Automobile seat defect detection method based on multi-feature fusion machine learning

A multi-feature fusion and car seat technology, applied in neural learning methods, optical testing flaws/defects, instruments, etc., can solve the problems of single type, low timeliness requirements, and low efficiency of multi-template matching of detection images, and achieve Matching effects with high efficiency and high timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0096] Provide a kind of concrete embodiment below:Taking the detection and sorting of several different seat defects on a certain production line as an example, the specific implementation method of this scheme is illustrated:

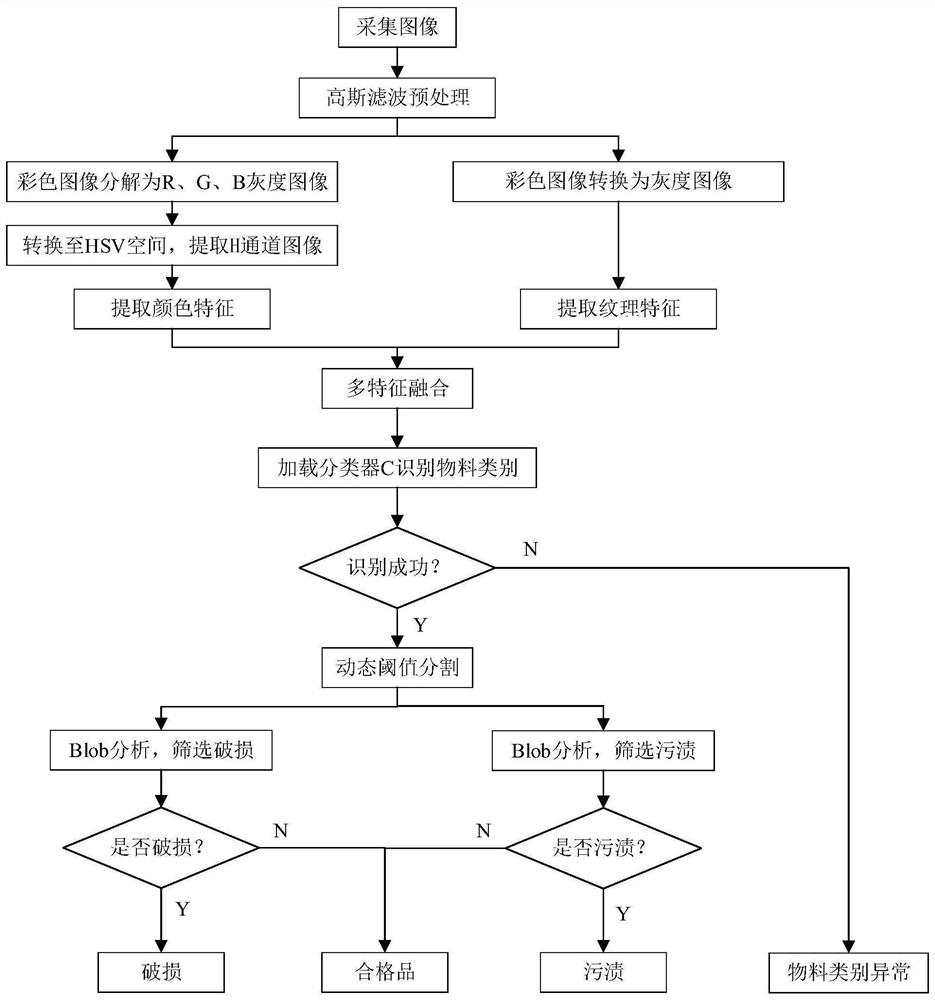

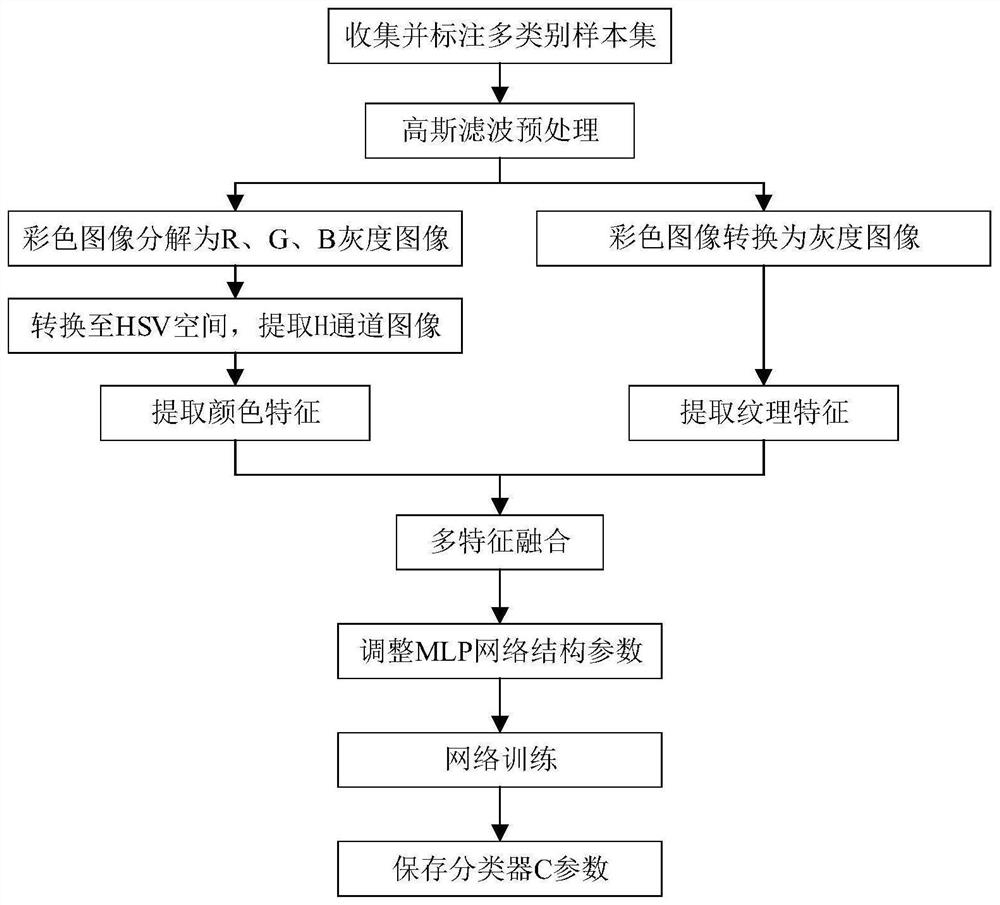

[0097] This embodiment takes car seats as the object, including front row and rear row seats, such as Figure 5 As shown in the figure, the seat is one of the core components of the vehicle. It consists of a headrest 1, a backrest 2, a seat cushion 3, and a hand pillow 4. Identify the colors and materials of different parts of the seat, including black velvet, black leather, and gray leather. Whether there is a material category exception, such as Image 6 As shown, and detect whether there are damages and stains in each part, and screen out unqualified products. According to the classification identification and defect detection results, the industrial robot grabs the workpiece and automatically sorts the four categories of abnormal, damaged, stain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com