Patents

Literature

48results about How to "Strong fastening force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

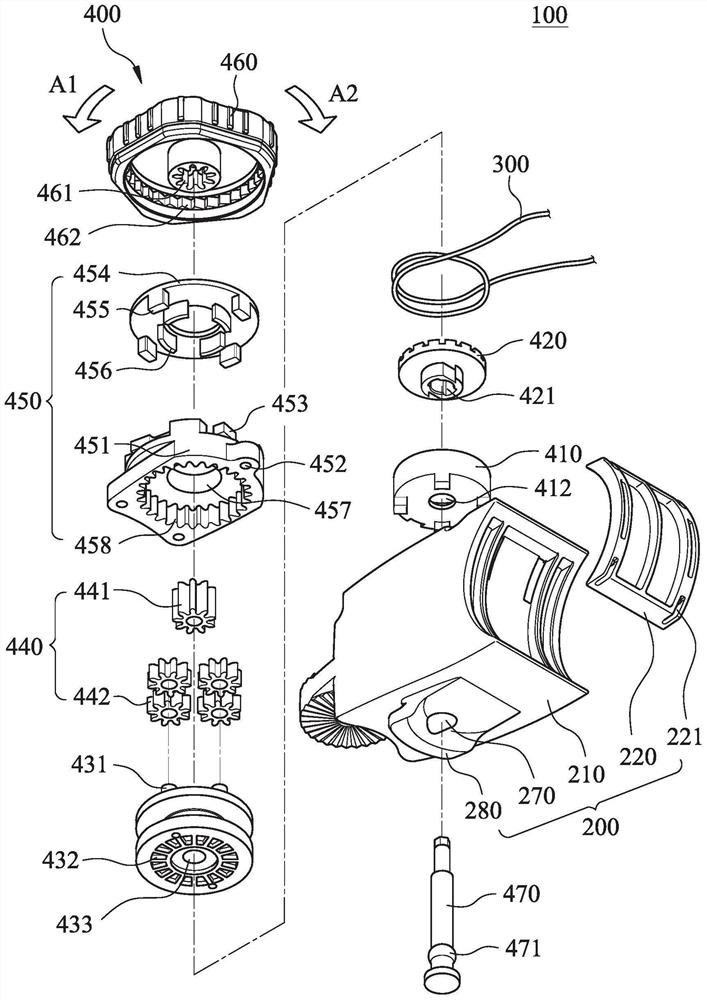

Steering device

ActiveUS7735391B2Improve the sense of operationAvoid operating efficiencyMechanical apparatusSteering columnsEngineeringMechanical engineering

