses a method for measuring the radius of curvature of a coiling machine based on depth camera, comprising of: obtaining a front image of the coiling machine not performing coilingby a first depth camera; obtaining a front image of the coiling machine performing coiling by the first depth camera; performing difference between the two images to obtain the front image of the current coil; through the coordinate system conversion, obtaining the representation of the front image of the current coil in the world coordinate system; filtering out the points on the x=x0 plane in the world coordinate system; selecting any three points to obtain the center coordinates of the coil; and obtaining the radius of curvature of the coil according to the coordinates of the center of thecircle and the coordinates of any selected points. Therefore, it is no longer necessary to manually measure the radius of curvature of the coil, and the automatic intelligent detection of the radius of curvature of the coil is achieved, and the accuracy and detection efficiency of detecting the radius of curvature of the coil are improved. The invention also discloses a method for measuring the thickness of a coiling machine based on depth camera.

Owner:山西吉诺科技有限公司

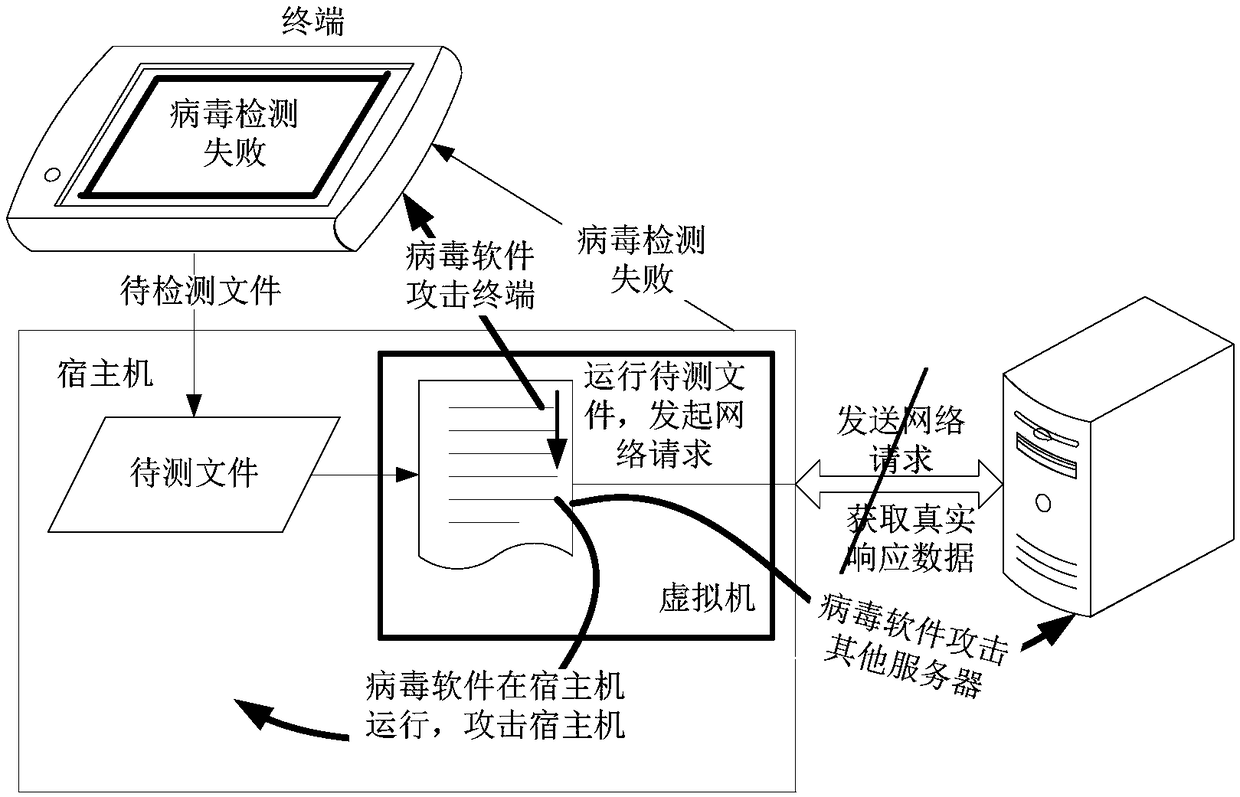

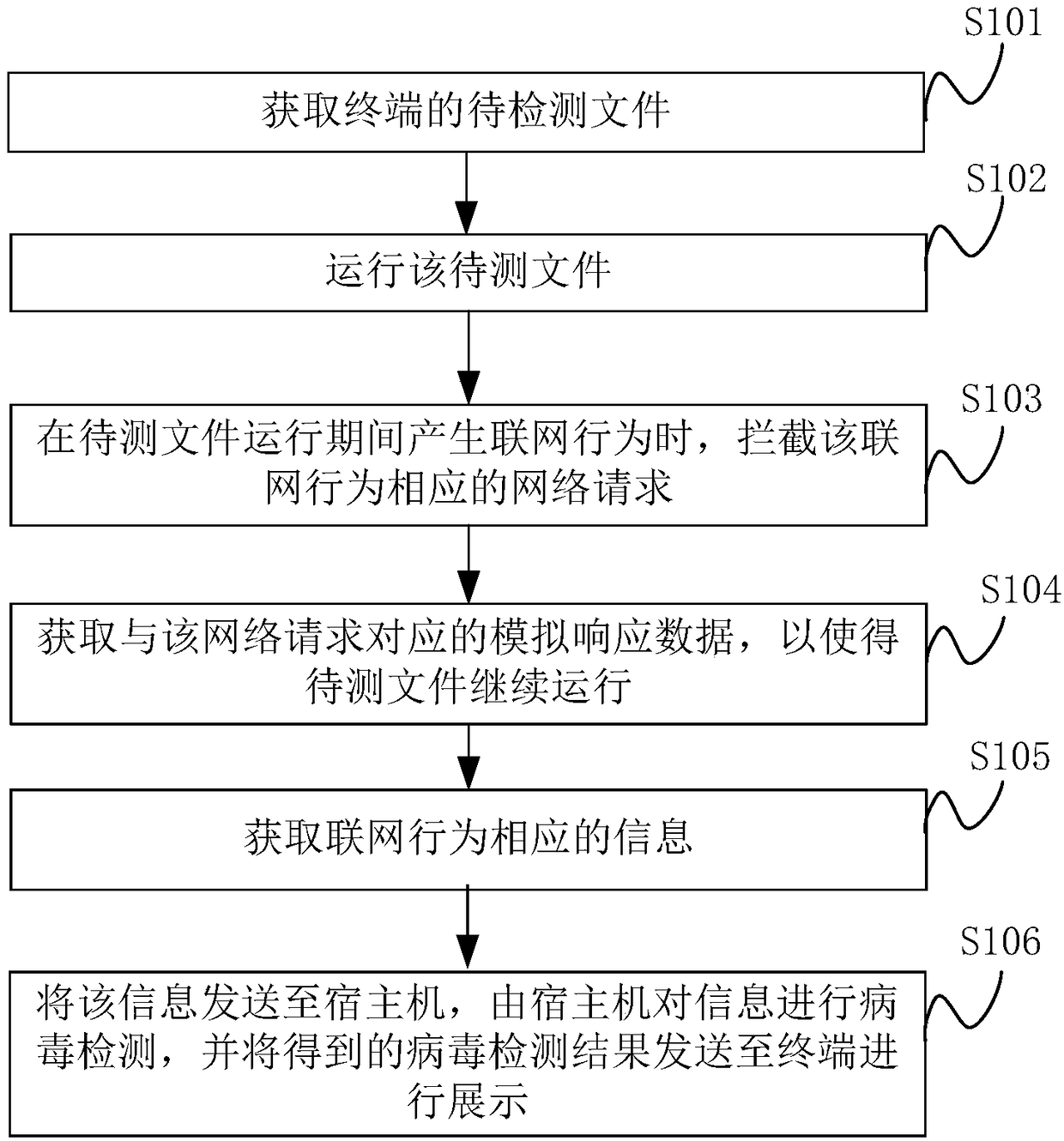

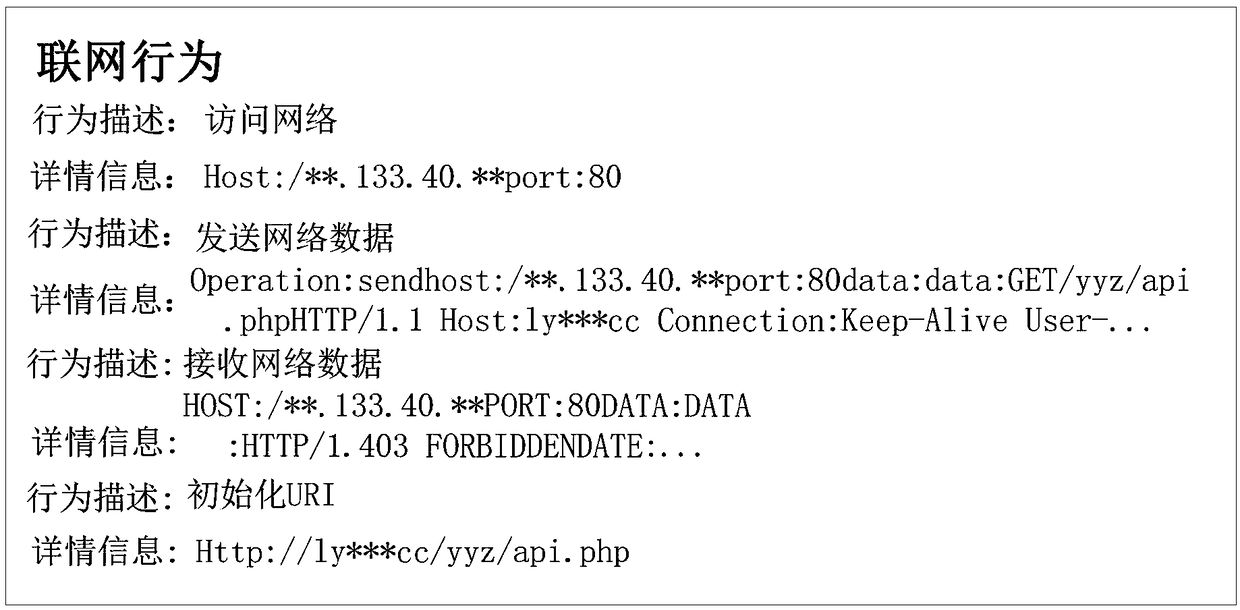

Virus detecting method, device, storage medium and computer equipment

ActiveCN108768960AImprove detection efficiency and accuracyGuaranteed uptimeTransmissionMalwareComputer equipment

The invention discloses a virus detecting method, a virus detecting device, a storage medium, and computer equipment provided by the embodiment. When the file to be detected generates a networking behavior during the operation of importing the file to be detected into the virtual machine, the embodiment may intercept the network request corresponding to the networking behavior to make the networkrequest unable to be sent to the real server, but directly obtain the pre-stored corresponding simulated response data, thereby avoiding the malware in the file to be detected from attacking the hostmachine and other equipment of the external network through the network, also ensuring that the file to be detected may be run to obtain information about all the networking behaviors that may be generated by the file to be detected, and further improving the detection accuracy and detection efficiency of the virus of the file to be detected.

