Overhead line device parameter detection method based on BIM and three-dimensional point cloud fusion

A technology of 3D point cloud and parameter detection, which is applied in image data processing, instrumentation, calculation, etc., can solve the problems of low detection efficiency, time-consuming and labor-intensive, complex structure of catenary support devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

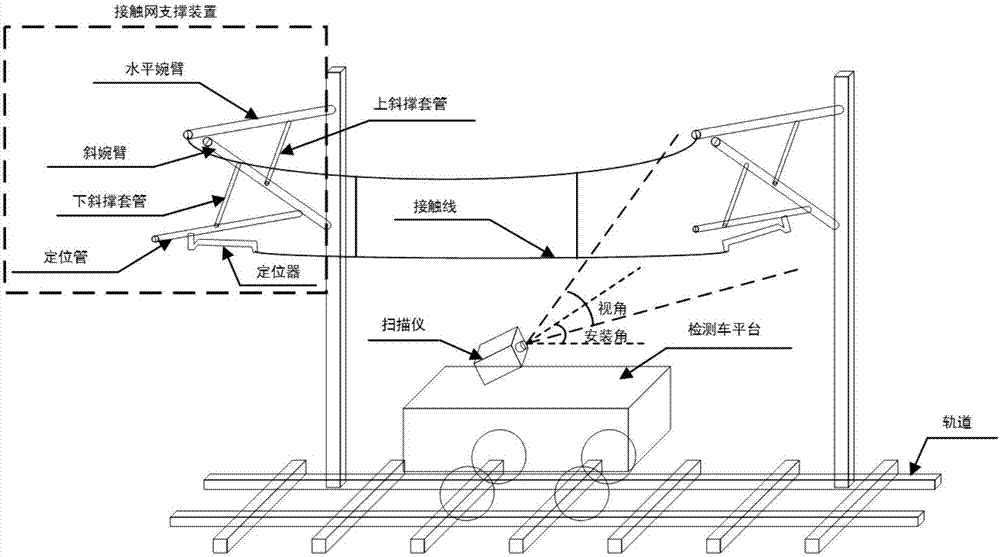

[0074] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. figure 1 It is a schematic diagram of the system detection device in this embodiment. By installing a 3D scanner above the detection vehicle, the 3D point cloud data image of the catenary support device is collected in real time.

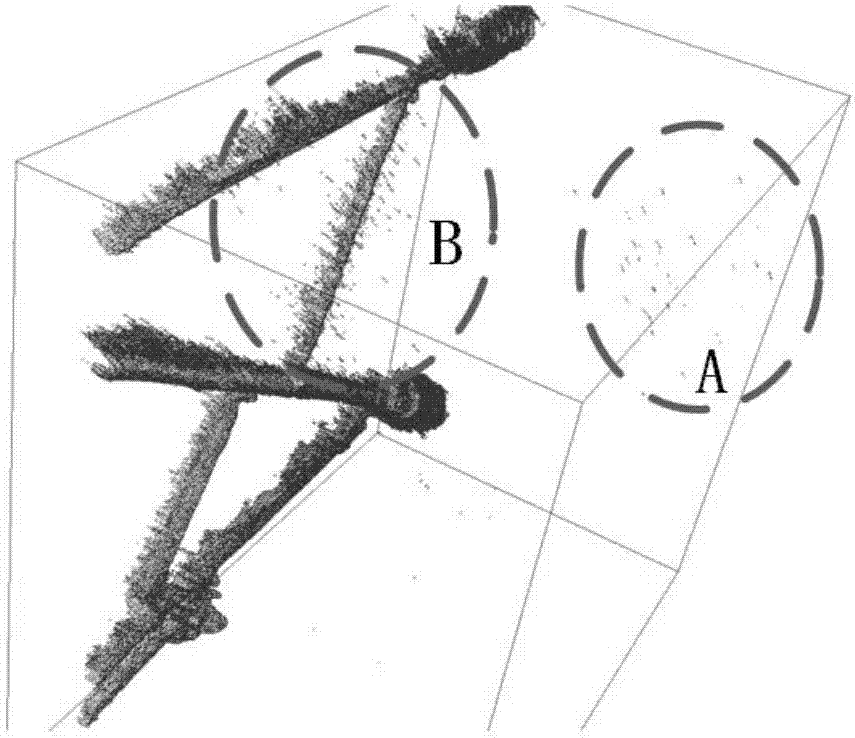

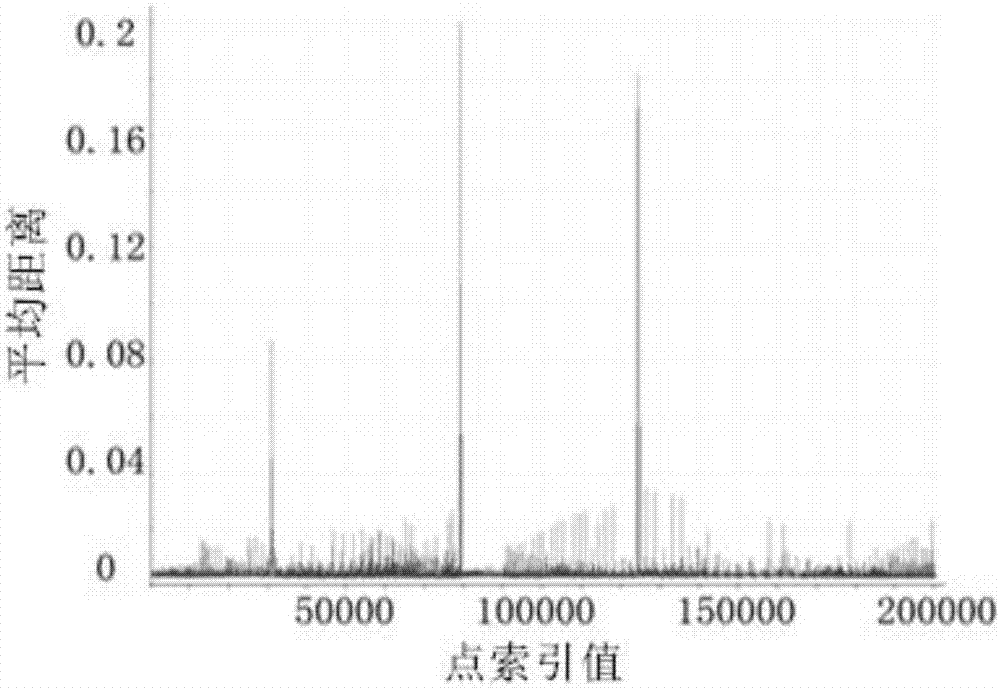

[0075] Then use mathematical statistics and RANSAC algorithm to realize point cloud data filtering and point cloud plane correction. The random sampling algorithm is used to perform point cloud operation on the BIM model of the catenary support device, and the point cloud data of the standard catenary support device is generated. The ICP algorithm is used to register the point cloud data of the catenary support device collected and the standard point cloud data of the catenary support device generated by the BIM model, and the local area segmentation of each component area of the catenary support device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com