Owner:YAMADA MANUFACTURING CO LTD

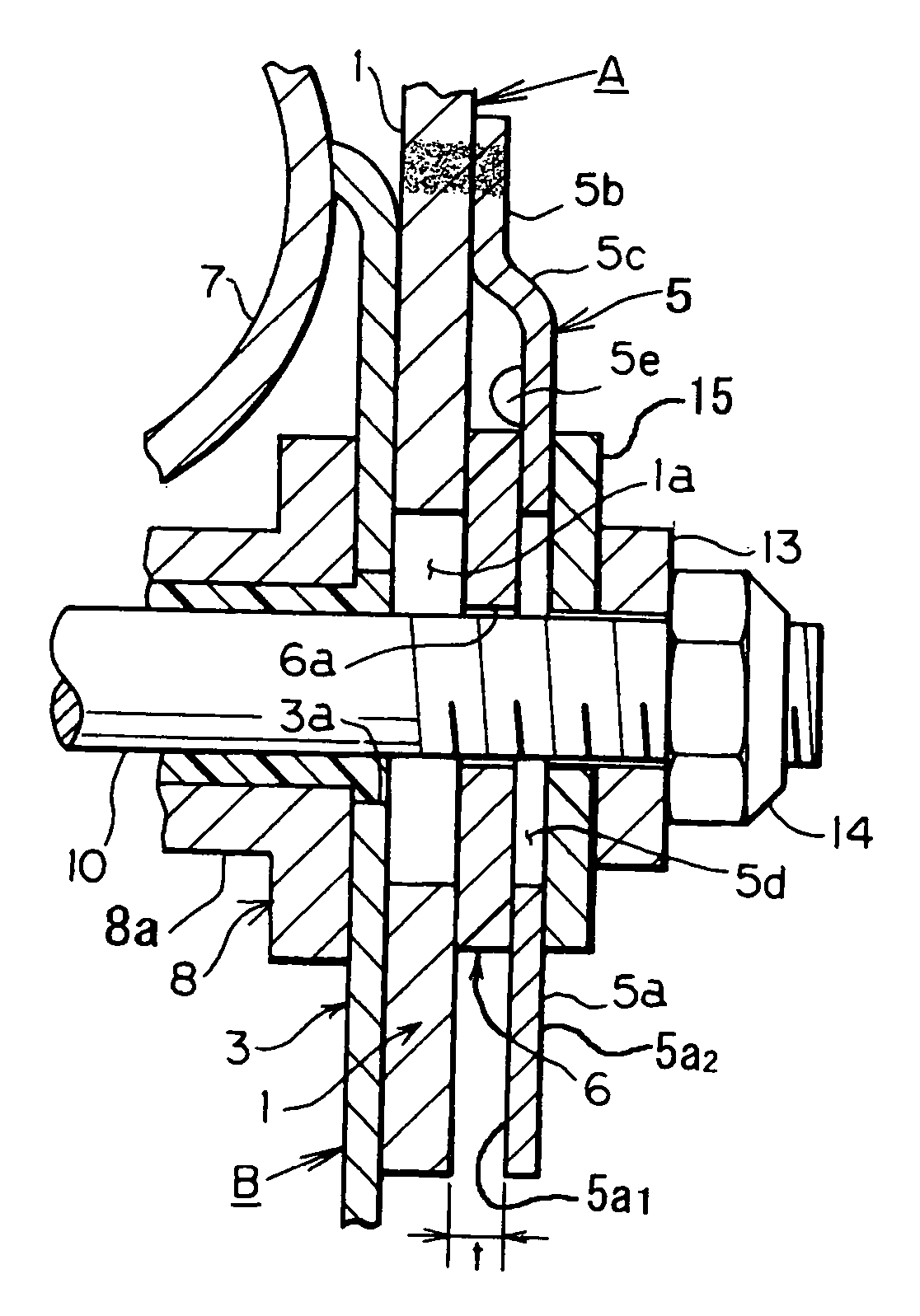

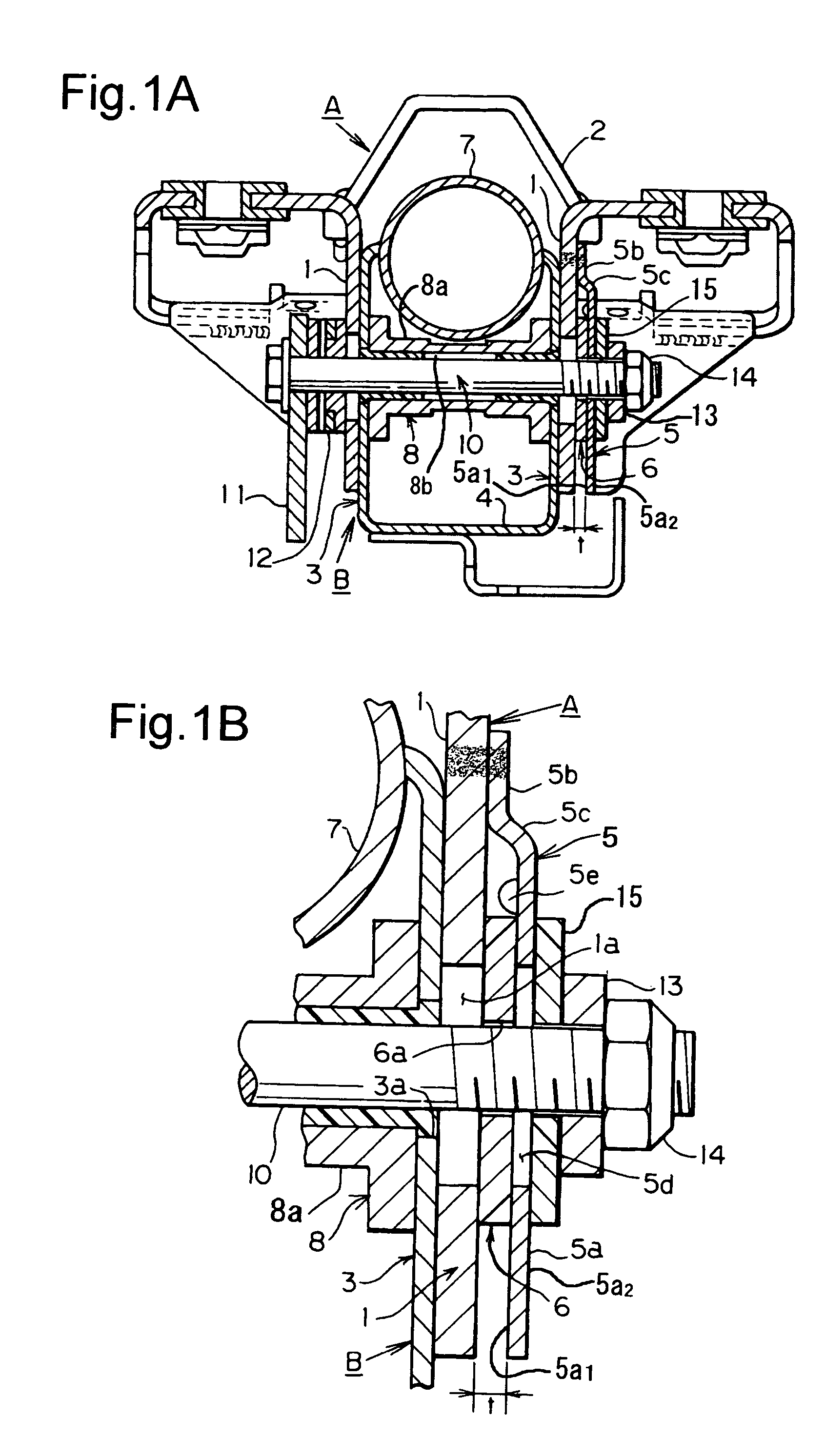

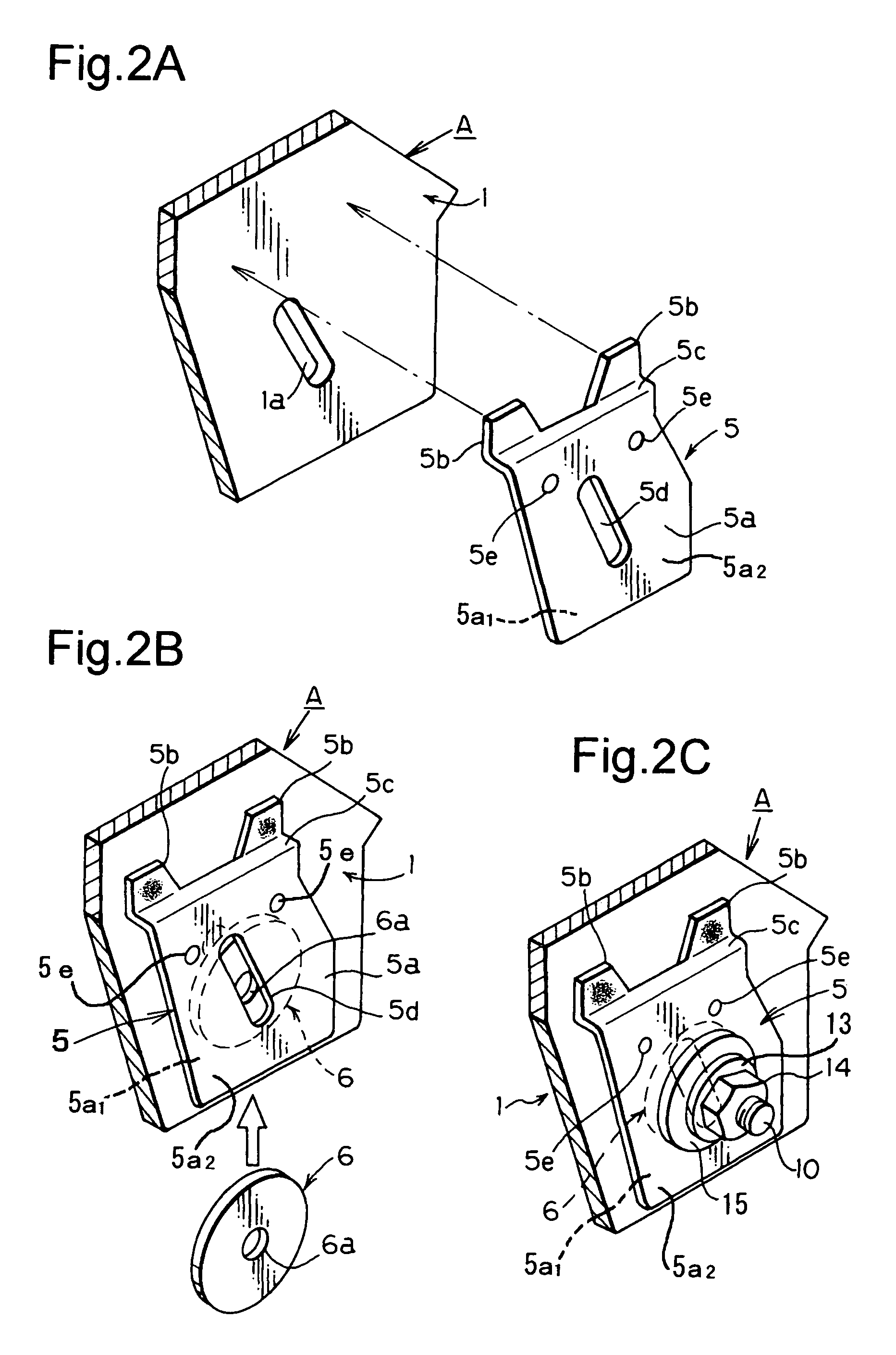

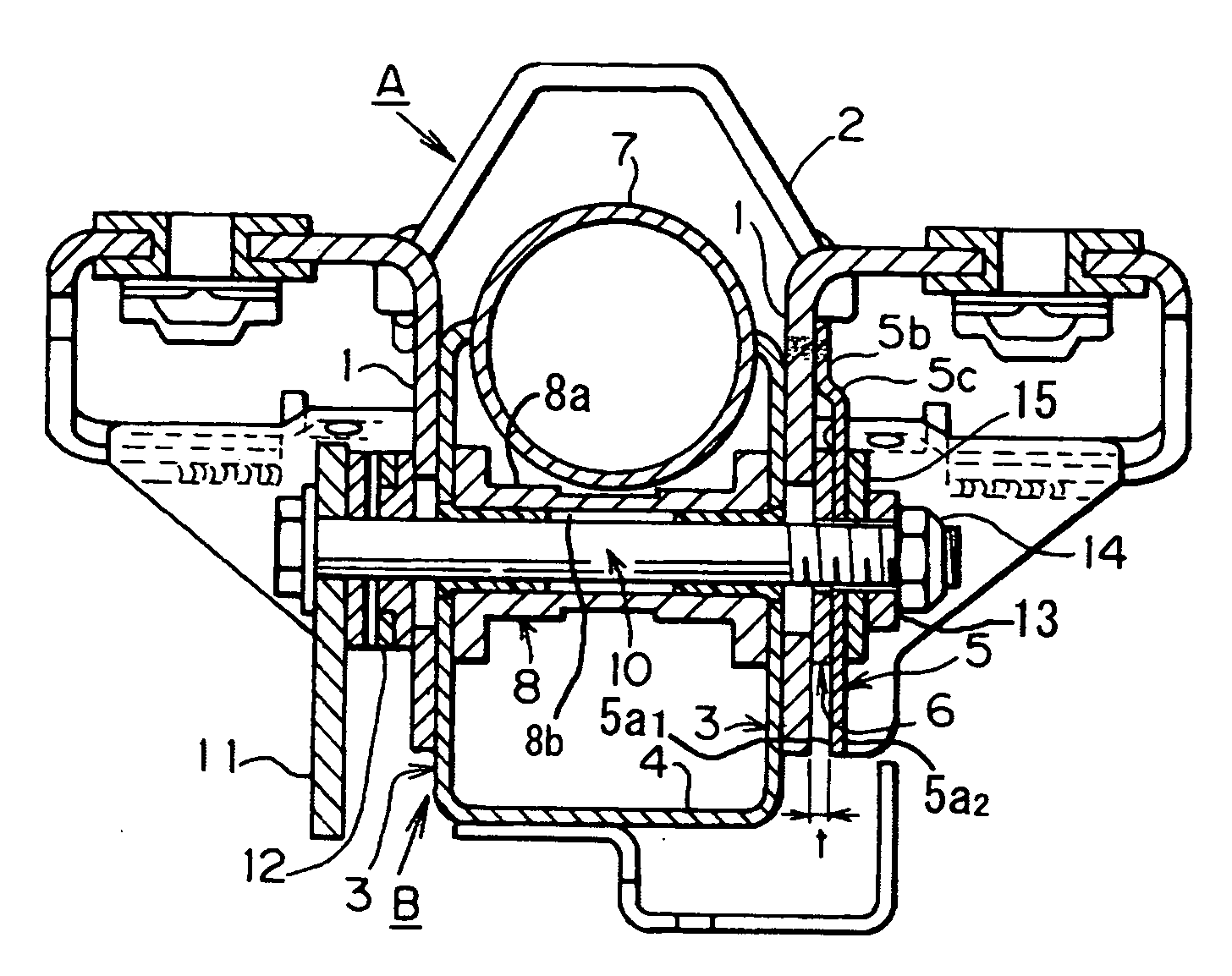

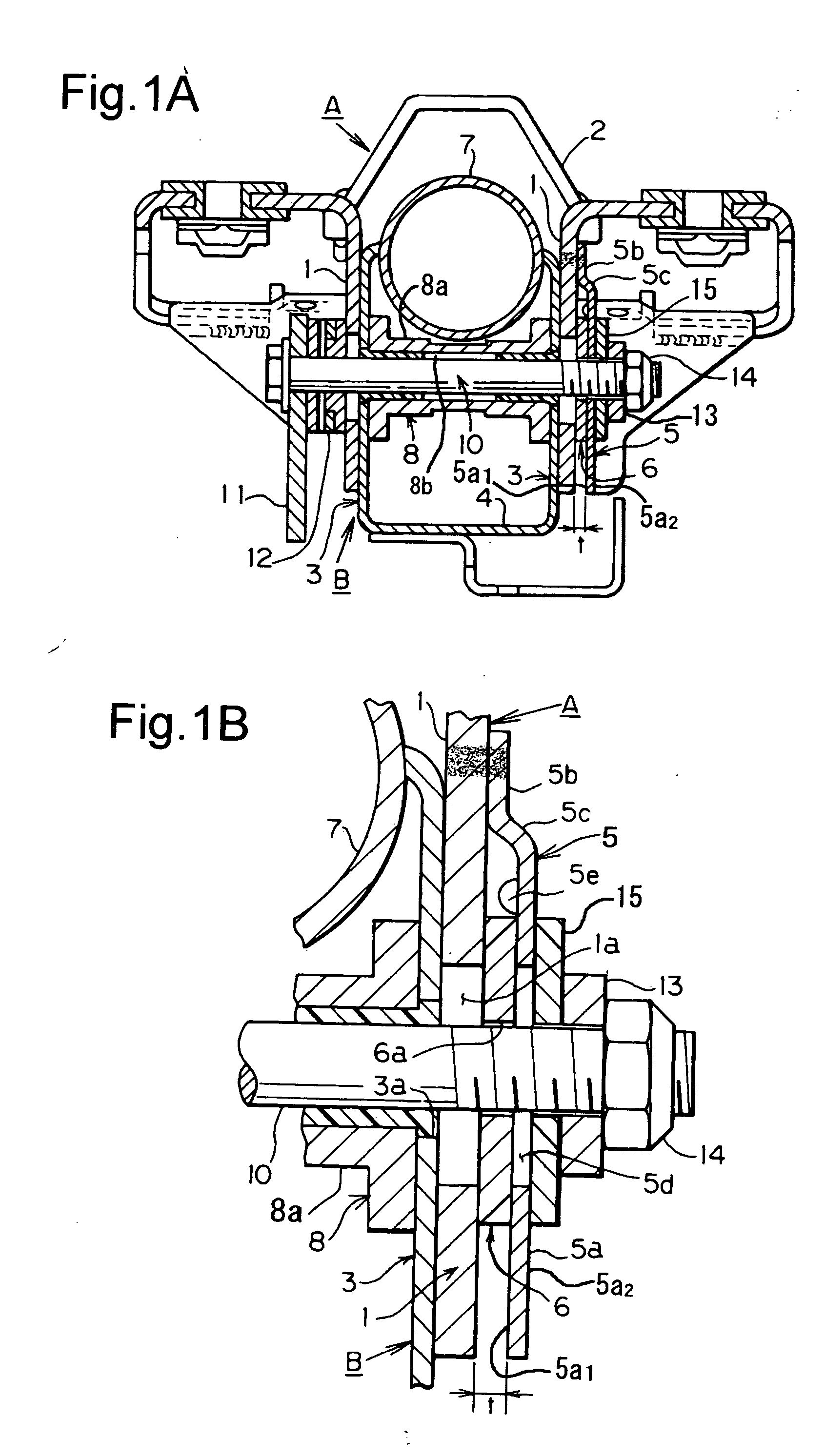

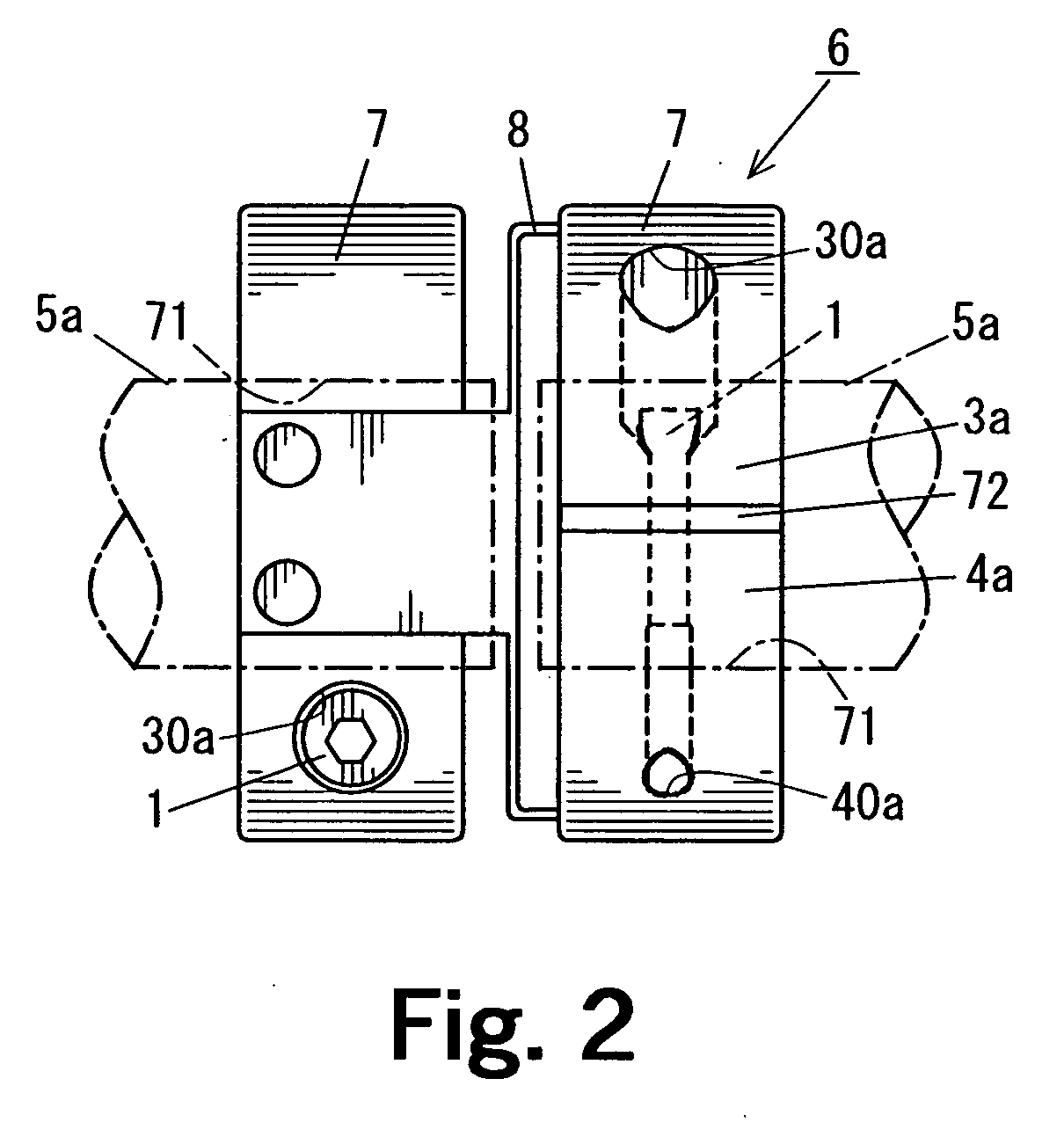

