Patents

Literature

90 results about "Blob analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blob Analysis. Introduction. Blob Analysis is a fundamental technique of machine vision based on analysis of consistent image regions. As such it is a tool of choice for applications in which the objects being inspected are clearly discernible from the background.

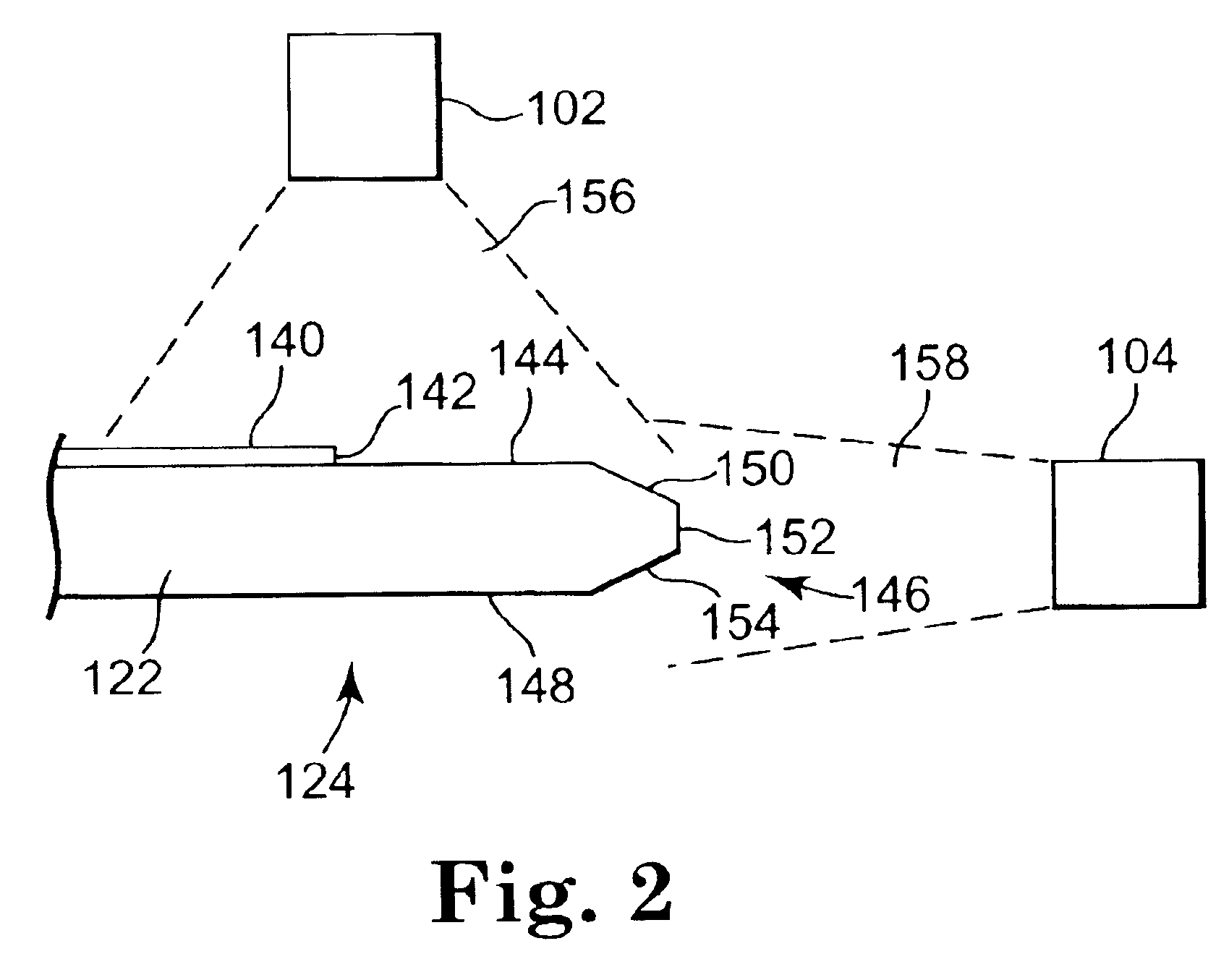

Methods and apparatuses for detecting classifying and measuring spot defects in an image of an object

InactiveUS7162073B1Improve accuracyImprove reliabilityImage enhancementImage analysisFiberComputer vision

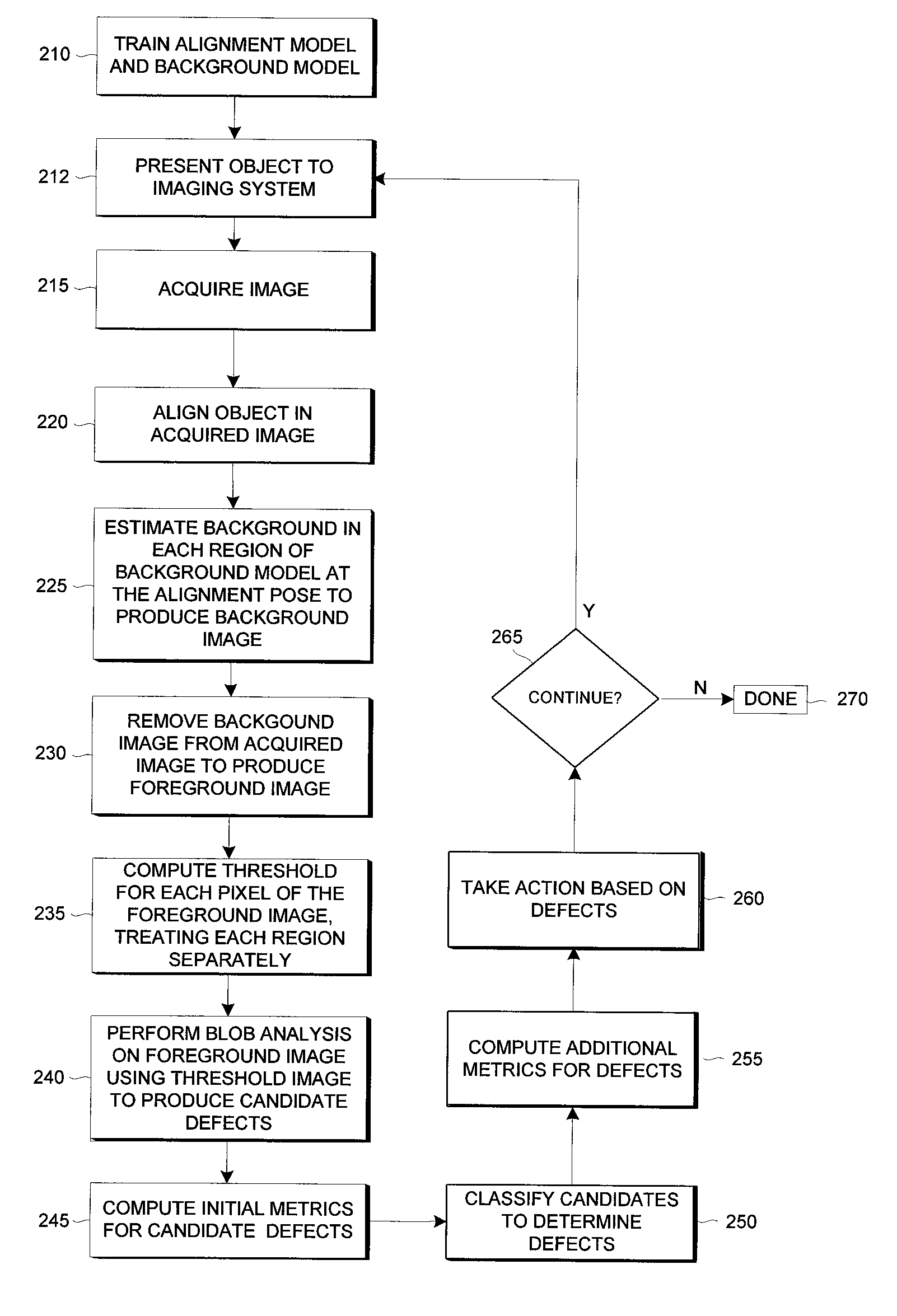

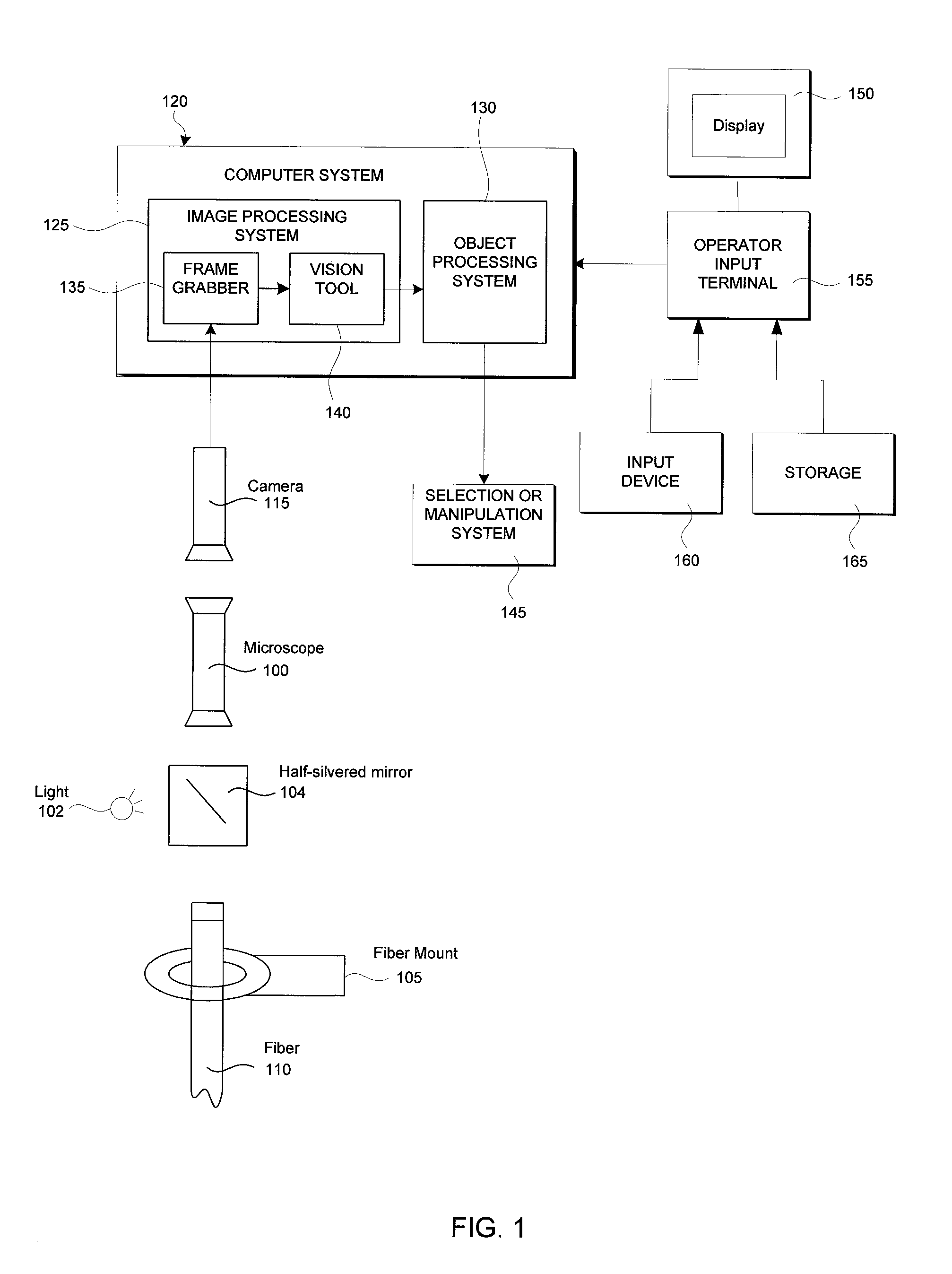

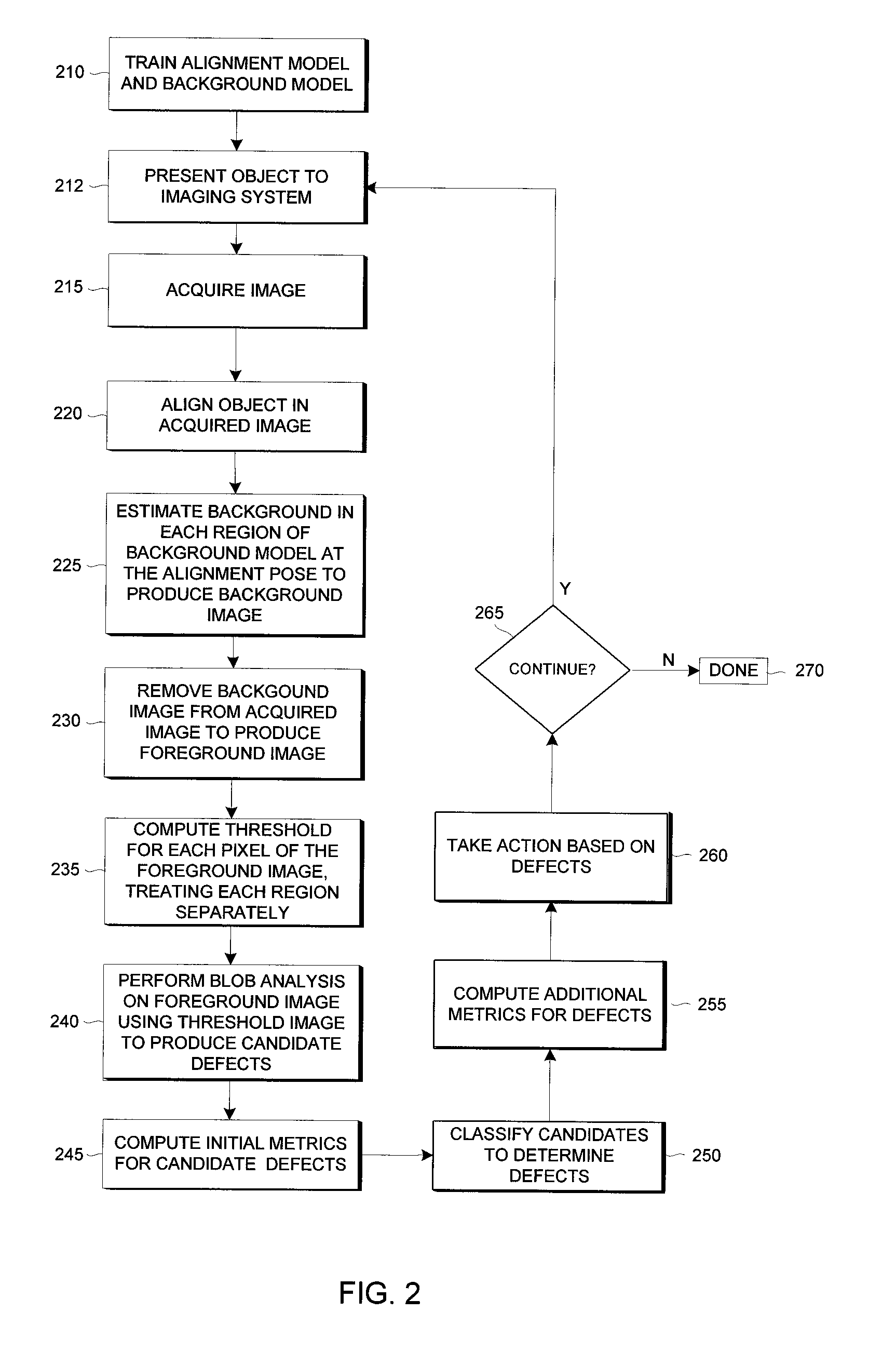

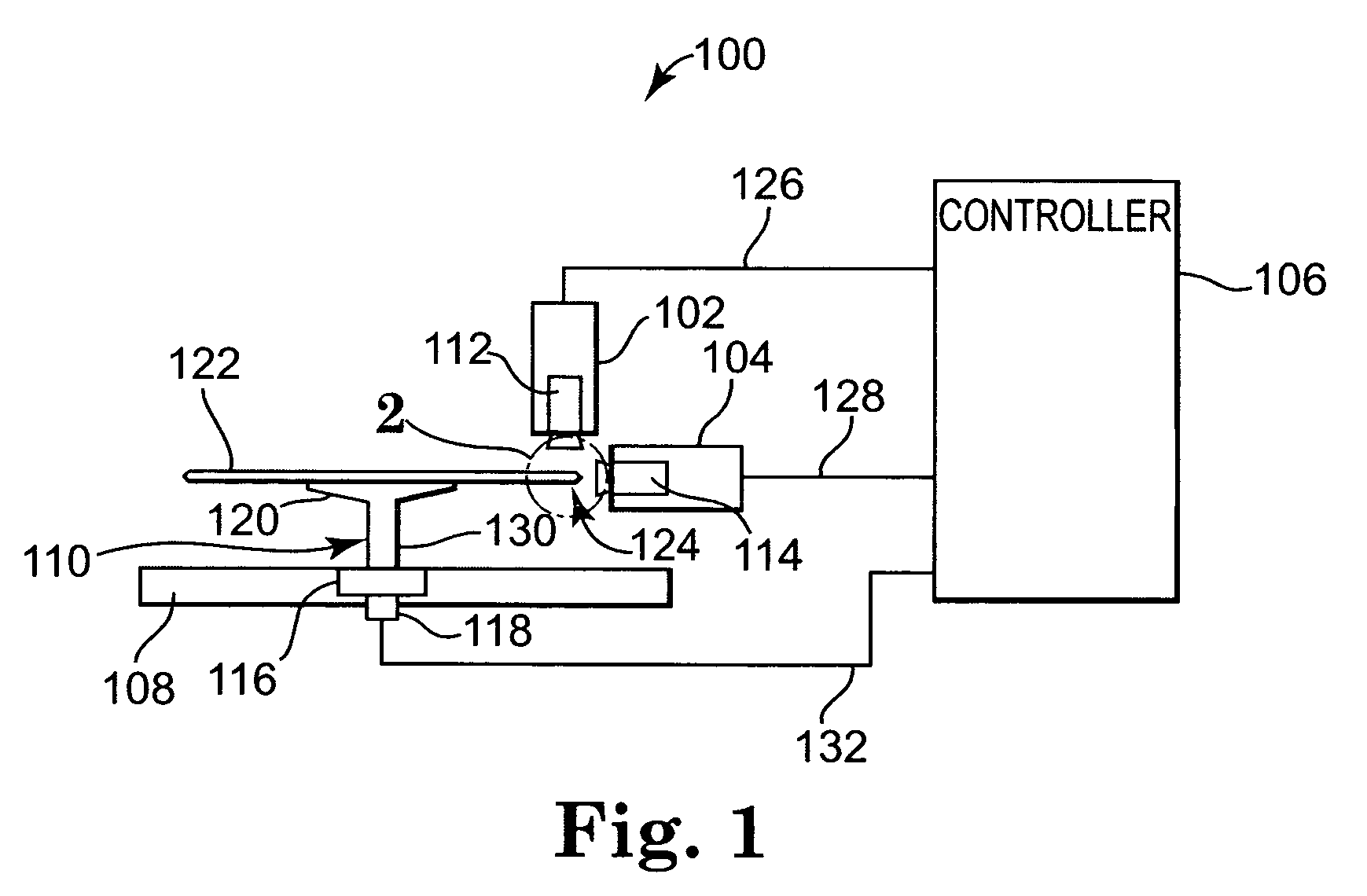

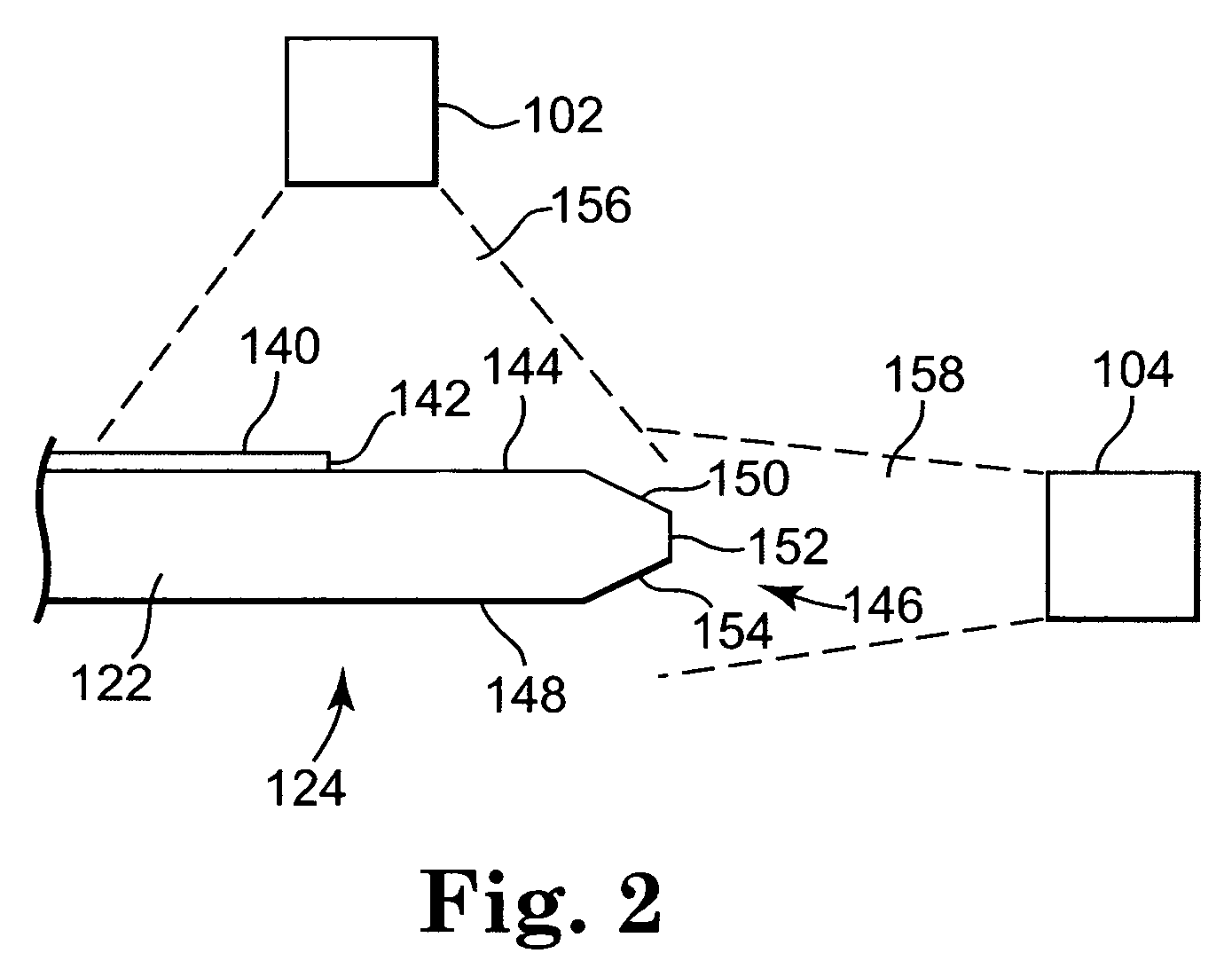

A method is provided for detecting spot defects on an object when an allowable variation (called the “background”) in the appearance of the object can be modeled. Methods are also provided for measuring and classifying detected spot defects. An alignment model is used to align the image of the object, a background model is then used to estimate the (possibly different) background in each region, and each background is substantially removed from the image so as to form a foreground image on which blob analysis can be applied to detect spot defects, the blob analysis using a threshold image that accommodates different noise statistics for each region. The method facilitates robust spot defect inspection of fiber optic end faces, or of any object with different object regions. The method also allows use of blob analysis over a larger range of conditions, including conditions that make simple blob analysis infeasible.

