Freezing fixation flexible clamp used for numerical control cutting machining of thin-walled part

A thin-walled part, cutting technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. problems, to achieve the effect of shortening the cooling time, easy access, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

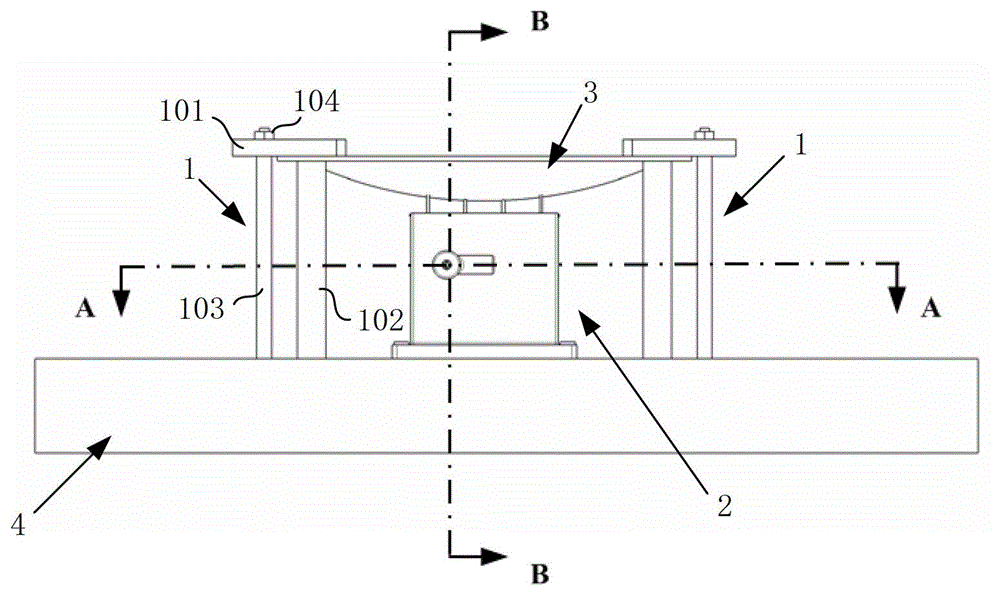

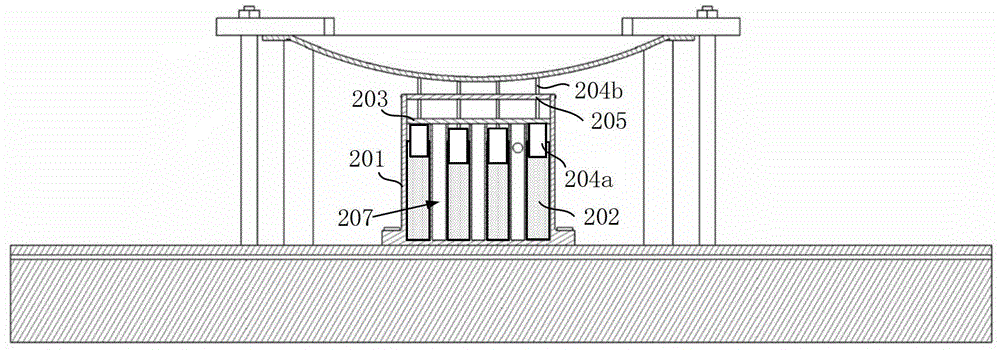

[0028] The present invention is used for the ice-solid flexible fixture of thin-walled part numerical control cutting process, comprises clamping mechanism 1 and longitudinal positioning mechanism 2, such as figure 1 shown.

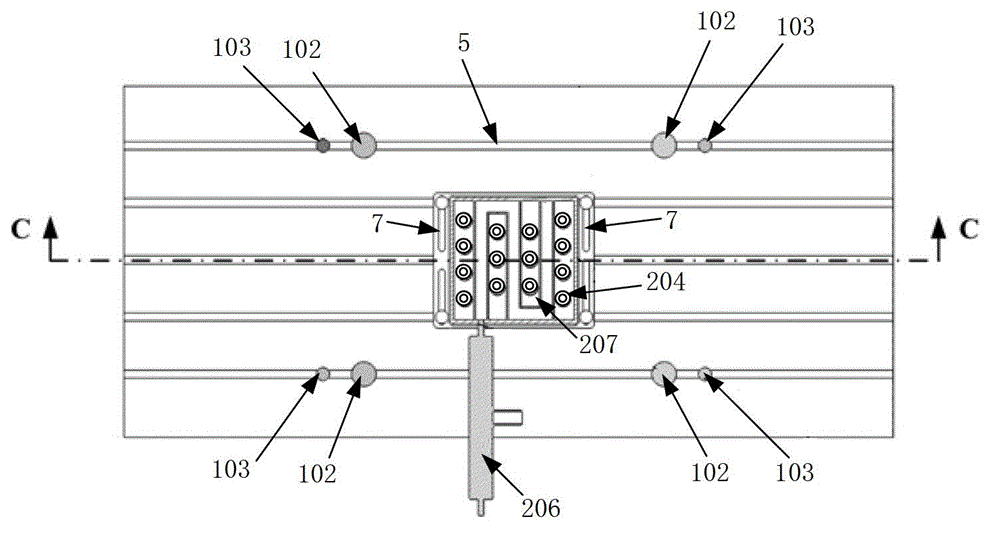

[0029] The clamping mechanism 1 is used to clamp the thin-walled part 3, and can be arranged on the machine tool 4 to realize the fixing of the thin-walled part 3 on the machine tool 4. The clamping mechanism 1 is composed of a pressing plate 101, a support column 102, an adjusting bolt 103 and The fixing nut 104 constitutes. Wherein, the support column 102 and the adjustment bolt 103 are all vertically arranged, and the height of the support column 102 is less than the height of the adjustment bolt 103; 4 The T-nuts 6 in the upper transverse T-shaped chute 5 cooperate with each other to realize the positioning between the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com