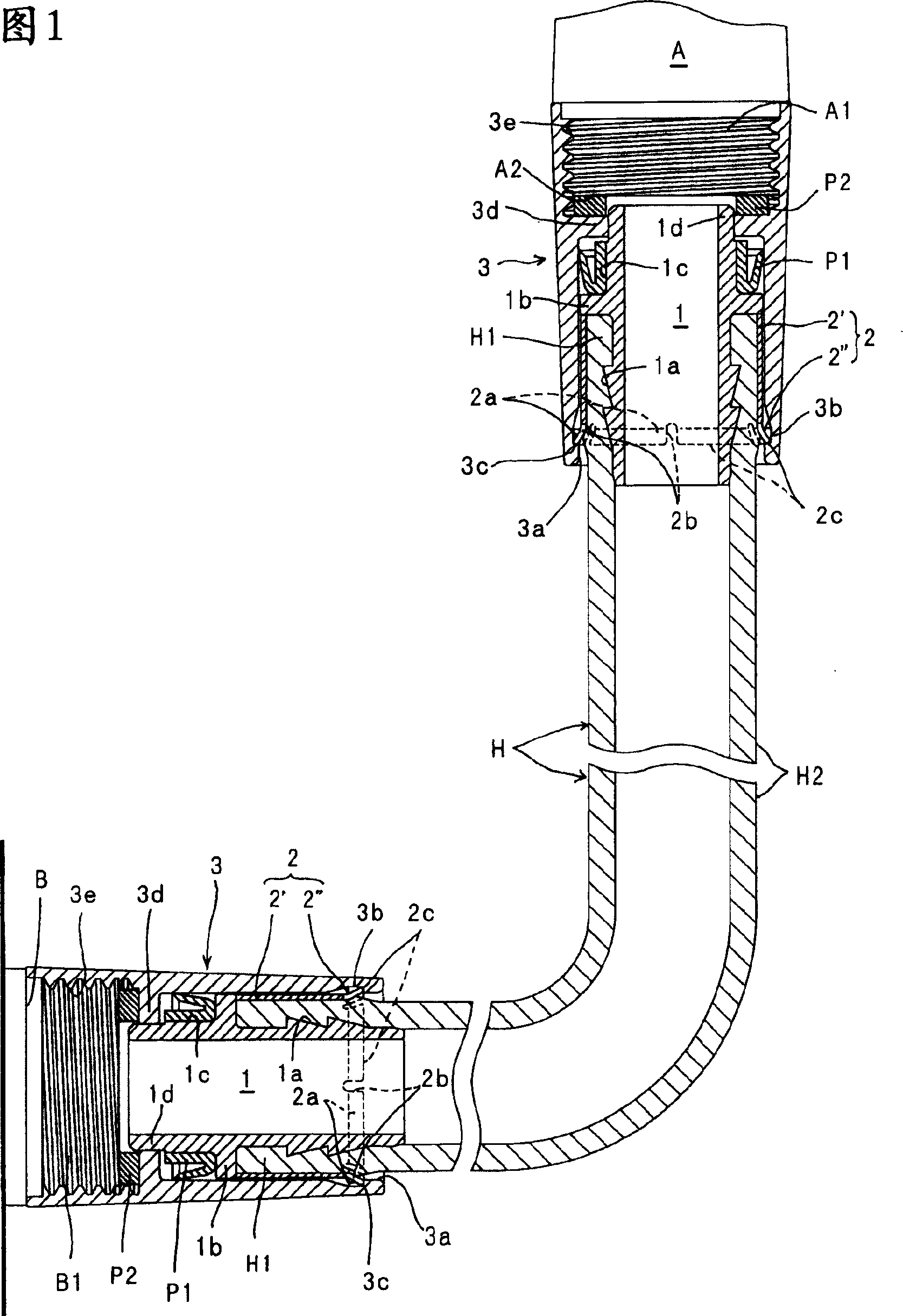

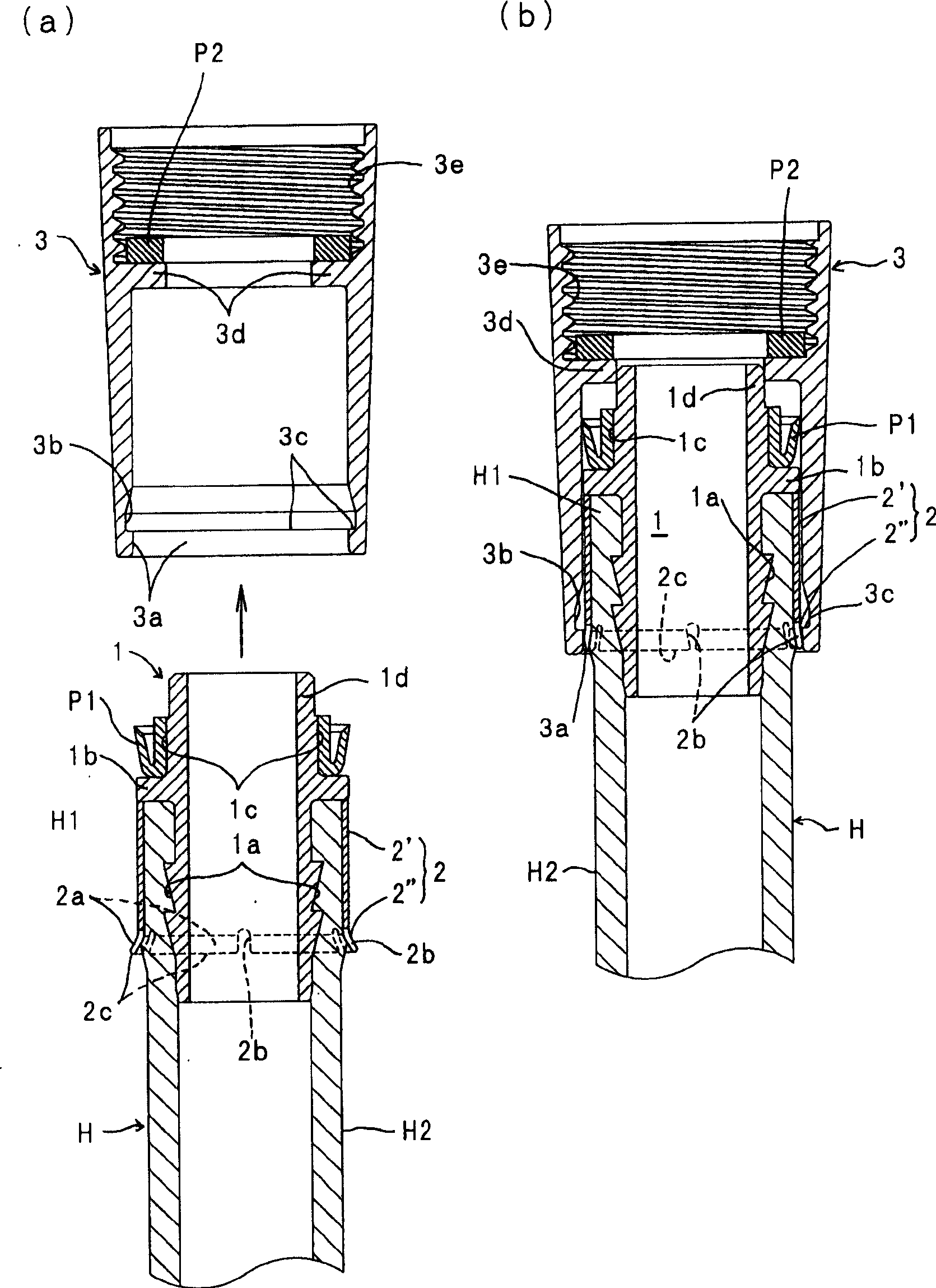

Steering device

ActiveUS20060243084A1Improve the sense of operationAvoid operating efficiencyManual control with multiple controlled membersMechanical apparatusEngineeringMechanical engineering