Owner:COGNEX TECH & INVESTMENT

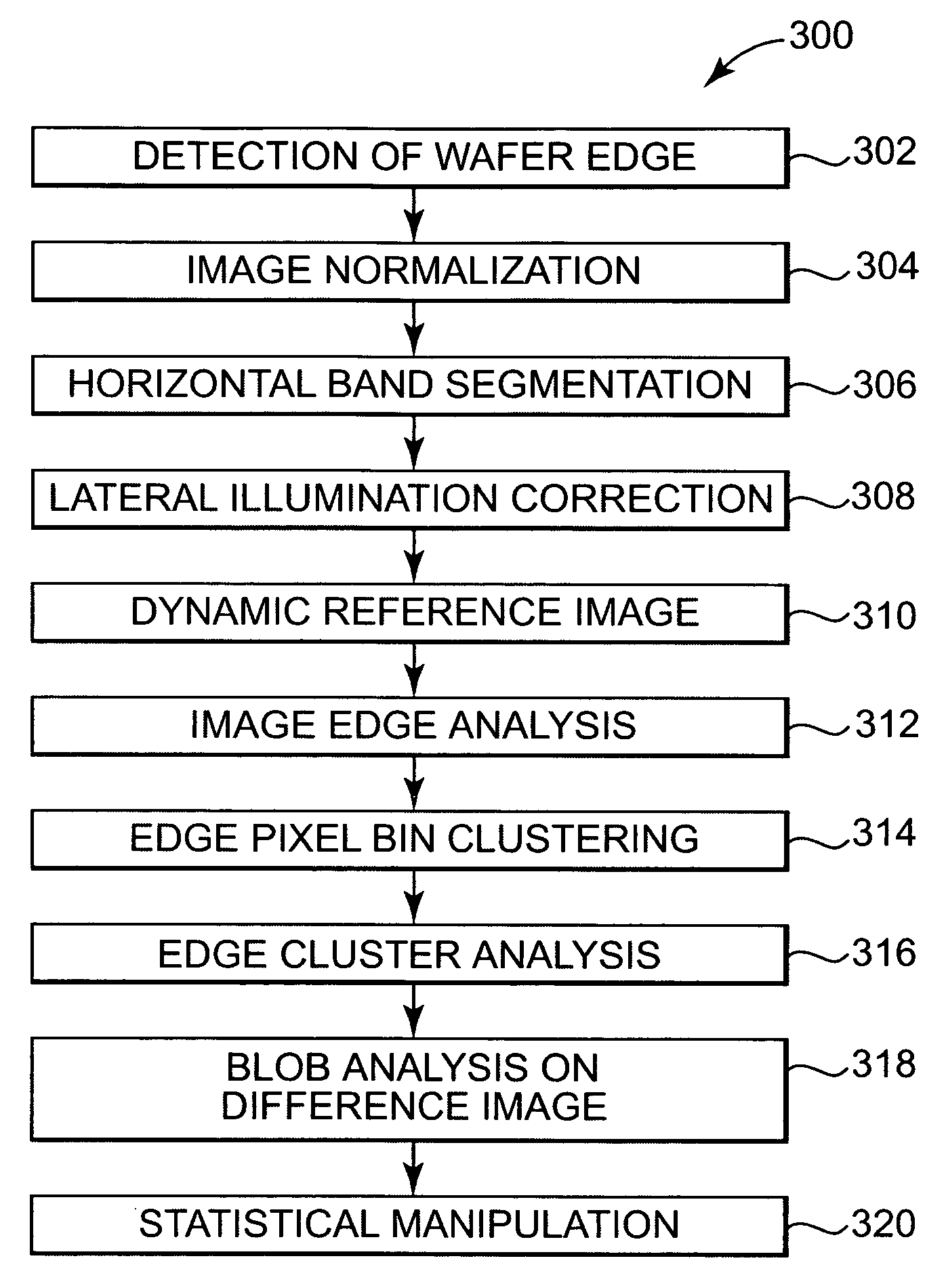

Edge normal process

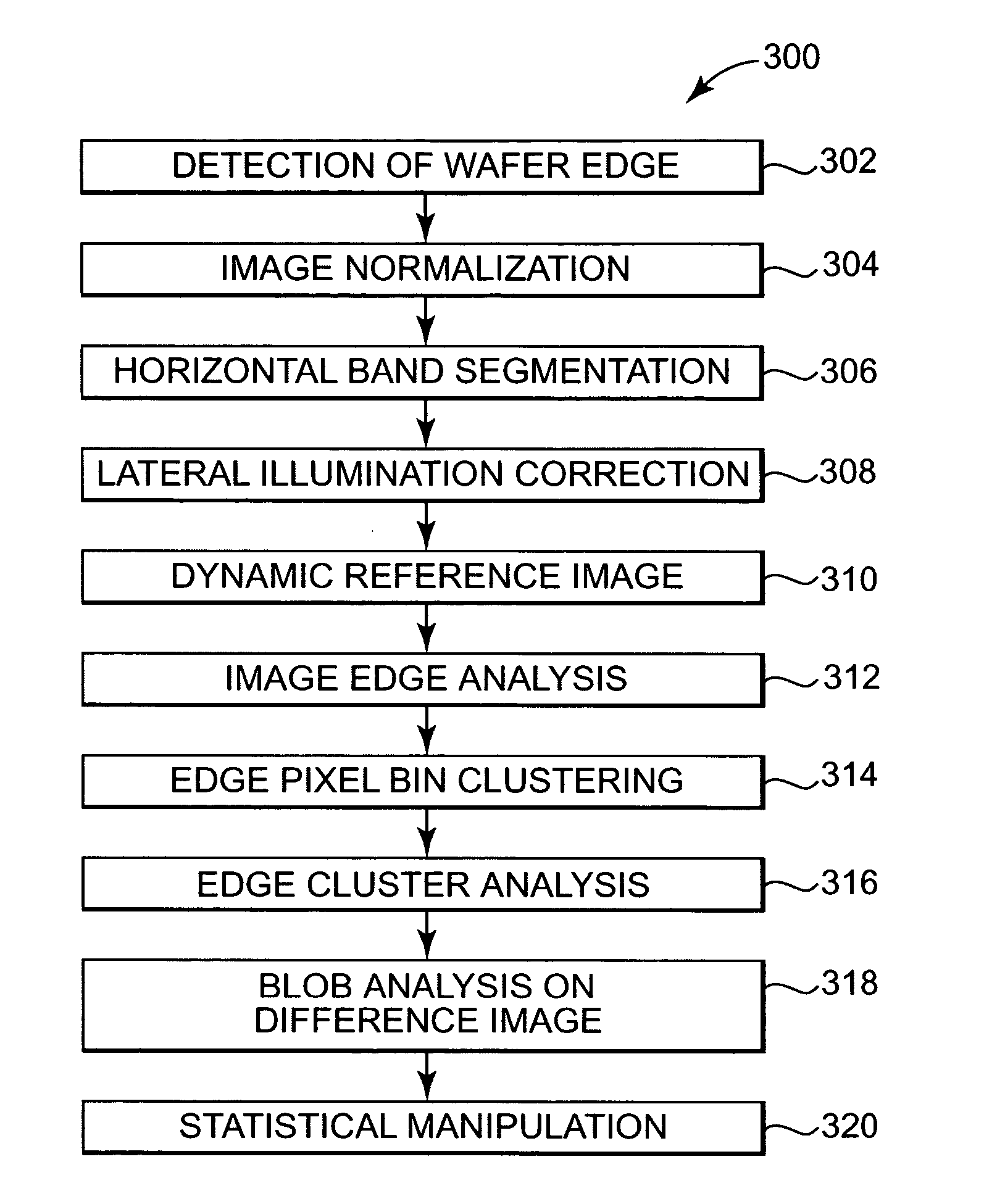

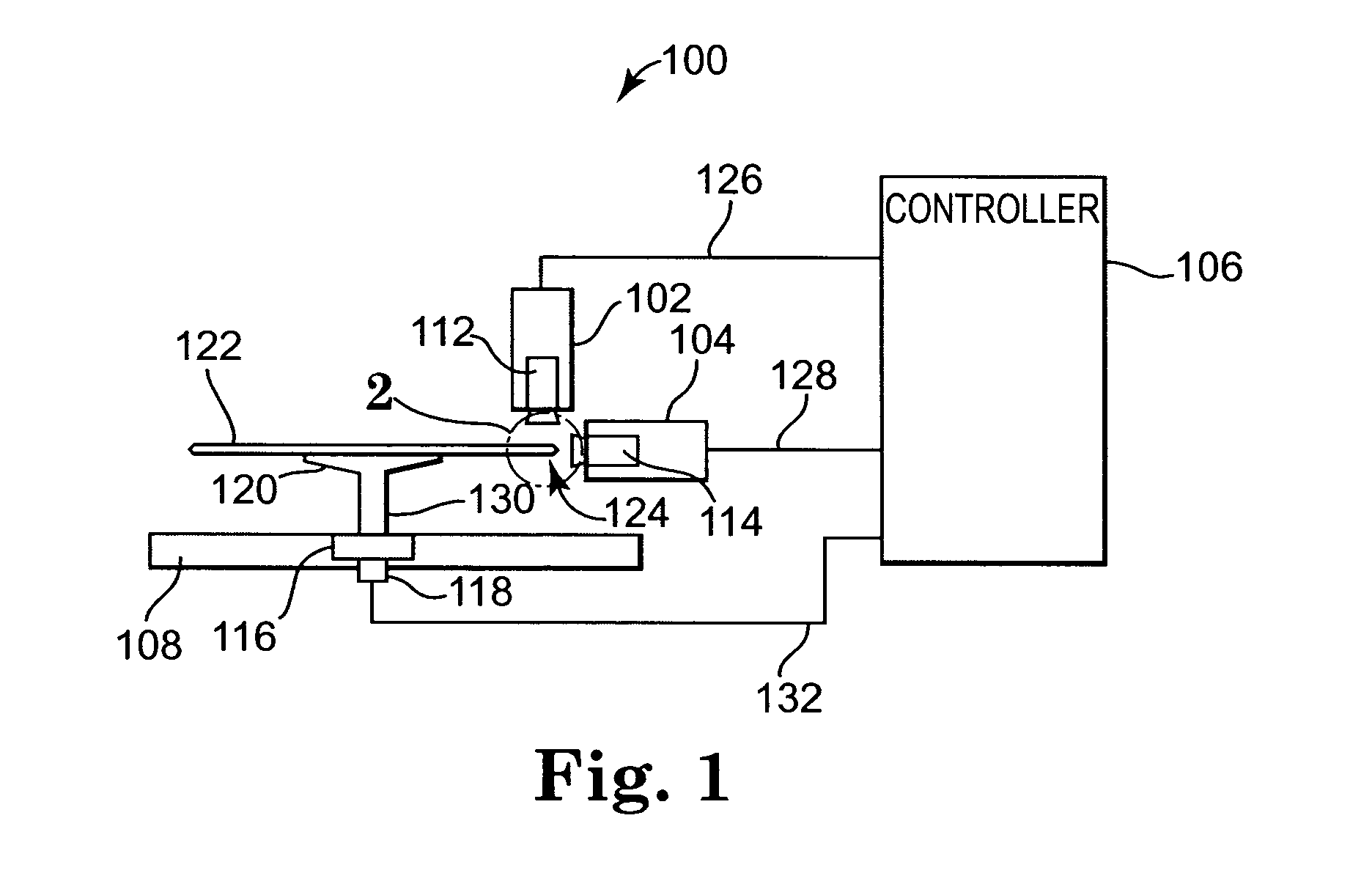

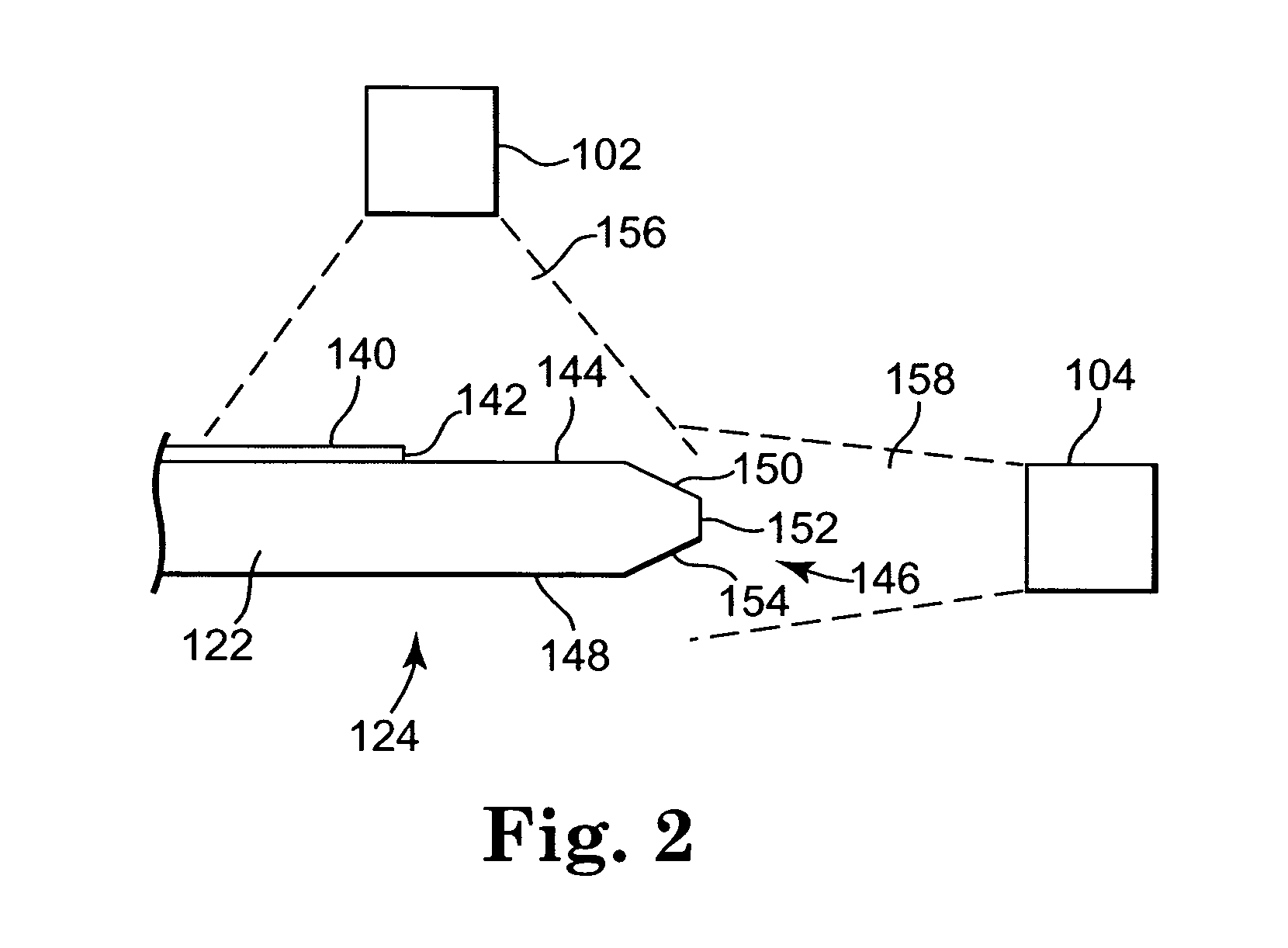

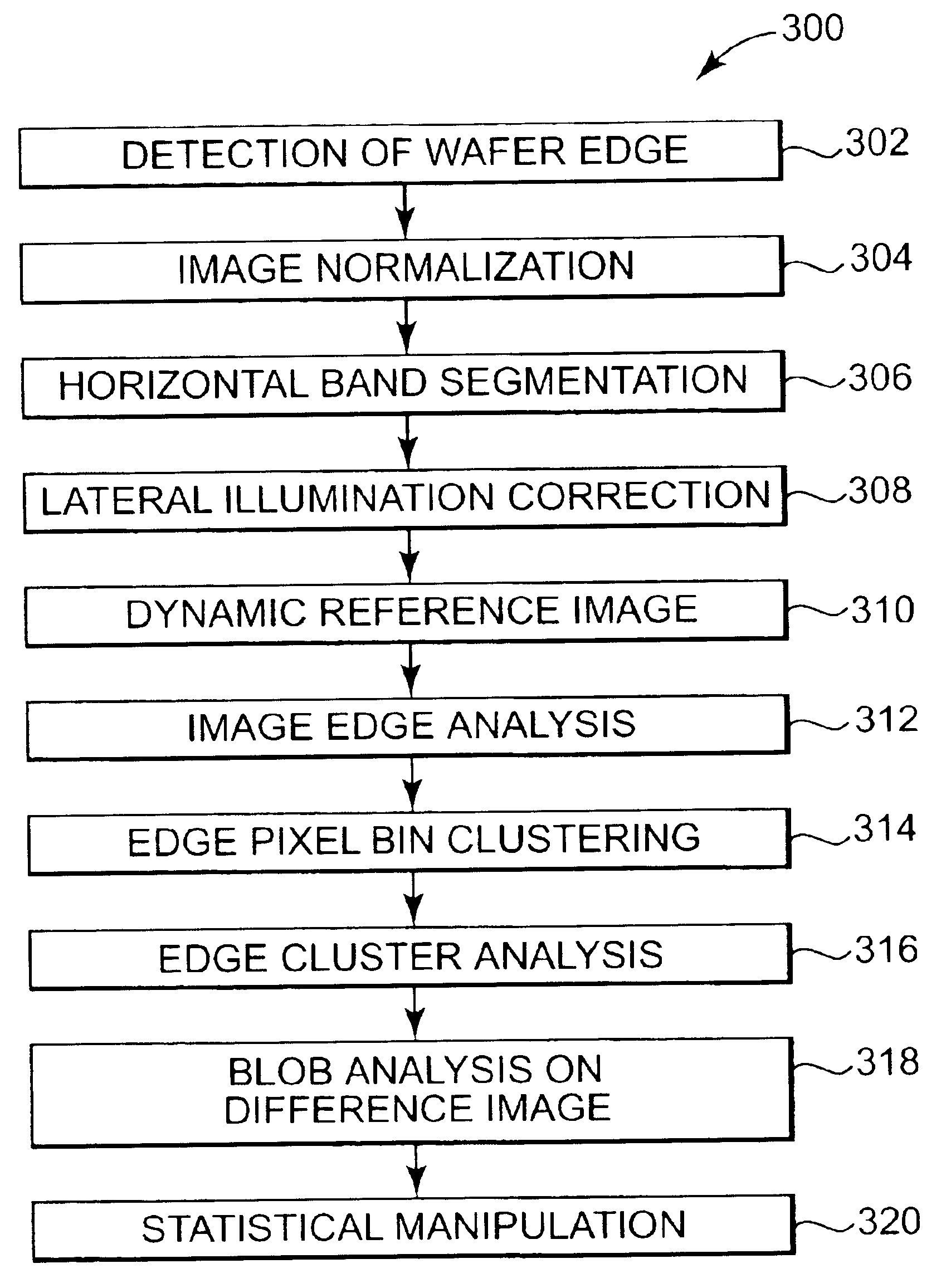

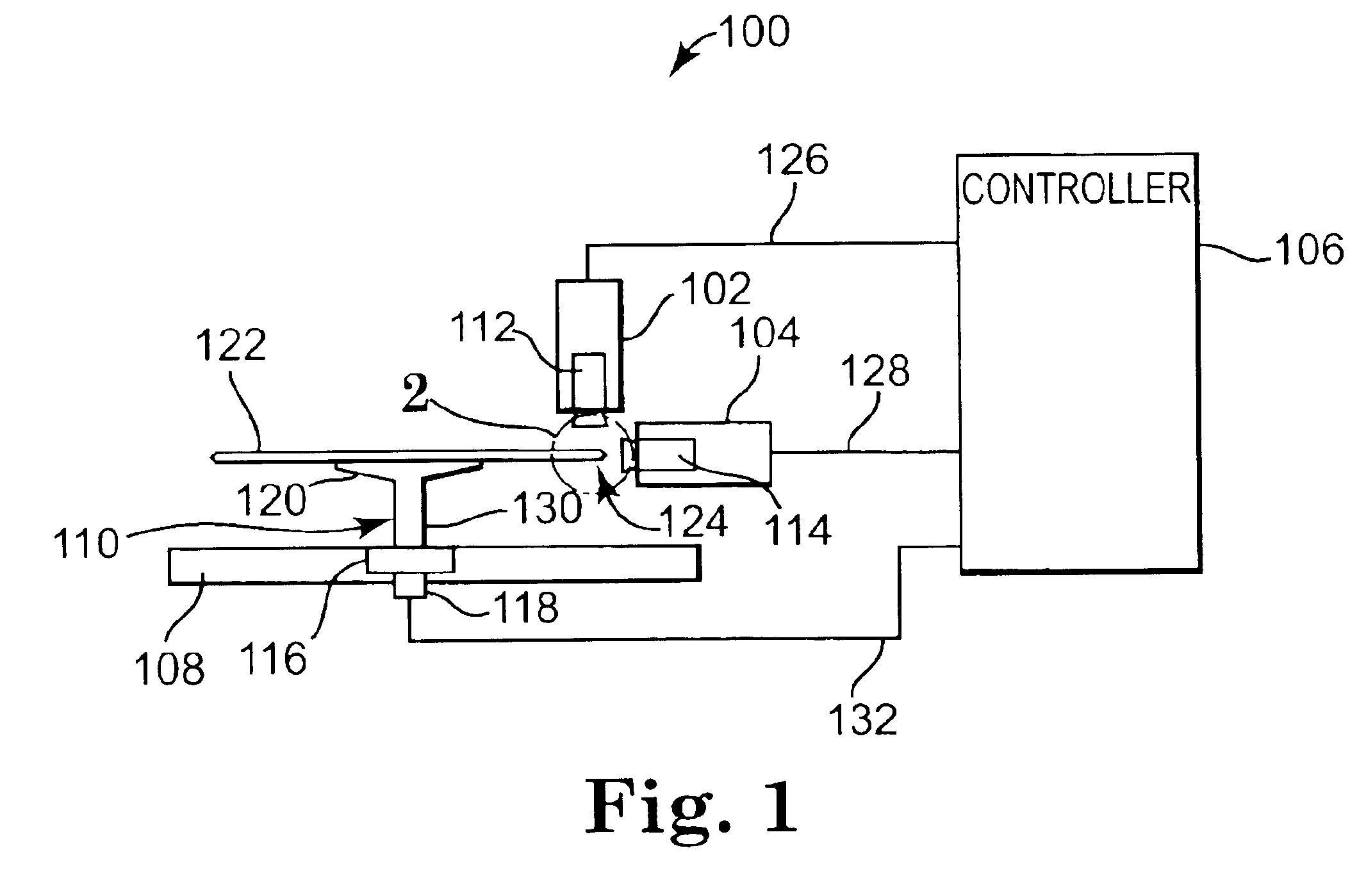

An edge inspection method for detecting defects on a wafer edge normal surface includes acquiring a set of digital images which captures a circumference of the wafer. An edge of the wafer about the circumference is determined. Each digital image is segmented into a plurality of horizontal bands. Adjacent edge clusters about the circumference of the wafer are combined into edge pixel bins. The edge pixel bins are analyzed via edge clusters analysis to identify defects. The edge pixel bins are also analyzed via blob analysis to determine defects.

Owner:ONTO INNOVATION INC

Edge normal process

Owner:ONTO INNOVATION INC

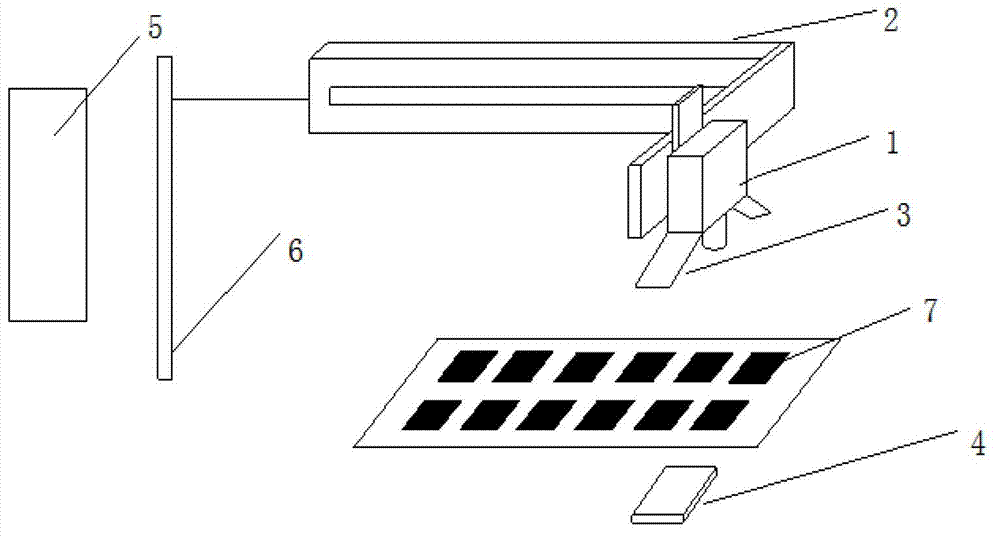

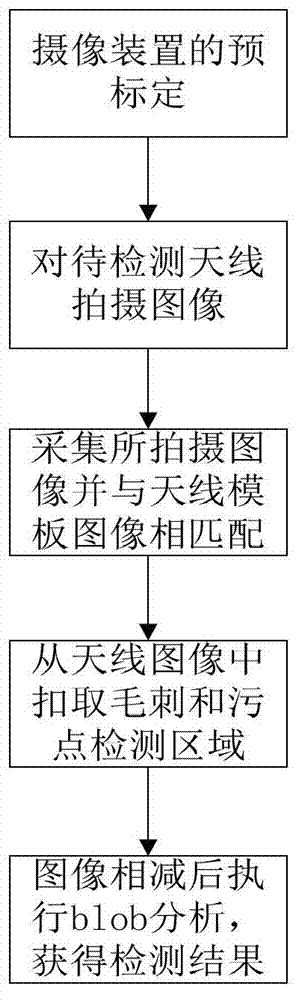

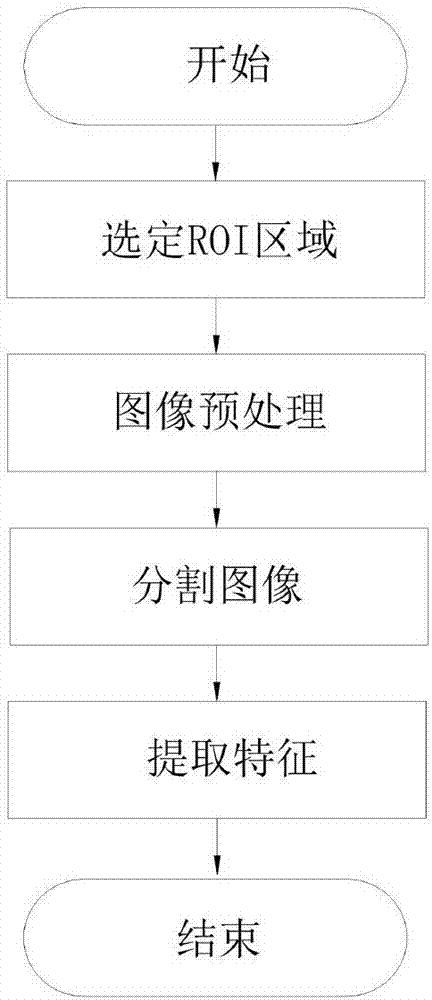

System and method for visual inspection on burrs and stain defects of radio frequency identification (RFID) antennae

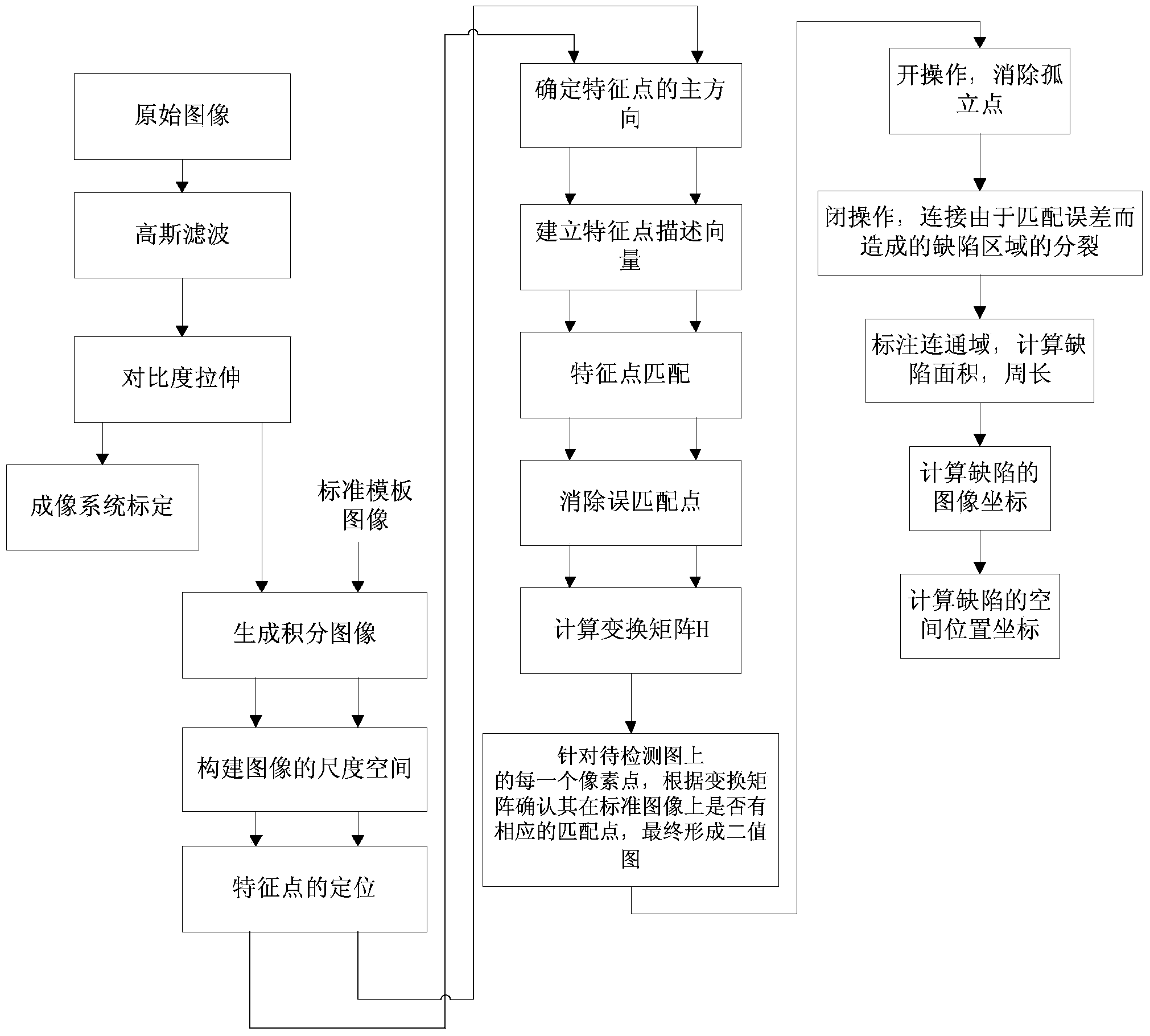

ActiveCN103091331AGuaranteed accuracyEnsure consistencyOptically investigating flaws/contaminationPattern recognitionImage subtraction

The invention discloses a method for visual inspection on burrs and stain defects of radio frequency identification (RFID) antennae. The method comprises the following steps of: calibrating a camera device, and then shooting images of each RFID antenna to be inspected through the cooperation of the camera device and a strip-type or backlight source; acquiring the shot images of the antennae, and matching the acquired shot images with images of an antenna template to obtain pre-alignment information; taking off corresponding burrs and stain inspection areas from the images of the antennae according to regions of interest (ROI) on the images of the antenna template and the pre-alignment information; respectively carrying out binary processing on the inspection areas taken off from the images and the ROI, and then carrying out image subtraction; and carrying out blob analysis on residual images subjected to the image subtraction, and determining results of the burrs and the stain defects. The invention also discloses a system for carrying out the corresponding visual inspection. Through the method and the system, the inspection process of the burr / stain quality of the RFID antennae can be carried out efficiently and accurately, and the positions of the defects can be accurately positioned, so that the method and the system are particularly suitable for industrial processing and manufacturing processes of the RFID antennae.

Owner:HUAZHONG UNIV OF SCI & TECH

Edge normal process

An edge inspection method for detecting defects on a wafer edge normal surface includes acquiring a set of digital images which captures a circumference of the wafer. An edge of the wafer about the circumference is determined. Each digital image is segmented into a plurality of horizontal bands. Adjacent edge clusters about the circumference of the wafer are combined into edge pixel bins. The edge pixel bins are analyzed via edge clusters analysis to identify defects. The edge pixel bins are also analyzed via blob analysis to determine defects.

