AOI (Automated Optical Inspection)-based display panel defect classification method and device

A technology for display panel defects and classification methods, which is applied in the directions of measuring devices, optical testing flaws/defects, and analyzing materials, etc., can solve the problems of difficult control of gray uniformity, high false detection rate, and complicated manufacturing process, so as to improve the The effect of detection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: A display panel defect level judging device capable of learning, classifying and judging the defect type of the display panel

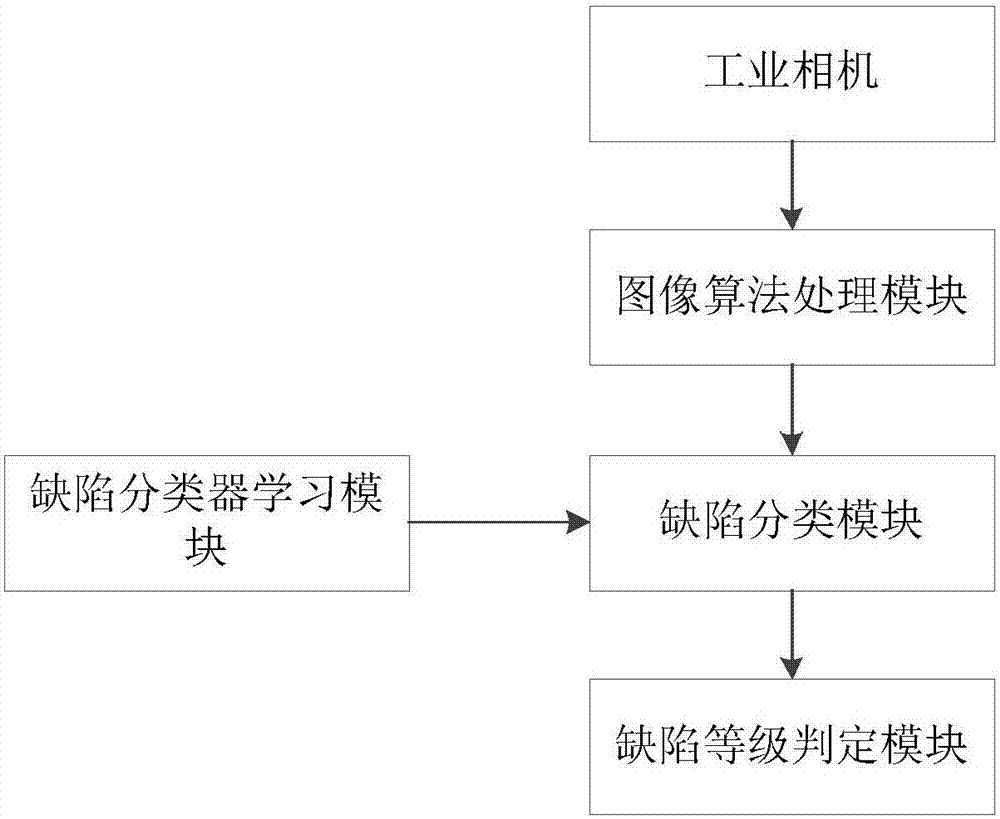

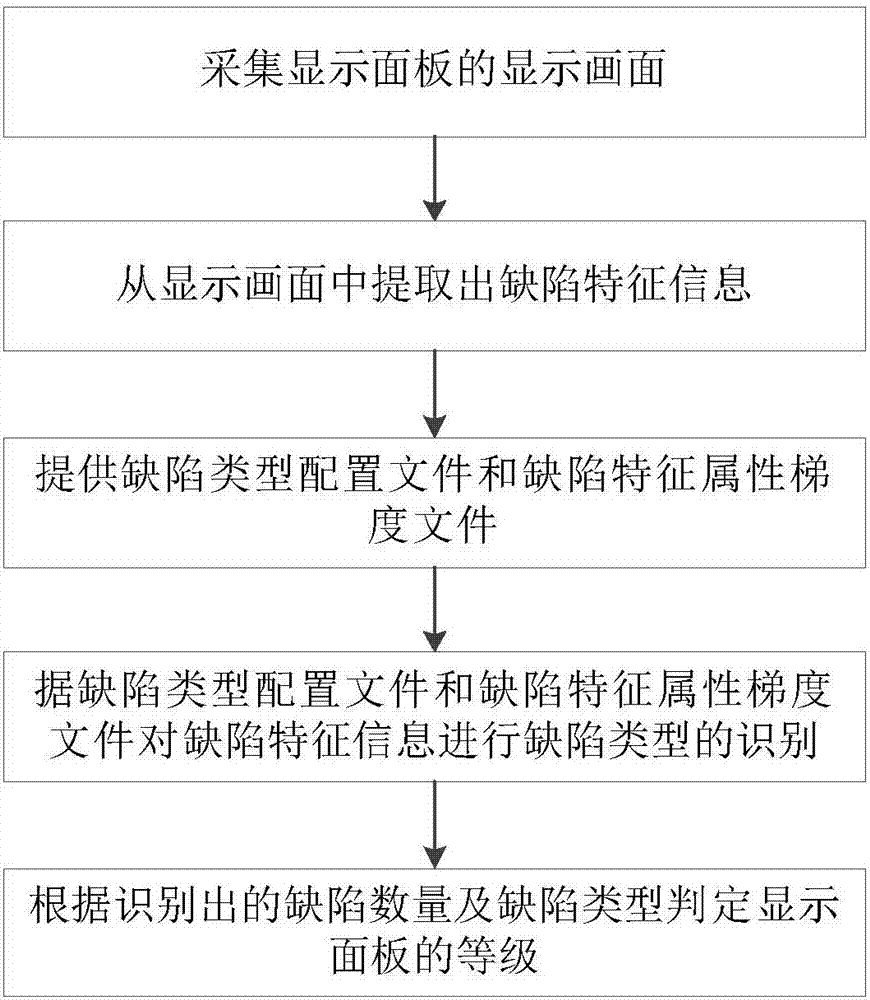

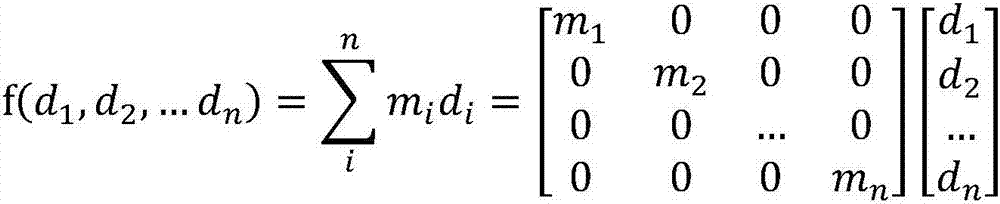

[0034] Such as figure 1 As shown, a display panel defect level determination device provided by an embodiment of the present invention mainly includes an industrial camera, an image algorithm processing module, a defect classifier learning module, a defect classification module, and a defect level determination module. Among them, the industrial camera is mainly used to collect the display screen of the display panel; the image algorithm processing module is mainly used to extract defect feature information from the display screen; the defect classifier learning module is used to provide defect type configuration files and defect feature attribute gradient files; The defect classification module is used to identify the defect type according to the defect type configuration file and the defect feature attribute gradient file; the defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com