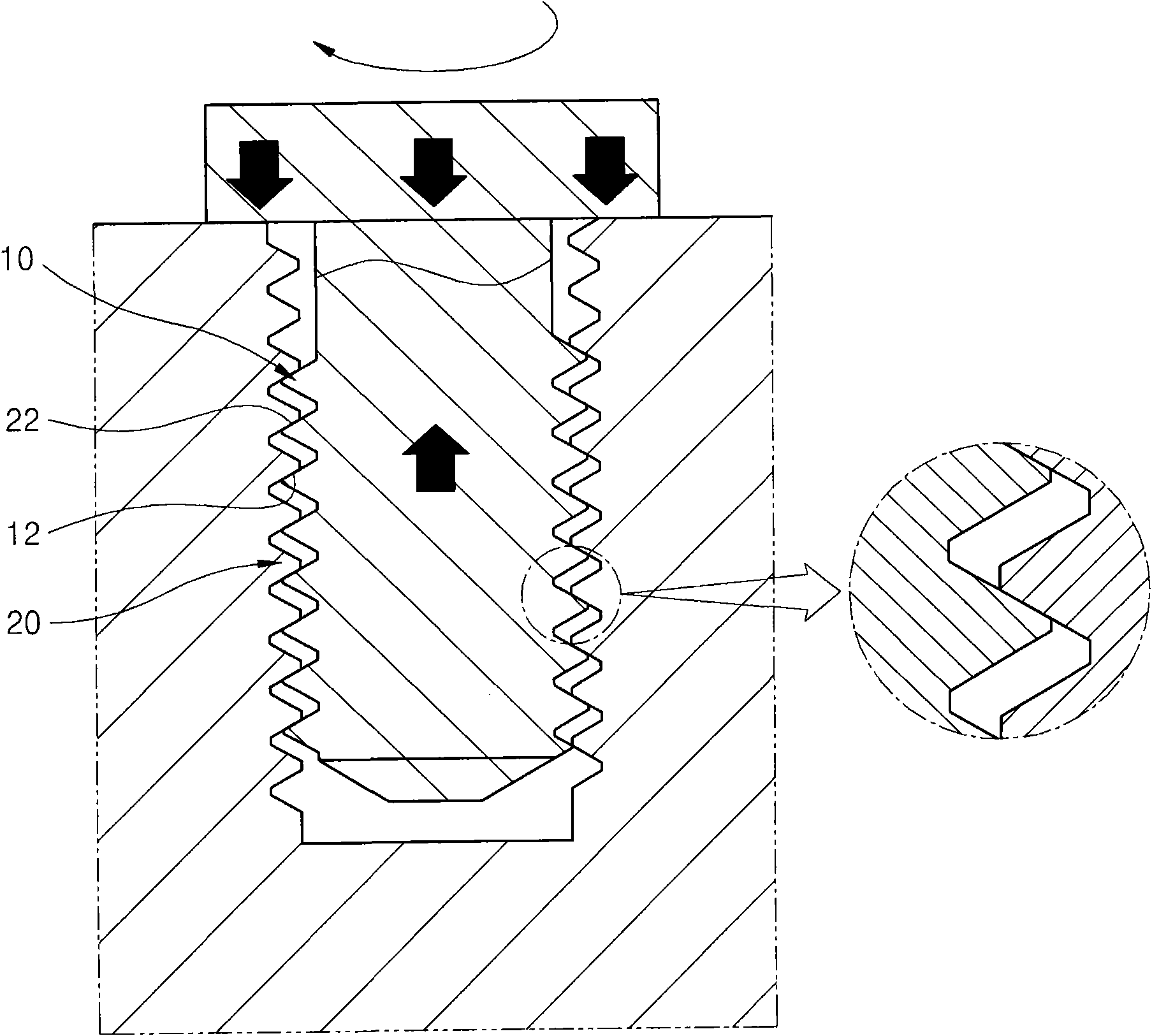

To provide a steering device for tilt and telescopic adjustments in which the locked condition can be made stronger, and when unlocked, tilt and telescopic adjustment can be smoothly carried out. A steering device, comprising: a fixed bracket having fixed side parts on both sides in the width direction; a movable bracket arranged between the fixed side parts; a friction plate fixed and oppositely arranged with a suitable gap with respect to at least one of the two fixed side parts of the fixed bracket; and a friction washer that is inserted between the fixed side part and the friction plate. A lock bolt passes through for connecting the fixed bracket, the movable bracket, the friction plate, and the friction washer to be freely locked and unlocked.