Owner:ONTO INNOVATION INC

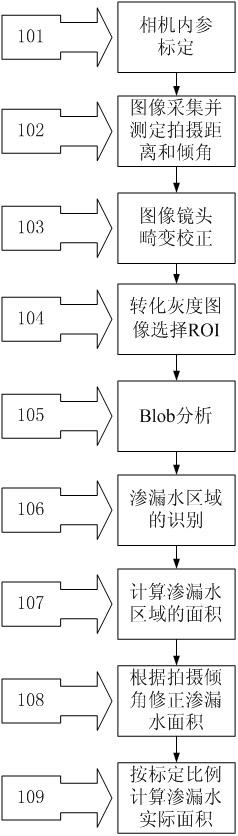

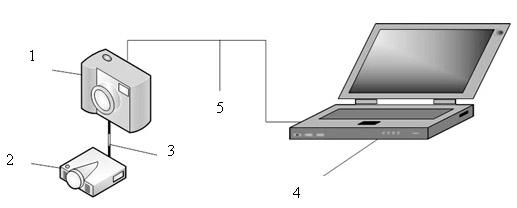

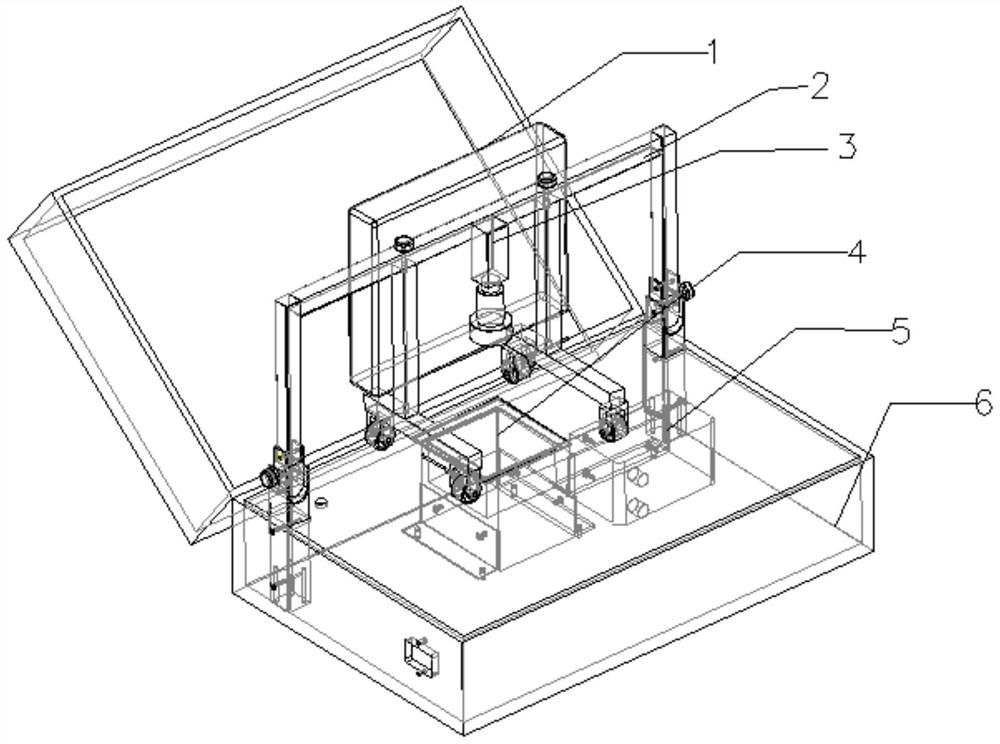

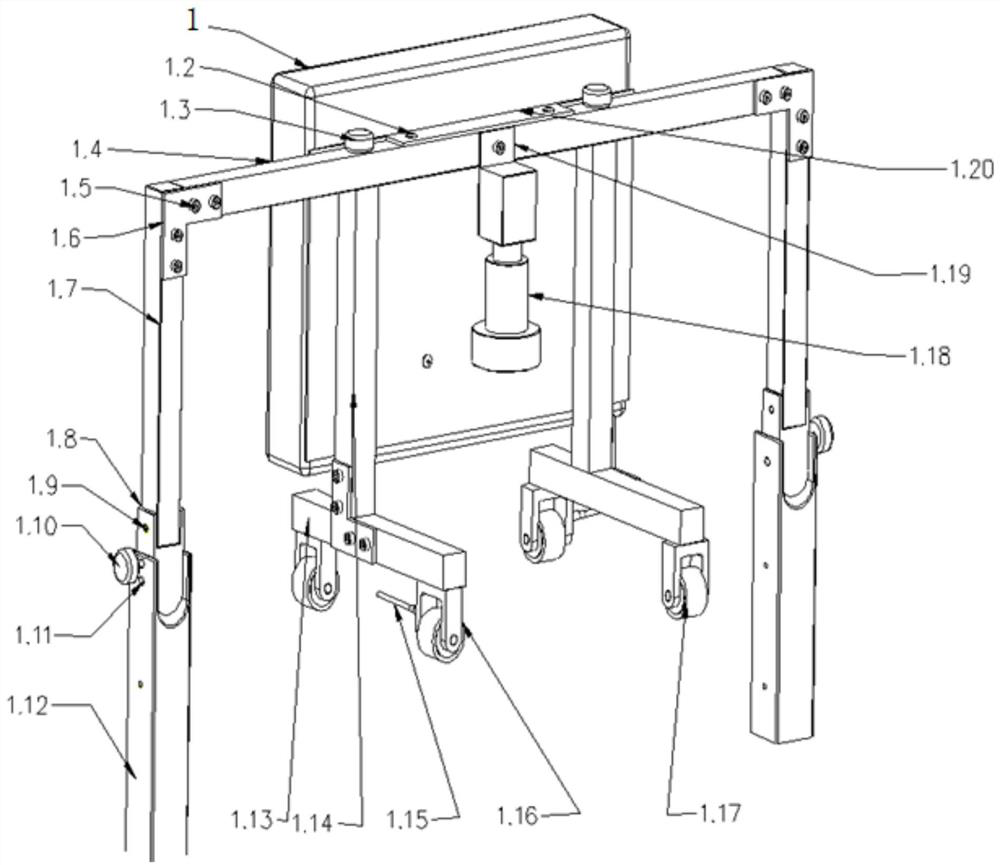

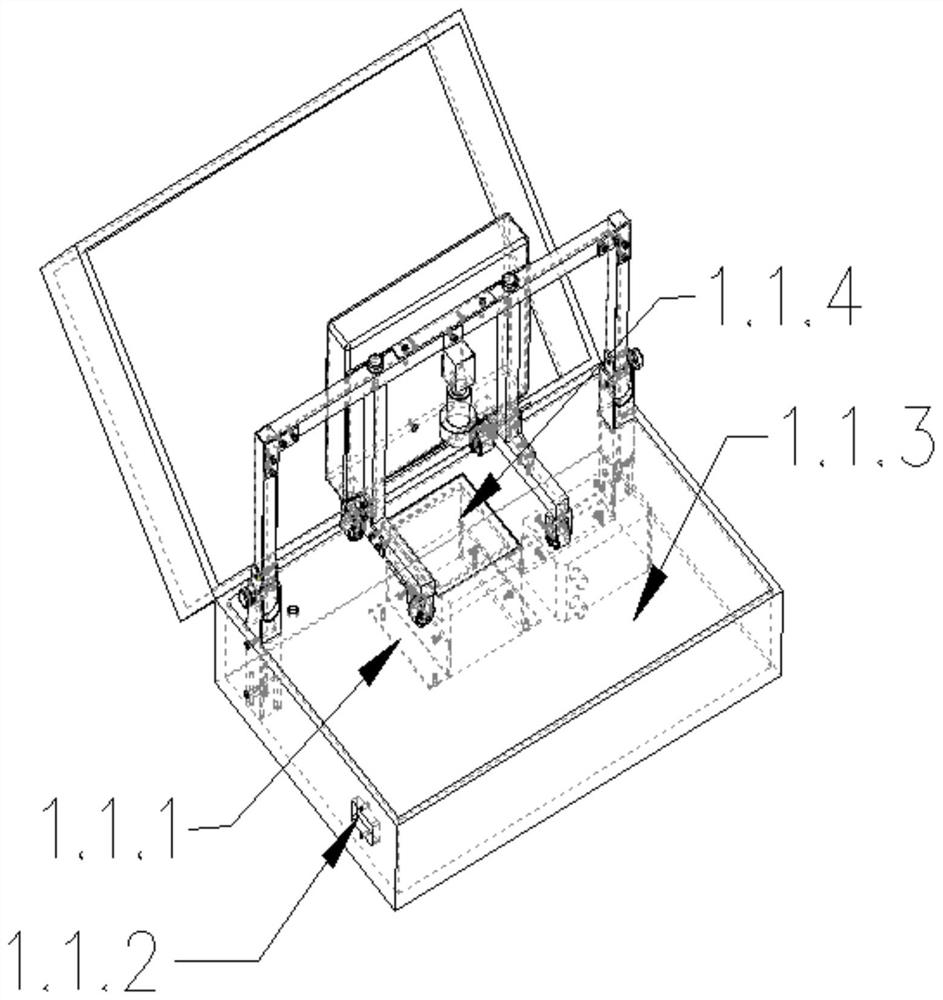

Method and device for measuring percolating water area of shield tunnel lining segment

The invention relates to a method and device for measuring the percolating water area of a shield tunnel lining segment. The method comprises the specific steps of: calibrating a camera by adopting a computer vision tool kit; acquiring an image of segment percolating water, measuring a shooting distance and a shooting inclination by using a laser distance measuring instrument; carrying out lens distortion correction on the acquired percolating water disease image by adopting a division distortion model; converting the acquired image into a gray image; carrying out Blob analysis on an ROI (Region of Interest), i.e., determining a maximum threshold and a minimum threshold of the ROI, and carrying out threshold segmentation to obtain region characteristics in the image including the segment percolating water region; carrying out connecting Blob analysis on the image obtained through primary segmentation, and connecting all target pixels judged as percolating water regions into a block; filling and filtering the percolating water disease region by adopting an opening operation and a closing operation to obtain a final percolating water region; calculating the area of the percolating water region; correcting the area of the segment percolating water region; and figuring out the actual area of the segment percolating water region. The method and device have the advantages of low cost, high precision, rapidness and convenience, and the like.

Owner:TONGJI UNIV

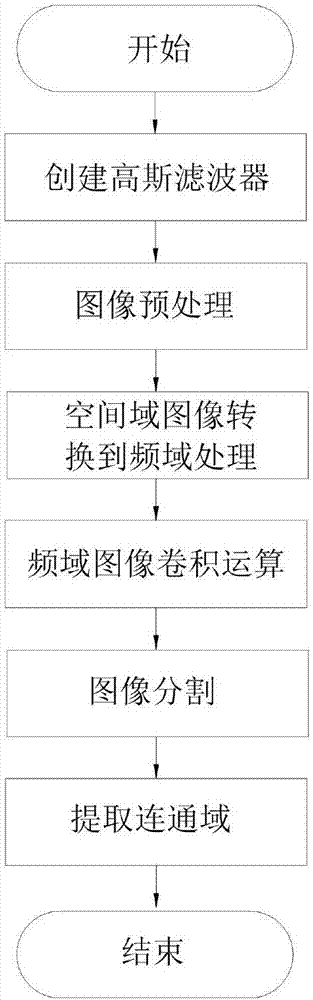

A stainless steel surface defect detection method based on machine vision

InactiveCN107478657AThe test result is accurateImprove detection efficiencyOptically investigating flaws/contaminationMachine visionFourier transform on finite groups

The invention relates to a stainless steel surface defect detection method based on machine vision. The method includes S1) collecting a surface image of stainless steel to be detected by adopting a CCD industrial camera; S2) subjecting the collected surface image of the stainless steel to be detected to two-dimensional defect detection based on Blob analysis; S3) subjecting the collected surface image of the stainless steel to be detected to three-dimensional defect detection according to frequency-domain-based Fourier transform; and S4) separating out the defective stainless steel according to two-dimensional and three-dimensional defect detection results. For two-dimensional defects, a surface detect detection algorithm based on the Blob analysis is provided, and a frequency-domain-based Fourier transform algorithm is provided for three-dimensional defects. Common surface defects, such as scratch, oil stain, rust, air bubbles, cracks, impurities, rolling marks and roll marks, of stainless steel products can be effectively detected. In addition, the detection results of a scheme are accurate and the detection efficiency is high.

Owner:GUANGDONG UNIV OF TECH

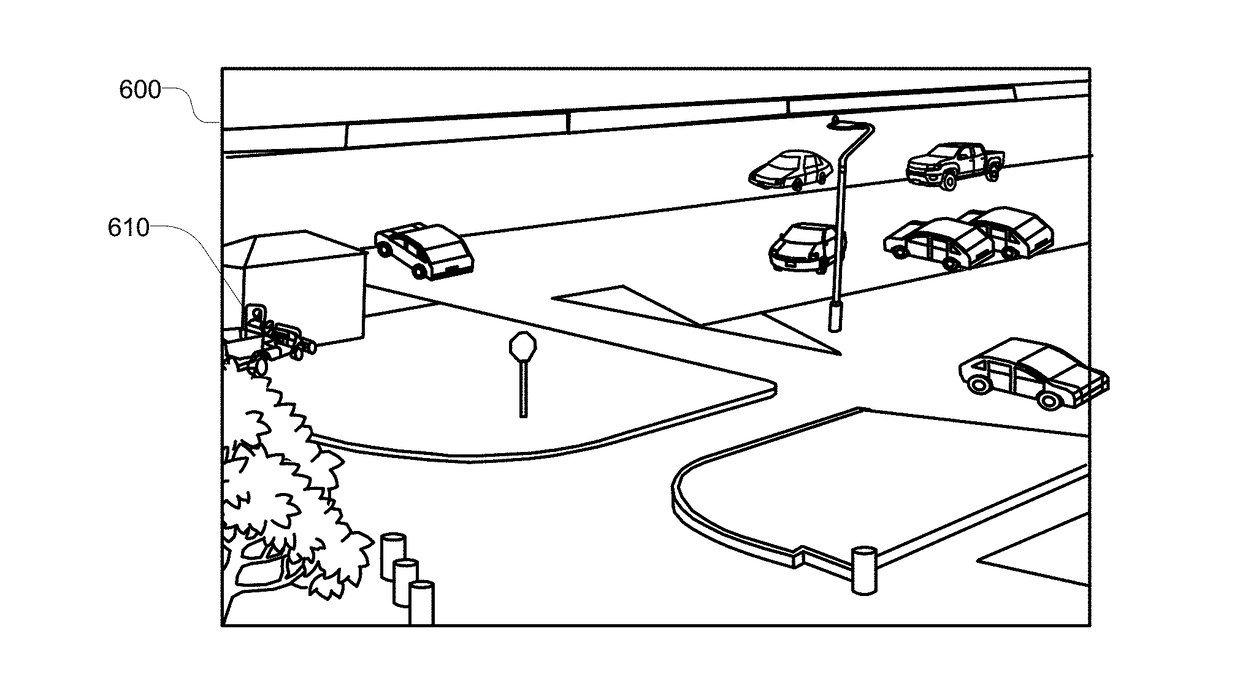

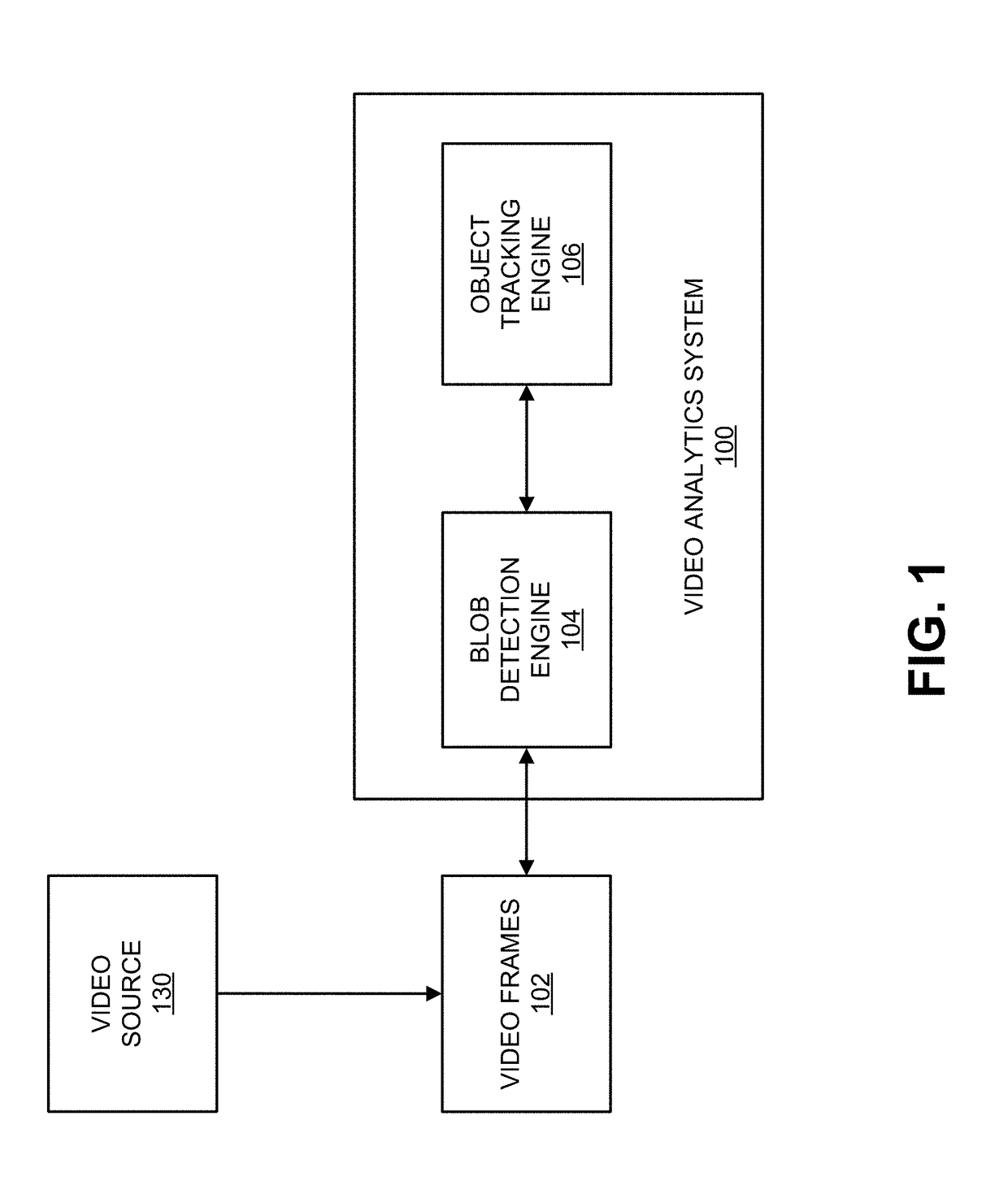

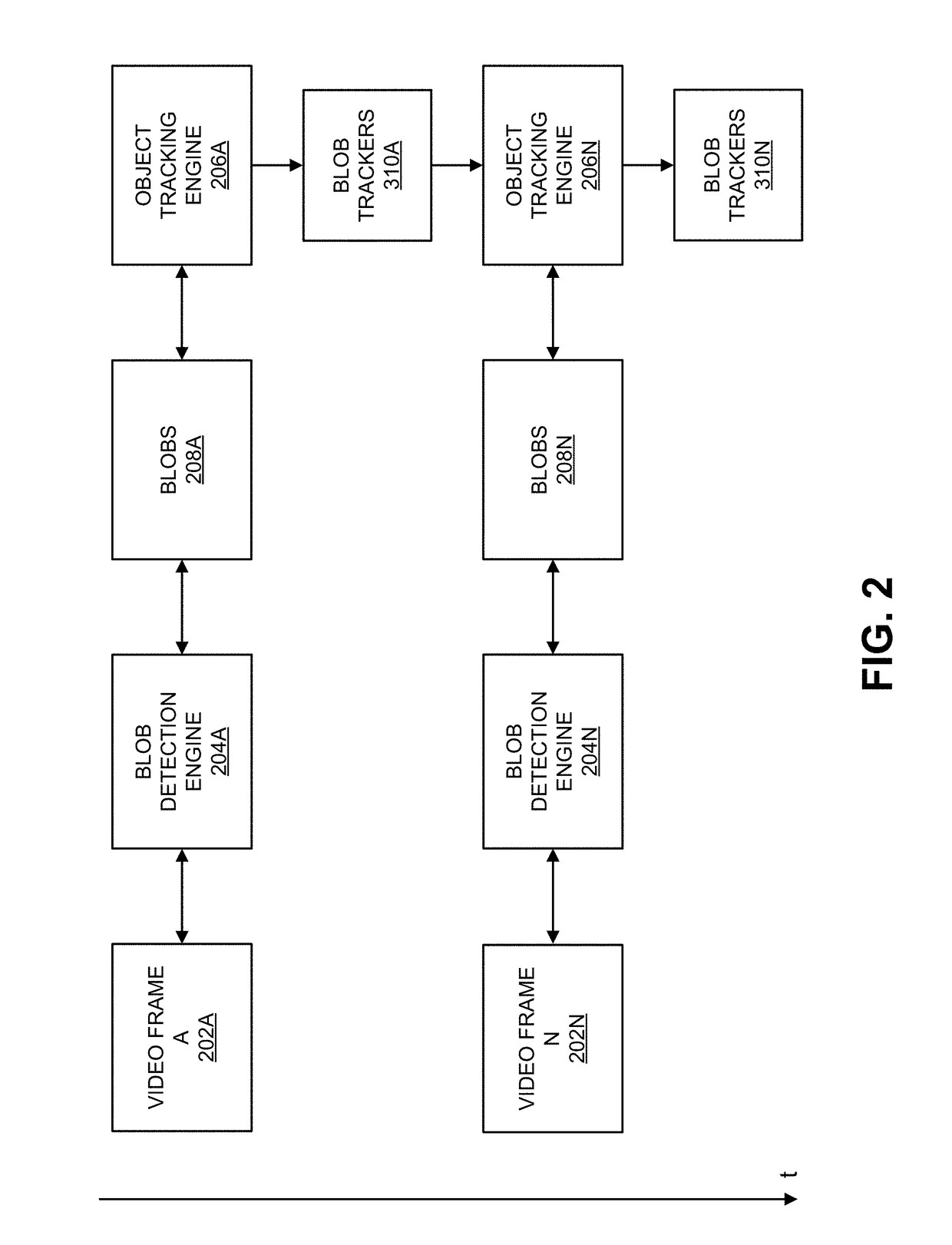

Adaptive bounding box merge method in blob analysis for video analytics

Provided are methods, apparatuses, and computer-readable medium for content-adaptive bounding box merging. A system using content-adaptive bounding box merging can adapt its merging criteria according to the objects typically present in a scene. When two bounding boxes overlap, the content-adaptive merge engine can consider the overlap ratio, and compare the merged bounding box against a minimum object size. The minimum object size can be adapted to the size of the blobs detected in the scene. When two bounding boxes do not overlap, the system can consider the horizontal and vertical distances between the bounding boxes. The system can further compare the distances against content-adaptive thresholds. Using a content-adaptive bounding box merge engine, a video content analysis system may be able to more accurately merge (or not merge) bounding boxes and their associated blobs.

Owner:QUALCOMM INC

Edge normal process

An edge inspection method for detecting defects on a wafer edge normal surface includes acquiring a set of digital images which captures a circumference of the wafer. An edge of the wafer about the circumference is determined. Each digital image is segmented into a plurality of horizontal bands. Adjacent edge clusters about the circumference of the wafer are combined into edge pixel bins. The edge pixel bins are analyzed via edge clusters analysis to identify defects. The edge pixel bins are also analyzed via blob analysis to determine defects.