Owner:TENCENT TECH (SHENZHEN) CO LTD

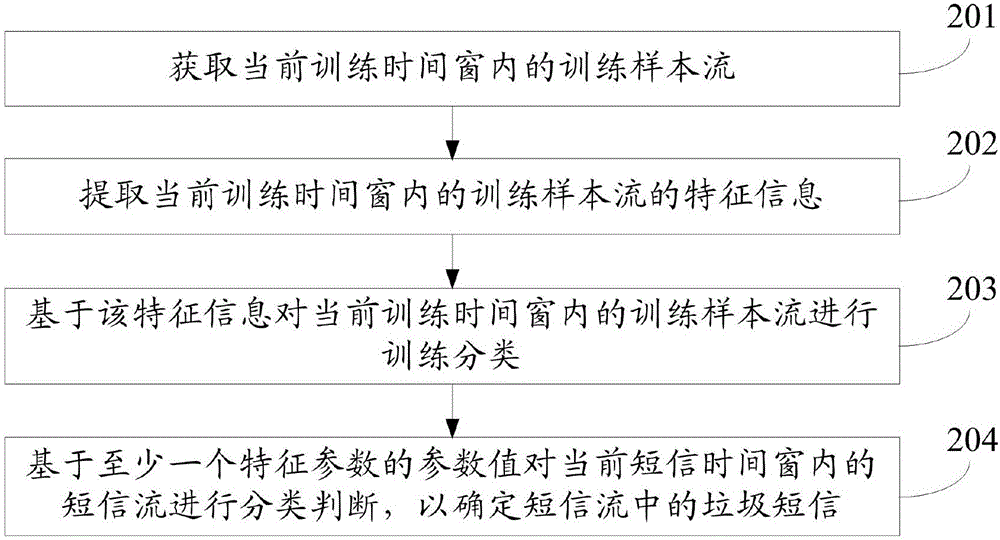

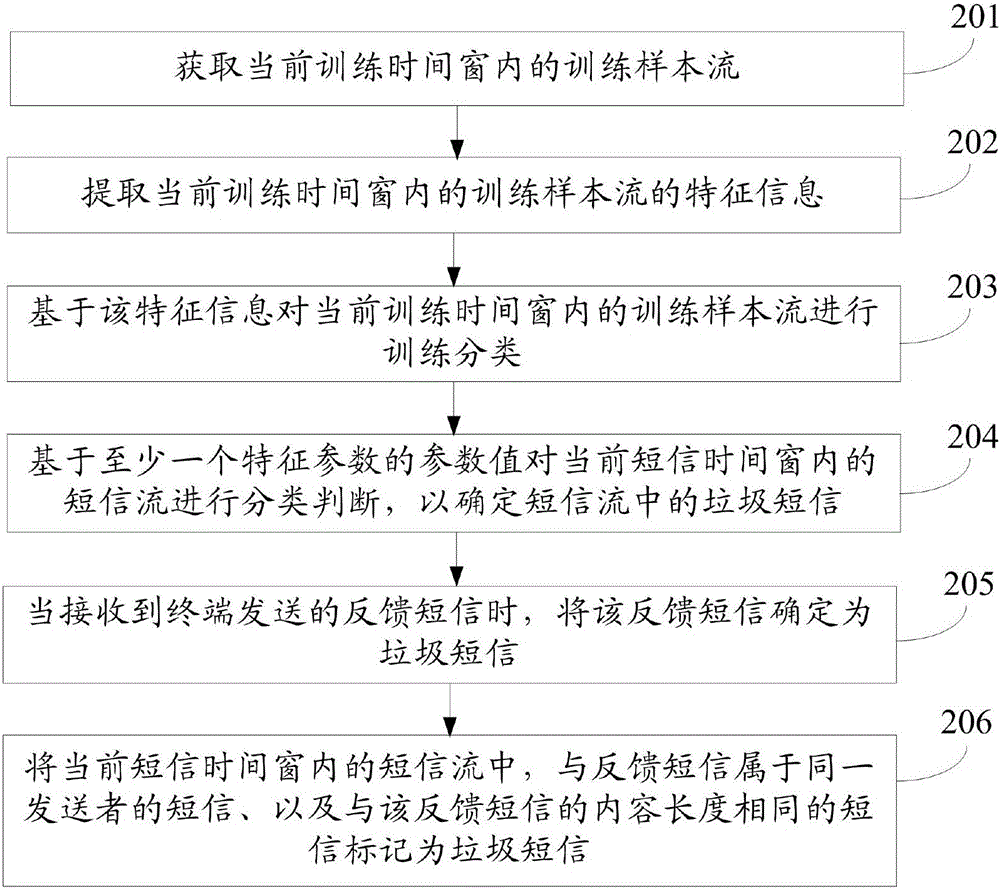

Junk short message detecting method and device

InactiveCN105828306AReal-time detectionImprove detection efficiency and accuracyMessaging/mailboxes/announcementsSecurity arrangementText messagingMessage flow

The invention provides a junk short message detecting method and device, relates to the field of information processing, and aims at improving the accuracy and efficiency of junk short message detection. The method comprises that a training sample flow of a present training time window is obtained according to a last short message time window; feature information is extracted from the training sample flow of the present training time window, comprises a short message sending feature and a short message content feature, and includes at least one feature parameter; the training sample flow in the present training time window is trained and classified on the basis of the feature information, and values of the at least one feature parameter corresponding to a normal short message and a junk short message are obtained; and on the basis of the values of the at least one feature parameter, a short message flow in a present short message time window is classified and determined, and the junk short message of the short message flow in the present short message time window is determined.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