Owner:YAMADA SEISAKUSHO KK

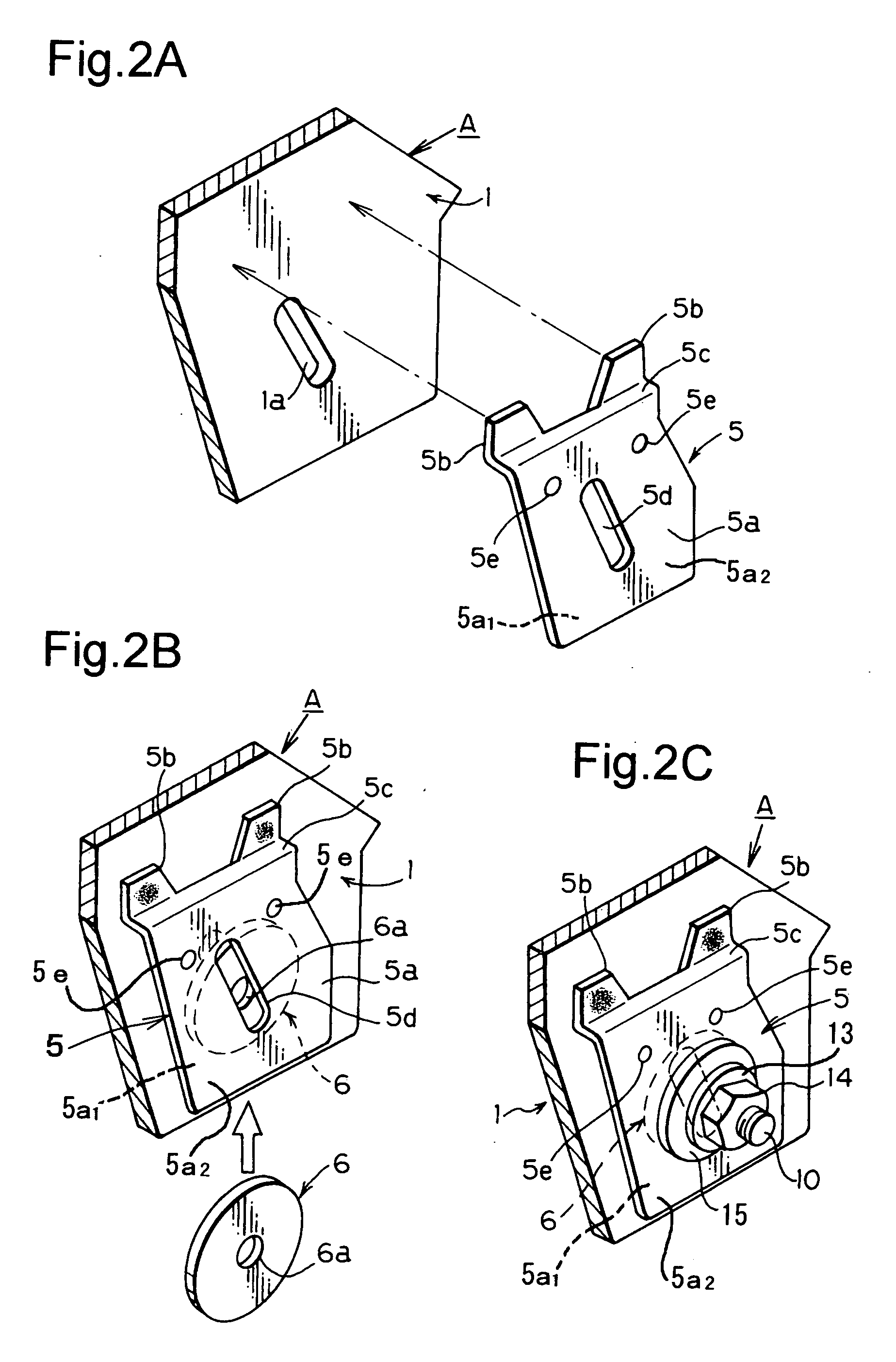

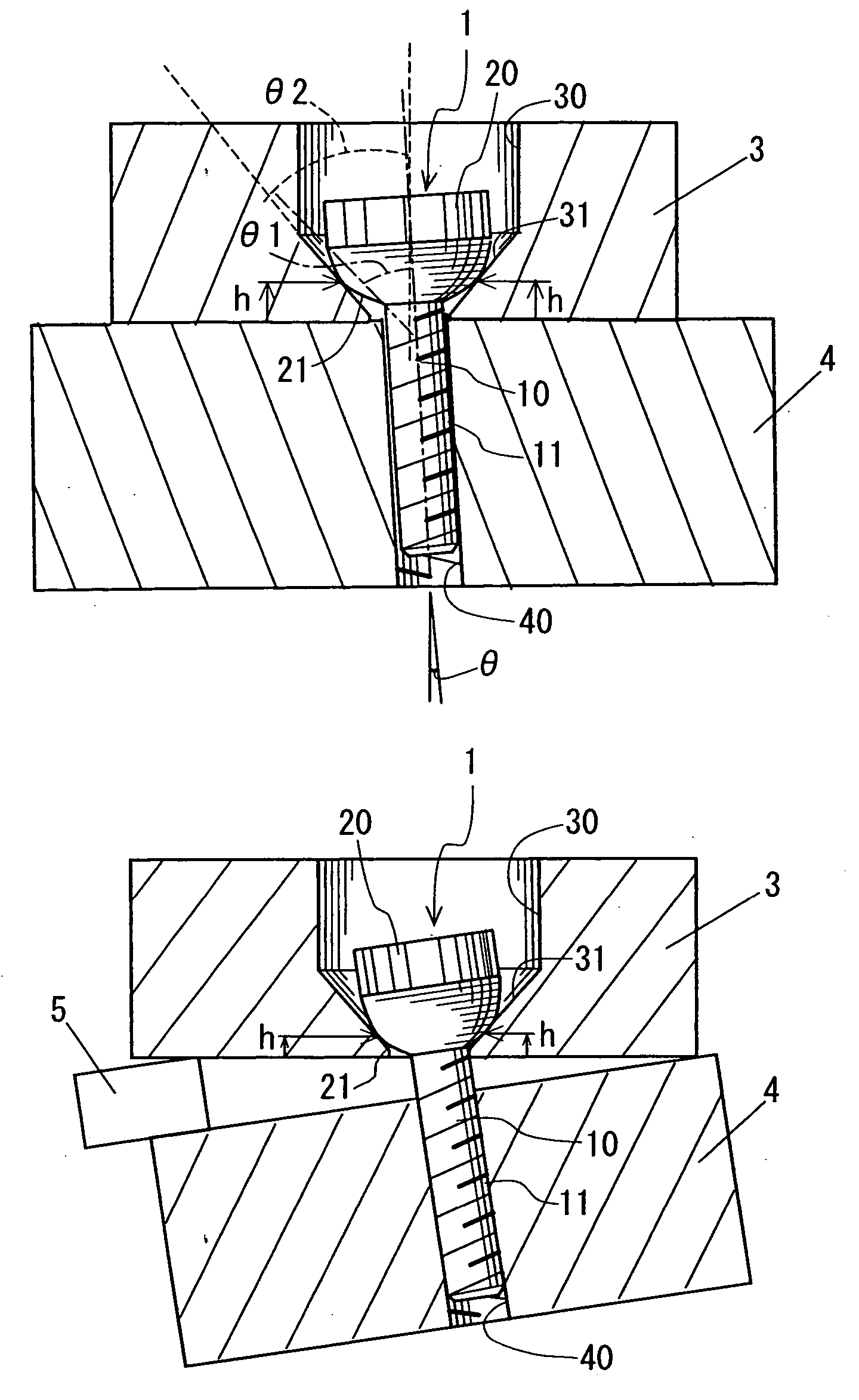

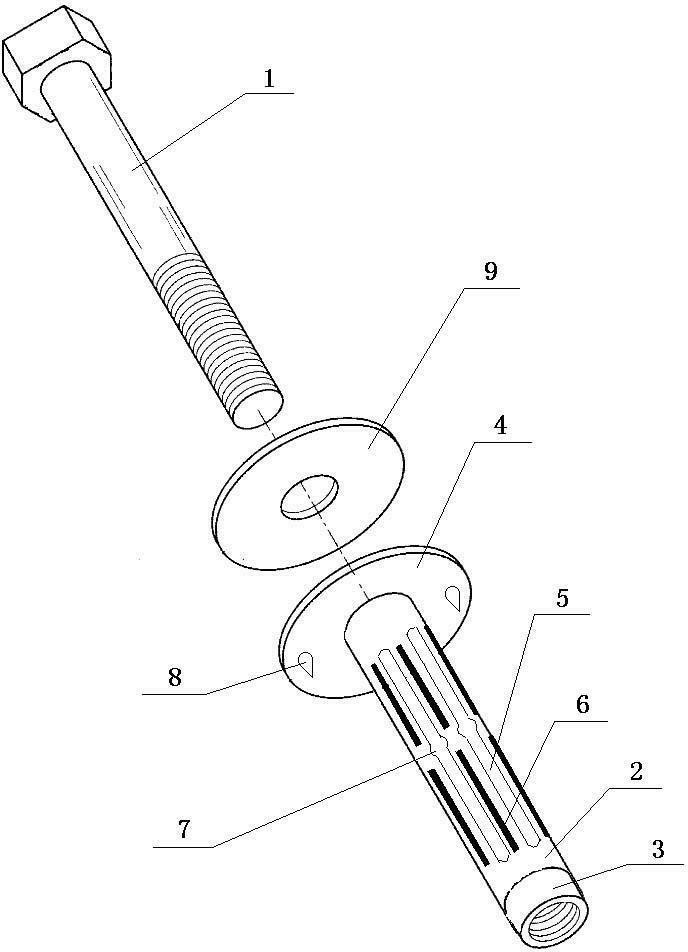

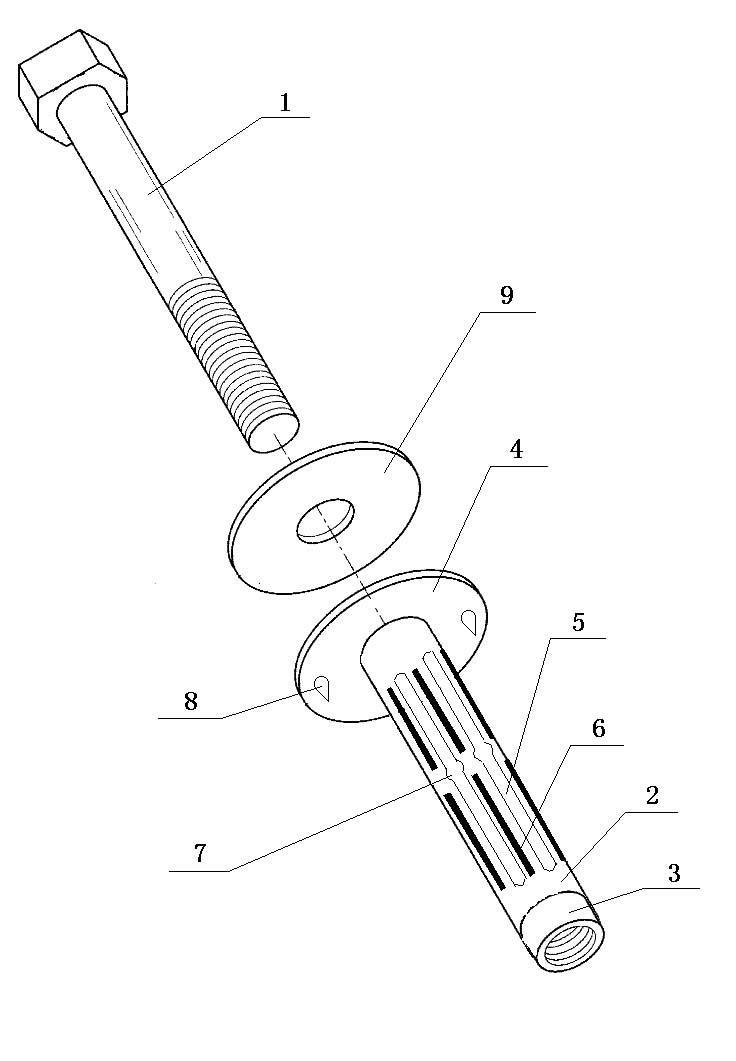

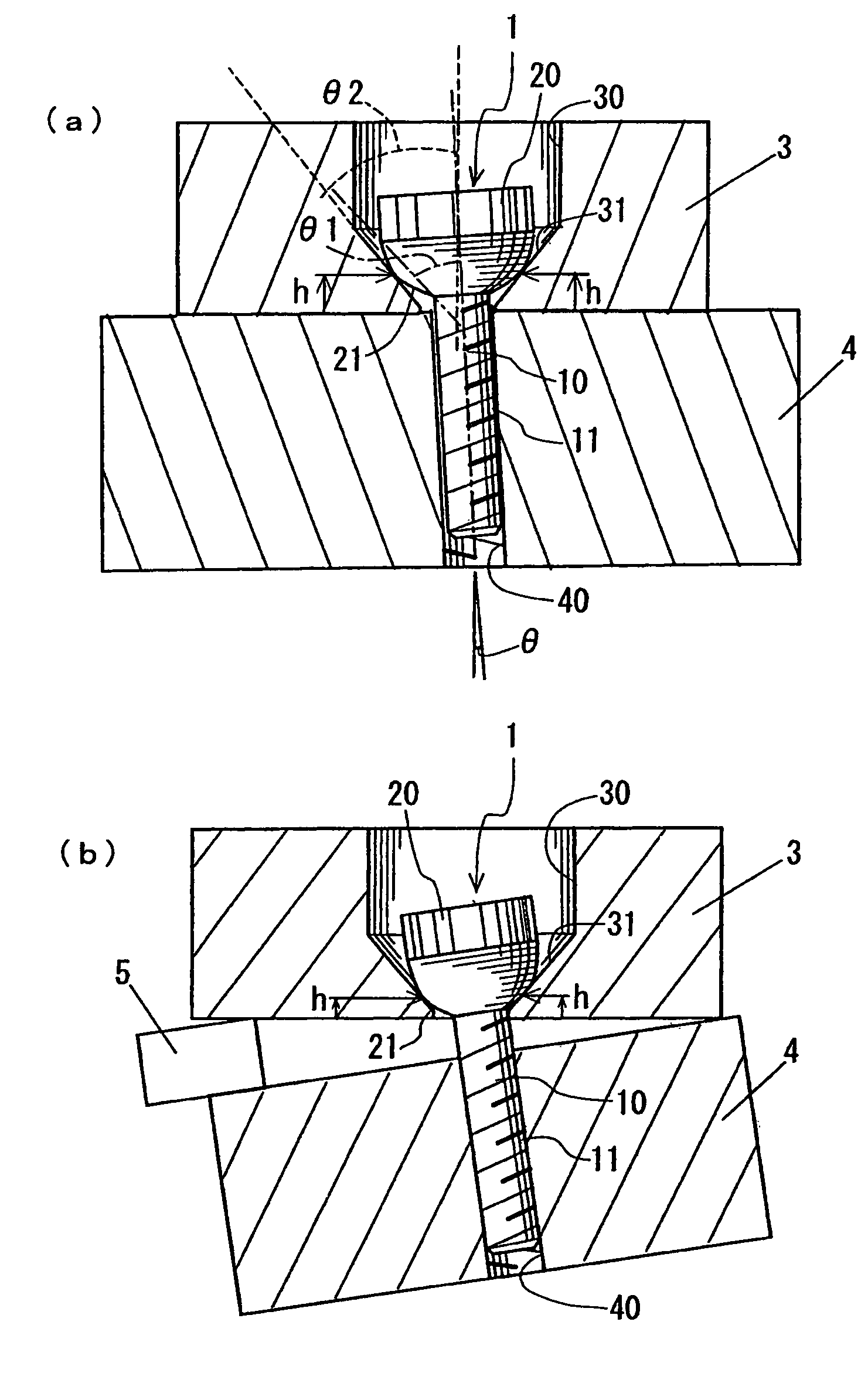

