Machine tool self-adaptive control method considering flutter suppression

A technology of adaptive control and chatter, which is applied in the direction of computer control, program control, general control system, etc., can solve the problems of lack of systematicness and lack of chatter suppression in adaptive control methods, so as to improve processing efficiency and suppress cutting chatter Vibration, the effect of saving production time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

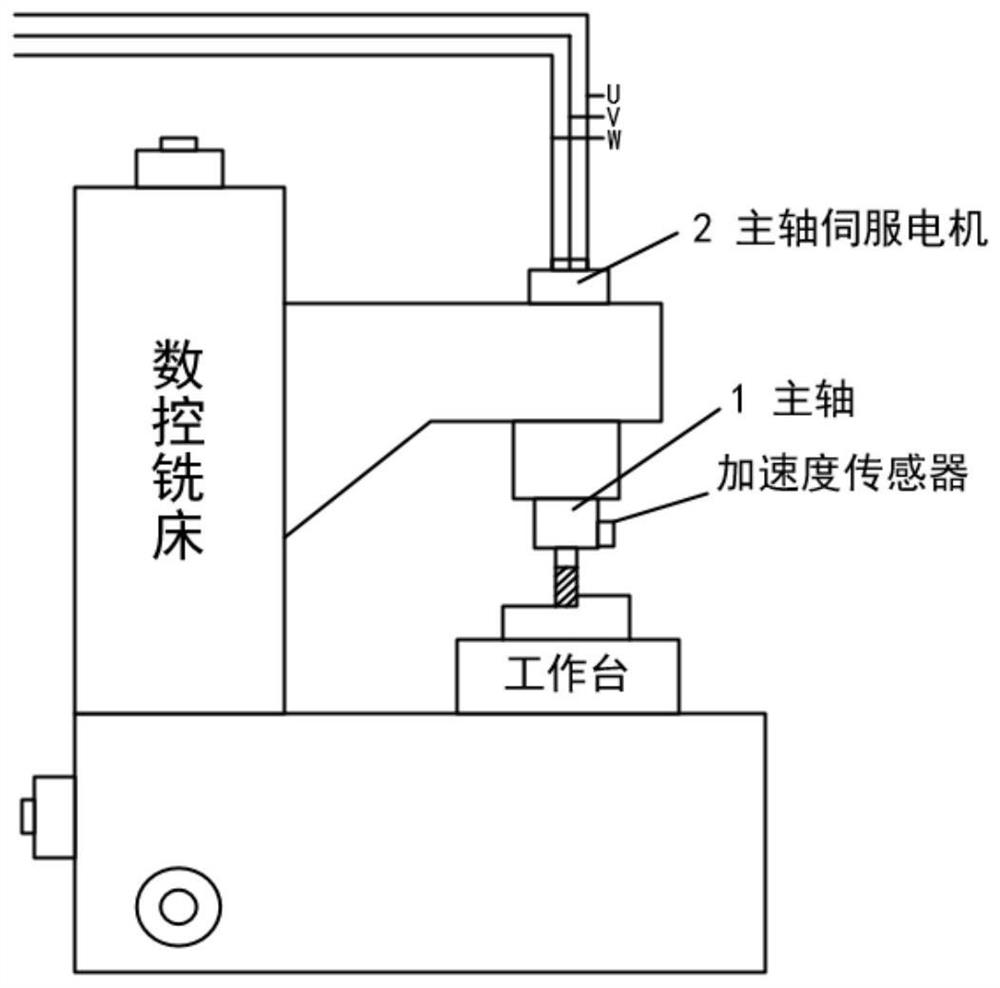

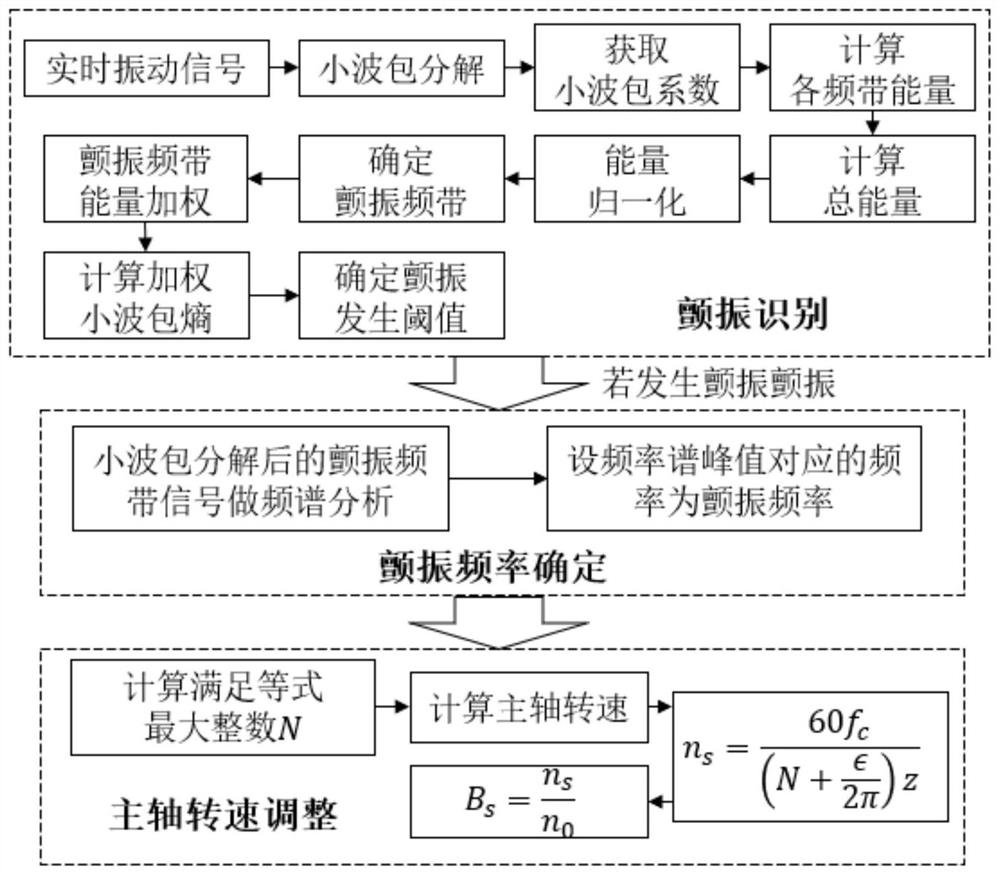

[0071] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings, taking a certain type of vertical milling machine as an example to describe the implementation of the present invention in detail.

