Circumferentially-distributed crawler wheel type pipeline detection robot capable of actively adapting to pipe diameter changes

An active self-adaptive, pipeline detection technology, applied in the direction of pipes/pipe joints/fittings, special pipes, pipe components, etc., can solve the limitations of pipeline climbing ability, poor controllability of crawler wheels, robot movement flexibility and reliability limitations and other problems, to achieve the effect of improving initiative and controllability, improving stability, and improving the ability to actively adapt to pipe diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

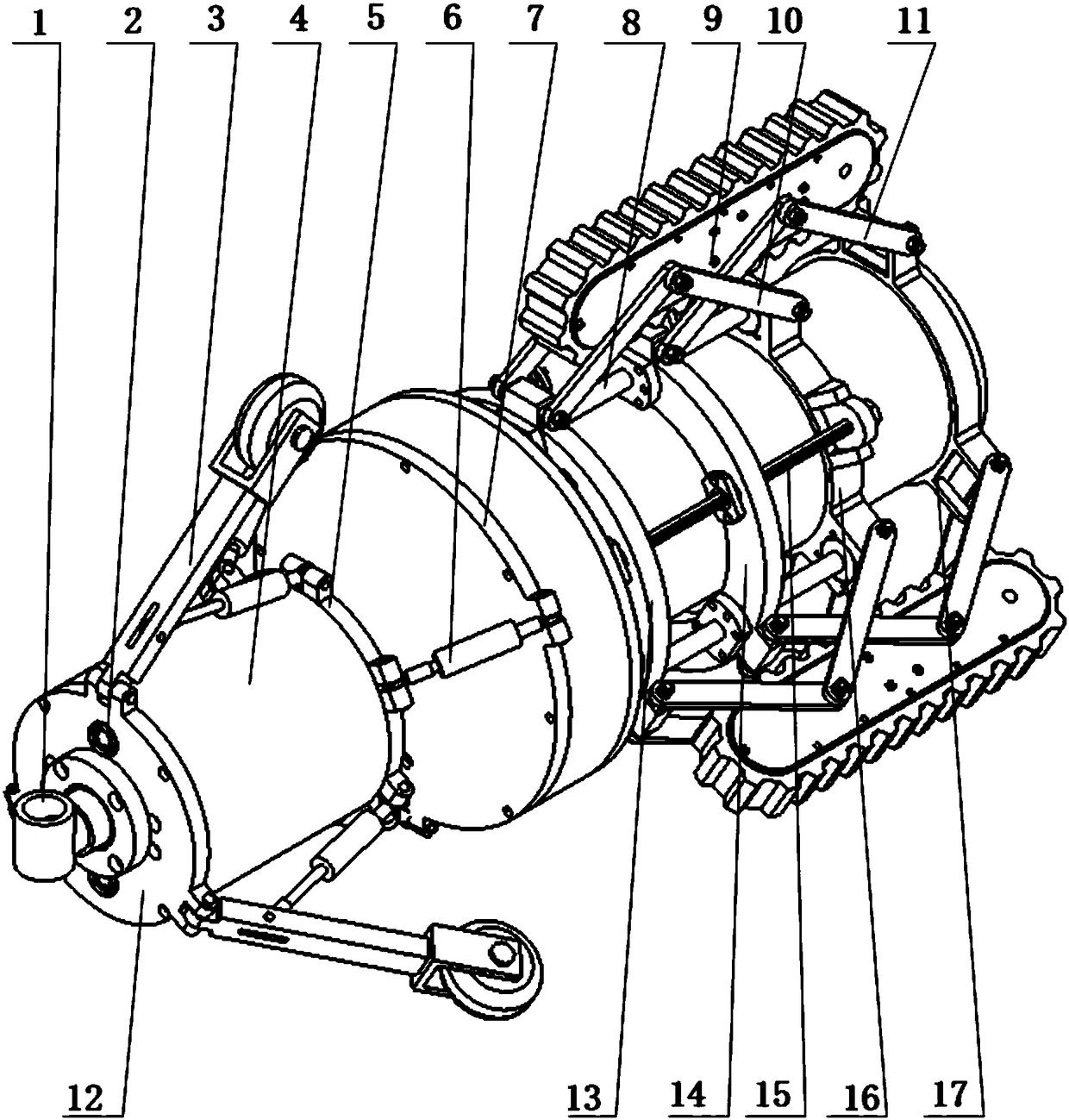

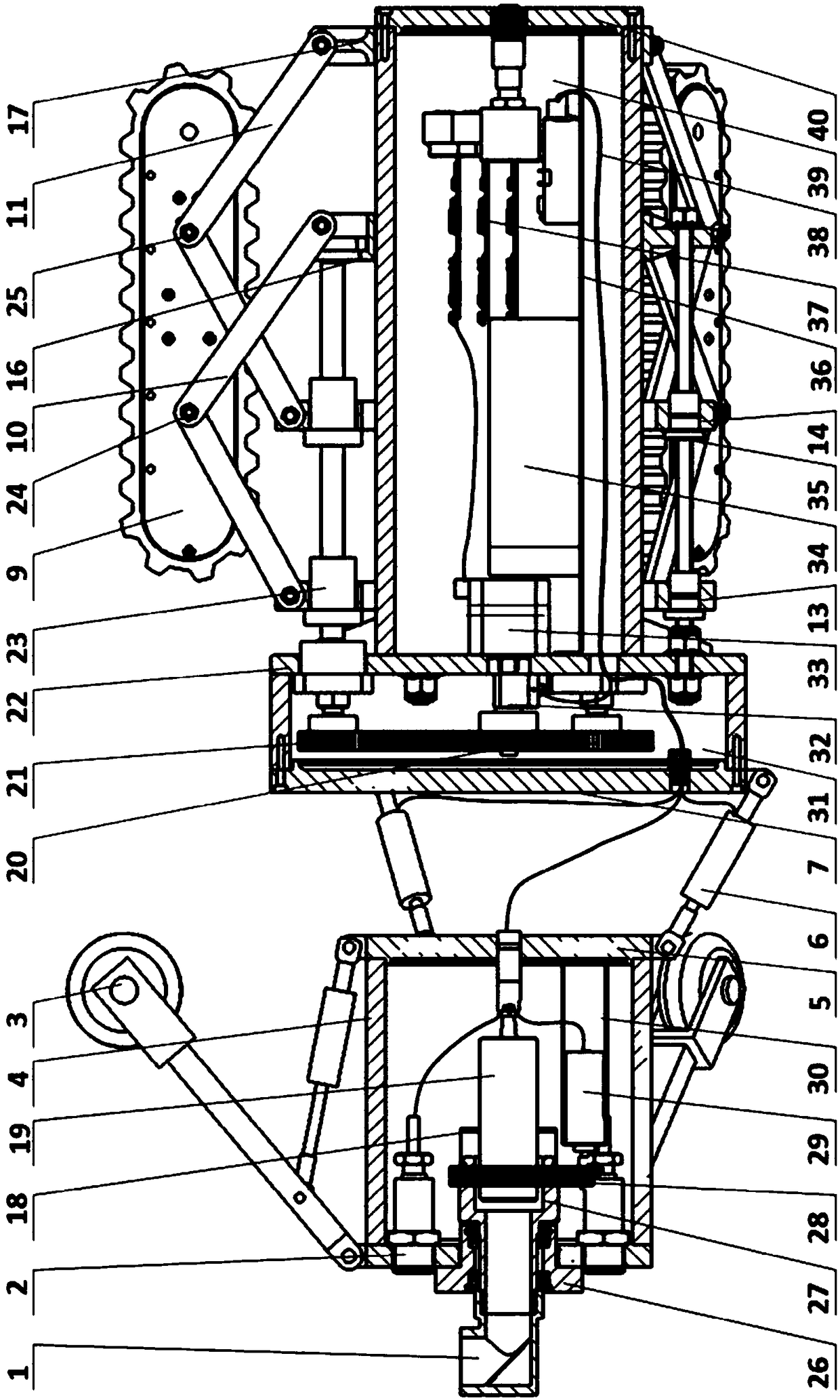

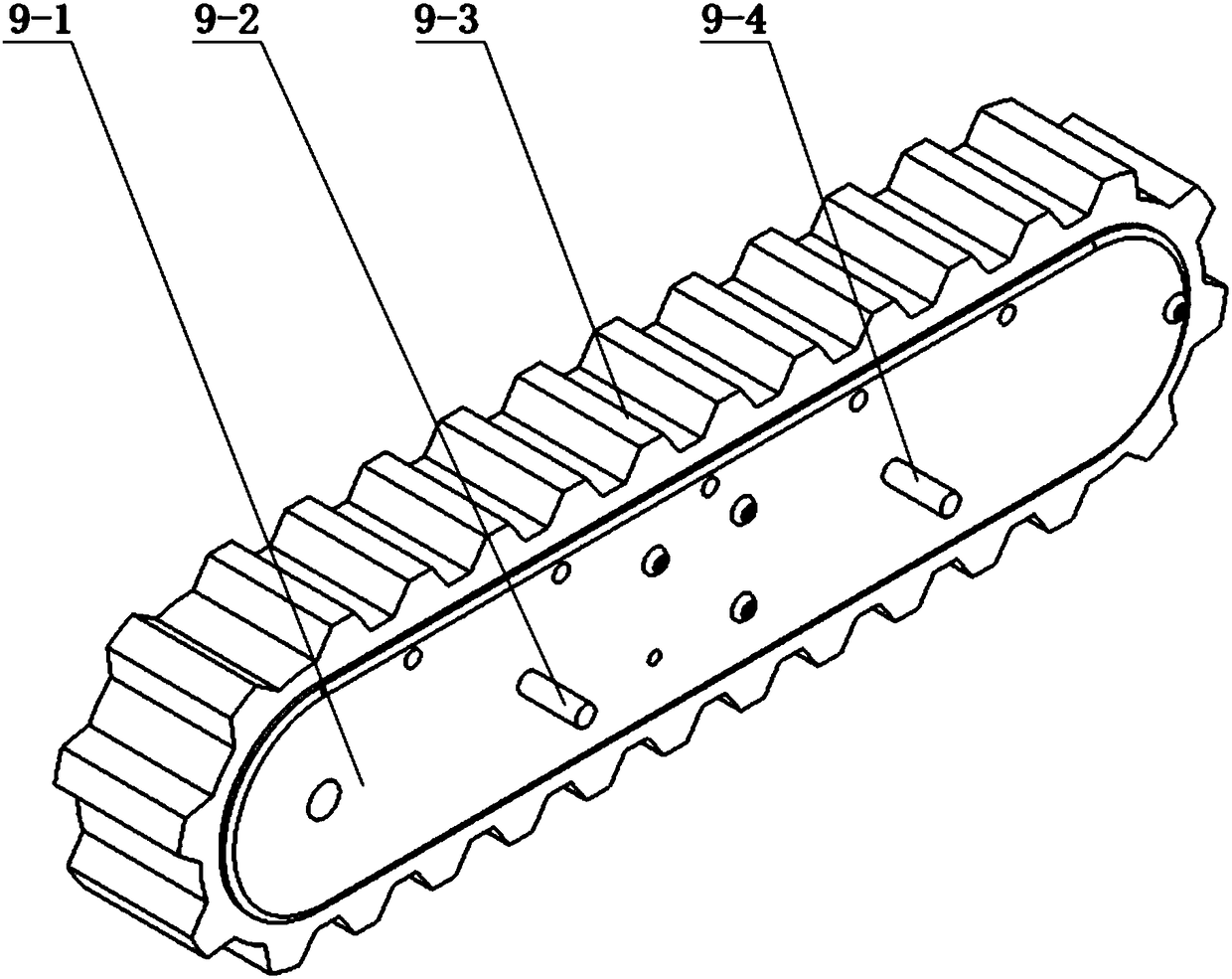

[0022] see Figure 1-4 Structurally, the present invention includes a cylindrical main body structure, a pressing force feedback pipe diameter adapting mechanism, a built-in driving track wheel traveling mechanism, a multi-electric cylinder parallel turning mechanism, an ultrasonic detection and video imaging mechanism and other parts connected to each other.

[0023] Cylindrical main body structure The pressing force drive motor 33 located in the center of the middle partition plate 22 of the main body drives three sets of ball screws 8 simultaneously through the pressing force transmission center bull gear 20 and three circumferentially evenly distributed pressing force transmission pinions 21 work, thereby driving the pressing force adjusting ring fixed on the ball screw nut 23 and the linear bearing 35 to move axially along the cylindrical main body sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com