Owner:ONTO INNOVATION INC

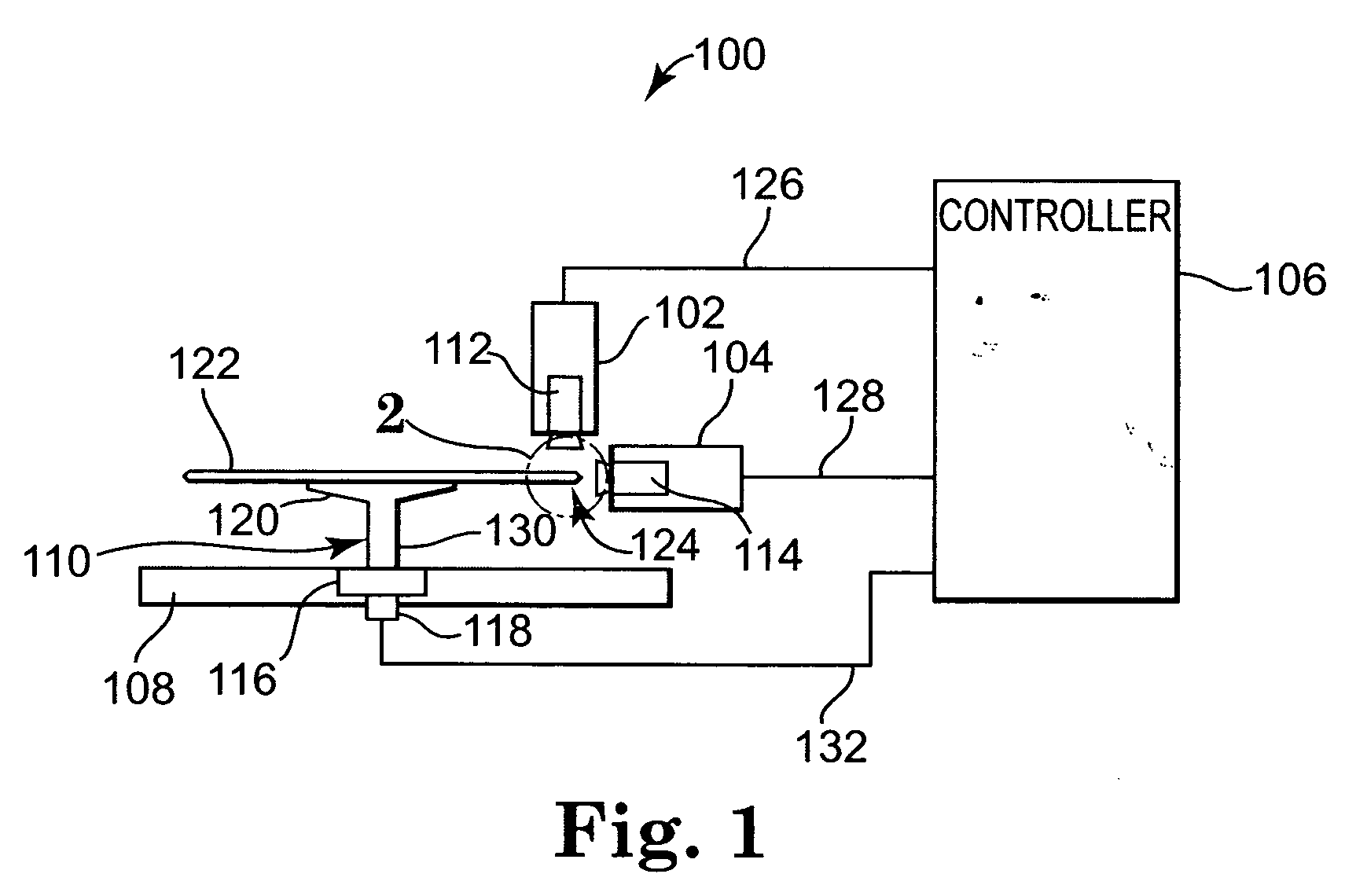

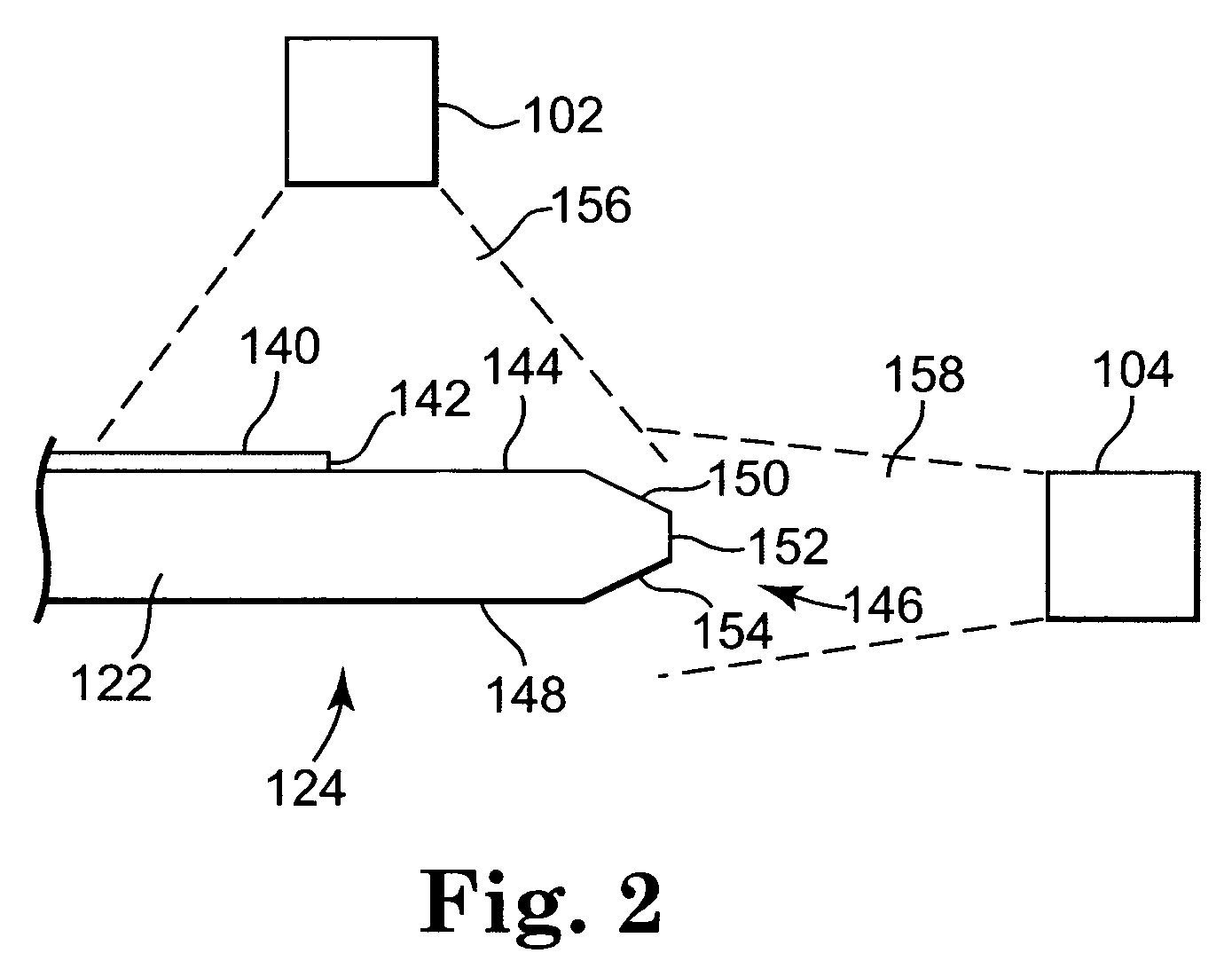

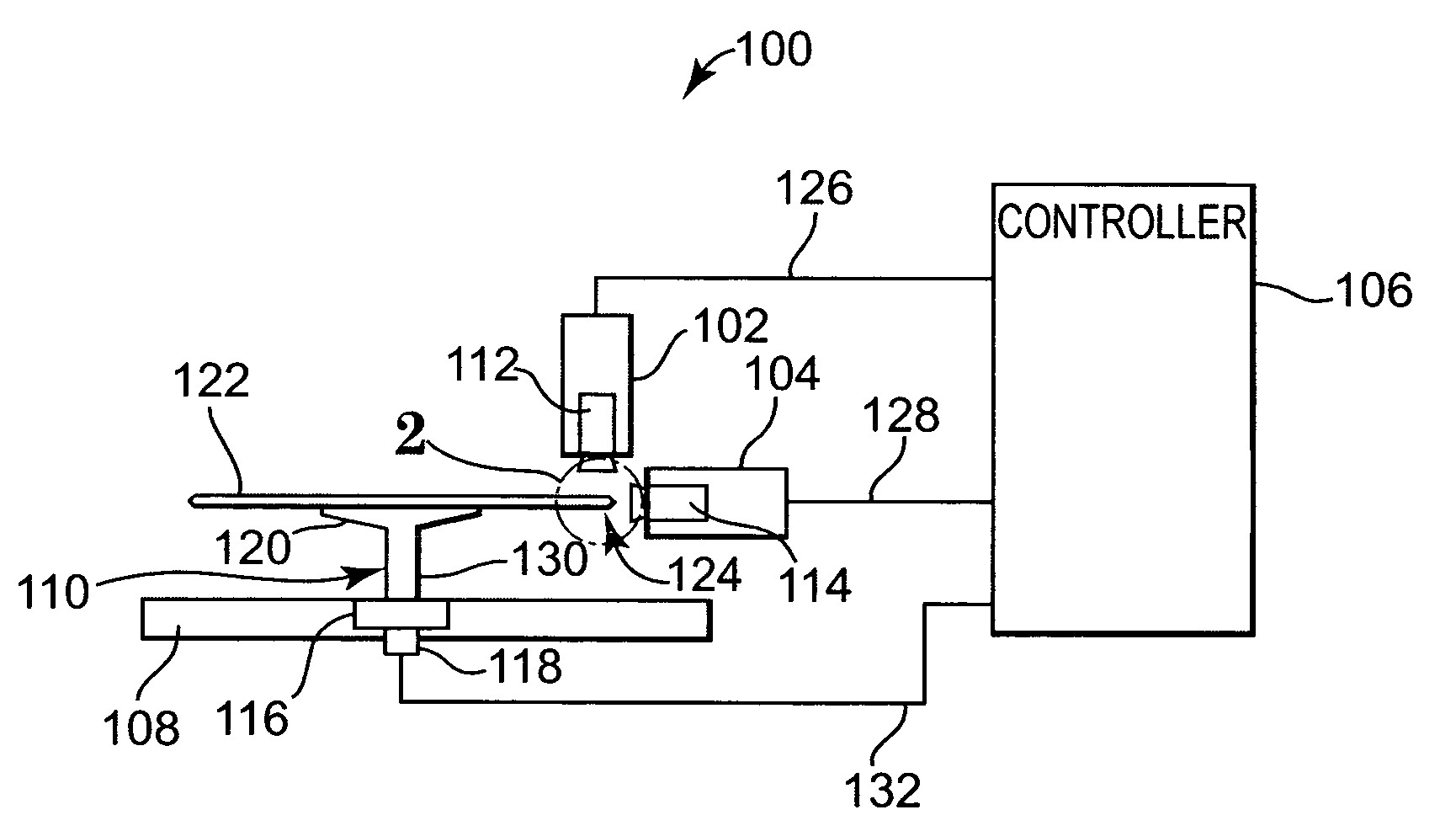

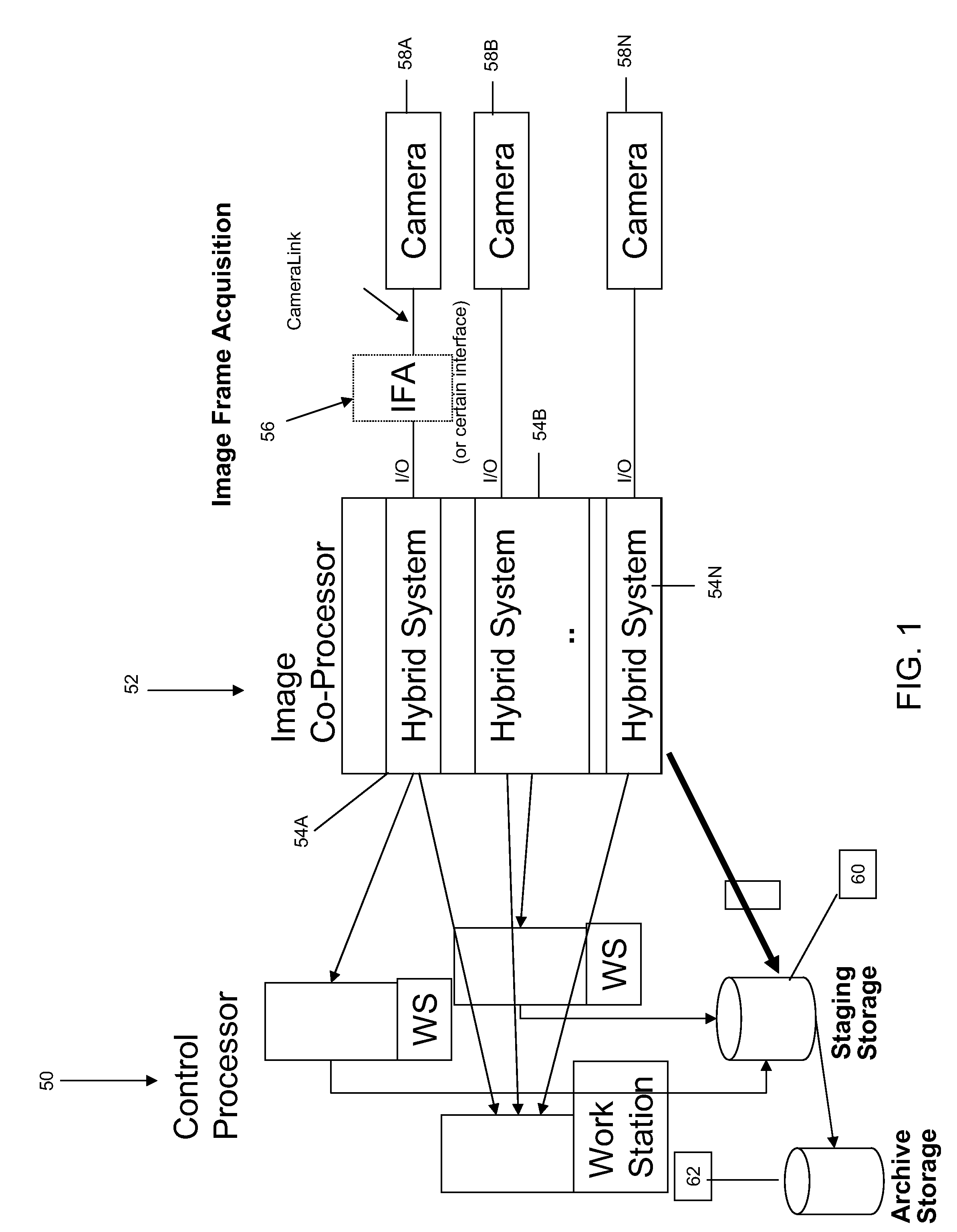

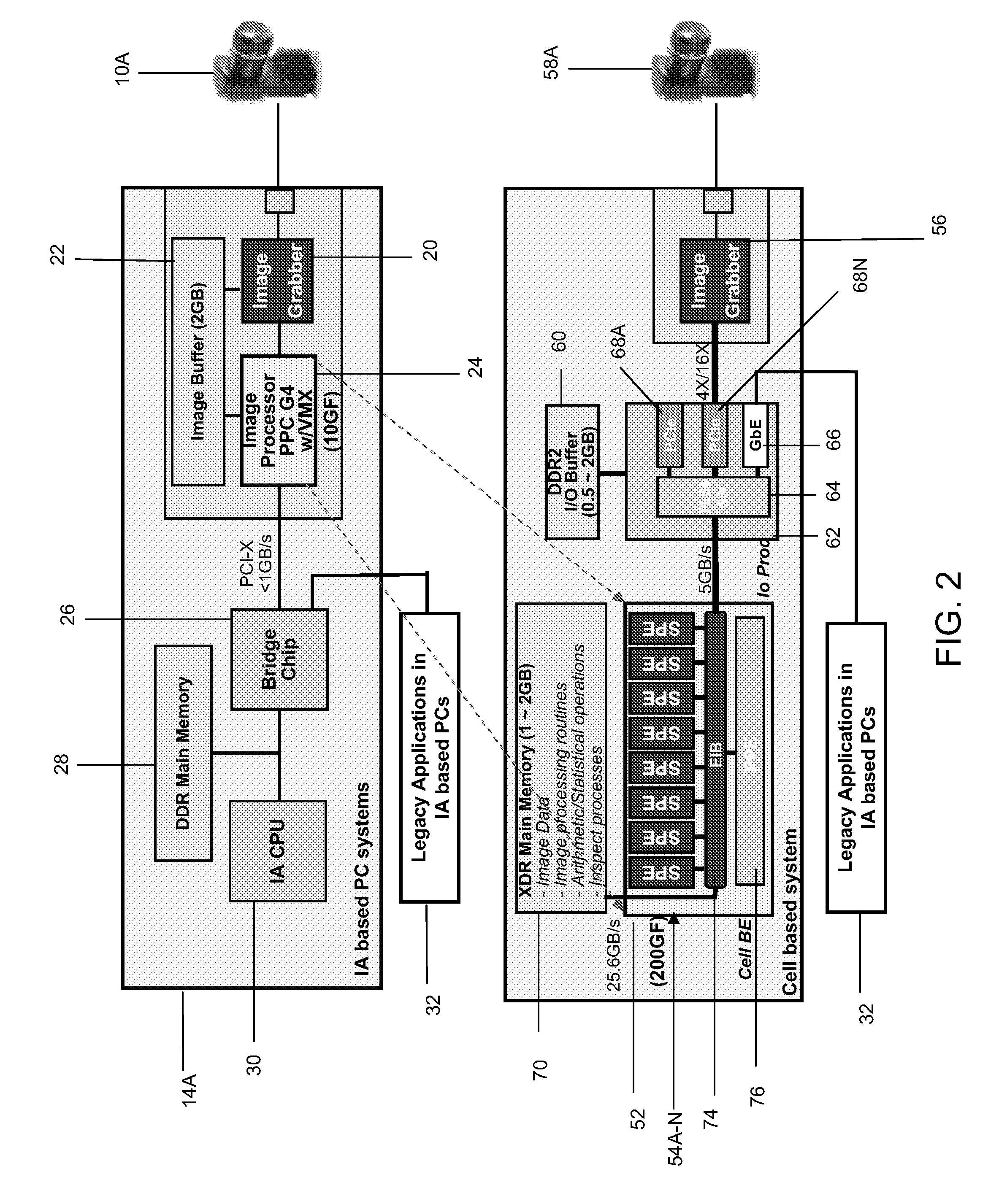

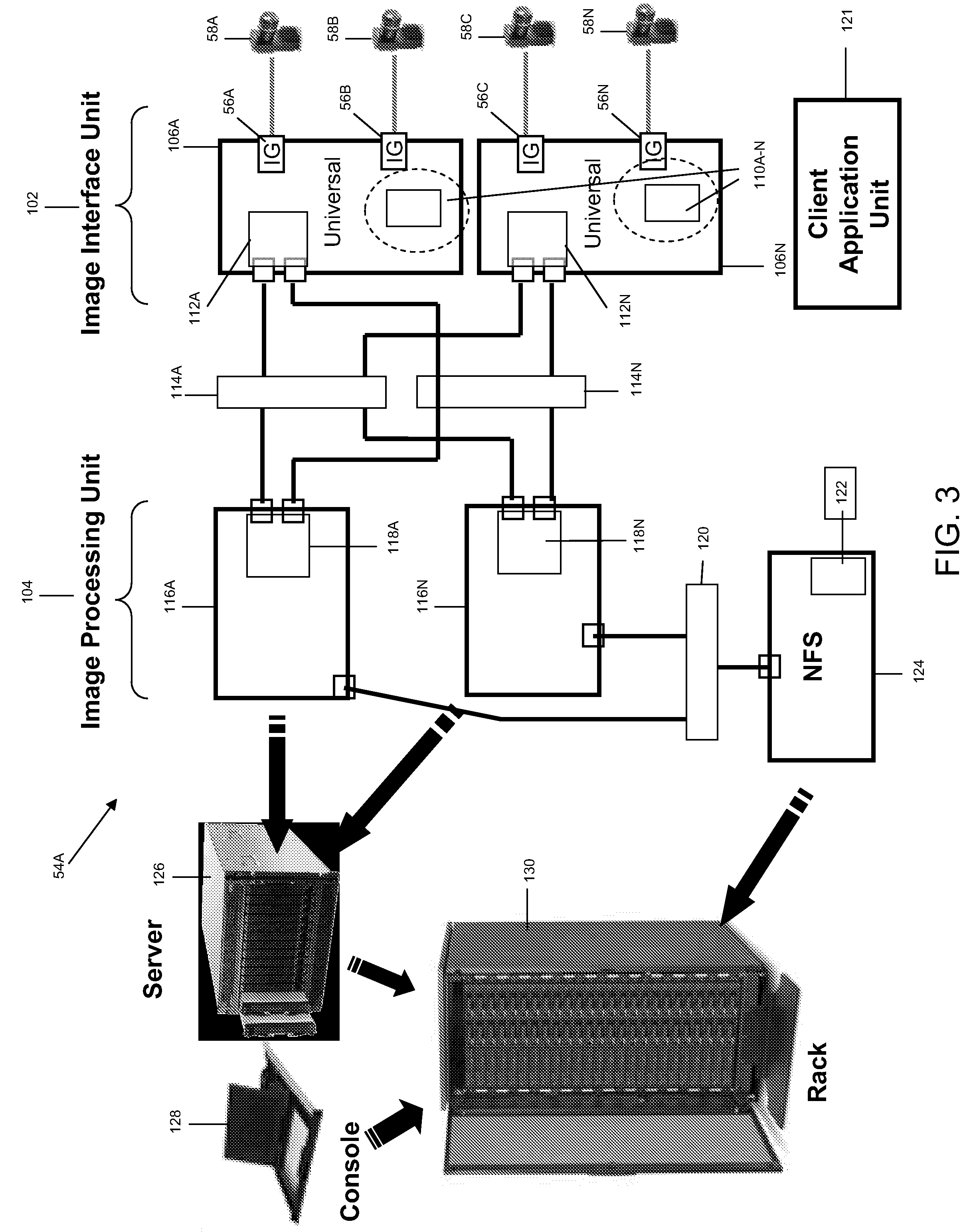

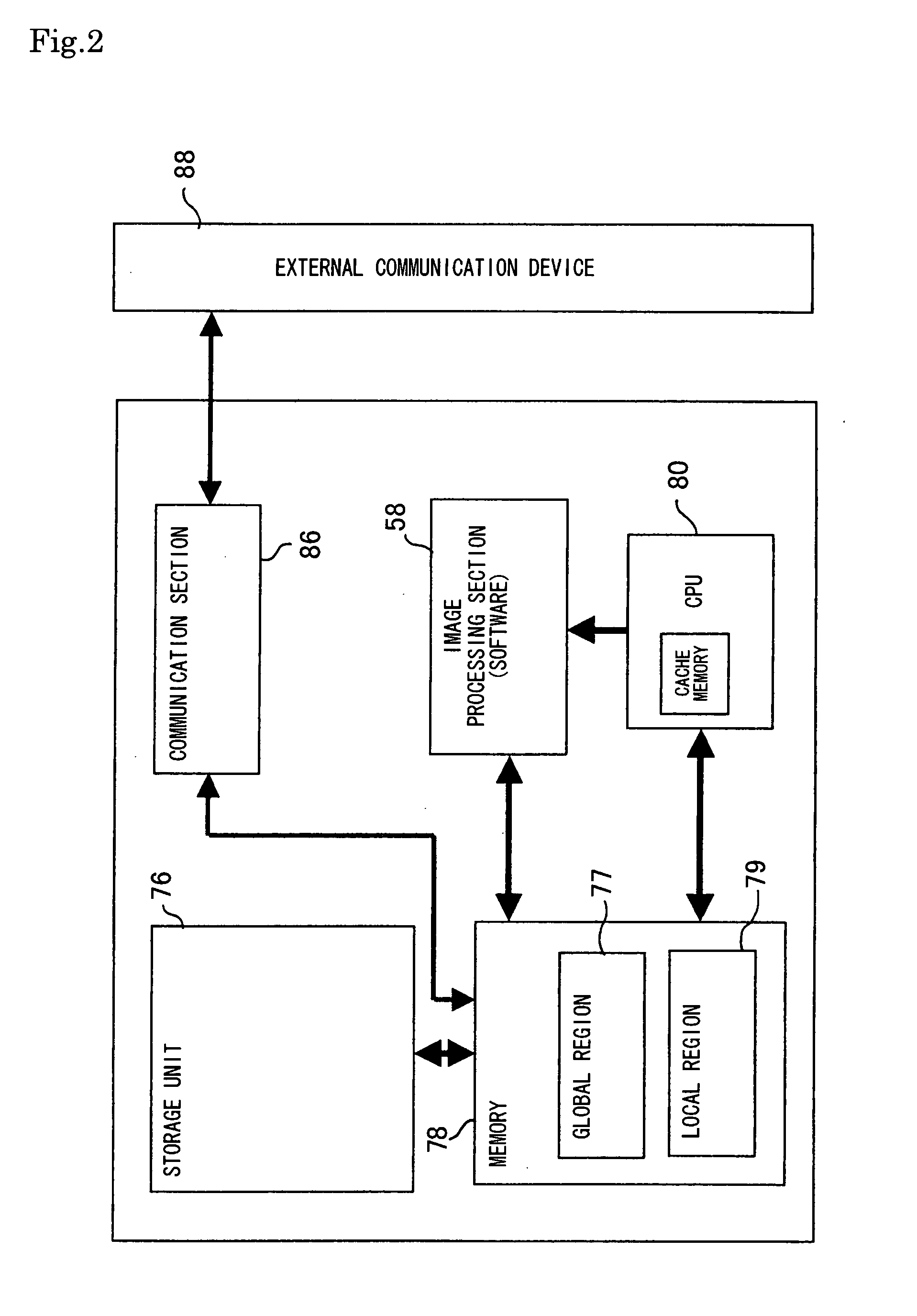

Pre-processing optimization of an image processing system

InactiveUS20090202149A1High bandwidthReduce memory bandwidthImage enhancementImage analysisProcess optimizationImaging processing

The present approach increases bandwidth by performing at least two functions at the pre-processing level. Specifically, under the present approach, program code is structured so that the segmentation and binarization functions / modules (and optionally a blob analysis function / module) are merged into a single module to reduce memory bandwidth. In addition, each image frame is segmented into a plurality of partitions (e.g., vertical strips) to enhance the reusability of the image data in LS already fetched from main memory. Each partition is then processed by a separate one of a plurality of processing engines, thereby increasing the utilization of all processing engines and allowing the processing engines to maintain good bandwidth.

Owner:IBM CORP

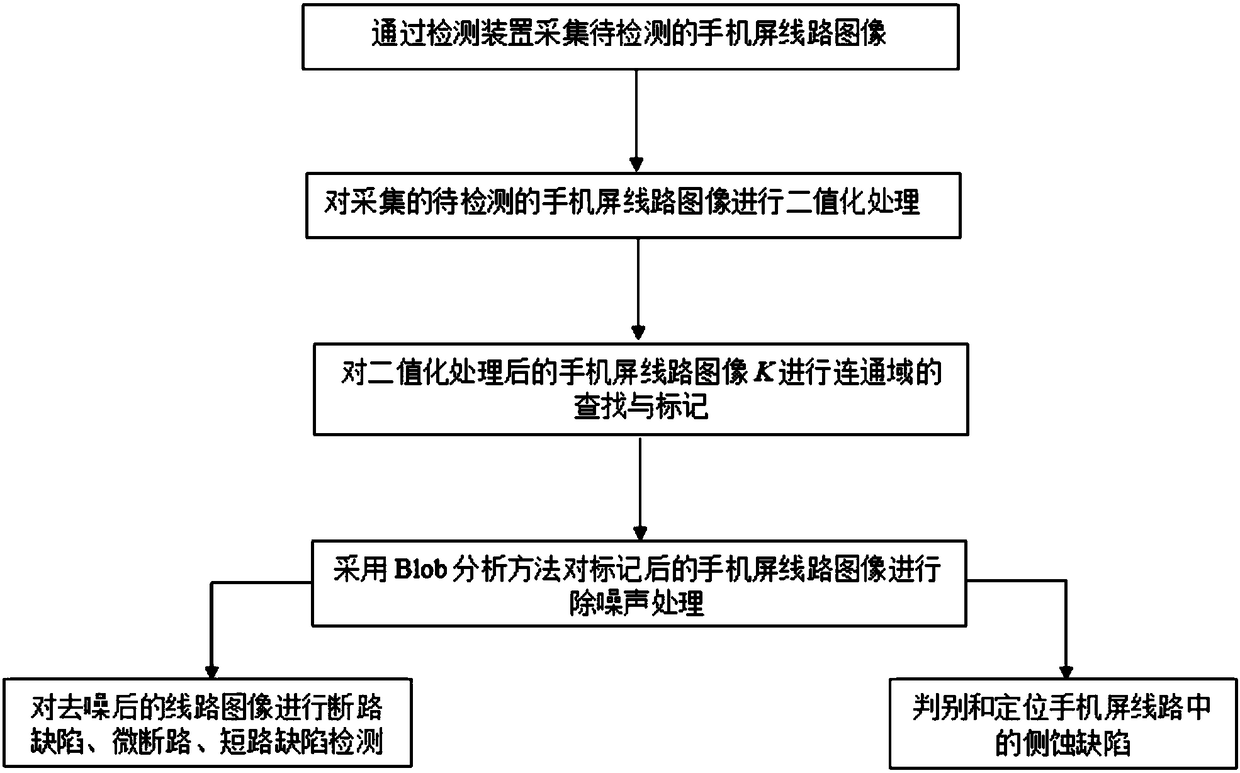

Mobile phone screen line detection method based on machine vision

ActiveCN108510476AImprove detection efficiencyImprove effectivenessImage enhancementImage analysisMachine visionBlob analysis

The invention relates to a mobile phone screen line detection method based on machine vision. The method comprises the following steps: S1), acquiring a mobile phone screen line image to be detected by a detecting device; S2), performing binarization processing on the acquired mobile phone screen line image to be detected; S3), searching and marking the connected domain of the mobile phone screenline image K subjected to binarization processing; S4), using a Blob analysis method to de-noise the marked mobile phone screen line image; S5), subjecting the de-noised line image to open-circuit defect, micro open-circuit defect, and short-circuit defect detection; S6), determining and locating the lateral erosion defect in the mobile phone screen line. The method has low detection cost, good practicability and high detection efficiency, and only takes about 50 ms to detect one circuit diagram. In addition, the method has high stability and a low miss detection rate, and improves the accuracy of circuit detection by simultaneous detection of the open-circuit defect, micro open-circuit defect, the short-circuit defect, and the lateral erosion defect.

Owner:WUYI UNIV

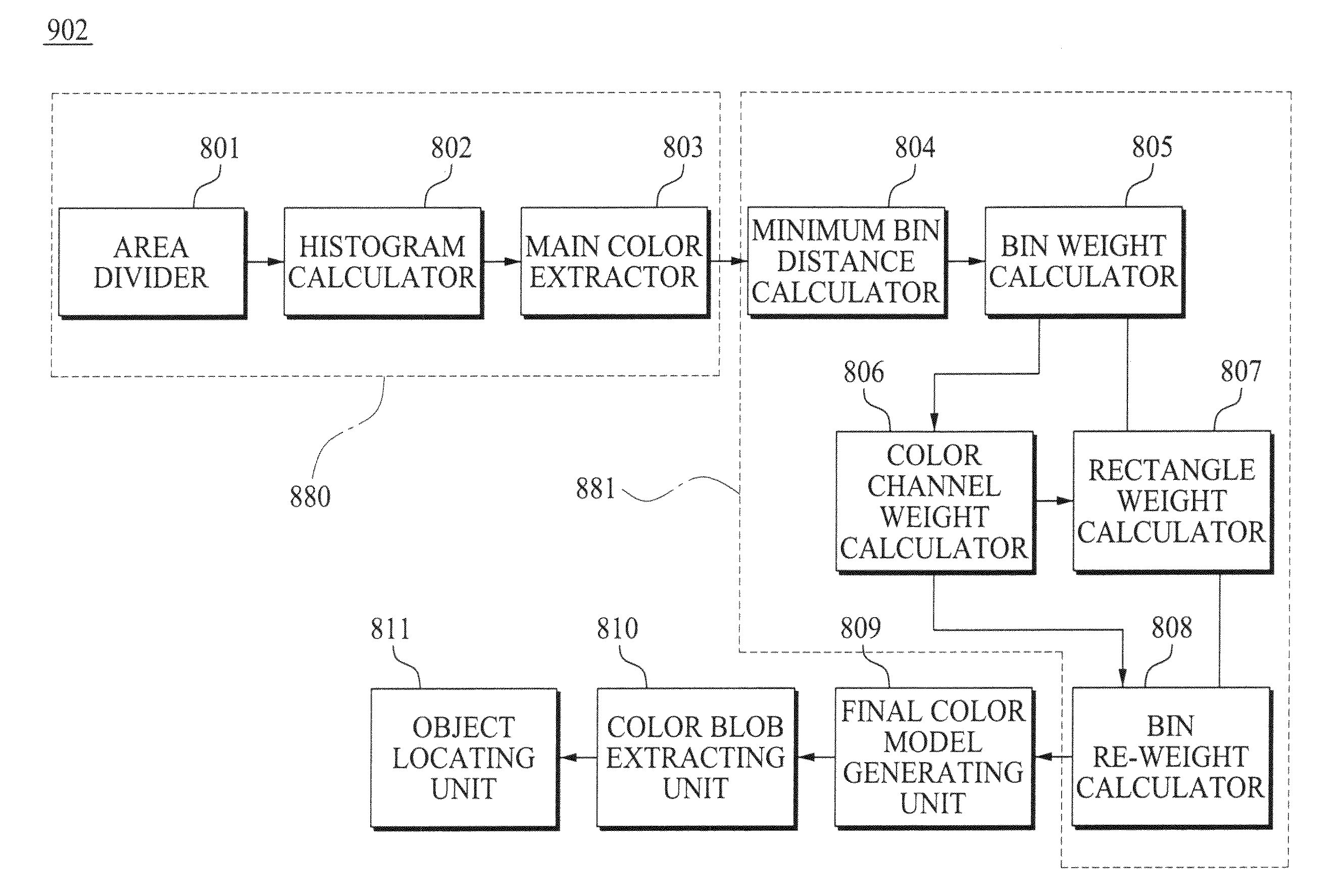

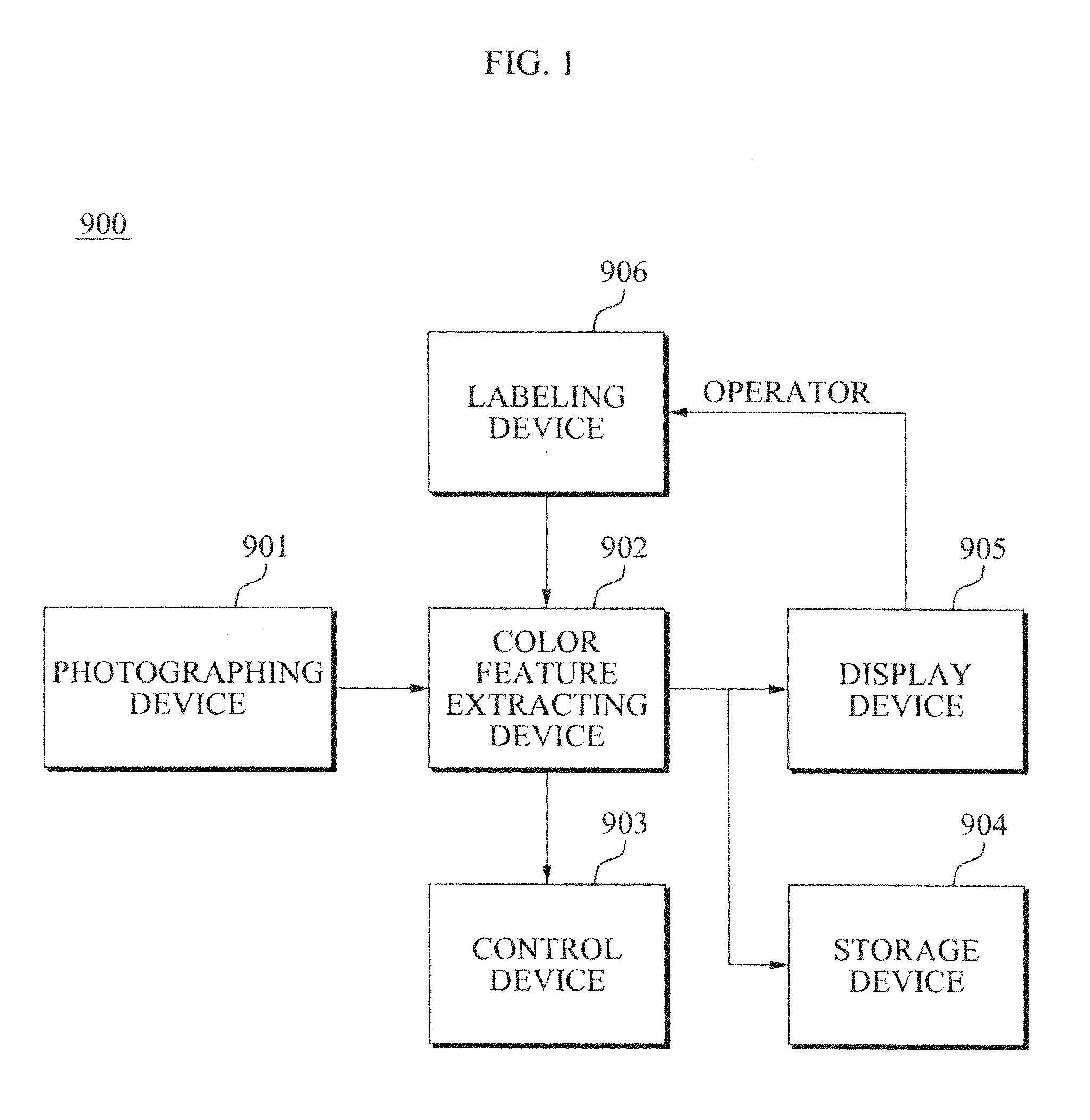

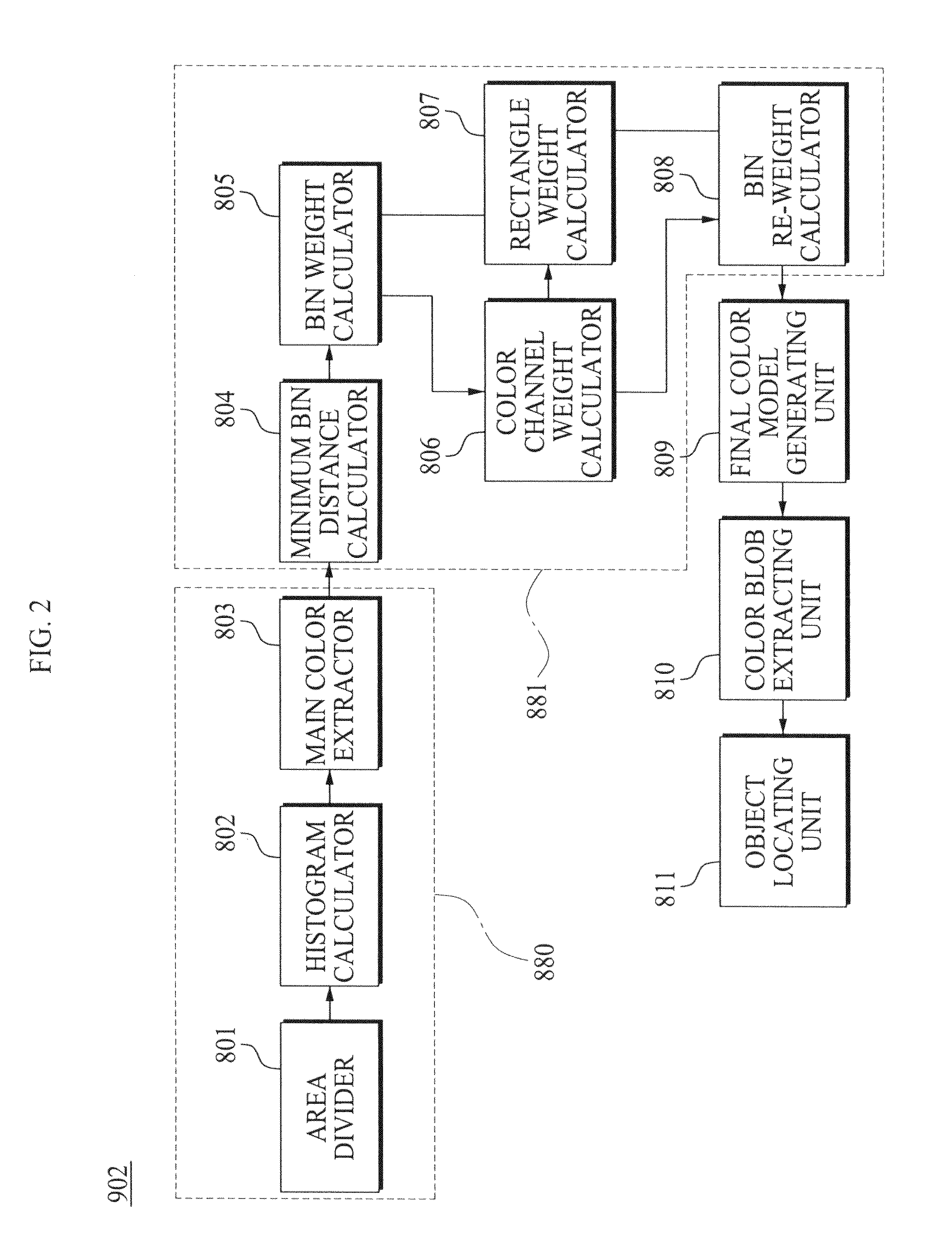

Image forming system, apparatus and method of discriminative color features extraction thereof

ActiveUS20090087088A1Reduce colorGood colorBiometric pattern recognitionFeature extractionObject based

Provided are an apparatus and method of extracting a discriminative color feature, and an image forming system including: a photographing device to photograph an image of an object; a color feature extracting device receiving the image from the photographing device, extracting a discriminative color feature from the image, generating a final color model of the object, extracting a color blob of the object based on the final color model, performing blob analysis on the extracted color blob, and generating parameters to control a posturing of the photographing device according to the blob analysis; a control device receiving from the color feature extracting device the parameters to control the posturing of the photographing device, and controlling the posturing of the photographing device; a storage device storing the photographed image of the object; and a display device displaying the photographed image of the object.