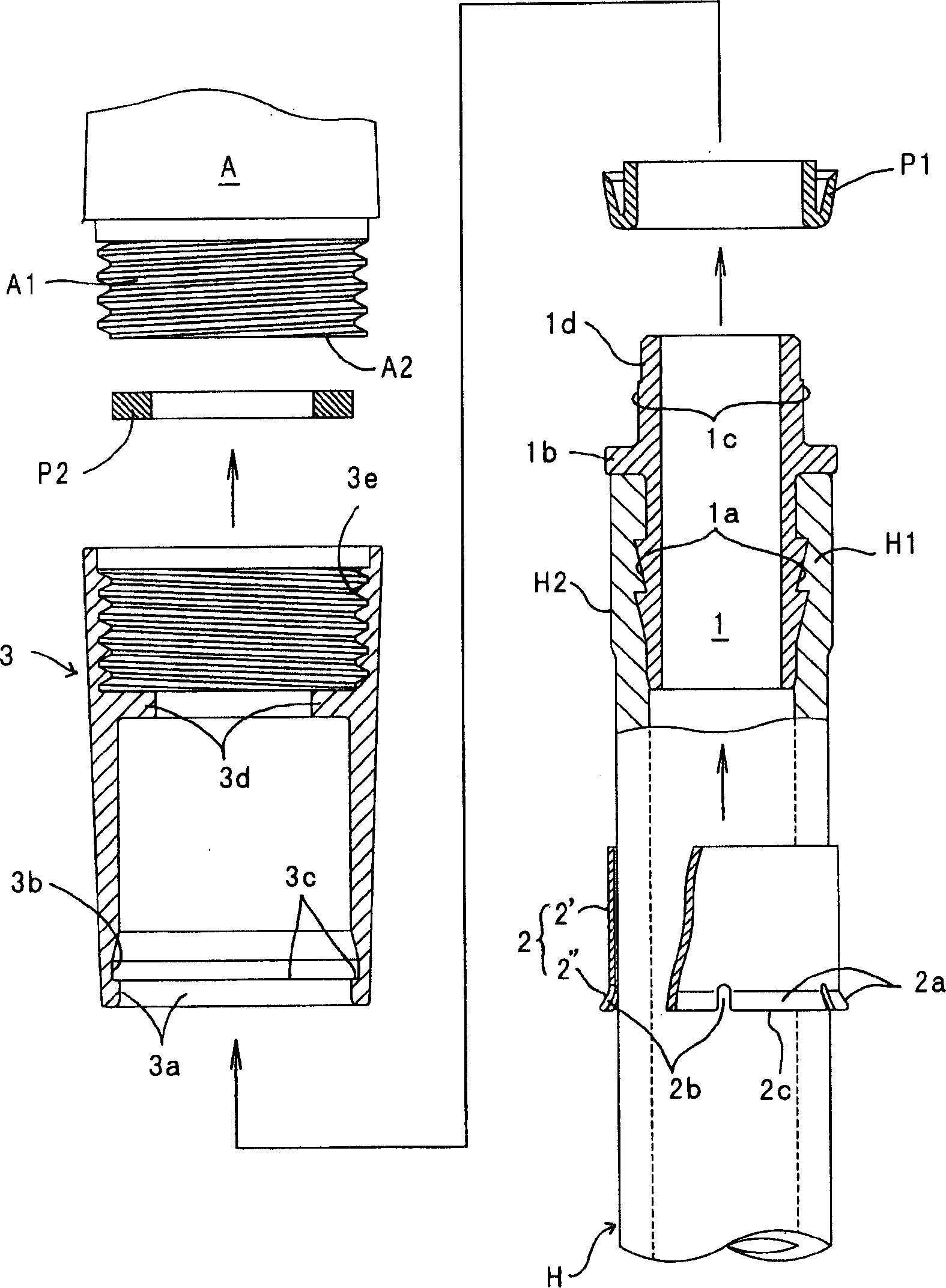

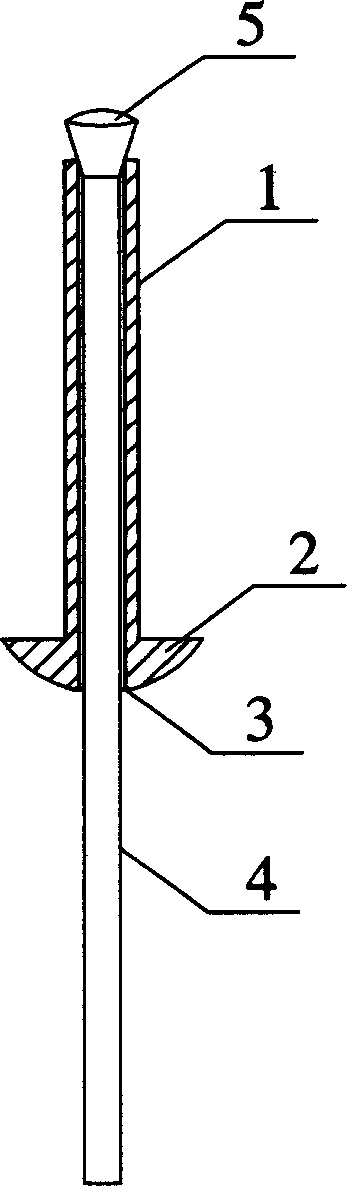

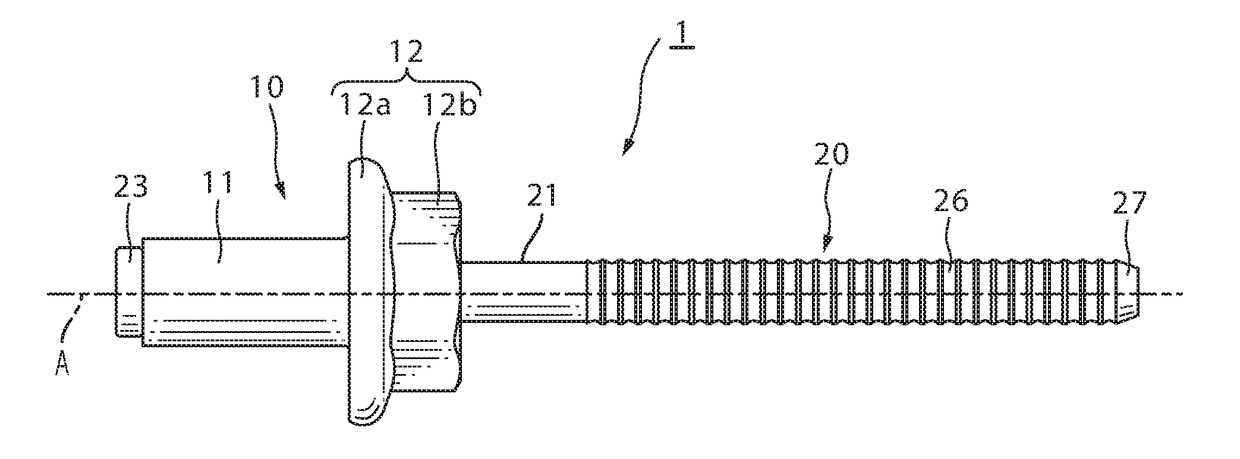

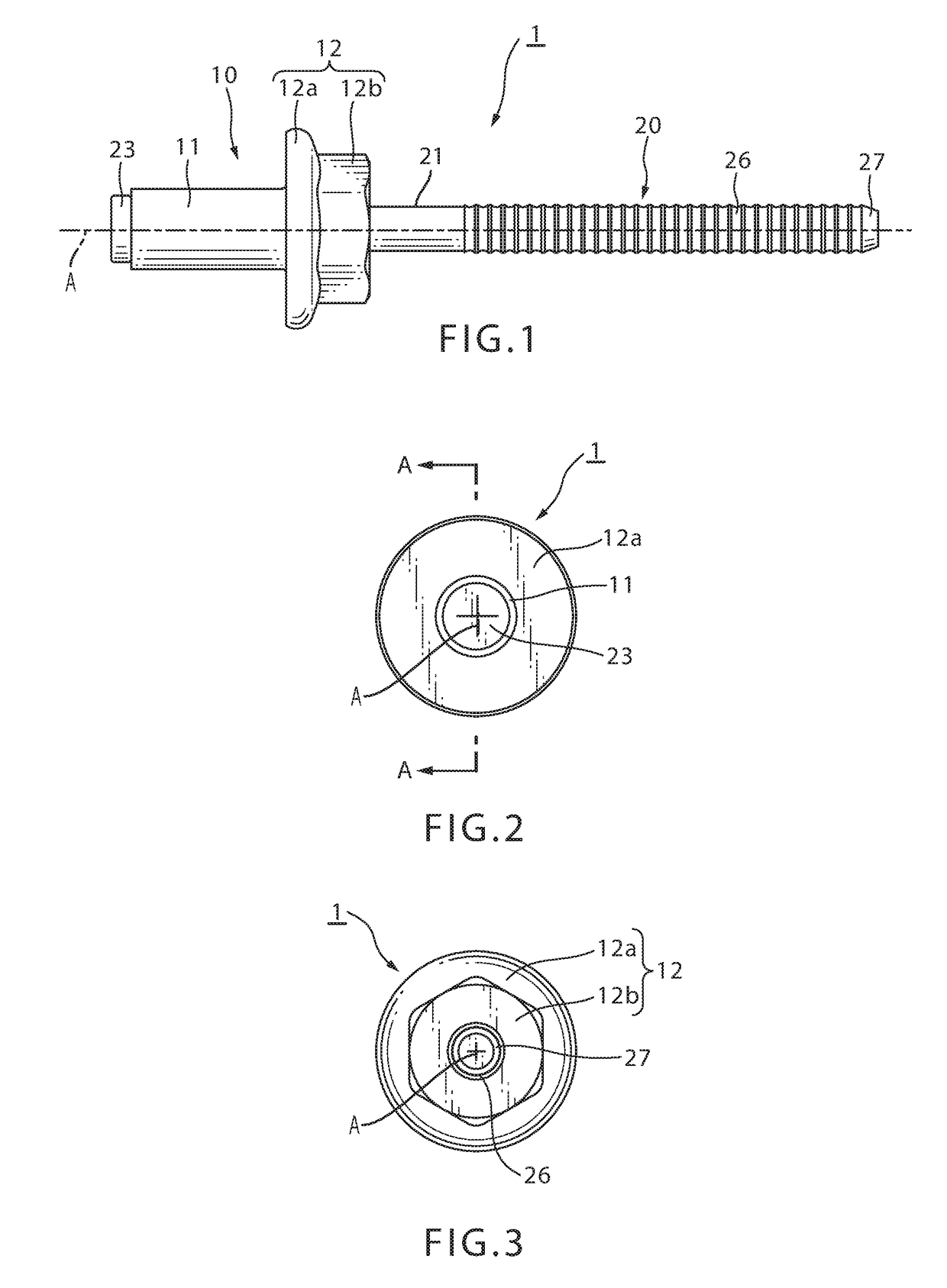

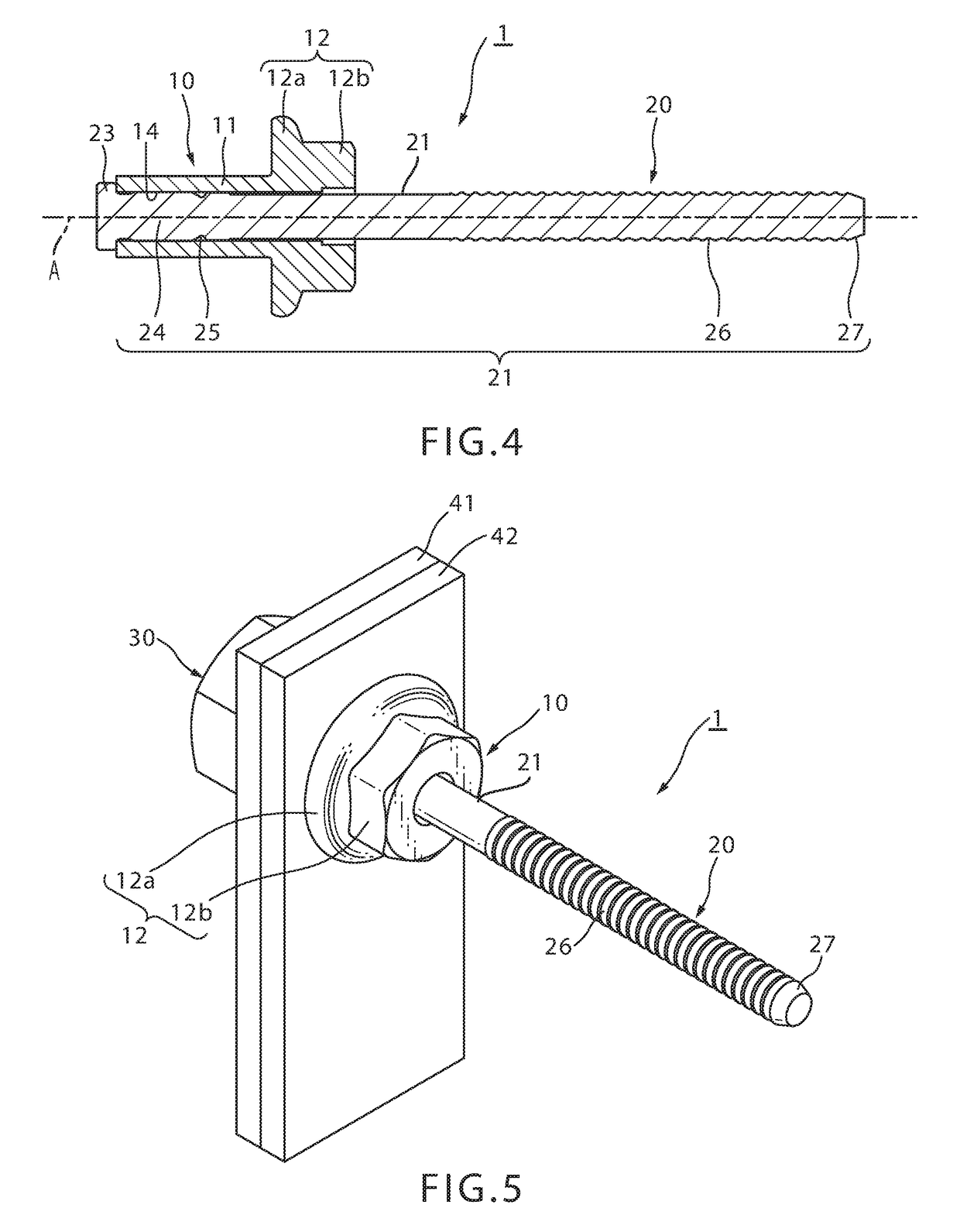

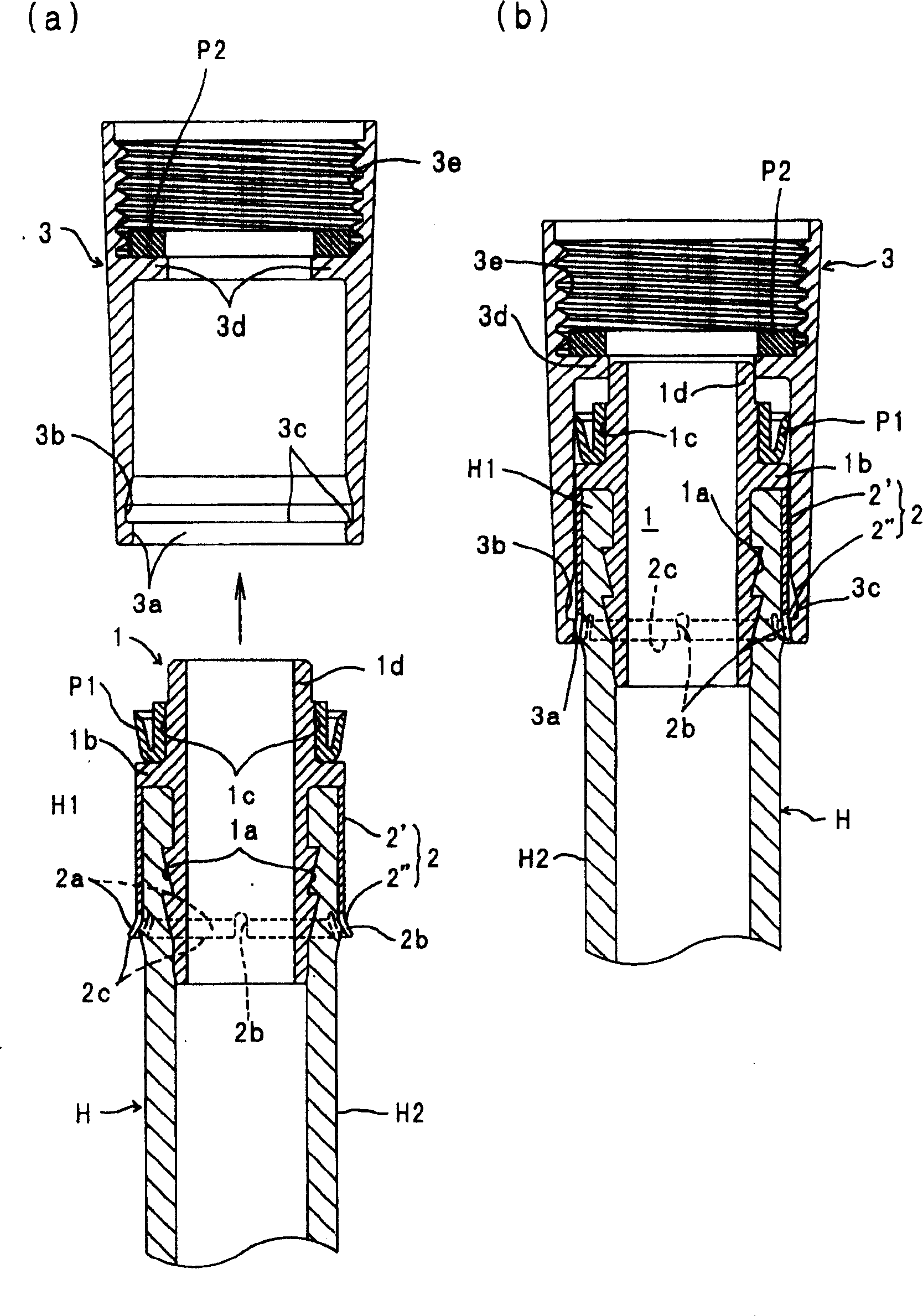

