BGA solder ball three-dimensional detection method based on depth image processing

A depth image, three-dimensional detection technology, applied in image data processing, image enhancement, image analysis and other directions, can solve the problem of high time-consuming processing methods and can not meet the requirements of real-time detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

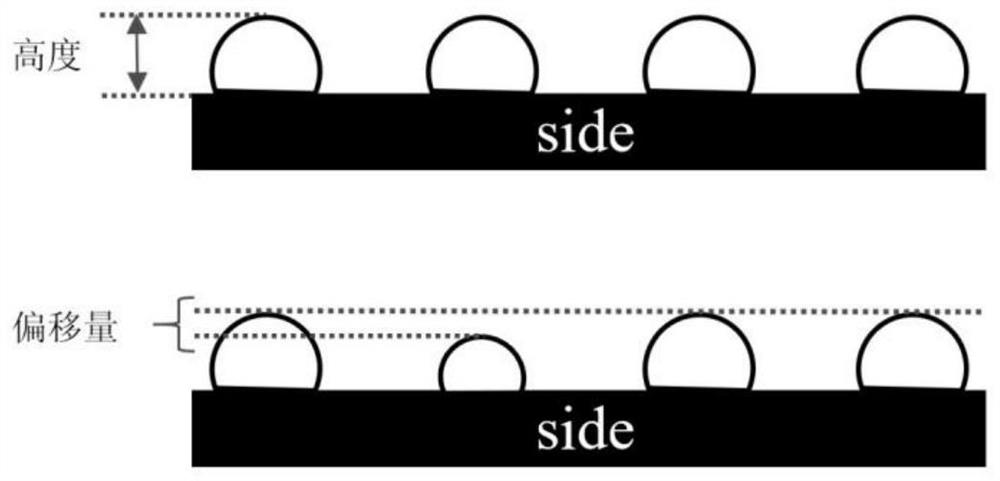

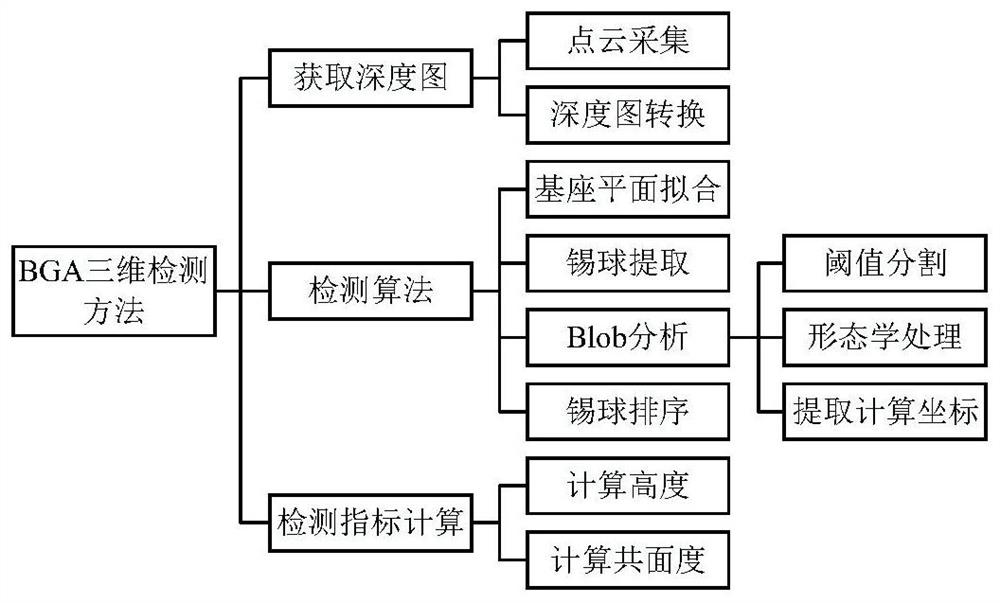

[0035] Such as figure 2 As shown, a BGA solder ball three-dimensional defect detection method based on depth image processing, first converts the collected chip point cloud into a depth image, fits the base plane of the chip and uses Blob analysis technology to mark each solder ball area, and then extracts the solder ball area. The 3D coordinate points corresponding to the 2D center point of the ball area and its 8 neighboring pixels are averaged and assigned to the 3D point on the top of the solder ball. In order to improve the robustness of the algorithm, when marking the solder ball area, the morphological method is combined to approximate the circular shape of the solder ball. Finally, calculate the distance from the vertex to the plane to obtain the solder ball height and coplanarity.

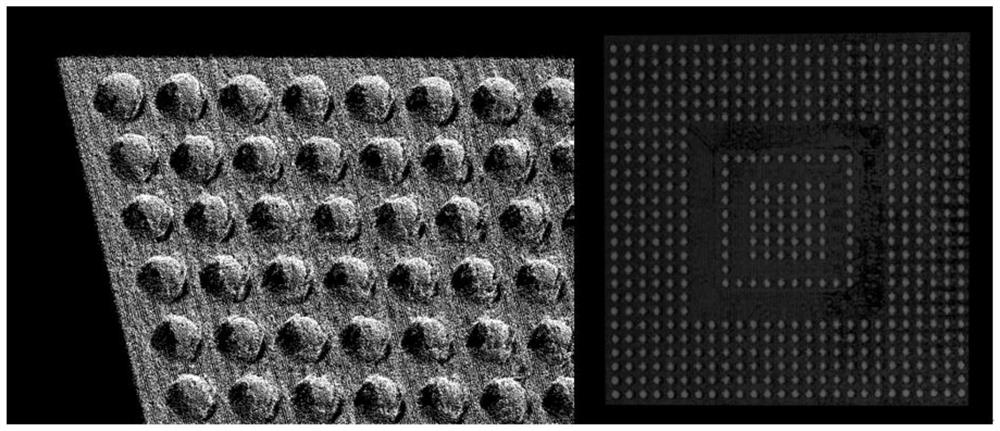

[0036]In this embodiment, the BGA chip point cloud data is obtained by a binocular 3D line-scanning camera modeled as Chromasens-3DPIXA, and displayed using the CloudCompare software pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com