Owner:SAMSUNG ELECTRONICS CO LTD

Step-by-step approximation sub-pixel image positioning method and system

InactiveCN108460799AImprove accuracyReduce the probability of mistakingImage enhancementImage analysisImage contourLeast squares

The invention discloses a step-by-step approximation sub-pixel image positioning method and system, comprising the following steps of obtaining initial image information, extracting the edge contour by using a BLOB analysis and morphological edge method, extracting the edge transition band by morphology expansion, edge shearing, Canny algorithm, a polygon approximation method, collinear joint algorithm, least square method linear fitting, image contour intersection point acquisition and image contour center point acquisition. Accurate positioning of the images is finally obtained. Compared with a traditional mode, the invention has the advantages of being high in positioning precision, small in error and strong in anti-interference capability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

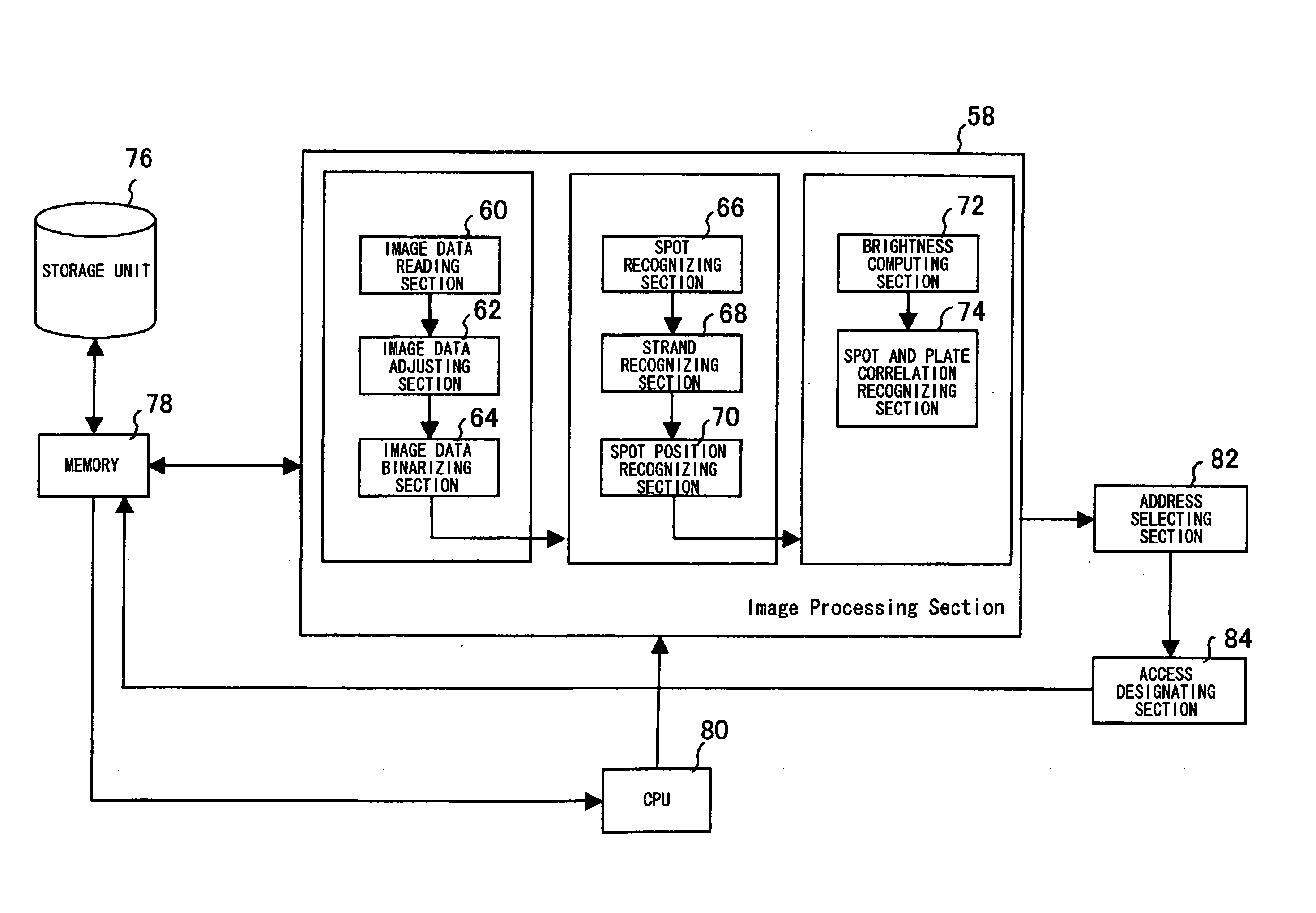

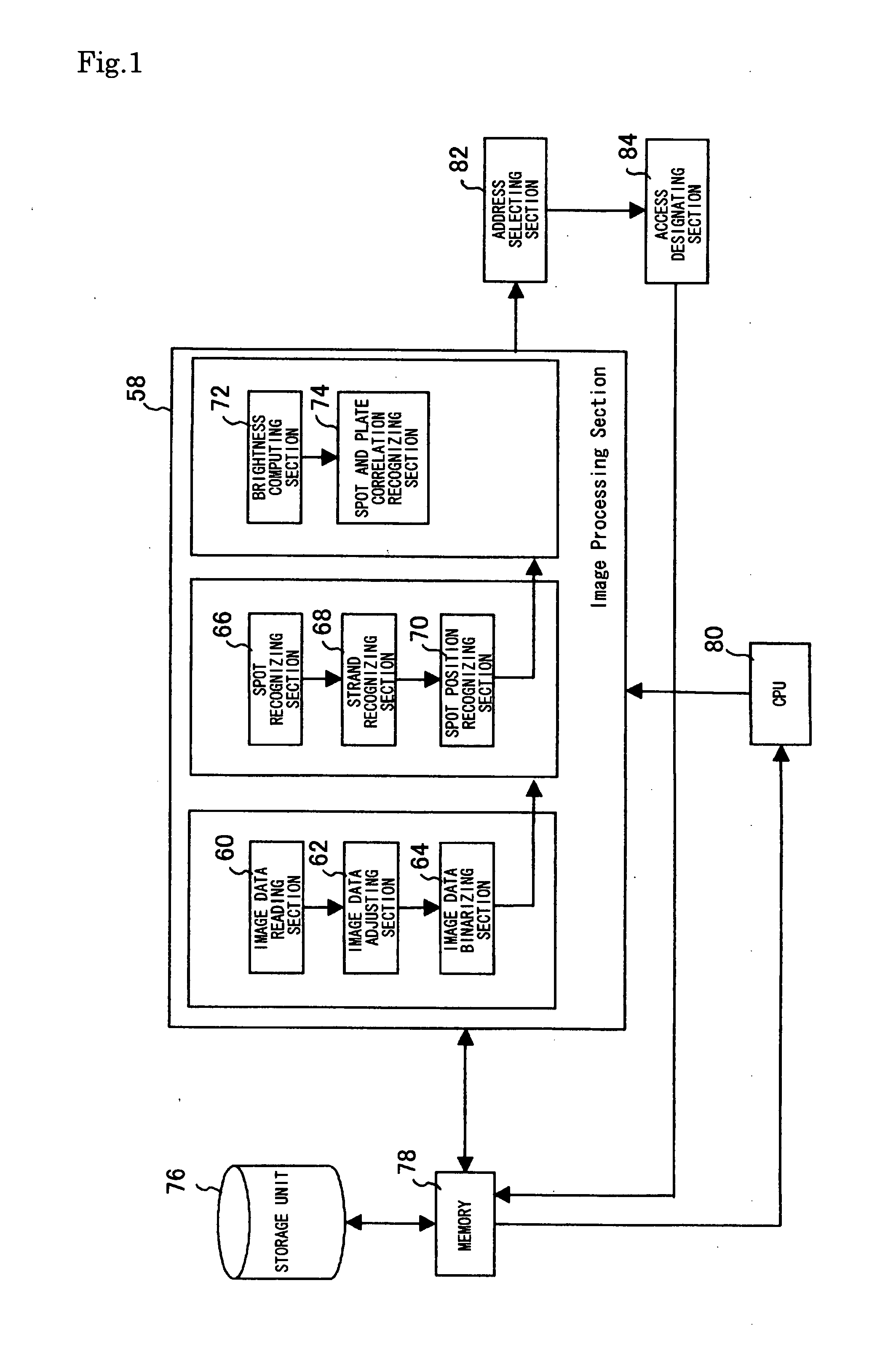

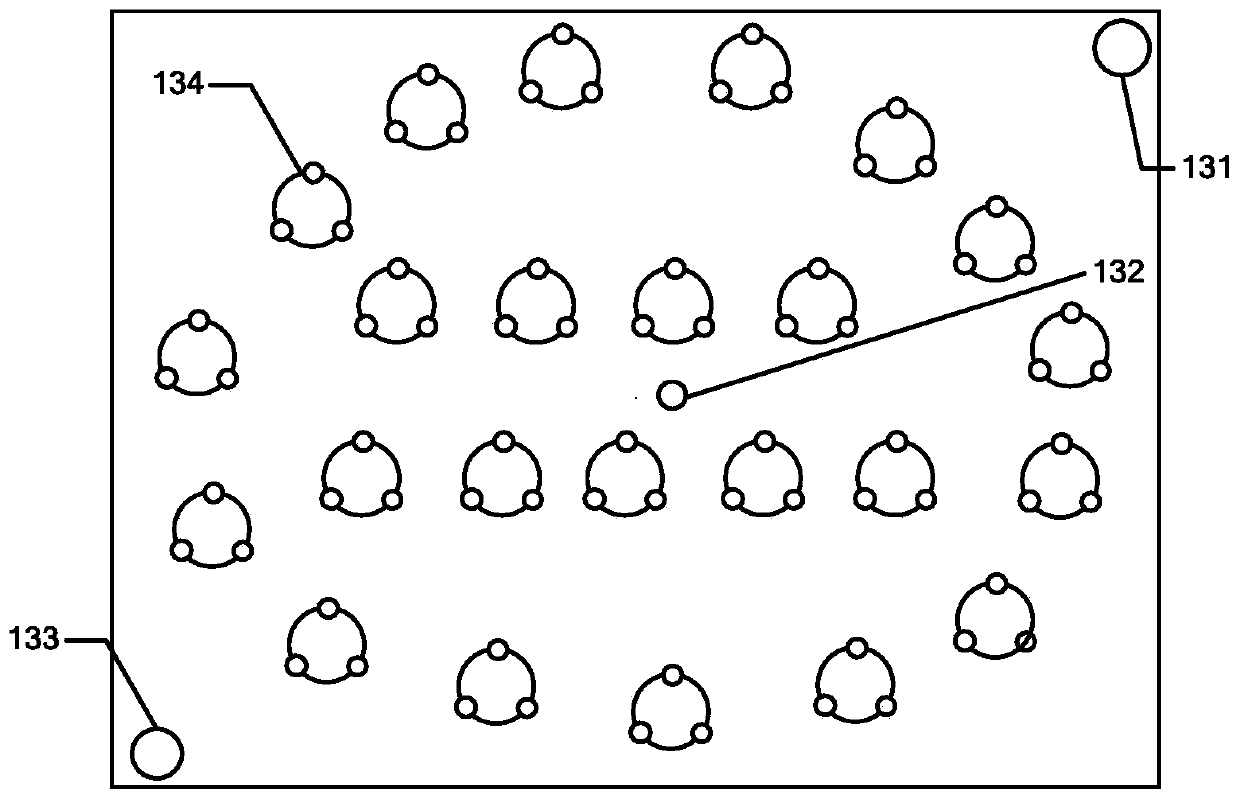

Analysis Processing Method and Device

InactiveUS20080232659A1High precision analysisAccurate acquisitionRecognition of DNA microarray patternImaging processingTest sample

The invention relates to image processing, and to a method and device for recognizing the reaction results of a test sample in which various reagents are arranged on a surface, by image analysis, and assay. An object is to provide an analysis processing method and an analysis processing device which can obtain analysis results efficiently and with high accuracy, for objects which are integrated using a wound body which is wound with a linear base substance, and for which positions are uncertain. An analysis processing method for performing analysis based on optical information from a wound object which is wound with a linear base substance in which biological substances of previously determined types are immobilized, and a plurality of these immobilized spots are arranged at previously determined positions, includes: detecting a partial region belonging to the spots, by means of optical information obtained by scanning a surface of the wound body; specifying the spots belonging thereto, based on the detected partial region for the detected spots; and performing analysis of the spots based on the optical information from the specified spots.

Owner:UNIVERSAL BIO RESEARCH CO LTD

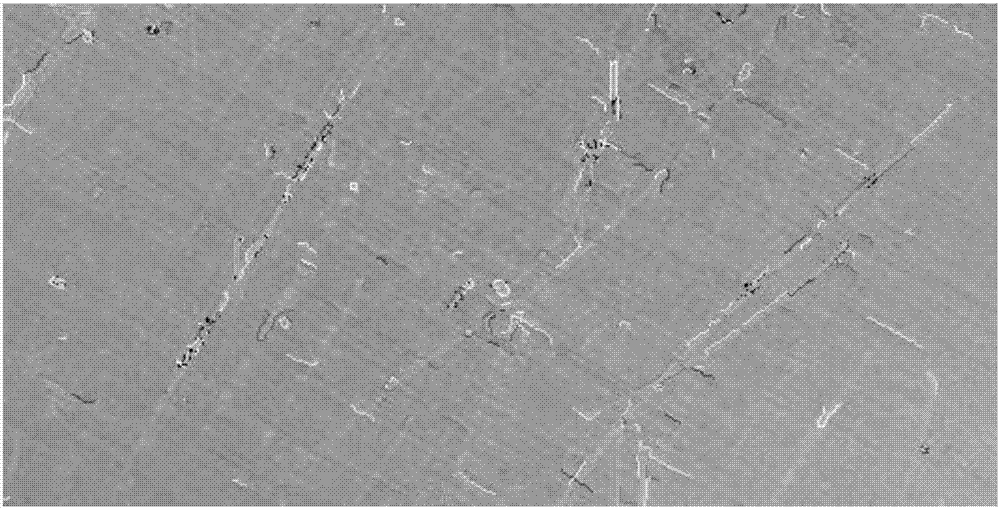

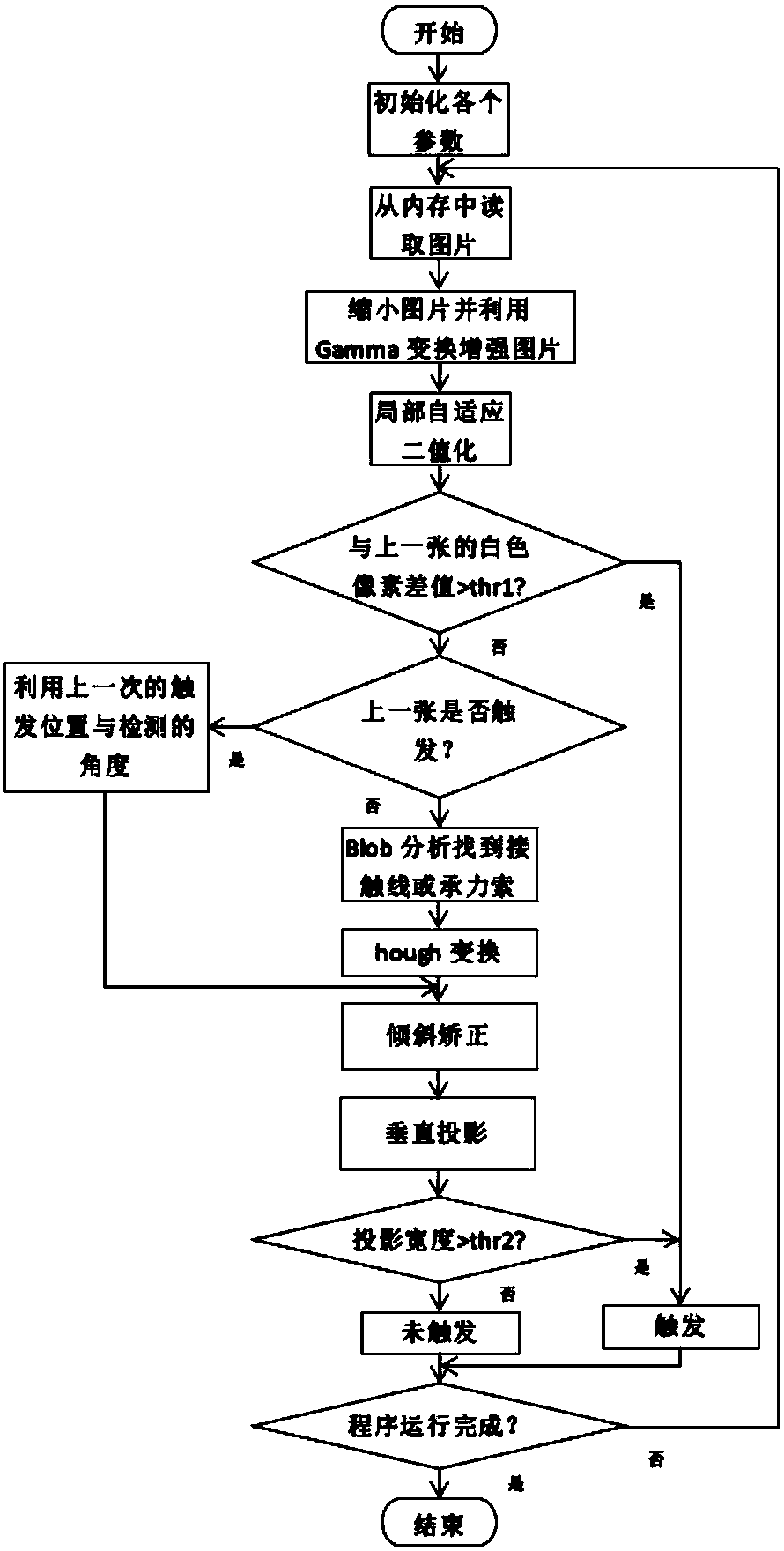

Image processing-based electrified railway catenary dropper detection method

InactiveCN108256483AAvoid influenceMeet the requirementsImage enhancementImage analysisVertical projectionImaging processing

The invention provides an image processing-based electrified railway catenary dropper detection method. The detection method includes the following steps of: (1) inputting a photographed picture: thephotographed picture is processed into a 1280*400 grayscale picture, and the size of the 1280*400 grayscale picture is scaled down to 1 / 9 of the size of the original image; (2) performing Gamma transformation: grayscale correction is performed on the scaled-down picture through adopting the Gamma transformation, so that the brightness of the picture can meet processing requirements; (3) performingbinarization processing; (4) performing hough transformation; (5) performing tilt correction; (6) performing vertical projection; and (7) performing width analysis. According to the detection method,the Gamma transformation, local adaptive binarization, blob analysis, hough transformation, affine transformation, and projection method are comprehensively used, and therefore, dropper detection hashigh recognition performance and high speed, and can be applied to various detection conditions.

Owner:HUNAN HUAHONG RAILWAY HIGH TECH DEV CO LTD

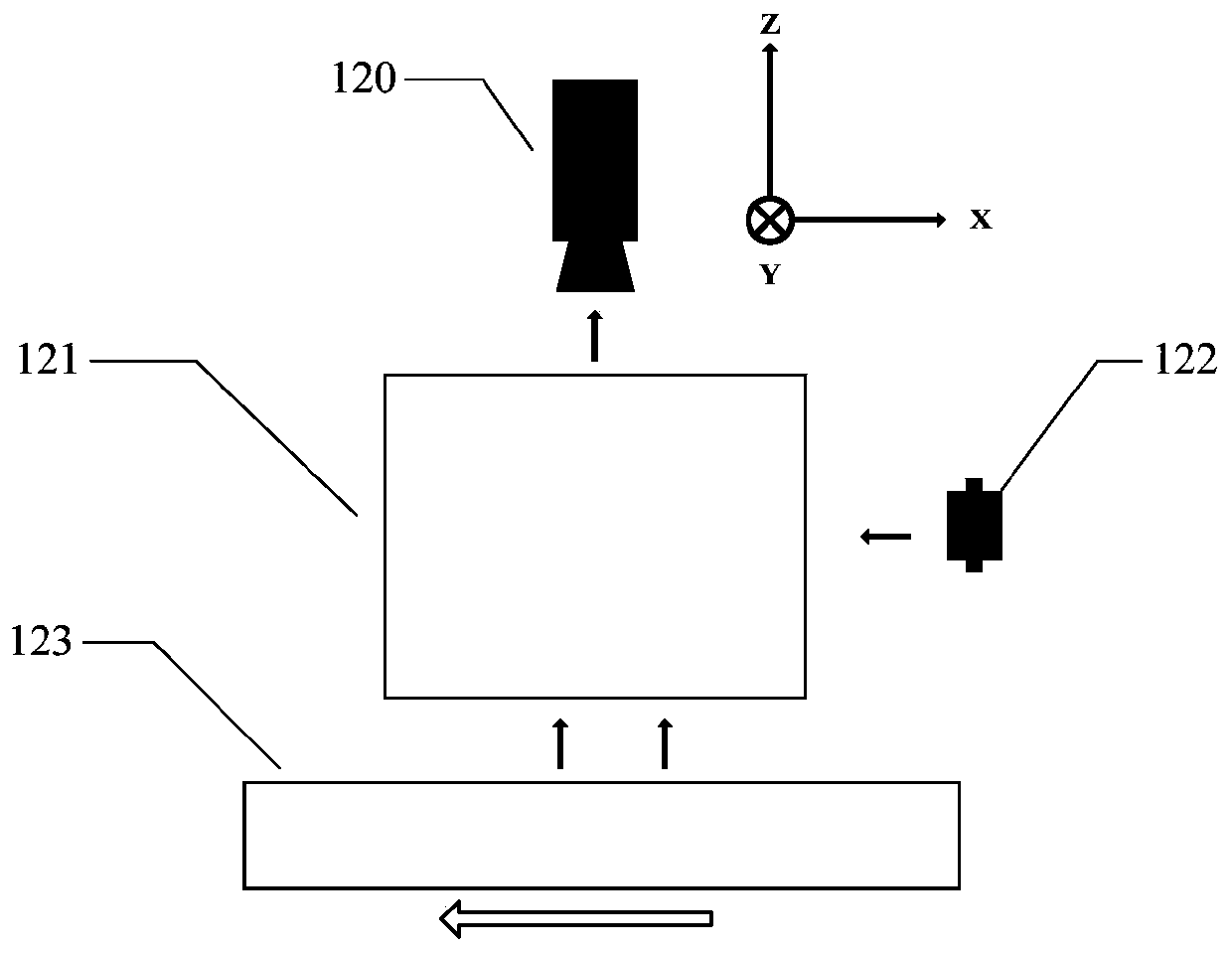

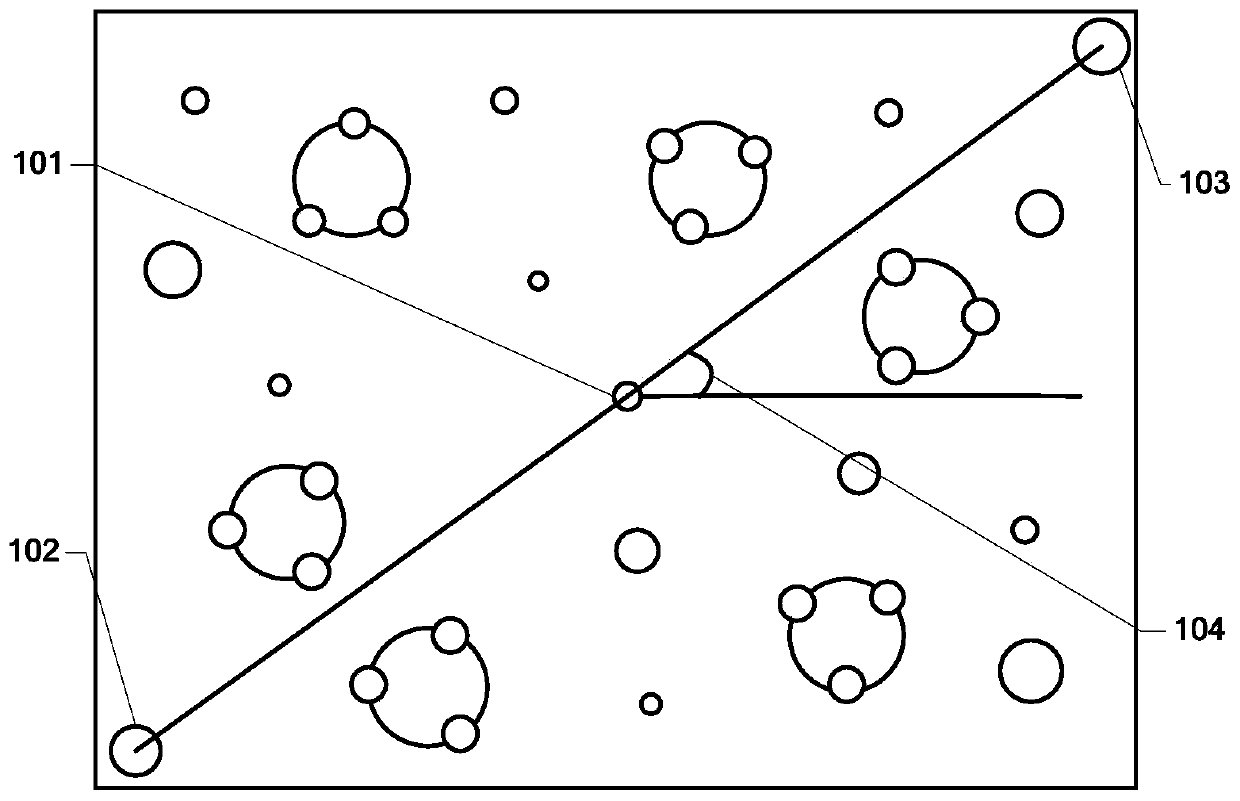

Multi-target positioning system and method based on single imaging large-view-field LED lens mounting

ActiveCN110211183AAvoid interruptionFast positioningImage enhancementImage analysisImage segmentationAluminum substrate

The invention discloses a multi-target positioning system and method based on single imaging large-view-field LED lens mounting. The system comprises the steps of large-format image acquisition, target positioning and position correction. The invention also provides the multi-target positioning method. The method comprises a treatment method of a first standard sample and treatment methods of second to N samples. Processing steps of the standard sample comprise acquiring an aluminum substrate image, setting a target and Mark point area, segmenting the image, carrying out BLOB analysis, carrying out feature extraction and target positioning, carrying out Mark point center positioning, and acquiring a midpoint and an inclination angle of a connecting line of the Mark point center positioningand the midpoint; and processing steps of 2-N samples comprise: acquiring images, positioning the centers of Mark points and positioning the midpoints of the straight line segments of the Mark pointsto obtain offset of angles and displacements of the samples, constructing a rigid body transformation matrix, and carrying out affine transformation on multiple target points of the standard sample.The system and the method provided by the invention have the advantages that the positioning speed is high, full automation can be realized, the target point can be acquired without manual teaching intervention, and uninterrupted continuous production can be realized.