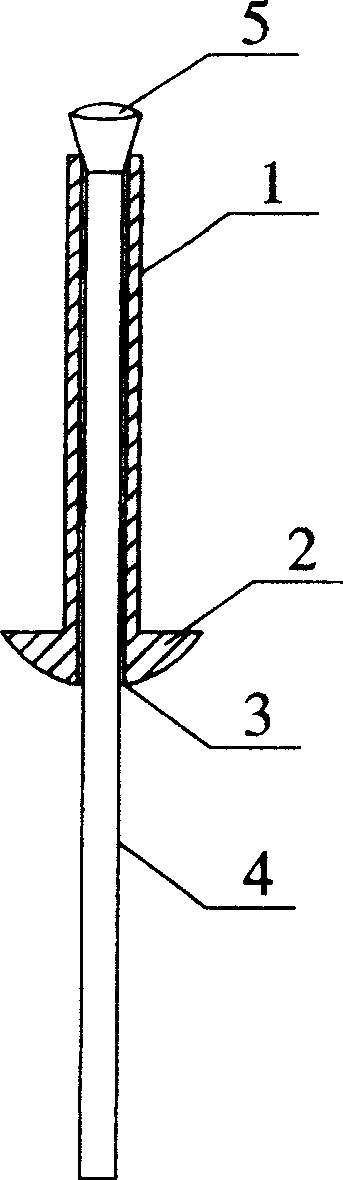

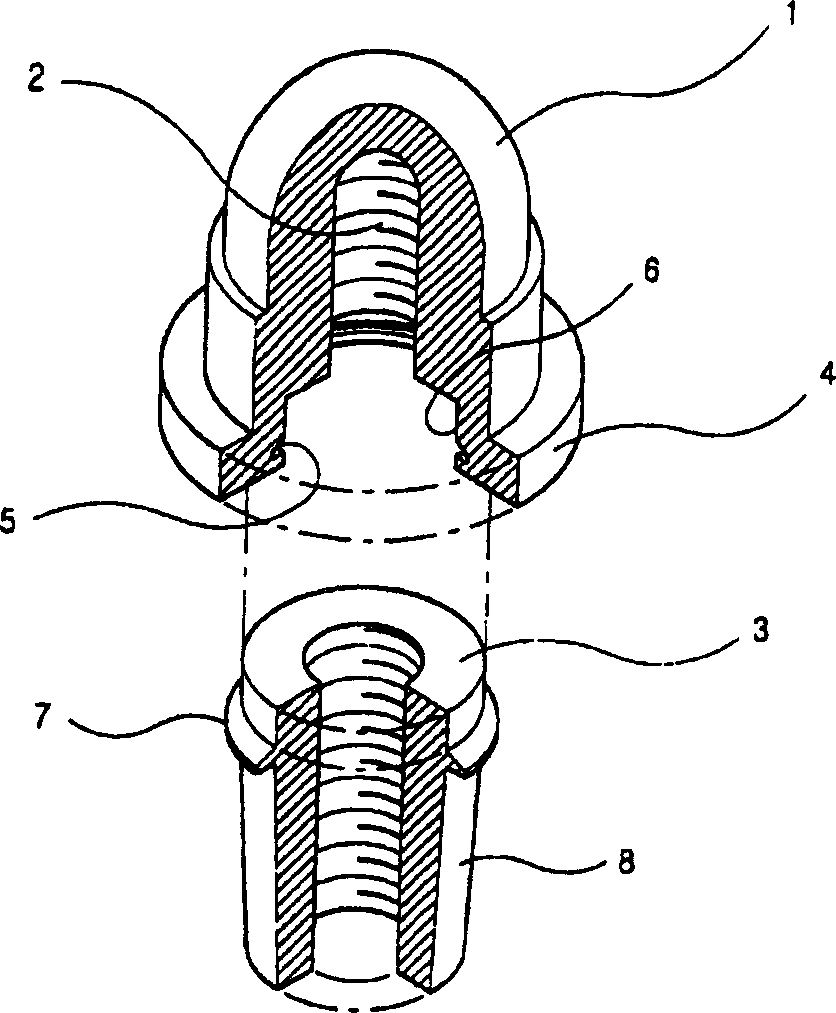

Fastening tool and fastening bolt

ActiveUS20050079012A1Sufficiently secureHigh strengthSnap fastenersWashersEngineeringMechanical engineering

