Device for real-time detecting product of production line of remote control

A real-time detection and production line technology, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of inability to monitor the qualified rate of production batches in real time, time-consuming and labor-intensive, etc., and achieve the effect of improving detection efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

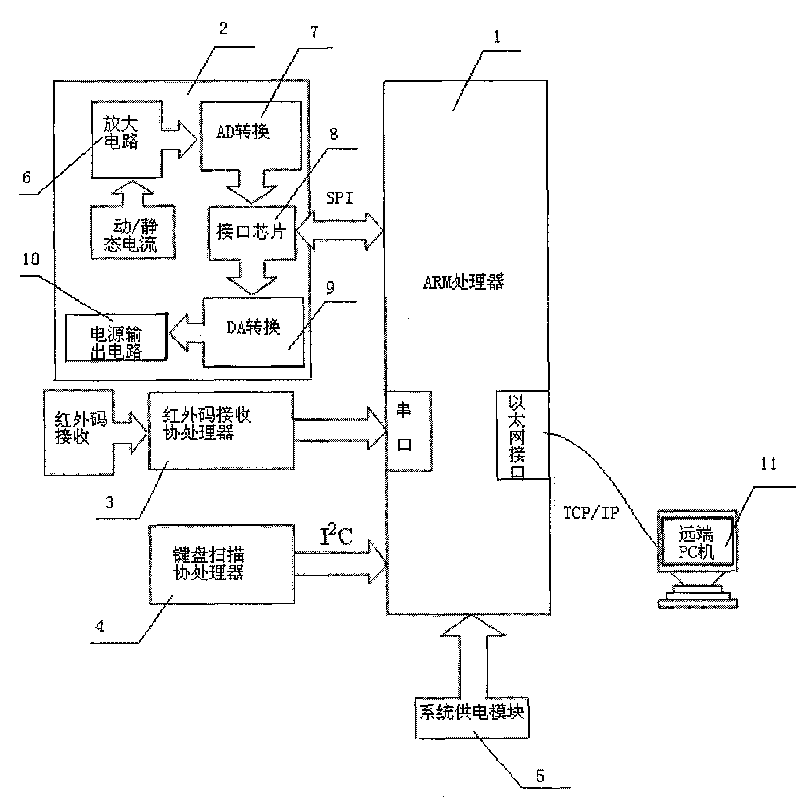

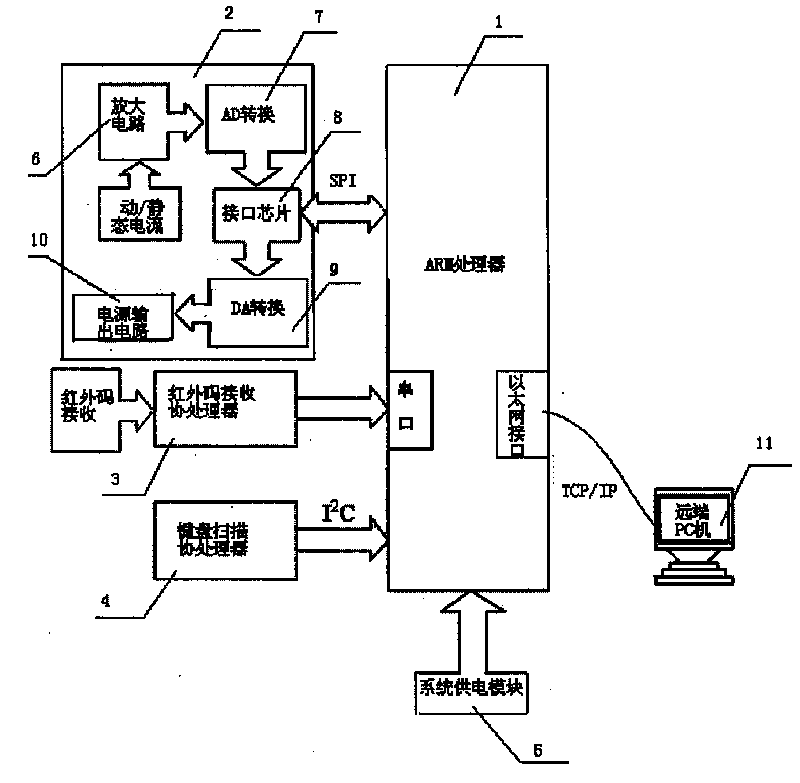

[0012] Such as figure 1 As shown, a real-time detection device for remote control production line products includes an embedded CPU module 1, a dynamic and static current detection and voltage regulation module 2, an infrared code receiving coprocessor 3, a keyboard scanning coprocessor 4 and a system power supply module 5. The system power supply module 5 is connected with the embedded CPU module 1 to supply power to it. Described embedded CPU module 1 is ARM9 processor, and the hardware resource that ARM9 processor module carries is abundant, comprises crystal oscillator circuit, reset circuit, JTAG mouth, FLASH, SDRAM, buzzer, indicator light, eight segment digital tube, system Expansion bus, serial port circuit, USB HOST host interface, SD card interface, LCD display and corresponding keyboard control circuit, etc. In order to facilitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com