Owner:GUANGZHOU PANYU POLYTECHNIC

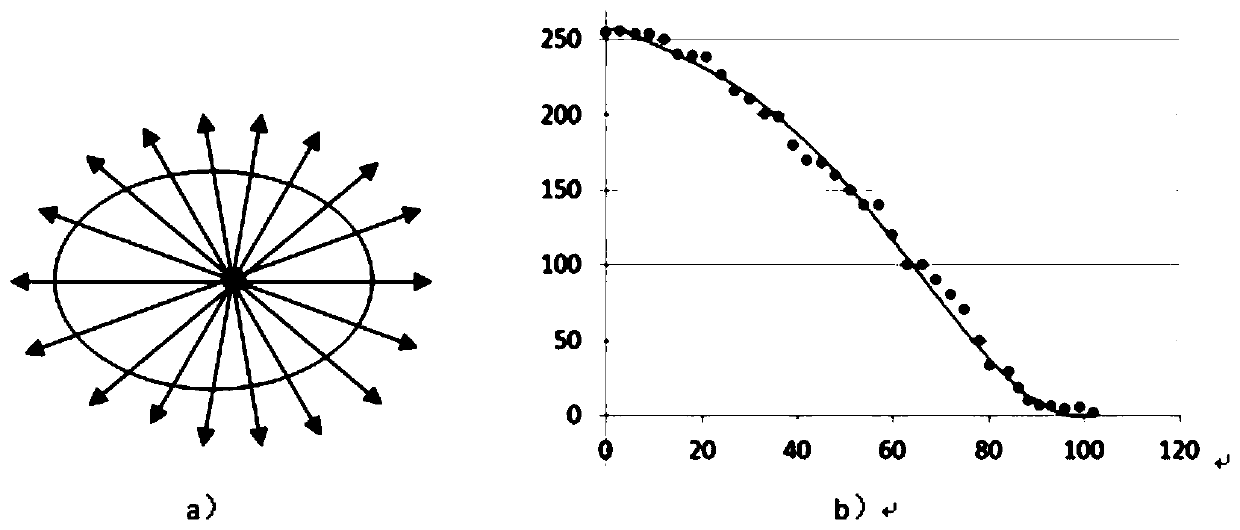

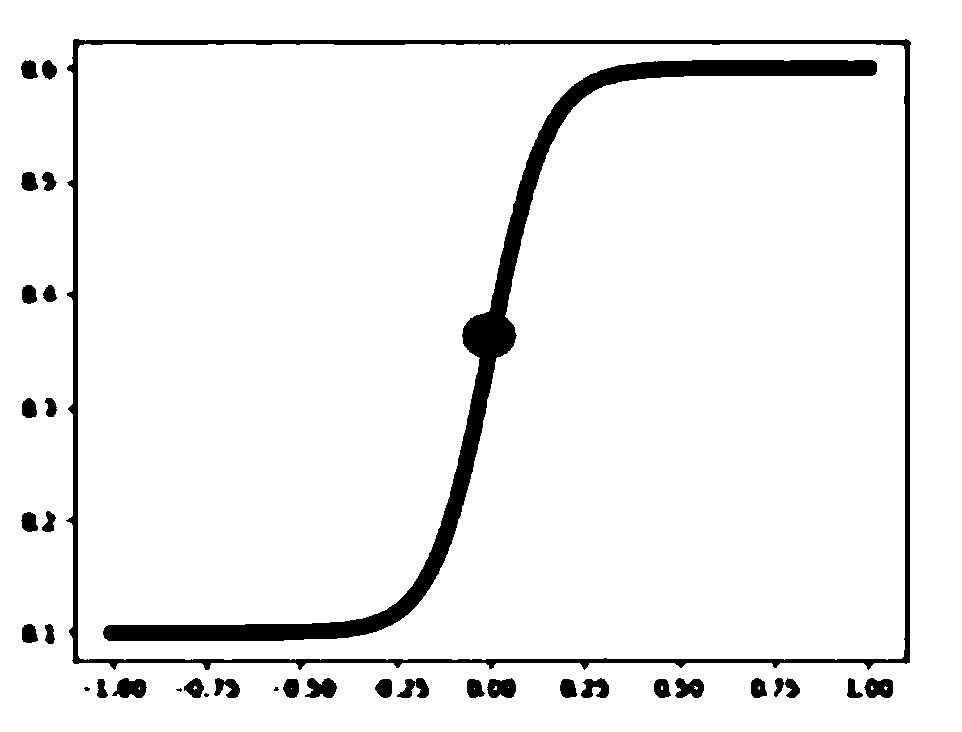

Image processing method for obtaining corneal vertexes

The invention discloses an image processing method for obtaining corneal vertexes. The method comprises the following steps of continuously acquiring N frames of images at a high speed to synthesize aframe of image with minimum noise; acquiring a potential corneal reflection area through image binaryzation and blob analysis so that a to-be-processed area is reduced; carrying out gray stretchingon the potential light spot area; carrying out double-threshold binarization and blob analysis; obtaining a gray gravity center and a light spot boundary coordinate of a cornea vertex area; taking a gray vertex as a center; pulling the ray outwards every a certain angle to obtain a gray sequence on the ray; carrying out gaussian fitting based on a nonlinear least square method on gray scale data of the strip ray group to acquiresub-pixel coordinate values of corneal vertexes; finally, according to the jump of the gray value on the ray at the boundary; solving a sub-pixel-level coordinate boundary; corneal vertex and light spot boundary information obtained through the method can be combined with pupil center position and other related information obtained through other devices to obtain Kappa angle Alpha angle and other related information of eyes, and reliable basic data are provided for subsequent further eye refraction parameter obtaining.

Owner:WENZHOU MEDICAL UNIV

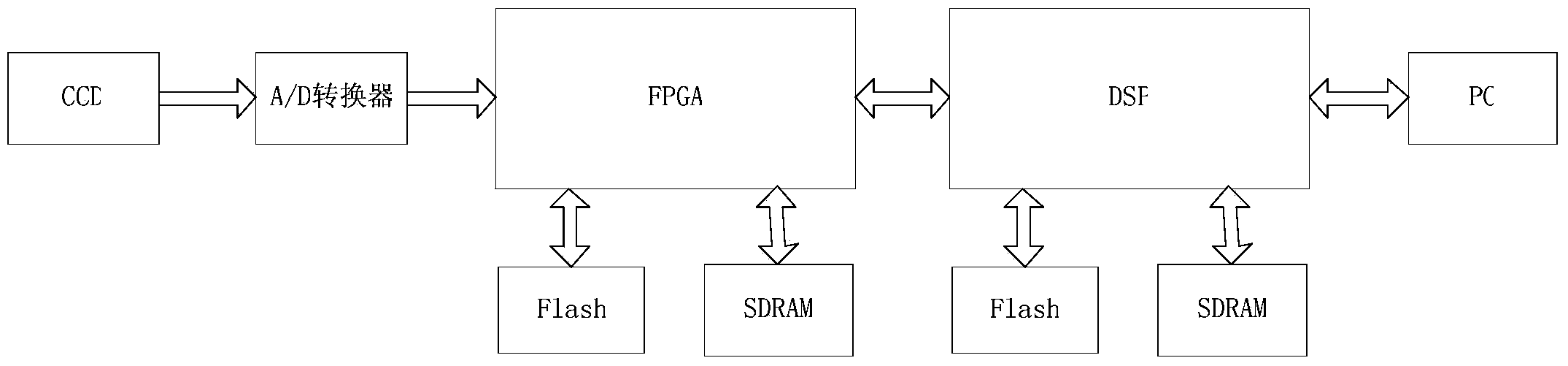

High-speed image recognition positioning information processor and processing method

ActiveCN103559706AReduce the burden onRelative throughput reductionImage analysisPattern recognitionImaging processing

The invention discloses a high-speed image recognition positioning information processor which comprises a CCD lens, an A / D converter, an FPGA, an FPGA extended SDRAM, an FPGA extended Flash, a DSP, a DSP extended SDRAM and a DSP extended Flash, wherein the CCD lens is used for obtaining an image analog signal of an object to be detected; the A / D converter is used for transforming the received image analog signal to a digital signal; the FPGA is used for collecting image data and preprocessing an image; the DSP is used for identifying and locating the image. A processing method comprises the steps of firstly, calibrating an imaging system in the DSP before identifying and locating are performed, secondly, calculating a transformational matrix H, thirdly, completing matching between the image and a standard image, fourthly, completing morphological image processing and finally completing Blob analysis, labeling connected domains, calculating the area of defects and the perimeter of the defects and completing the spatial physical location prediction of the defects. According to the high-speed image recognition positioning information processor and the processing method, the defects in an integrated circuit can be fast identified and located in a high-accuracy mode.

Owner:SOUTH CHINA UNIV OF TECH

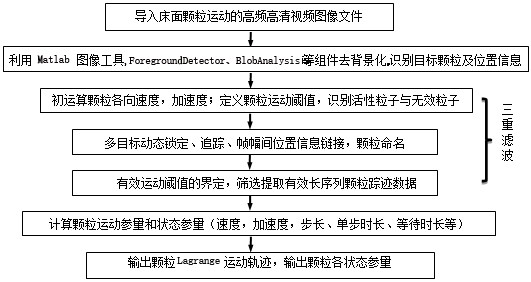

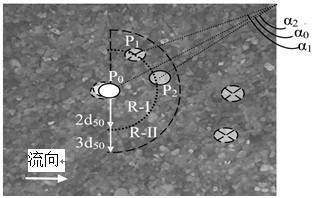

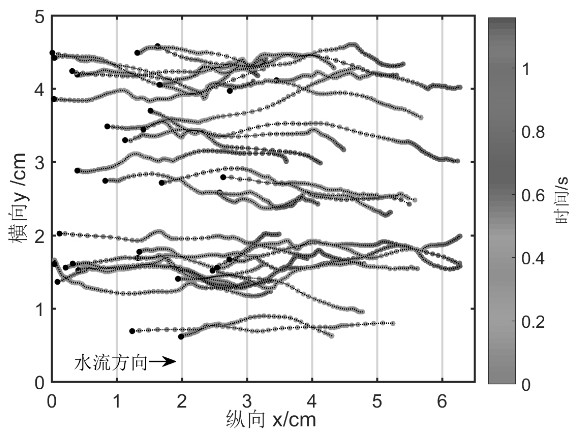

Bed surface particle identification tracking method based on motion image backtracking

PendingCN112967313ARealize fine identificationRealize multi-dimensional information collectionImage enhancementImage analysisData setAlgorithm

The invention discloses a bed surface particle identification tracking method based on motion image backtracking. An identification and tracking task is completed through nine steps. And carrying out resolution adjustment preprocessing on the qualified bed surface particle motion image by using a binary method. A two-dimensional Gaussian mixture model is adopted to carry out background removal on the moving particles; a motion backtracking method is used, based on an inter-frame particle identification model, target particle motion positions in continuous frames are determined, and a dynamic threshold value and a spot analysis method are used for filtering data noise. Through active and inert state identification and establishment of an effective active particle data set, a particle trajectory sample set and a space coordinate data set with all behavior characteristics of motion and waiting are screened out. Moving particles are tracked in continuous frames of images to form a coordinate trajectory chain, and multi-scale motion information is obtained; a particle positioning error elimination and optimal identification link technology is adopted, so that the quality of effective active particle motion data is improved; fine identification, multi-dimensional information acquisition and whole-process tracking of target particle motion are realized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Insulation blanket micro-defect identification device

PendingCN113686869APrecise identification and location of defectsOptically investigating flaws/contaminationImaging processingMachine vision

The invention discloses an insulation blanket micro-defect identification device, comprising: an image acquisition unit which is used for acquiring an image of an insulation blanket; an illumination unit which is used for providing illumination when the image acquisition unit performs image acquisition; an image processing unit which is used for firstly filtering the acquired image, then binaryzing the image, finally marking connected regions with abrupt gray level change in the image through Blob analysis, and extracting the characteristics of the regions, so as to mark the positions of defects existing in the sampled insulation blanket and the pixel sizes of the defects; and an image output unit which is used for outputting and displaying the insulation blanket image marked with the defect positions and the pixel sizes. Based on a machine vision technology, the defects of the insulation blanket are automatically detected with machine eyes instead of human eyes, and the defects which cannot be detected by the human eyes and a two-electrode method at present are overcome.

Owner:ZHEJIANG ZHONGXIN POWER ENG CONSTR CO LTD +1

Method for detecting barrel head foreign matters

InactiveCN108038854AEffective filteringAccurately determineImage enhancementImage analysisForeign matterEngineering

The invention relates to a method for detecting barrel head foreign matters. The method for detecting barrel head foreign matters comprises the following steps that: collecting one normal barrel headimage, and taking the barrel head as a template image; through Hough transform detection circle, determining the position of the barrel head; obtaining a barrel head image with foreign matters, and determining the position of the barrel head through the Hough transform detection circle again; through the circle area of the obtained barrel head image and the round area of the template barrel head image, carrying out differential treatment, and highlighting the foreign matters; and carrying out Blob analysis on the differential treatment image. The sizes of the foreign matters calculated by theBlob are filtered, a threshold value M is set, foreign matters are in the presence on the barrel head when the size is smaller than the threshold value M, and the foreign matters are in the presence if the size is greater than the threshold value M.

Owner:TIANJIN PUDA SOFTWARE TECH

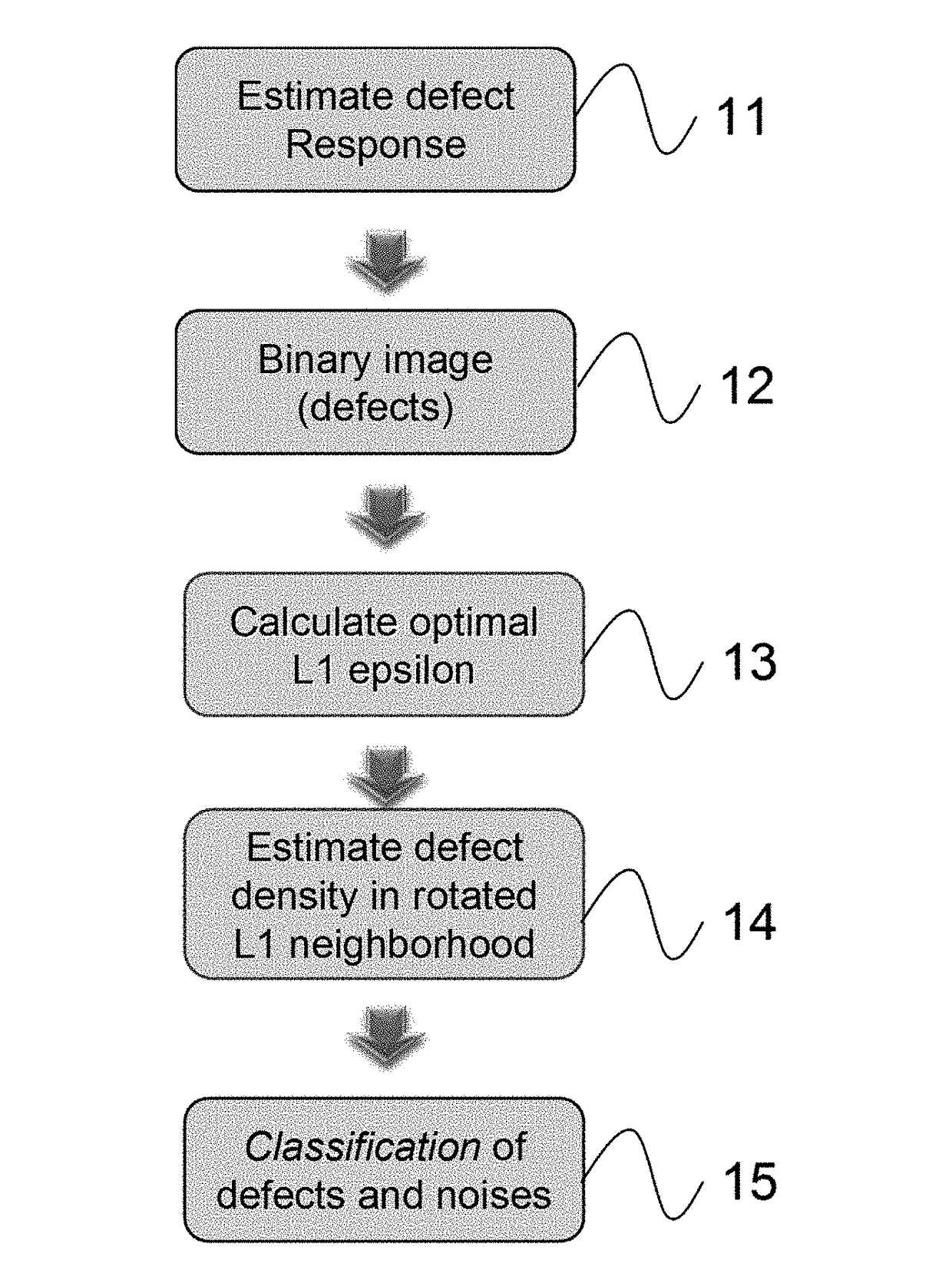

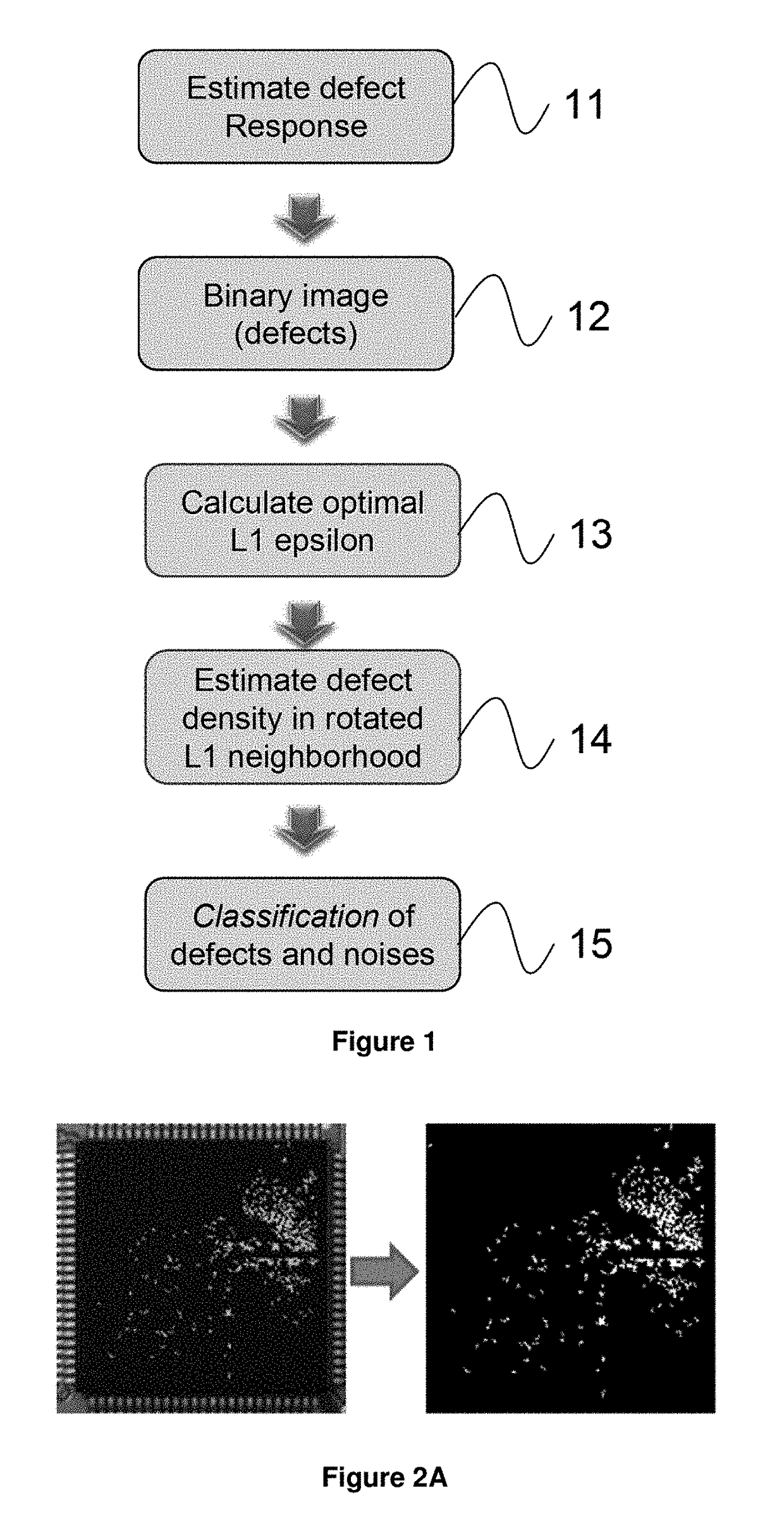

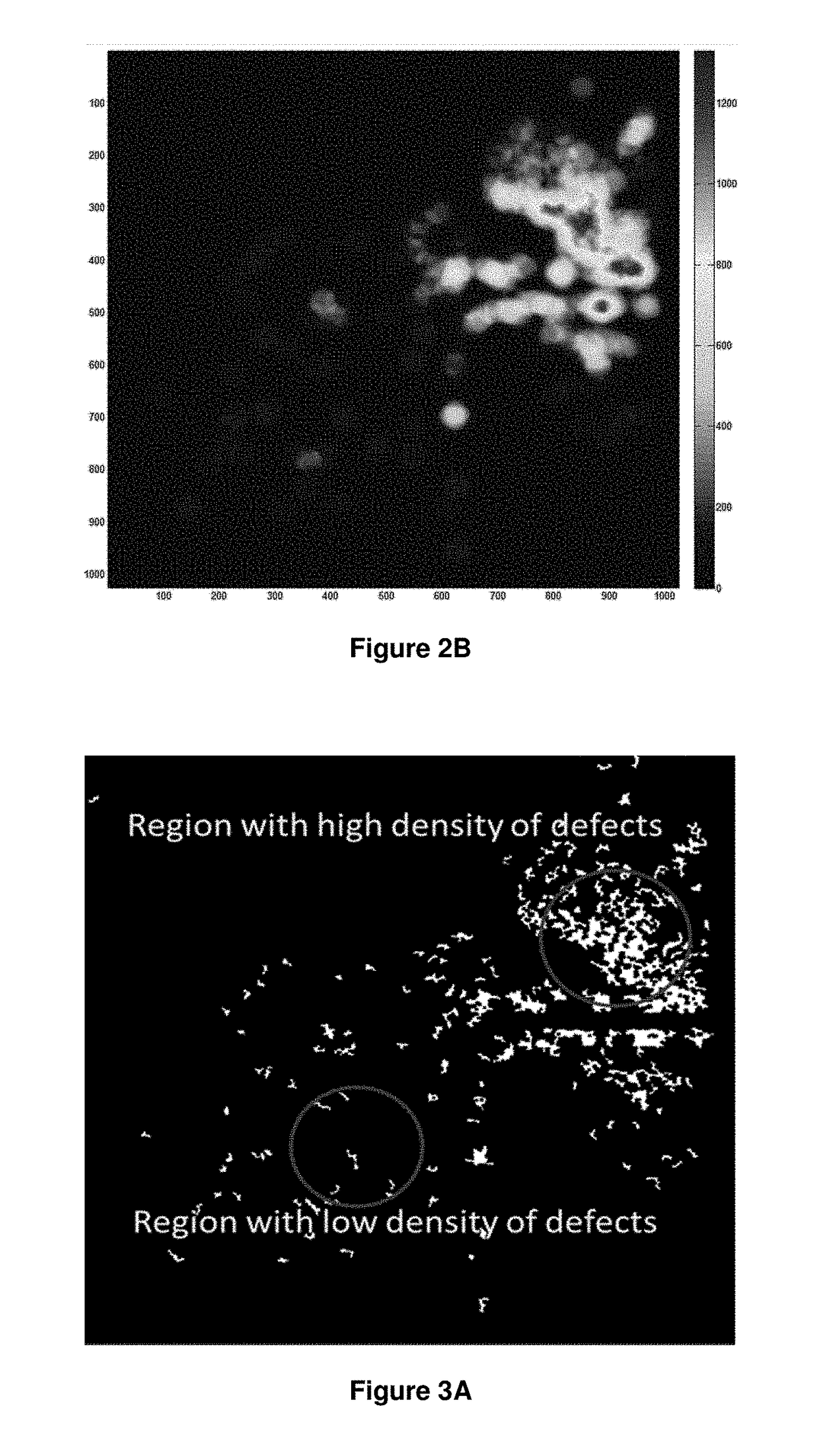

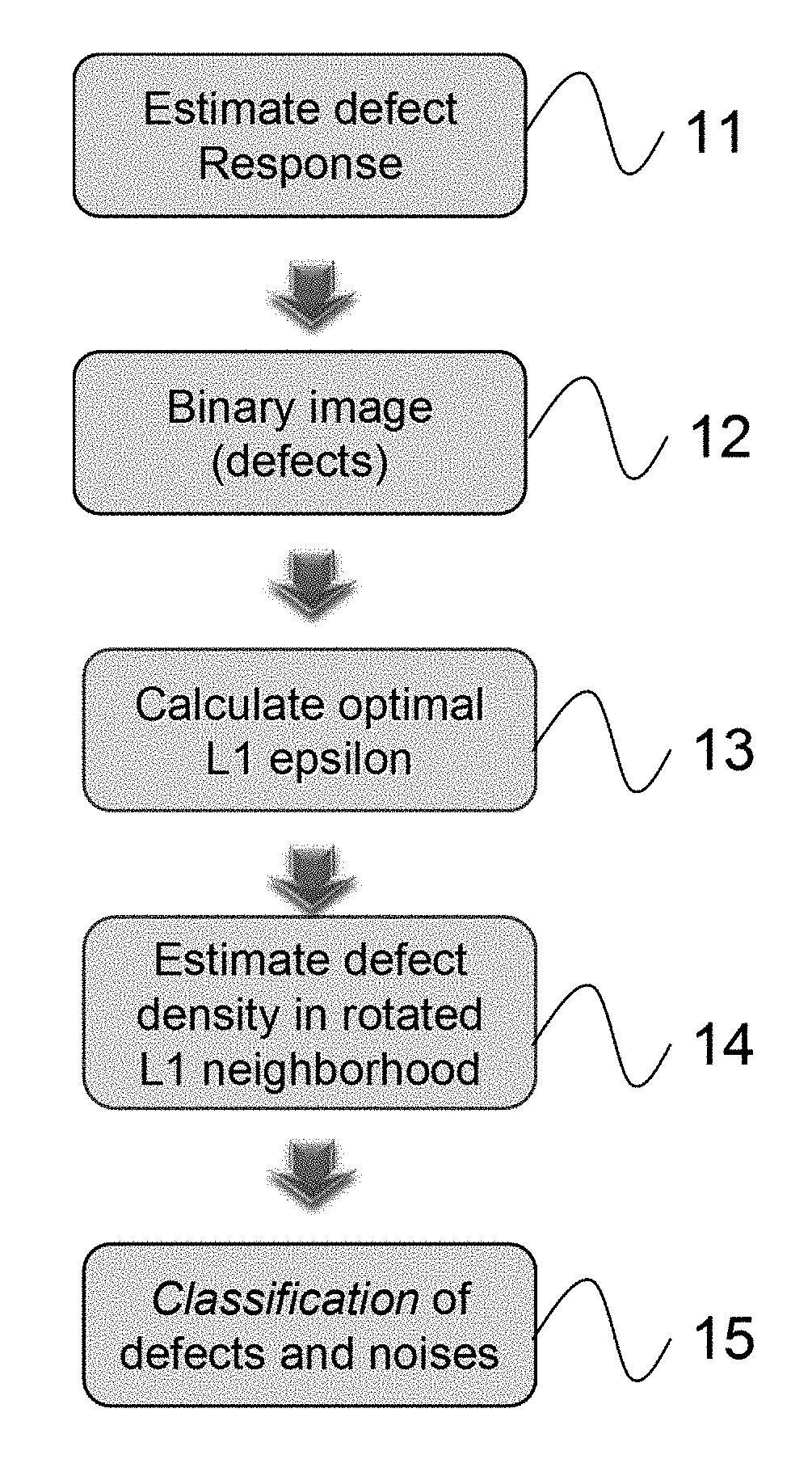

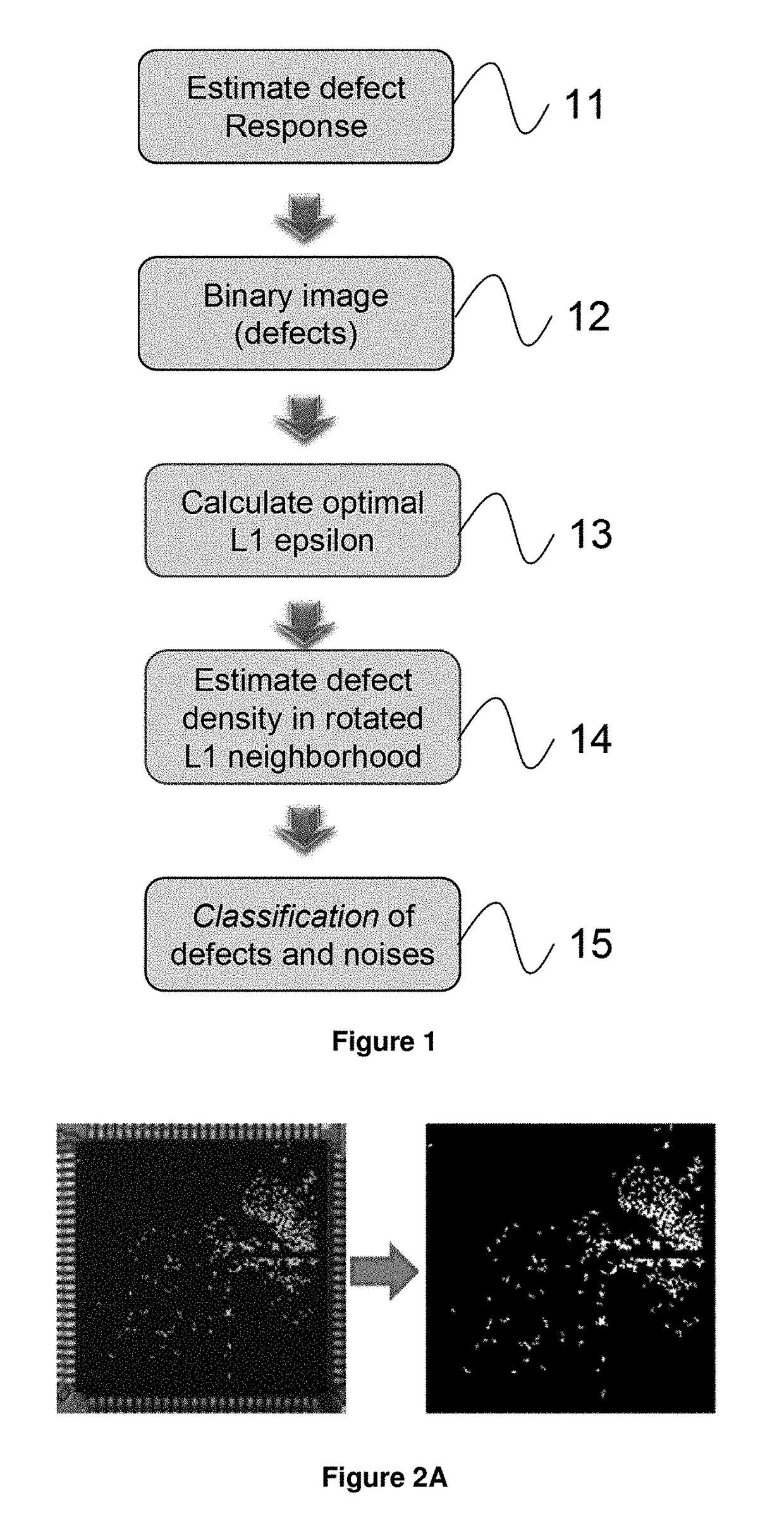

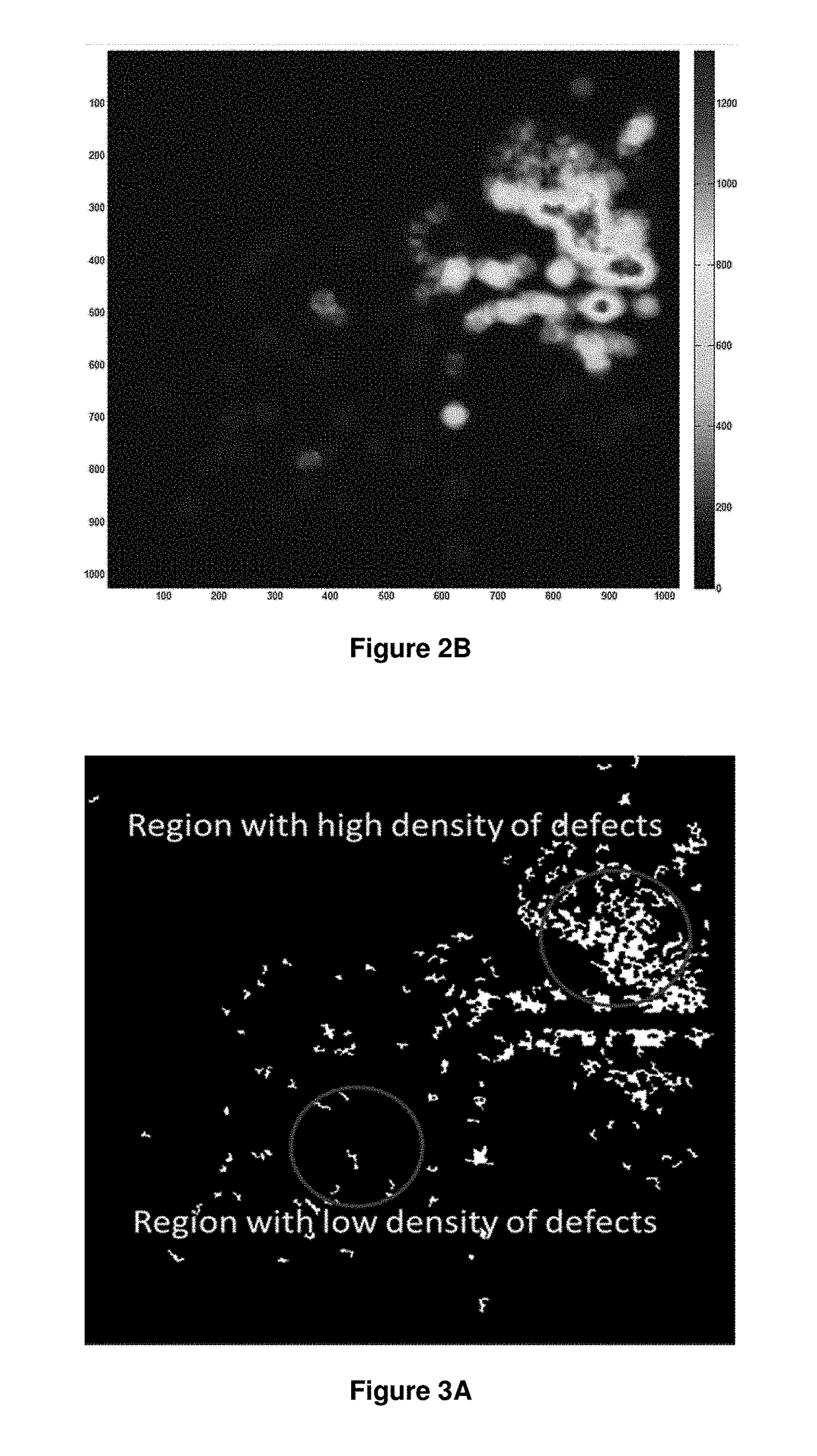

Fast density estimation method for defect inspection application

The present invention provide a high speed spatial density estimation algorithm to estimate defect density maps for blob analysis in an image processing field for inspection. The method of the present invention uses a rotated L1 epsilon-ball neighborhood mask for determining a defect density for each of target pixels to generate a defect density map for defect detection of an object. The present method is capable of providing high detection speed and substantially eliminating influence of the noise from images.