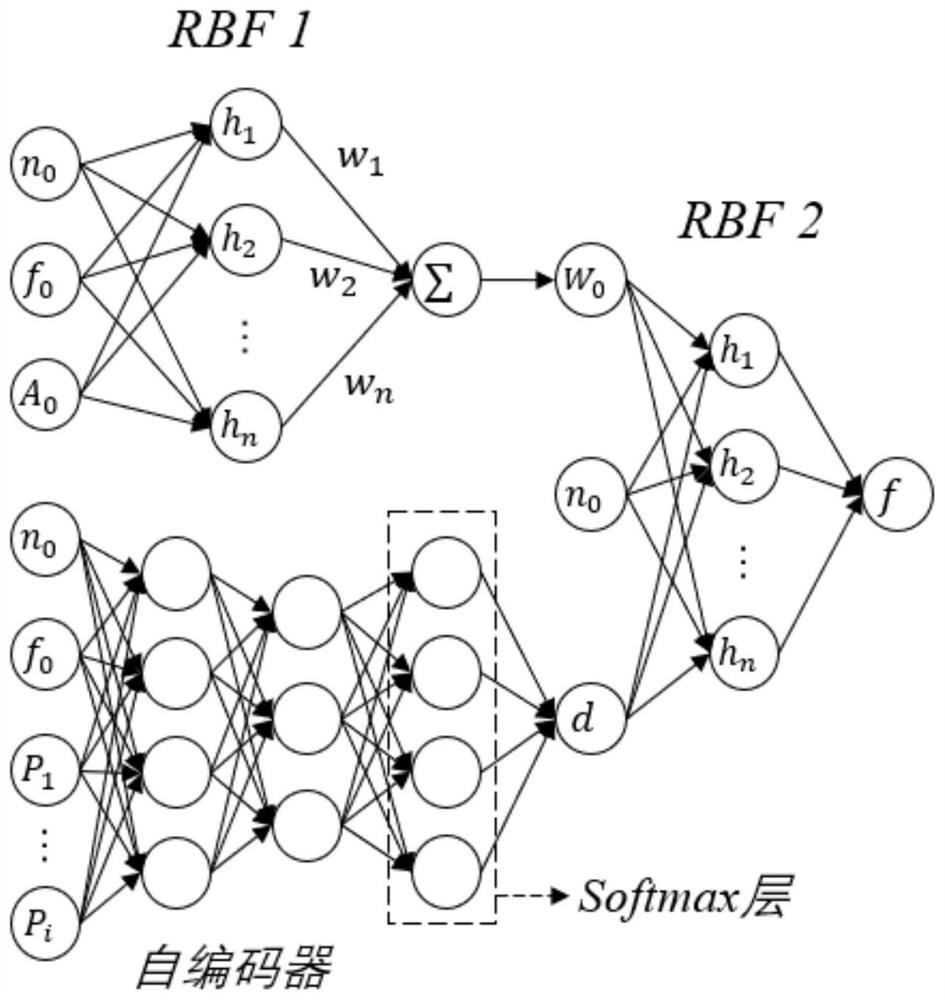

[0072] The first step is to establish a feed speed adaptive control model

[0073] This step is mainly divided into the acquisition and processing and feature extraction of spindle power data with variable cutting parameters, and the establishment and training of deep learning networks.

[0074] (1) Data acquisition, processing and feature extraction of spindle power with variable cutting parameters

[0075] Such as figure 1 As shown, the power sensor is arranged on the spindle motor (2), and its three coils are respectively set on the three power lines of the spindle motor UVW.

[0076] The machining process with variable cutting parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com