Method for determination of tin content in tin-lead solder by complexometric titration method

A technology of tin-lead solder and complexometric titration, which is applied in the direction of chemical analysis by titration, can solve the problems of unguaranteed sealing performance and repeatability, cumbersome operation, and difficulty in mastering, so as to improve detection efficiency, accuracy, and operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: a kind of method for measuring the amount of tin in tin-lead solder by complexometric titration, its steps are as follows:

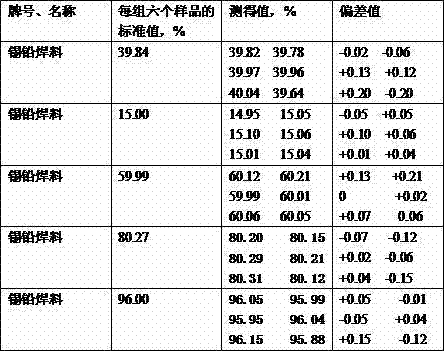

[0022] 1. Sample weight: weigh a total of five groups of 30 samples according to the range specified in Table 1 and measure them respectively.

[0023] Tin content, % Sample weight, g 15~60 0.2000 >60~96 0.1000

[0024] 2. Determination:

[0025] 1) Place the sample in a 250 ml conical beaker.

[0026] 2) Add 8ml of hydrochloric acid, 1~2ml of nitric acid, heat to dissolve at low temperature, when there are many small bubbles at the beginning of the reaction, remove the triangular beaker, wait for the reaction to slow down, then place the triangular beaker at a low temperature in the electric furnace to continue dissolving . If white particles appear in the solution (samples with high lead content will appear), crush the white particles with a glass rod, continue heating and steaming to about 5ml or when sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com