Owner:HONG KONG APPLIED SCI & TECH RES INST

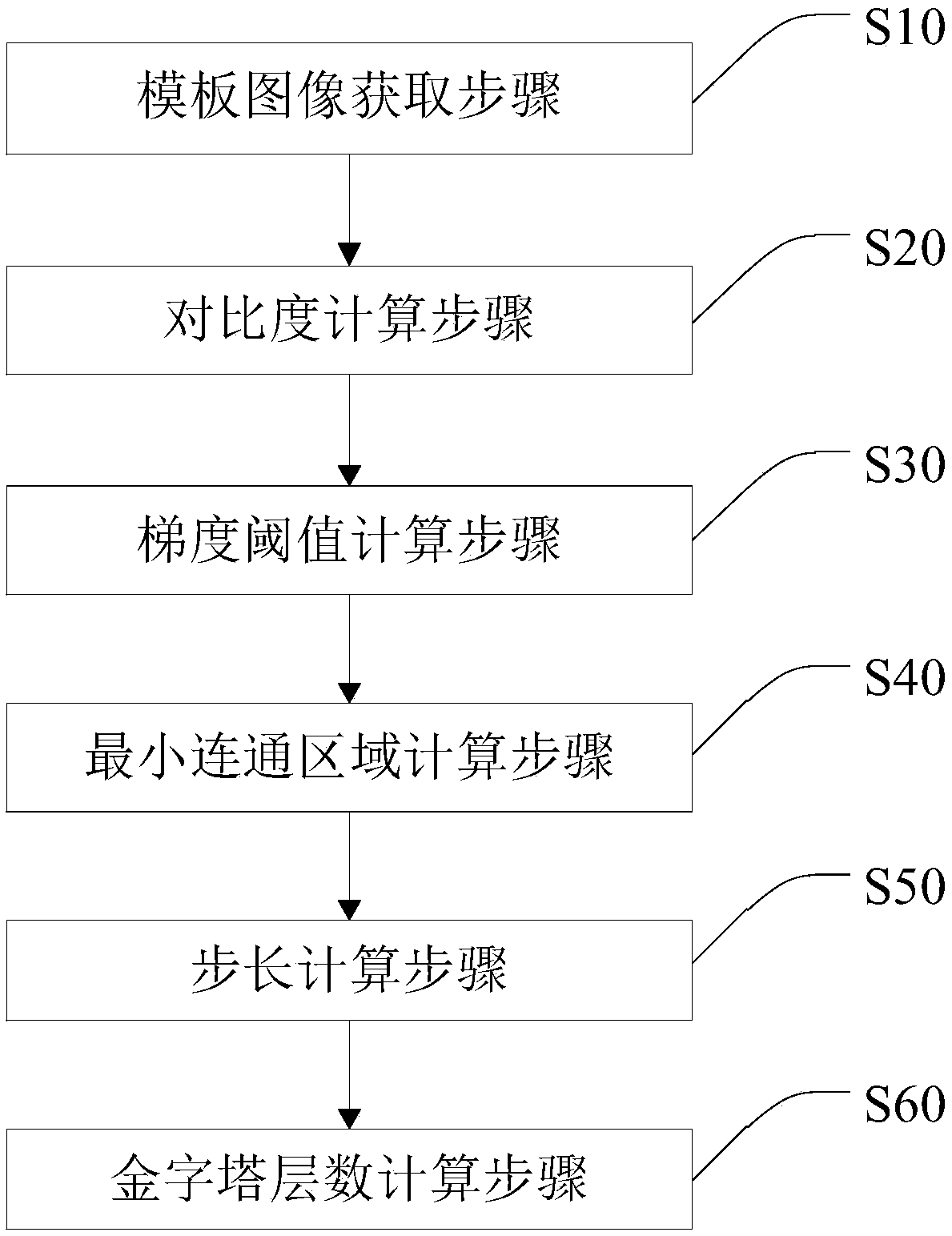

Self-adaption method and system of parameters in template matching

The invention discloses a self-adaption method and system of parameters in template matching. The self-adaption method of parameters in template matching includes the steps: through a template image,calculating the contrast variance or contrast standard deviation of the template image; performing edge detection on the template image, and setting the value range of a gradient threshold; accordingto the gradient threshold, acquiring the edge region of the template image; performing Blob analysis on the edge region to obtain a communication region, and calculating the average length or mean intensity of the communication region; taking the average length or the mean intensity as the correlation function of the gradient threshold; in the value range, taking the gradient threshold corresponding to the maximum correlation function as the gradient threshold parameter; and acquiring the position of the edge pixel through the gradient threshold parameter so as to calculate and obtain the angle step and the zoom step. Therefore, the self-adaption method and system of parameters in template matching can automatically calculate and obtain the gradient threshold parameter only by setting thetemplate image, reduces the dependence on the experience of operators for parameter setting, so that the operators do not need know about the implementation principle of the algorithm and only need performing the basic operation.

Owner:SHENZHEN HUAHAN WEIYE TECH

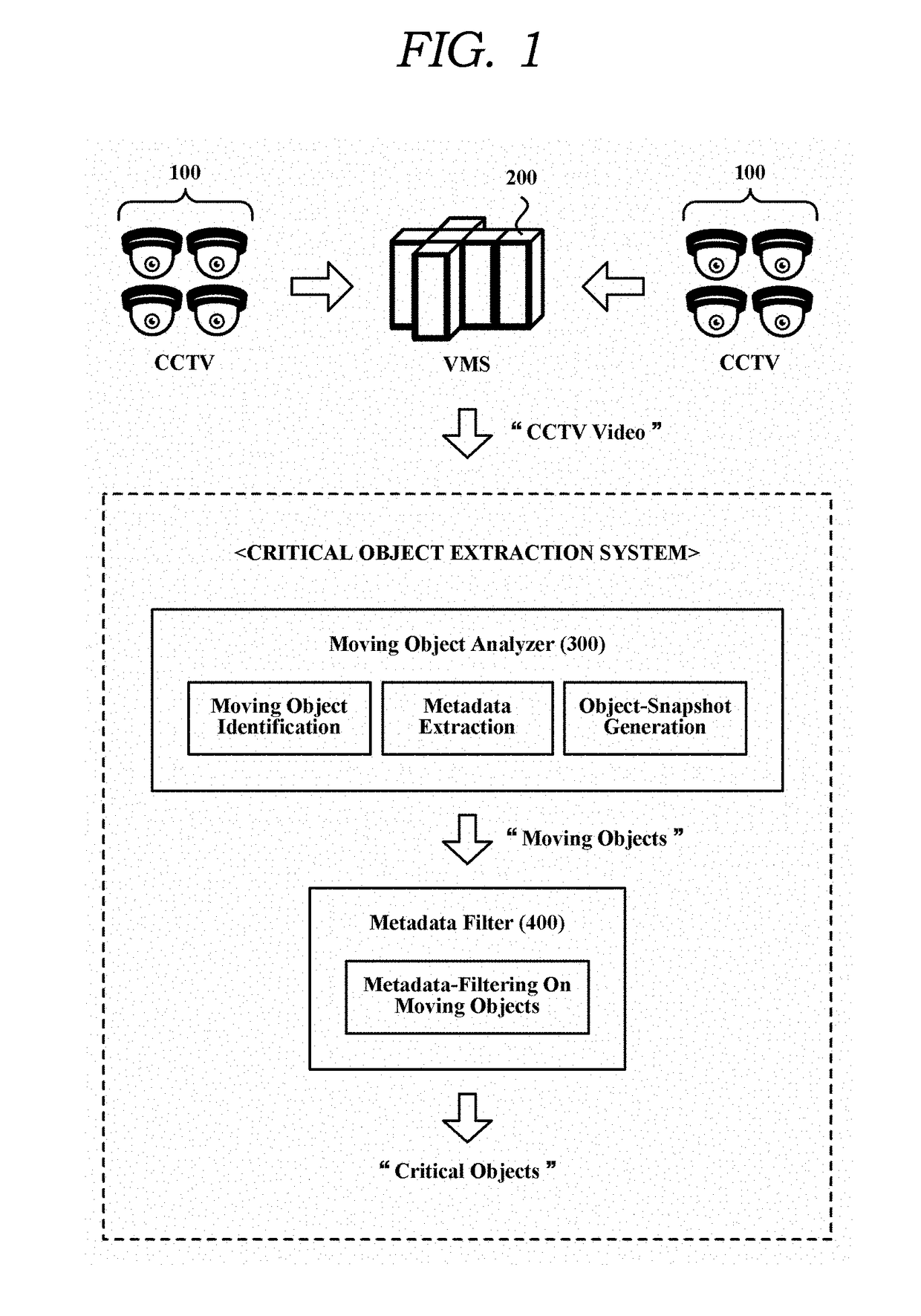

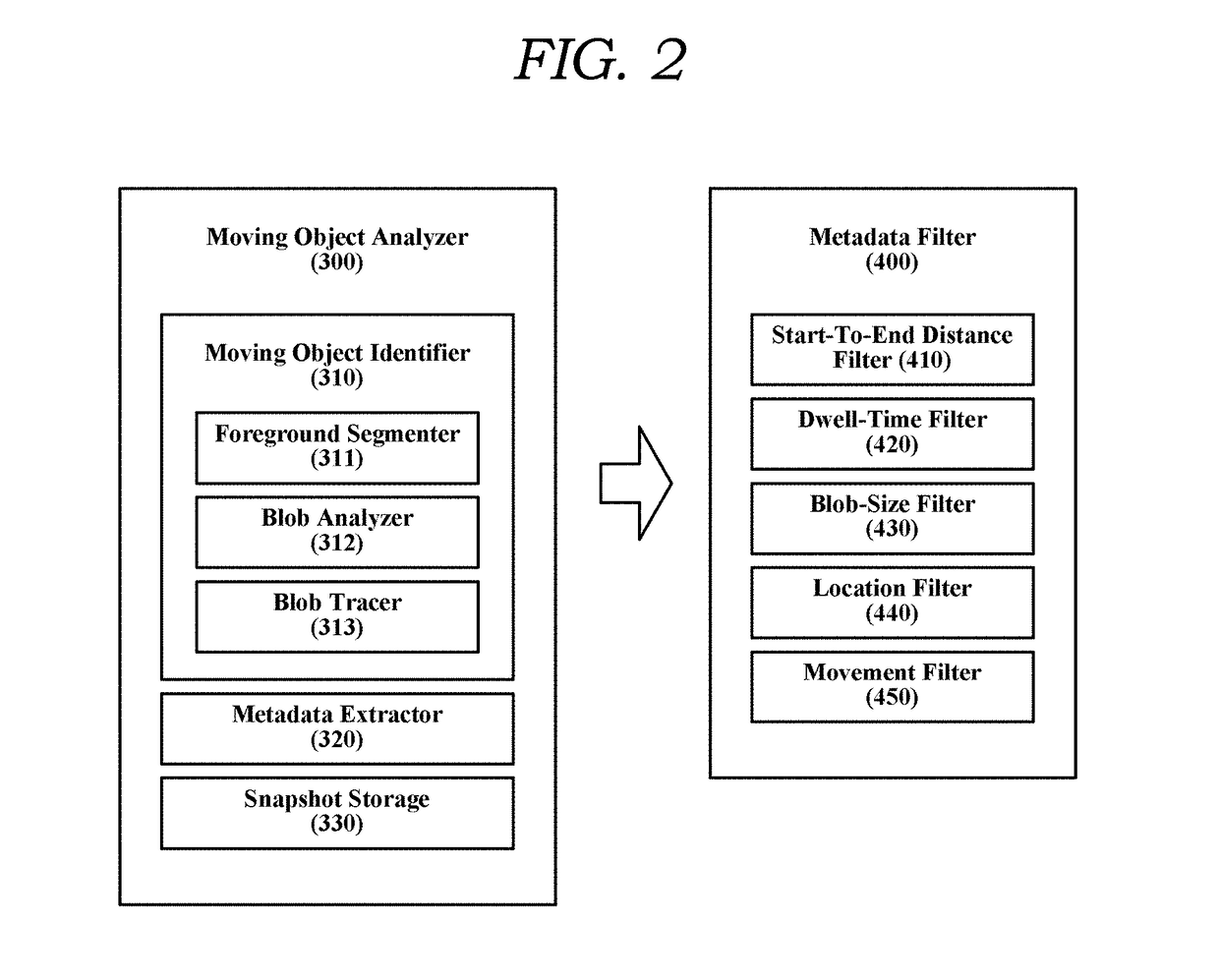

Method of detecting critical objects from CCTV video using metadata filtering

ActiveUS20180241972A1Effective monitoringImage enhancementImage analysisDistribution characteristicBlob analysis

The invention provides a method of detecting critical objects out of video produced in CCTV cameras. More specifically, the invention provides a method of detecting critical objects out of CCTV video, in which lightweight algorithms of foreground segmentation and blob analysis are applied to the CCTV video in order to detect moving objects and then object filtering is performed based on distribution characteristics of metadata in order to propose critical objects contained in the CCTV video, whereby a few staff members in the integrated control center may efficiently monitor display screen of a large number of CCTV cameras. The invention makes it possible to detect critical objects out of CCTV video with utilizing lightweight algorithms, which enables real-time processing by video analysis servers of normal computing power. Therefore, the efficiency of integrated control centers may be improved where massive CCTV videos are gathered from a large number of CCTV cameras.

Owner:INNODEP

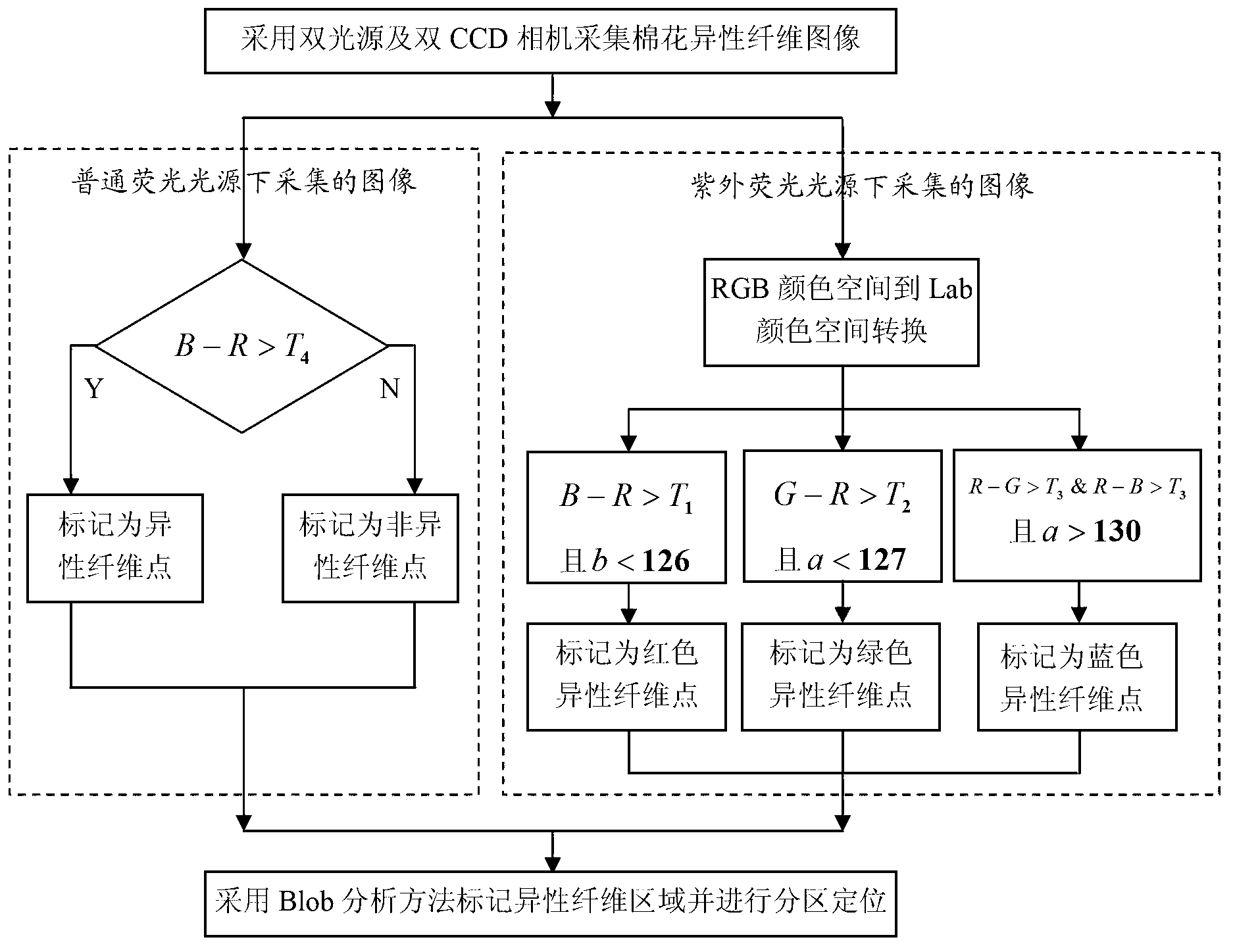

Detecting and positioning method of cotton foreign fibers

ActiveCN103234975ARapid positioningEasy to removeOptically investigating flaws/contaminationFiberColor image

The invention discloses a detecting and positioning method of cotton foreign fibers. The method comprises the following steps: respectively adopting a common fluorescent light source, an ultraviolet fluorescent light source and a twin-line-array CCD camera to obtain cotton foreign fiber color images; carrying out secondary cutting of images acquired under the common fluorescent light source in an RGB and Lab color space, and detecting foreign fibers having different colors; detecting foreign fibers containing a fluorescent whitening agent of images acquired by the ultraviolet fluorescent light source in the RGB color space; and labeling the detected foreign fibers through adopting a Blob analysis process, calculating to obtain a center coordinate, partitioning for opening the spray valves of corresponding partitions, and rejecting the foreign fibers. The method has the advantages of simple calculation, fast calculation speed, and suitableness for the online detection system of the cotton foreign fibers, and can be used for rapidly detecting and accurately positioning the foreign fibers contained in the cotton.

Owner:建湖上冈产业园服务有限公司

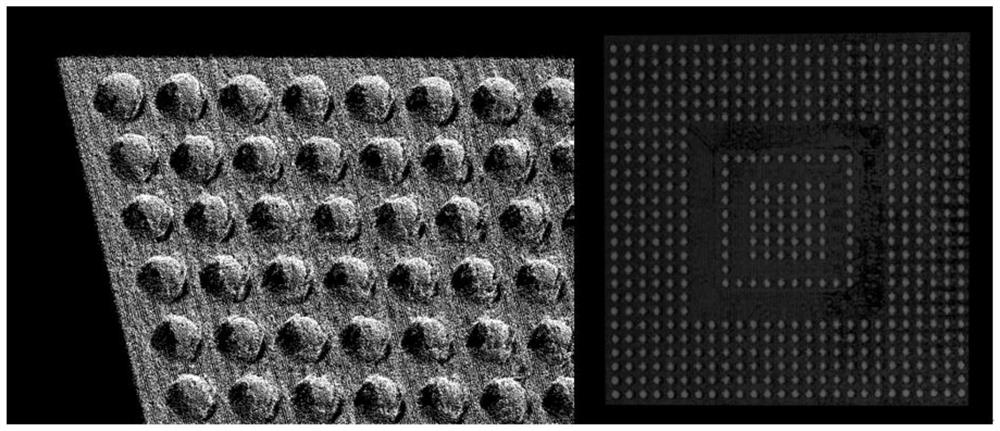

BGA solder ball three-dimensional detection method based on depth image processing

PendingCN113052797AGet quicklyGet efficientlyImage enhancementImage analysisImaging processingMachine vision

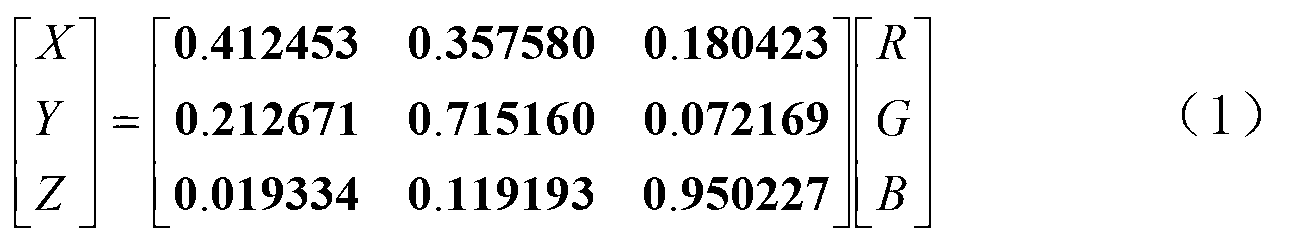

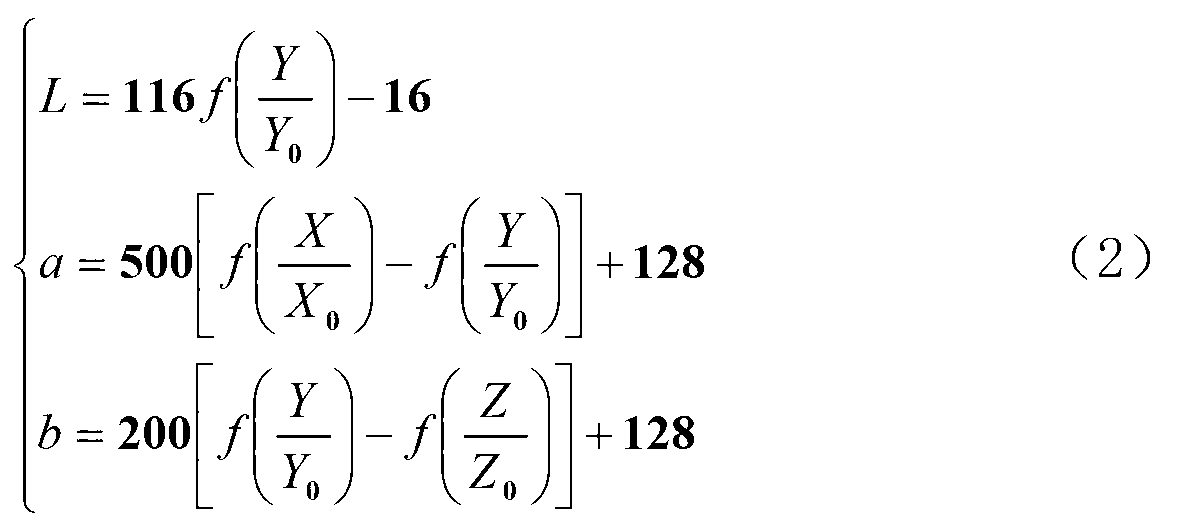

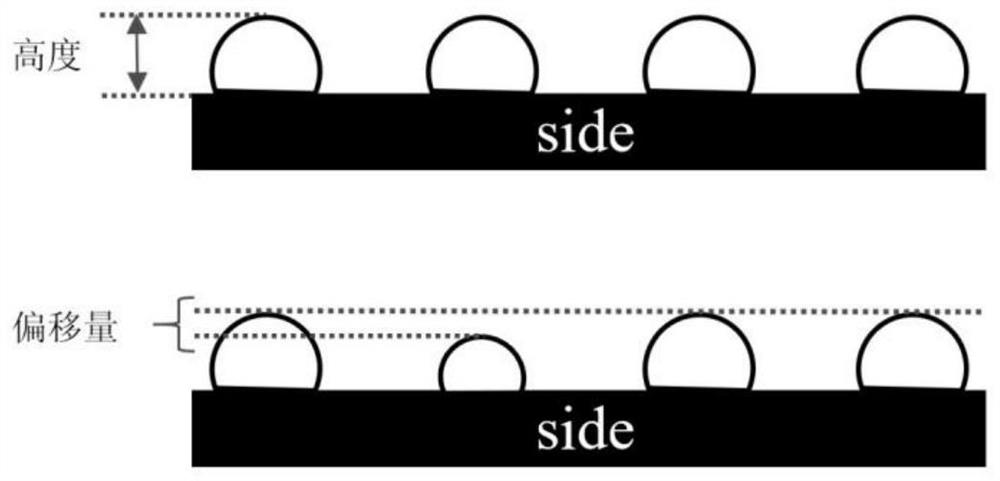

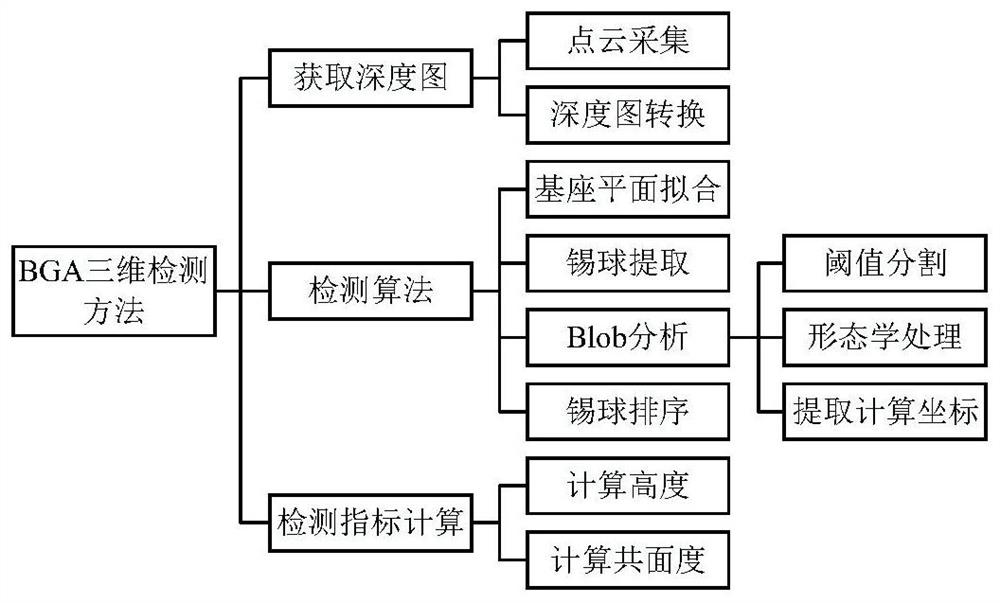

A BGA solder ball three-dimensional detection method based on depth image processing comprises the steps: converting a collected chip point cloud into a depth image, a base plane of a chip is fitted, and marking solder ball areas through a Blob analysis algorithm; extracting a two-dimensional central point of the solder ball region and three-dimensional coordinate points corresponding to eight neighborhood pixels of the solder ball region, performing averaging and assigning the average value to a three-dimensional point at the top of the solder ball; when the solder ball area is marked, combining with a morphological method to enable the solder ball to approach to circularity so as to improve the robustness of the algorithm; and finally calculating the distance from the vertex to the plane to obtain the height and coplanarity of the solder balls. According to the BGA solder ball three-dimensional detection method based on depth image processing, a machine vision technology is utilized, after depth image conversion is carried out on the collected chip point cloud by utilizing a point cloud and image processing technology, a solder ball three-dimensional detection index can be efficiently obtained, and the precision meets the detection requirement.

