Method for detecting position and type of workpiece on subway vehicle side inspection image

A subway and workpiece technology, applied in the field of machine vision industrial inspection, can solve a large number of manual operations and other problems, achieve the effect of reducing labor intensity, reducing difficulty, and facilitating the analysis of workpiece status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention is a method for detecting the position and type of the workpiece on the inspection image on the side of the subway car. The model training embodiment mainly describes that in order to obtain the workpiece detection model, the subway body image data is acquired, the workpiece target is marked in the image, and the YOLOv4 deep learning network is built. And training, as well as model output, the specific implementation process is as follows:

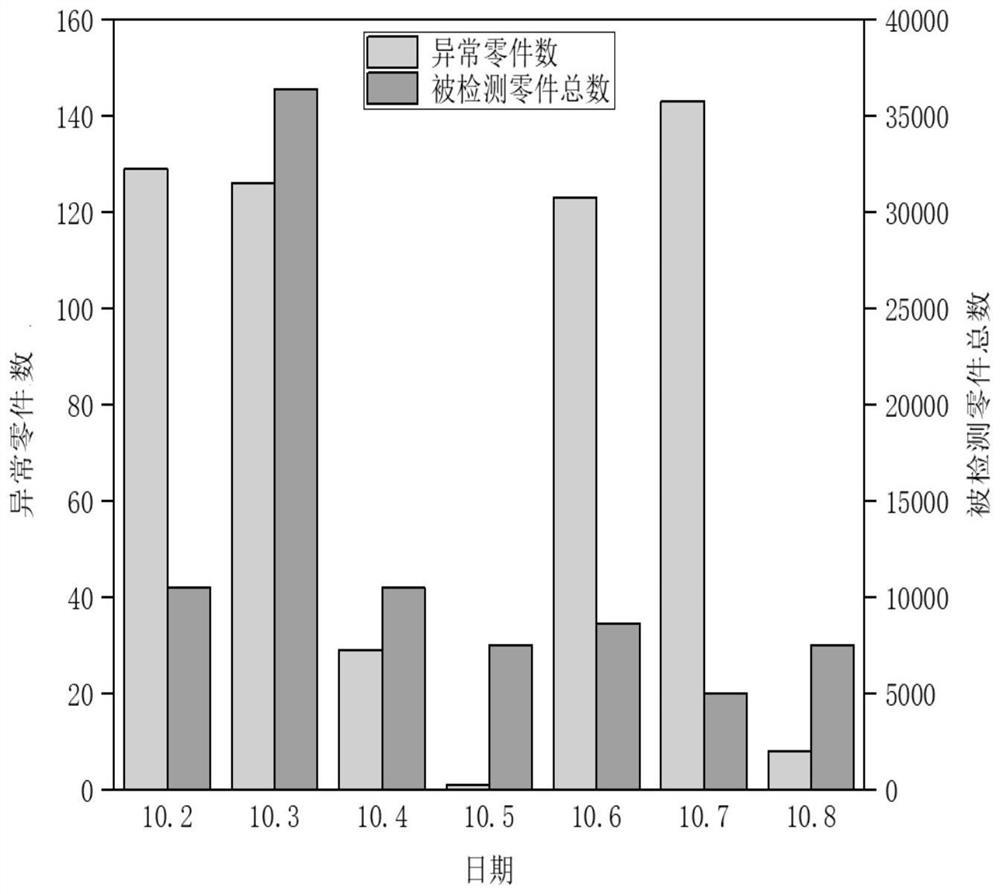

[0031] 1) Install two industrial cameras on both sides of the subway track to scan the body of the subway train, output the original scanned picture with a resolution of 65535×1808, and divide the original picture into sub-pictures of 1808×1808 size for storage.

[0032] 2) Use the Colabeler labeling tool to label each workpiece that appears on the picture. In this embodiment, it mainly includes different screws, upper brake pads, lower brake pads and iron wires. There are 10 workpiece target types in total. The...