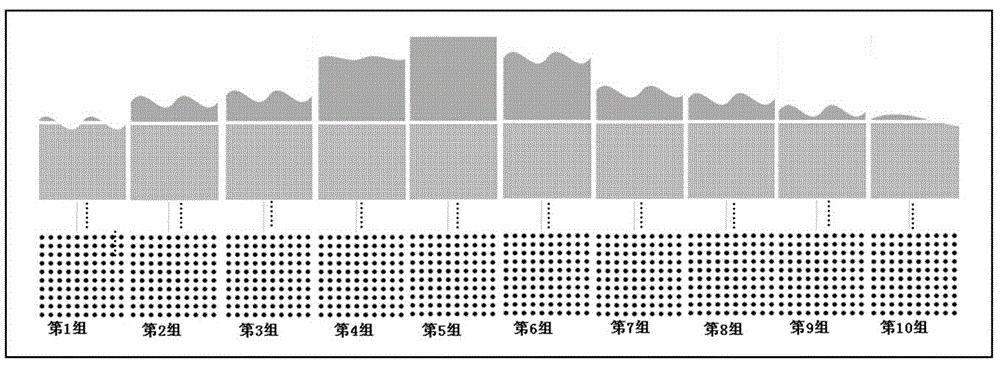

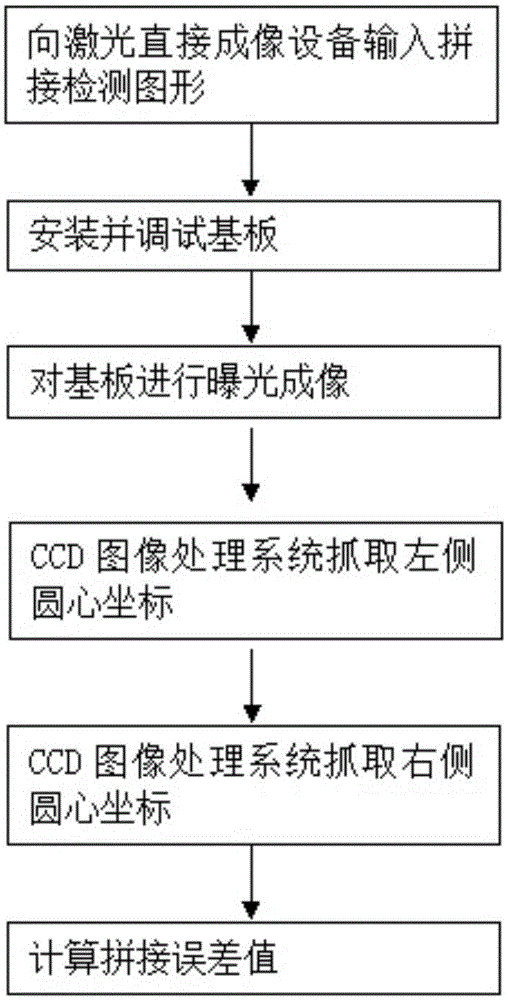

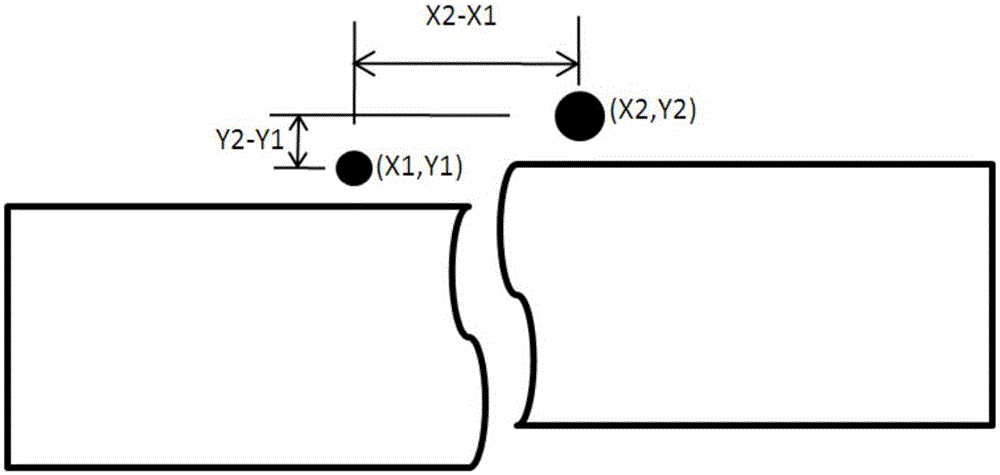

Detection method of figure splicing errors of laser direct imaging device

InactiveCN105115426AImprove detection efficiency and accuracyFewer measurement stepsUsing optical meansMicroscopeImaging equipment

The invention provides a detection method of figure splicing errors of a laser direct imaging device. The method includes the following steps that: splicing detection figures are inputted to the laser direct imaging device; a substrate is installed and commissioned; exposure imaging is performed on the substrate; a CCD image processing system captures the coordinates of the center of the circle at the left side; the CCD image processing system captures the coordinates of the center of the circle at the right side; and a splicing error value can be obtained. According to the detection method of the invention, a spatial light modulator directly images a laser beam on the substrate coated with a light sensing dry film; the CCD image processing system of the laser direct imaging device is utilized to capture the coordinates of the centers of the circles at two sides of a figure splicing position; and the error of the coordinates at the two sides in an X direction and a Y direction is calculated, and the error is a splicing error. According to the method, a chemical development step and a microscopic measurement step are omitted, and therefore, detection efficiency and accuracy can be greatly improved.

Owner:HEFEI ADVANTOOLS SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com