Chip surface defect detection method based on a convolutional denoising auto-encoder

A self-encoder and surface detection technology, which is applied in the direction of instruments, image data processing, biological neural network models, etc., to achieve the effect of enhancing contrast, high robustness, and suppressing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

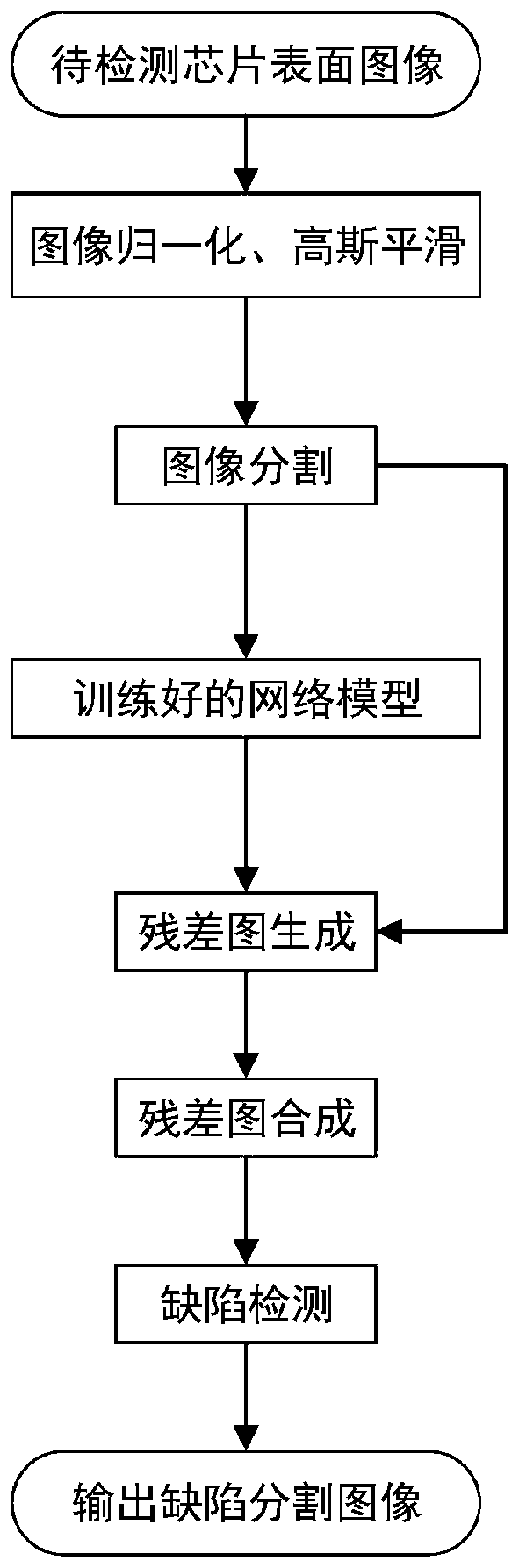

[0040] In this embodiment, a method for detecting chip surface defects based on convolutional denoising autoencoders, such as figure 1 shown, proceed as follows:

[0041] Step 1: Defect-free image reconstruction based on convolutional denoising autoencoder:

[0042] Step 1.1: Build a convolutional denoising autoencoder as a network model:

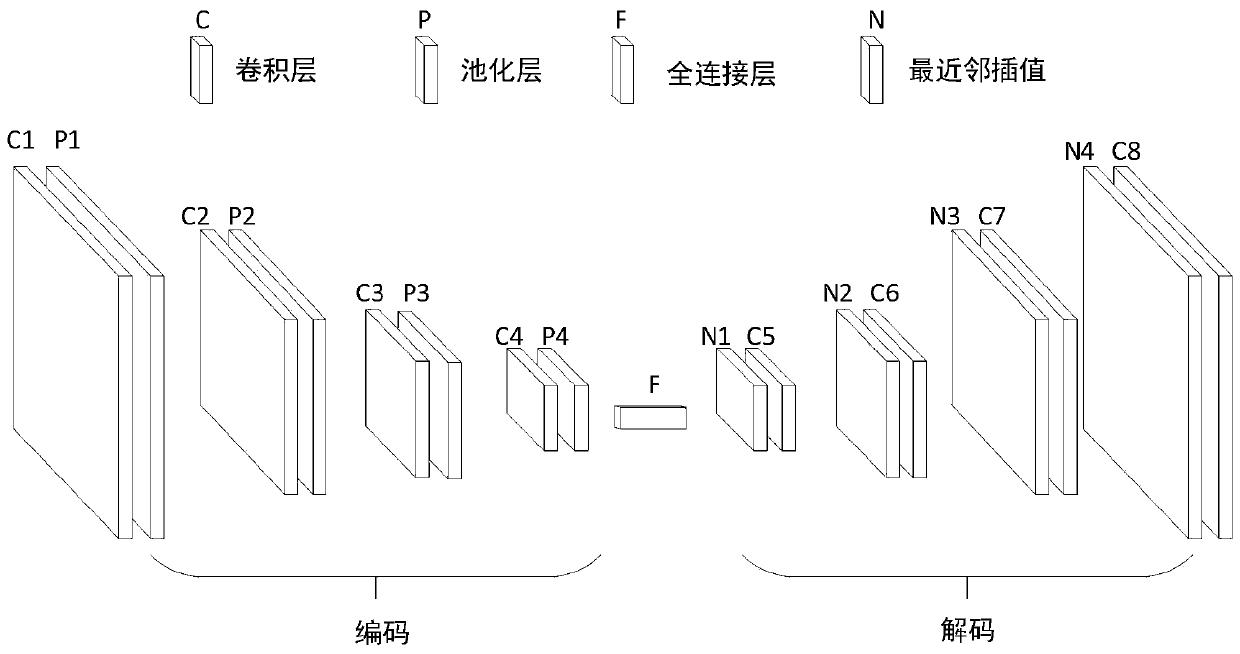

[0043]The network model is composed of an encoder, a fully connected layer and a decoder; the encoder is composed of n=4 convolutional layers and 4 pooling layers; the decoder is composed of 4 deconvolution layers; and the encoder and The decoder is connected through a fully connected layer; the 4 deconvolution layers use the nearest neighbor interpolation method and convolution to realize the deconvolution function. like figure 2 As shown, the specific parameters are as follows:

[0044] Input: 28×28×1 single-channel png format picture.

[0045] Encoder: Consists of 4 convolutional (C) layers and 4 pooling (P) layers, each followed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com