Embodiment 2

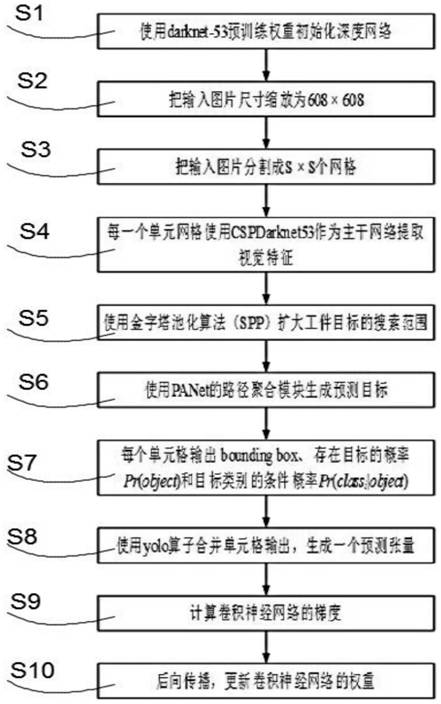

[0036] Such as figure 1 As shown, the invention builds a subway train workpiece detection model based on the YOLOv4 target detection network architecture. YOLO is a target detection model based on deep learning. The present invention builds a new subway workpiece detection model based on YOLOv4. The detection algorithm flow is as follows figure 1 As shown, the steps of model training are as follows:

[0037]a) First, use the pre-trained weights of the CSPDarknet53 network to initialize the backbone network of YOLOv4. The weights are trained using MS COCO target detection data, which can detect 80 objects in the MS COCO data set. In order to adapt to the application of subway body workpiece detection, it is necessary The output classification of YOLOv4 network is revised to the kind number of workpiece (being 10 kinds in the present invention), thereby can satisfy the condition of transfer learning;

[0038] b) For a sub-picture to be trained, its resolution is 1808×1808, and ...

Embodiment 3

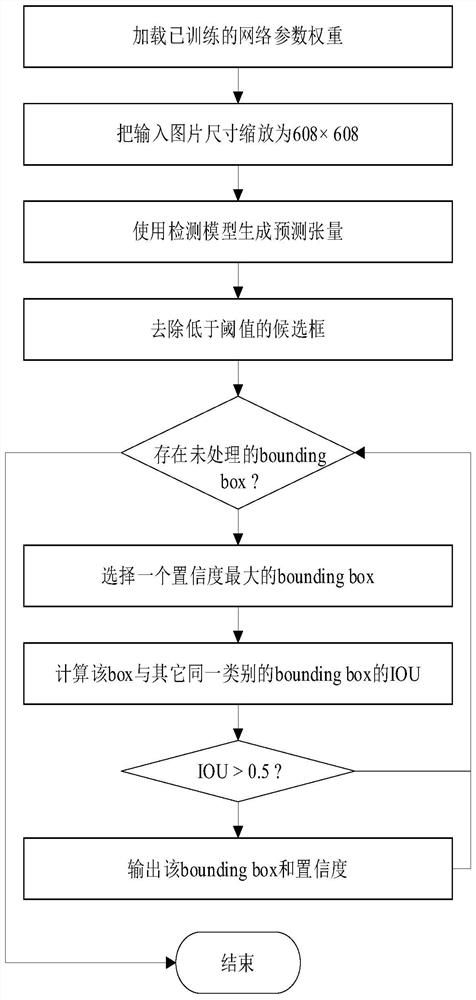

[0052] After the above-mentioned training method is trained in the subway car body workpiece detection data set, the present invention can obtain a trained workpiece detection model, which can run under the Darknet deep learning framework, and output a length of S × S × (B × 5+ C) prediction tensor, in order to detect the position of each workpiece and identify the type of the workpiece, the present invention introduces a non-maximum suppression algorithm (non maximum suppression, NMS) to find the target frame and confidence from the prediction tensor. The steps are as follows:

[0053] 1) Set a threshold and filter out all target candidate bounding boxes smaller than this threshold;

[0054] 2) Select the one with the largest target confidence of a certain workpiece candidate bounding box, which is box_best;

[0055] 3) Calculate the IOU (Intersection over Union) of box_best and other artifact candidate bounding boxes, that is, the intersection of the two boxes is more than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com