Owner:XUZHOU NORMAL UNIVERSITY

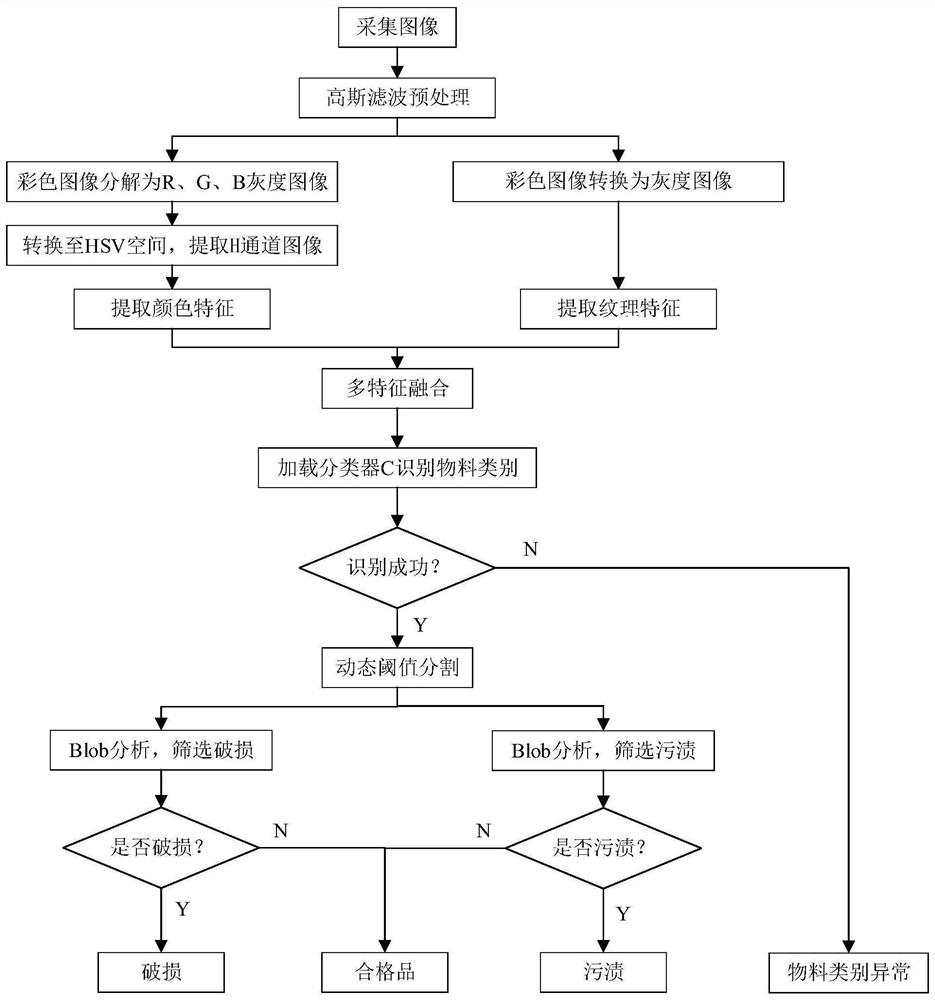

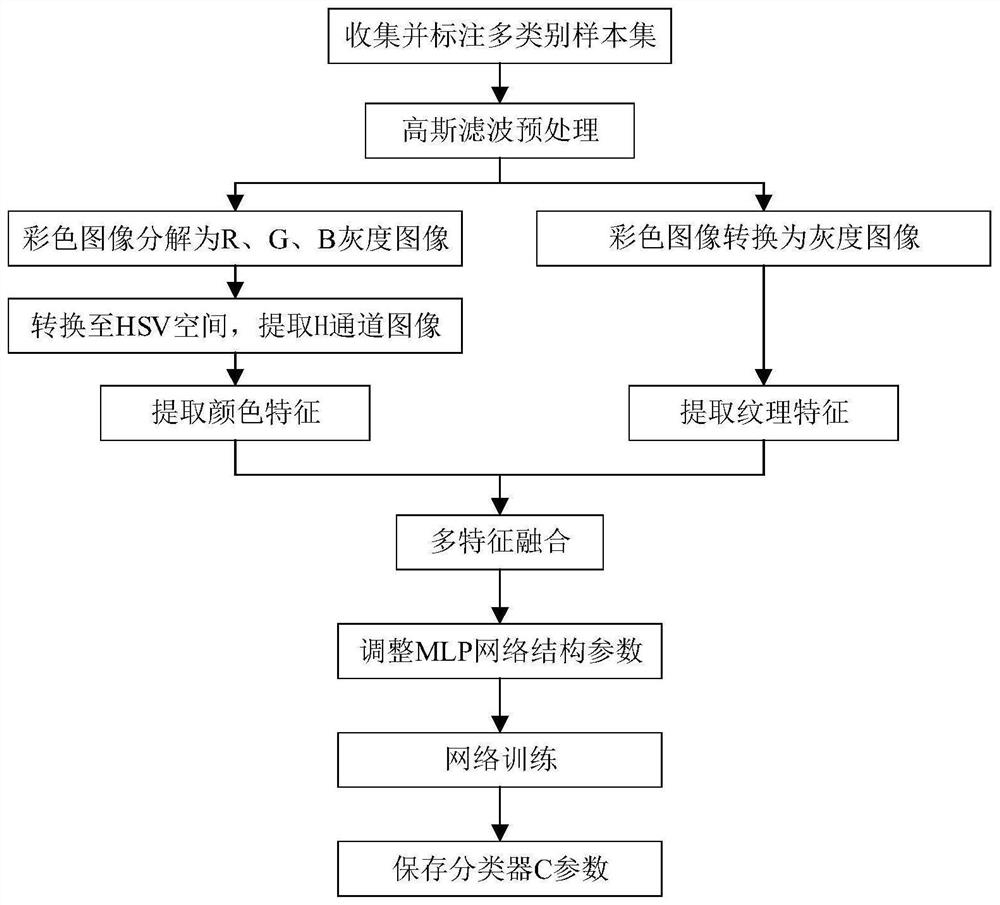

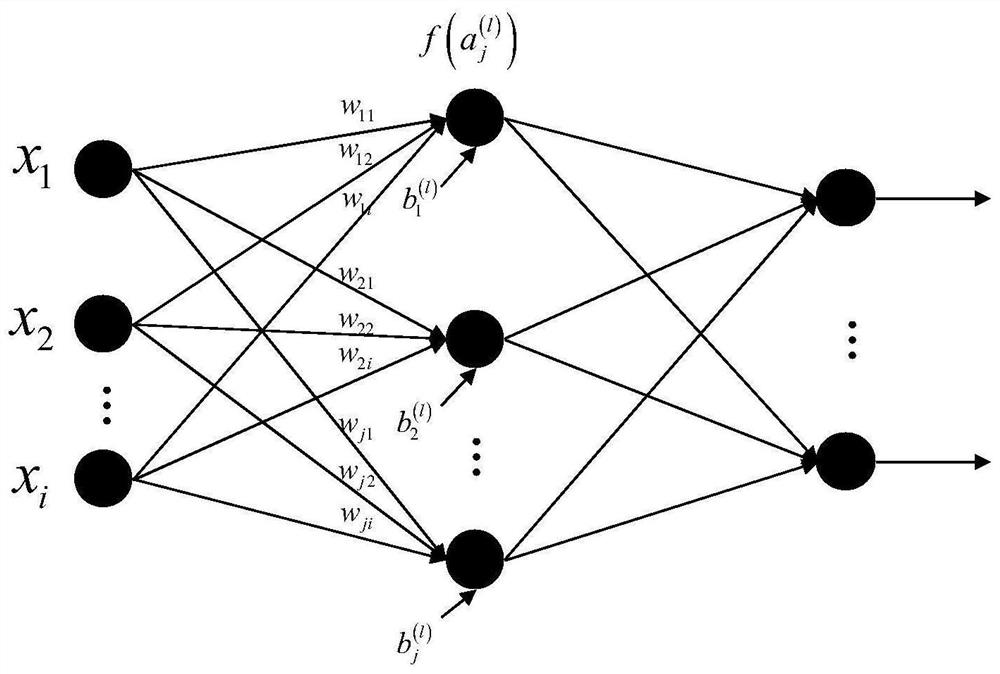

Automobile seat defect detection method based on multi-feature fusion machine learning

ActiveCN112232399AImprove matching efficiencyImprove timelinessImage enhancementImage analysisCar seatMachine vision

The invention relates to the field of machine vision detection, in particular to an automobile seat defect detection method based on multi-feature fusion machine learning. The invention discloses an automobile seat defect detection method based on multi-feature fusion machine learning, and the method is suitable for materials with different colors and materials, does not need multi-template matching, and enables an industrial robot to automatically sort the materials to a specified region according to a detection result. A multi-feature fusion classifier is trained to identify material category information by extracting color and texture features of multiple categories of automobile seat materials, and material category abnormities are screened; according to the classification result, defect detection is carried out in combination with blob analysis, and whether damage and stains exist or not is judged; and the industrial robot receives the defect detection result, grabs the workpieces, and automatically sorts the workpieces to specified areas of abnormal material types, damage, stains and qualified products. According to the invention, multi-template matching is not needed, timeliness is high, and efficient sorting of multiple types of automobile seat material defects is achieved.

Owner:NANJING ESTUN ROBOTICS CO LTD

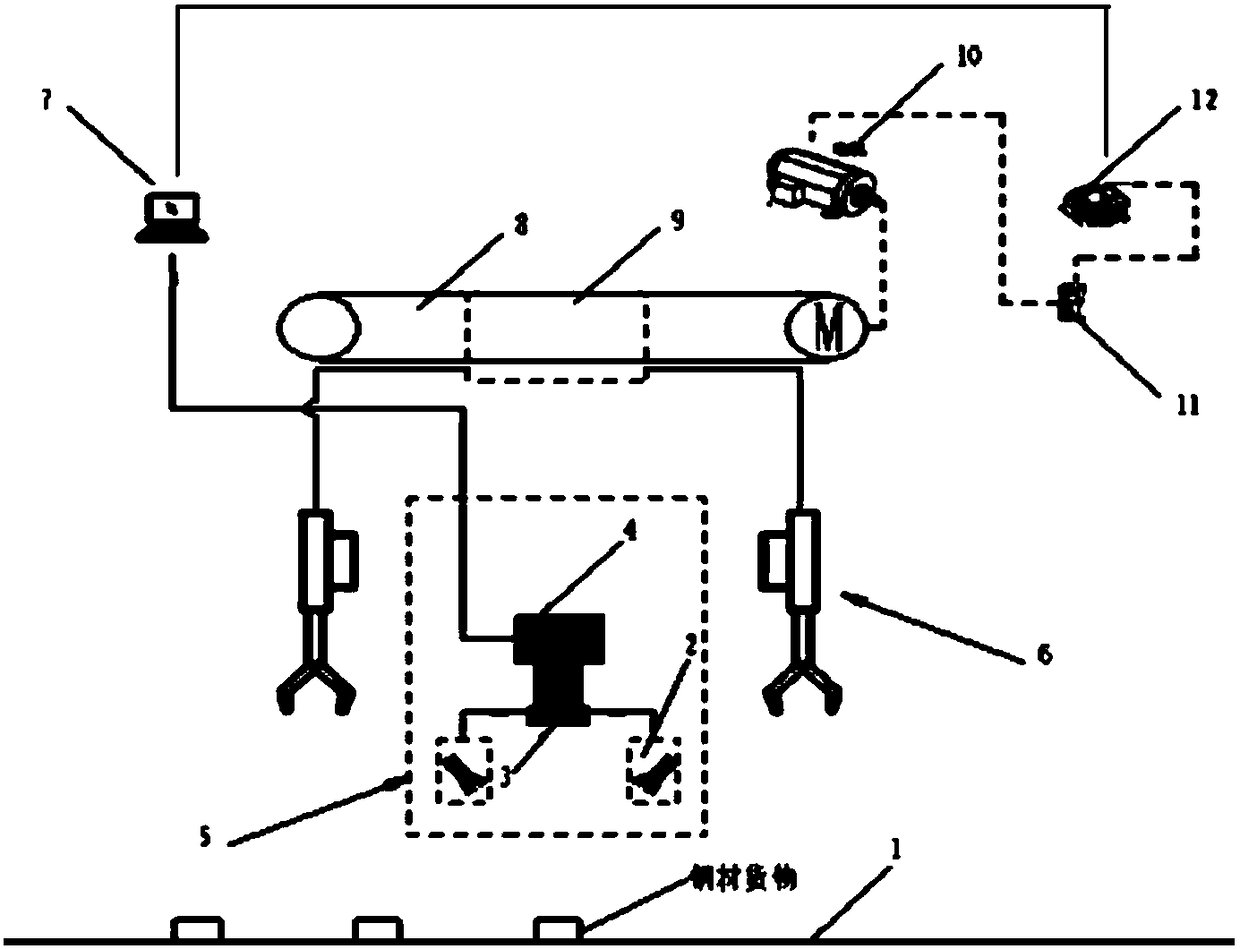

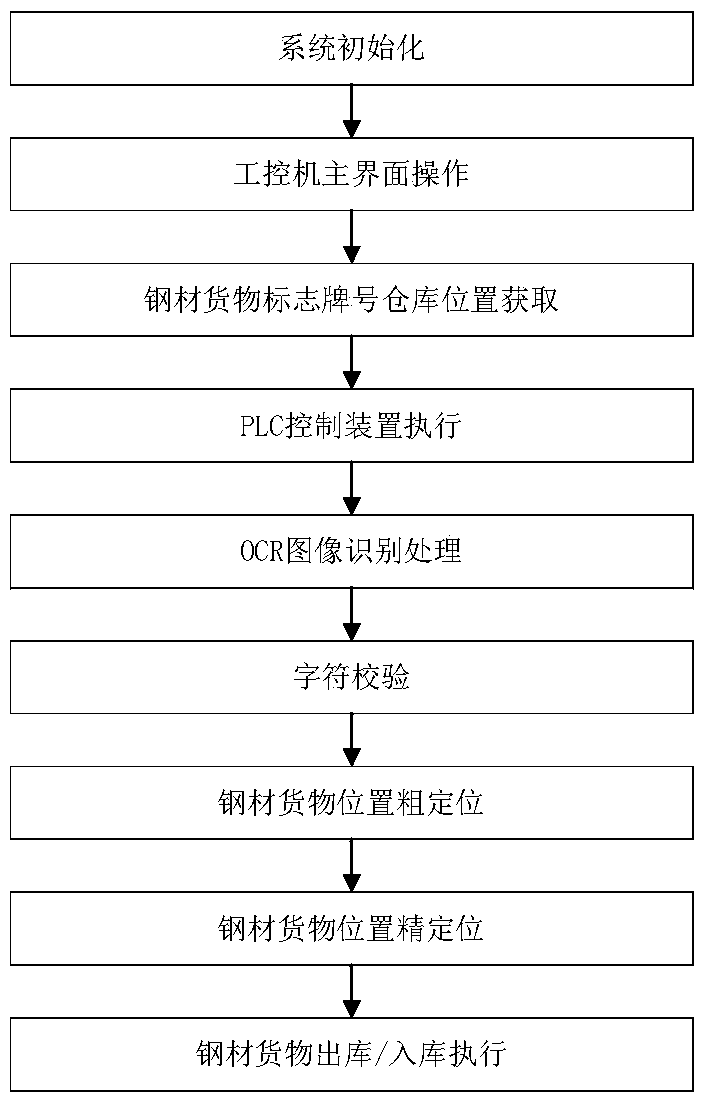

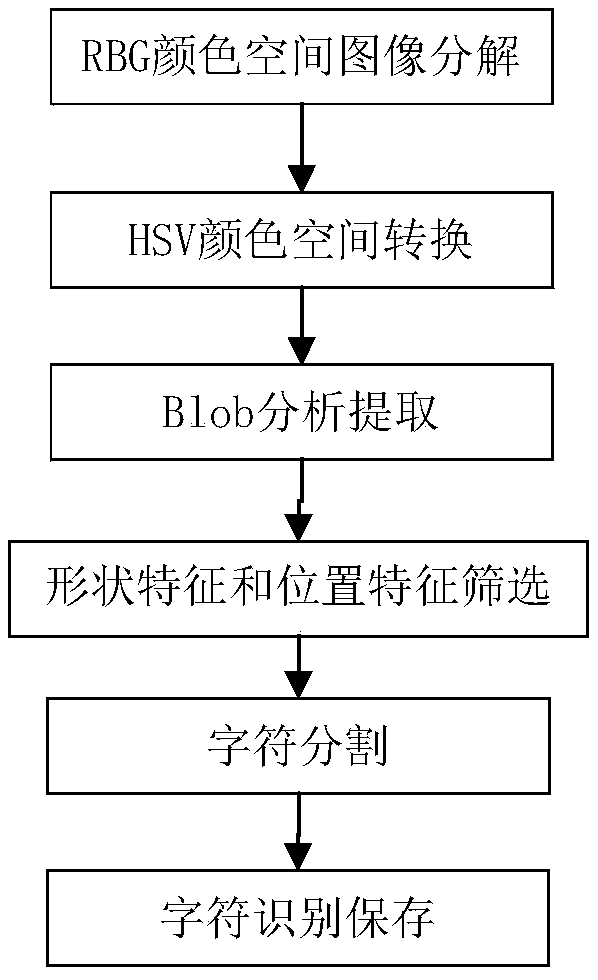

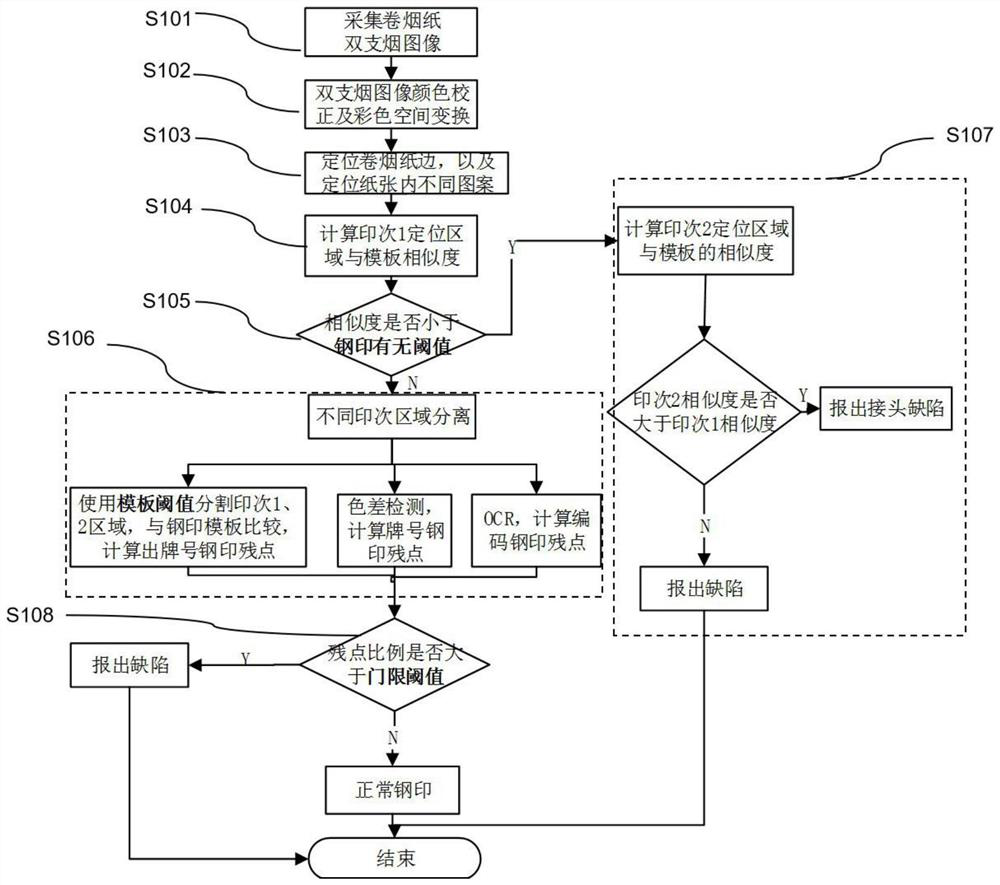

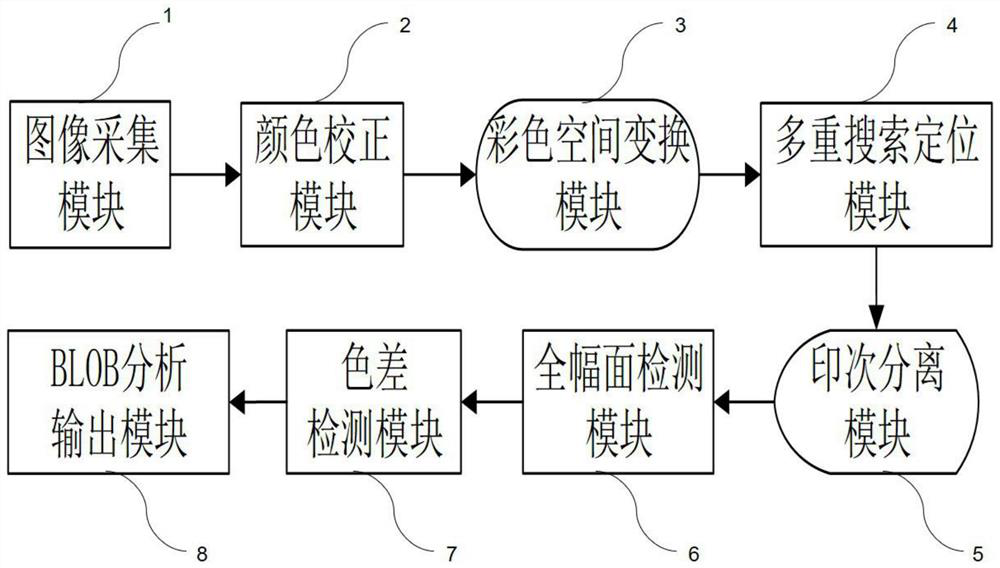

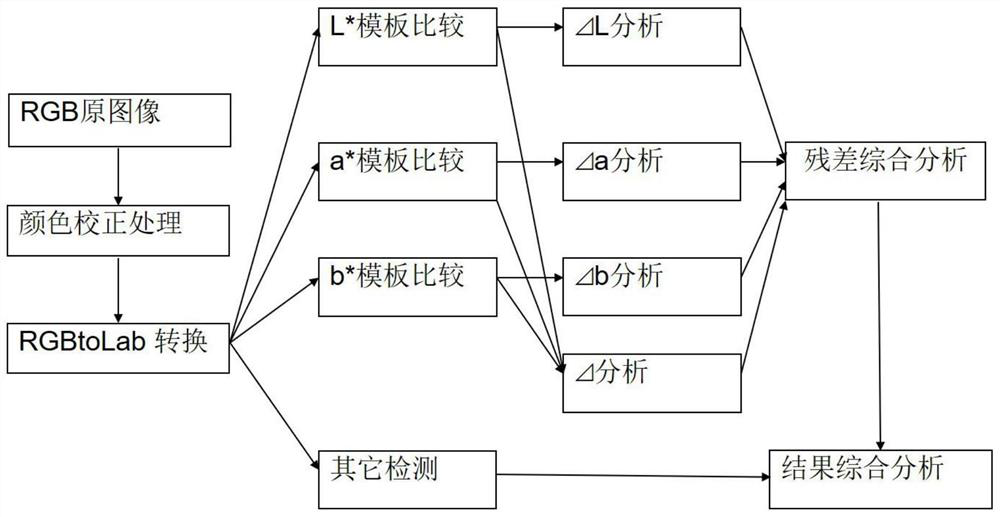

Steel seal online detection system and method based on color CCD

PendingCN111766248AImprove accuracyReal-time monitoring of productionImage enhancementImage analysisColor correctionEngineering

The invention discloses a steel seal online detection system and method based on a color CCD. The steel seal online detection system comprises an image acquisition module, a color correction module, acolor space conversion module, a multi-search positioning module, a printing frequency separation module, a full-width detection module, a color difference detection module and a BLOB analysis outputmodule. Accuracy of the steel seal detection system is improved through multiple positioning and color detection algorithms, and the system and the method can be applied to steel seals with complex patterns, textures, characters and colors; then, a production condition of cigarette paper can be monitored in real time in a cigarette paper printing process; and then, a problem that manual detectionis needed in a traditional detection method is solved, and labor cost is greatly reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

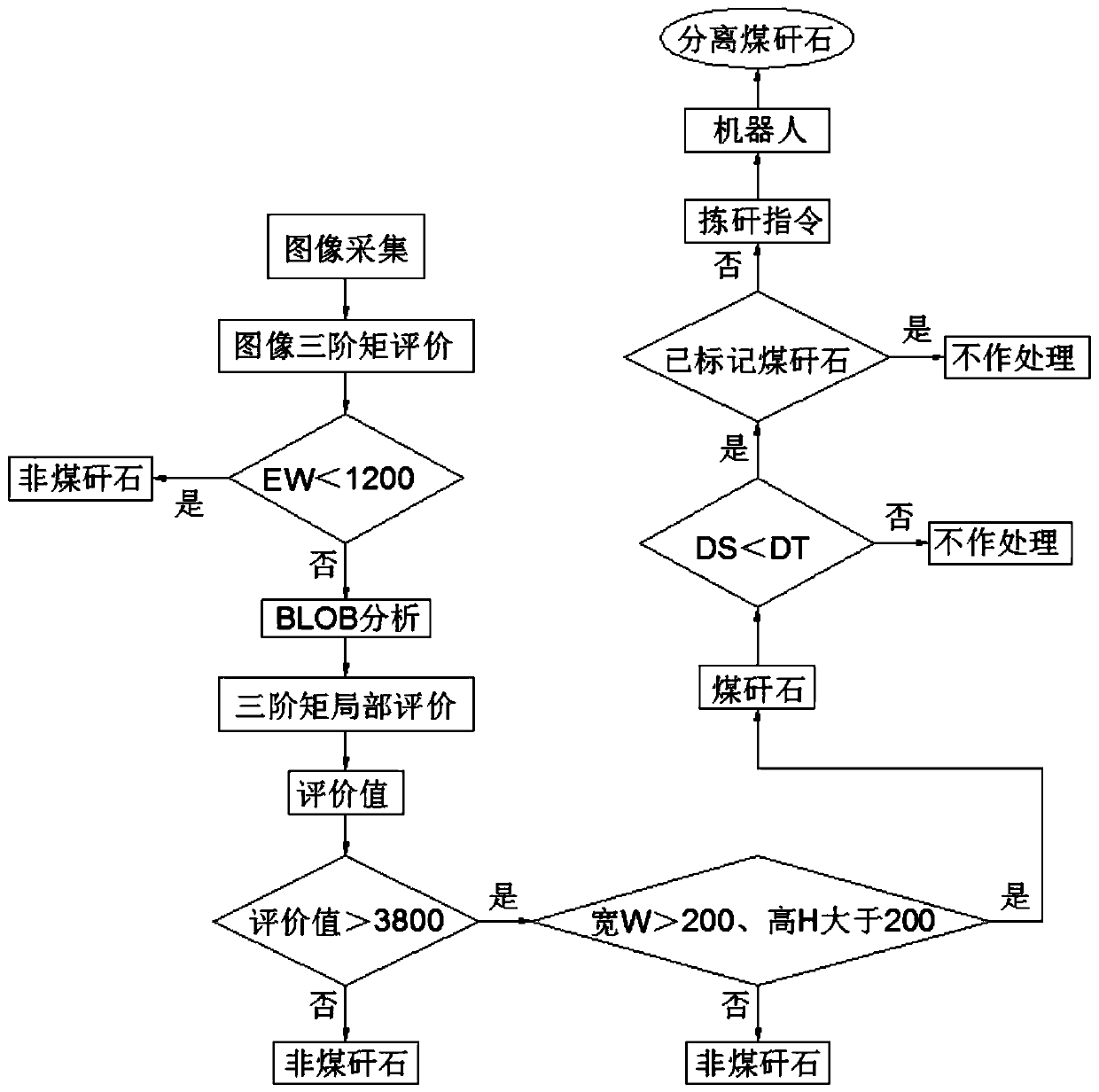

Gangue identification sorting method based on gangue-free image filtering and BLOB analysis

ActiveCN111036576AReduce wasteful computing timeReduce distractionsCharacter and pattern recognitionSortingImaging analysisProcess engineering

The invention discloses a gangue identification sorting method based on gangue-free image filtering and BLOB analysis. The method comprises the following steps of performing image acquisition on coal,calculating image three-moment evaluation on a received image by an industrial personal computer through computer software to obtain a three-moment evaluation value of the image, comparing the three-moment evaluation value of the image with a set initial threshold value, performing BLOB analysis on the image, and obtaining coordinates of a point at the upper left corner of the maximum partition and the width and height of distribution; performing three-moment local evaluation on the area range where the partition is positioned, judging whether the current gangue is marked gangue which sends an instruction or not, if yes, not performing processing, and if not, sending a gangue sorting instruction; and picking gangue through a robot. According to the method, full-image analysis can be transited to accurate analysis and judgment of a local attention area, interference of background and stray objects on recognition is reduced, gangue is effectively recognized, and then popularization andapplication are facilitated.

Owner:QINGYUAN POLYTECHNIC

Fast density estimation method for defect inspection application

ActiveUS20170278235A1Fast density estimationReduce noiseImage enhancementImage analysisPresent methodImaging processing

The present invention provide a high speed spatial density estimation algorithm to estimate defect density maps for blob analysis in an image processing field for inspection. The method of the present invention uses a rotated L1 epsilon-ball neighborhood mask for determining a defect density for each of target pixels to generate a defect density map for defect detection of an object. The present method is capable of providing high detection speed and substantially eliminating influence of the noise from images.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com