A stainless steel surface defect detection method based on machine vision

A defect detection and machine vision technology, applied in the field of iron and steel manufacturing, can solve problems such as difficulty in detection and the influence of subjective factors of inspection personnel in inspection results, and achieve the effect of high inspection efficiency and accurate inspection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with specific embodiment:

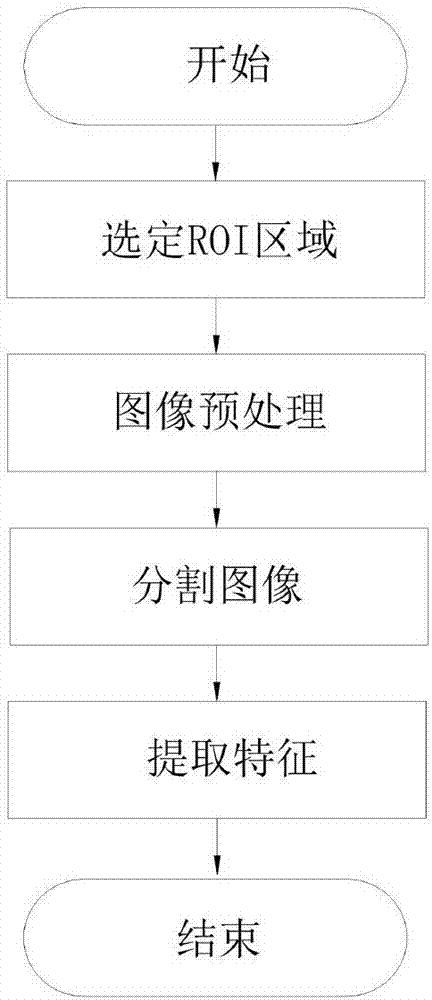

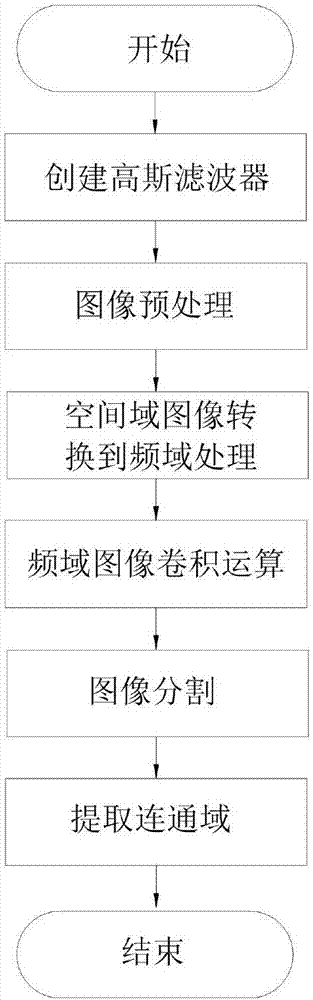

[0072] See attached Figure 1-2 As shown, the machine vision-based stainless steel surface defect detection method described in this embodiment includes the following steps:

[0073] S1. Use a CCD industrial camera to collect the surface image of the stainless steel to be detected;

[0074] S2. Perform two-dimensional defect detection based on Blob analysis on the collected stainless steel surface image to be detected, the steps are as follows:

[0075] S21. Select ROI area:

[0076] The global threshold method is used to segment the ROI area, that is, the stainless steel plate area, and then the connected domain of the stainless steel plate is extracted. Suppose the image to be segmented is f(x, y), and the image after threshold segmentation is S(x, y), then

[0077]

[0078] Among them, T is the segmentation threshold;

[0079] S22. Image preprocessing:

[0080] Per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com