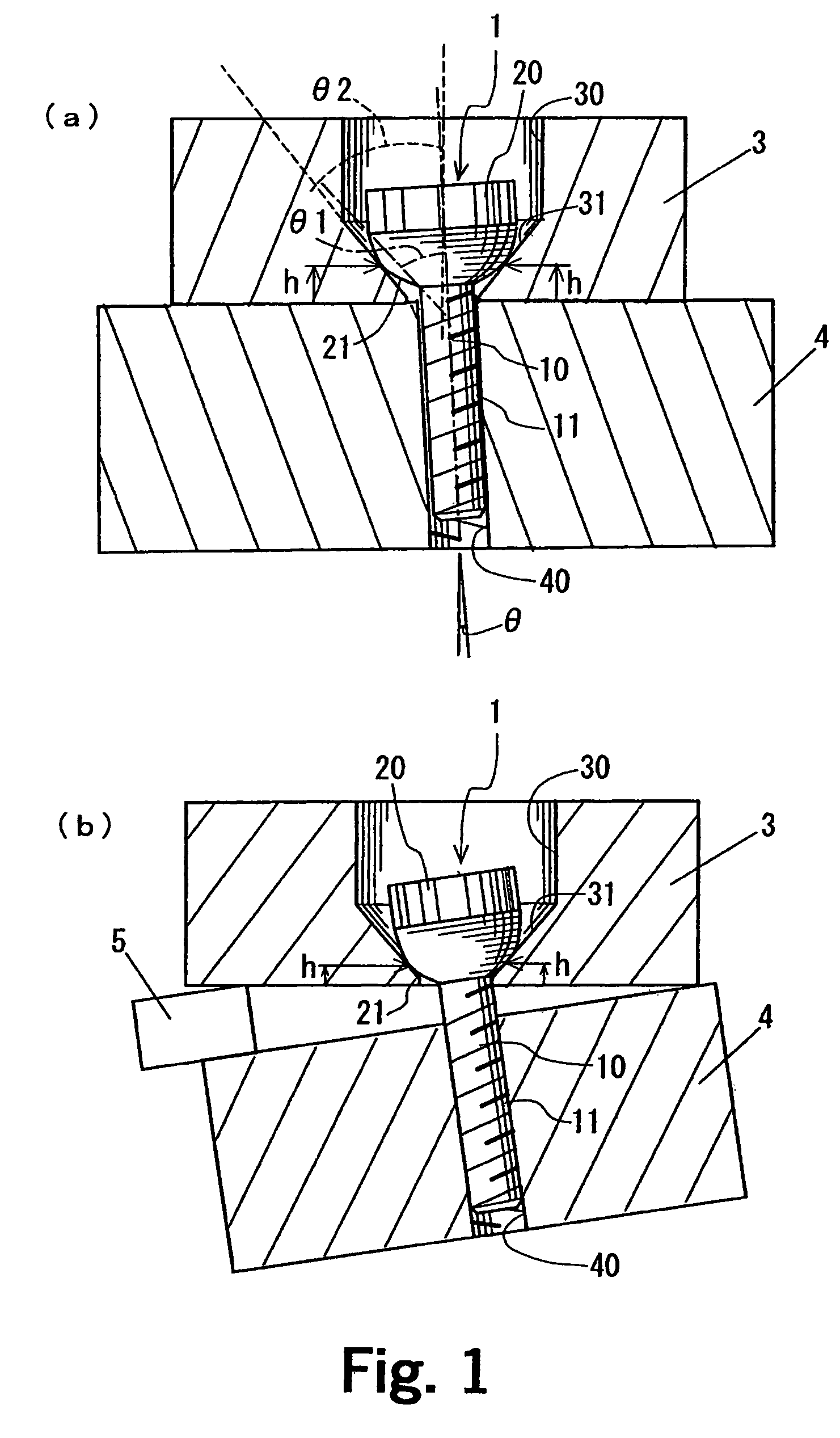

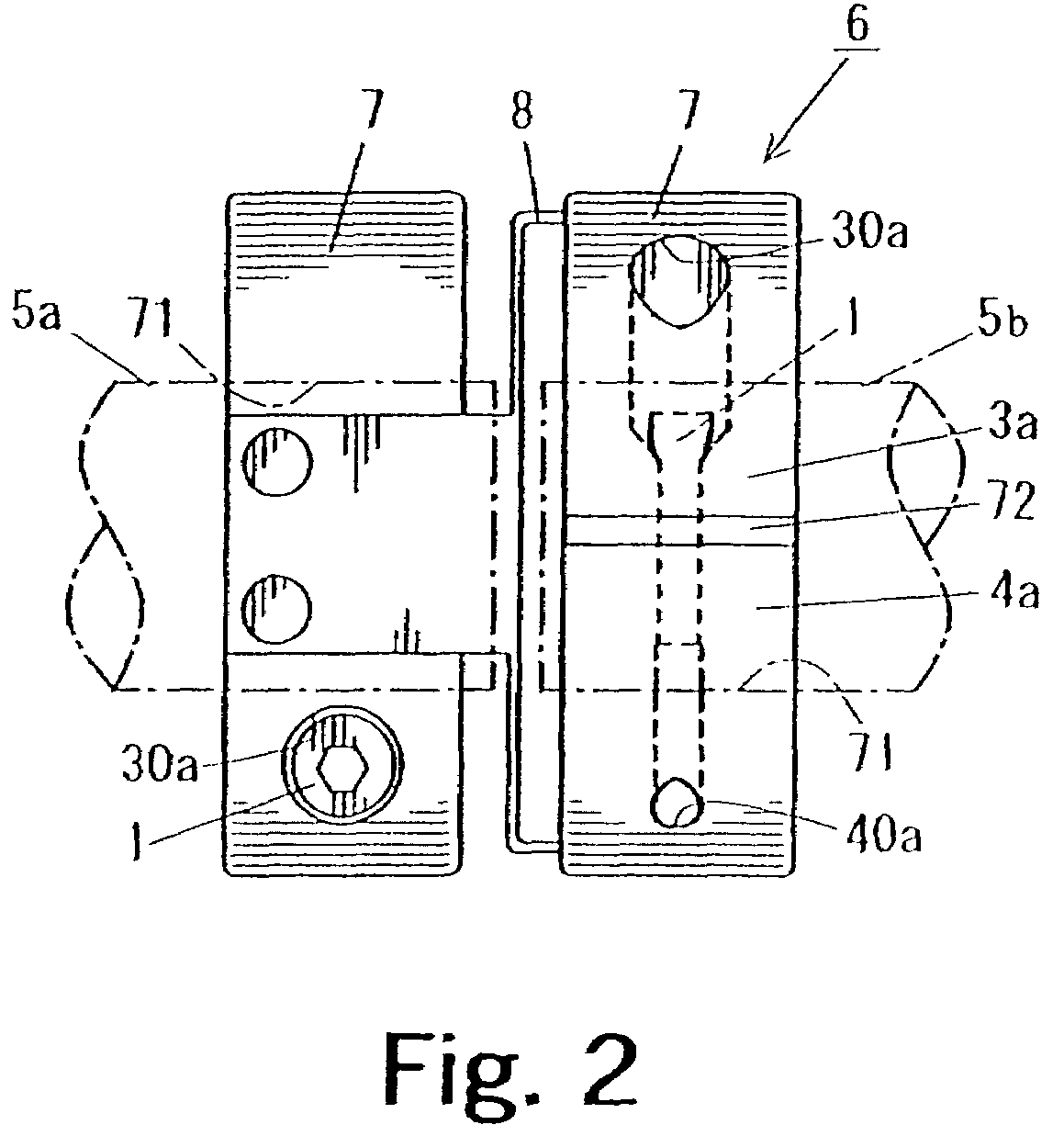

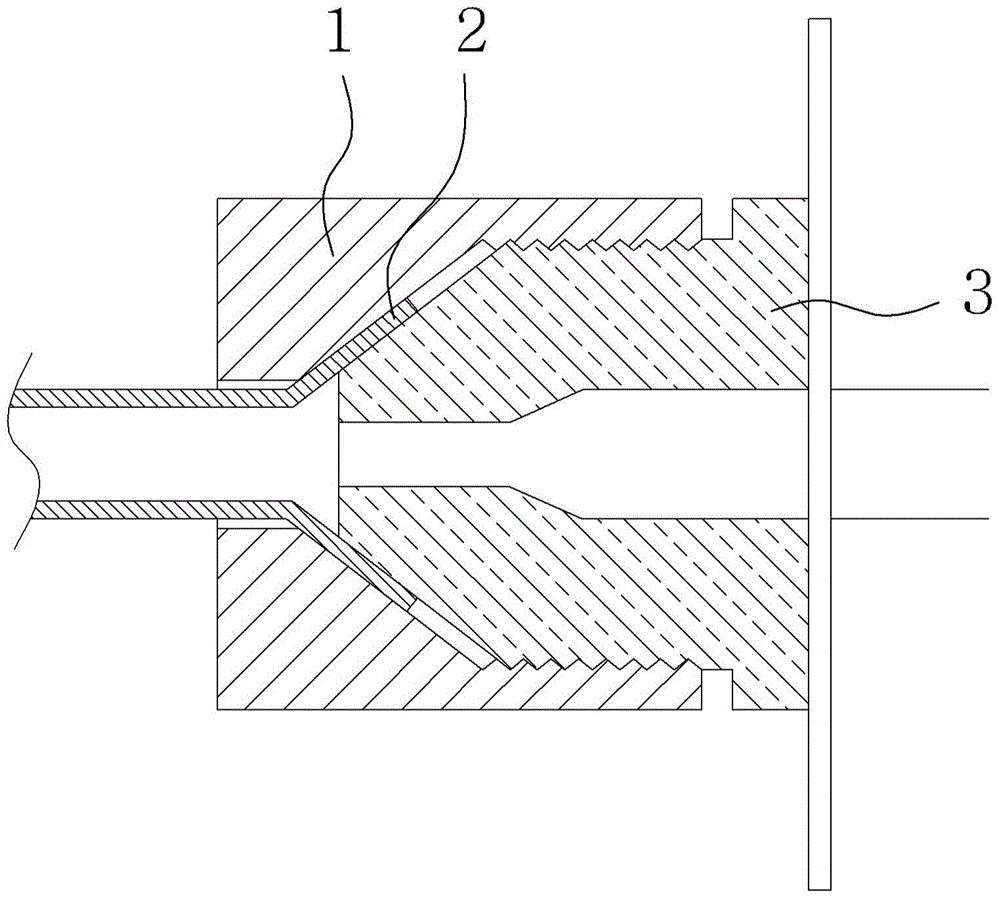

The present invention provides a fastening tool in which even when two members are inclined as the members are threadedly inserted, a displacement load is not applied to the members almost at all. A fastening bolt 1 of the fastening tool includes a rod-like bolt body 10 provided at its outer periphery with a male thread 11, and a head 20 provided on an end of the bolt body 10 and having a diameter greater than that of the bolt body 10. A lower surface of the head 20 is a tapered surface whose diameter is reduced toward the bolt body 10 so that the lower surface abuts against a tapered seat surface 31 of the first member 3 provided with a bolt through hole 31. This tapered surface is formed into a tapered curved surface 21 finished into a curved surface. With this structure, even if the threaded hole 40 of the second member 4 into which the fastening bolt 1 is threadedly inserted is inclined, the tapered curved surface 21 appropriately slides on the tapered seat surface 31 in the first member 3, the threadedly insertion direction of the bolt body 10 substantially matches with the axial direction of the threaded hole 40. Therefore, the fastening bolt 1 can easily enter concentrically with the threaded hole 40.

Owner:ISEL CO LTD

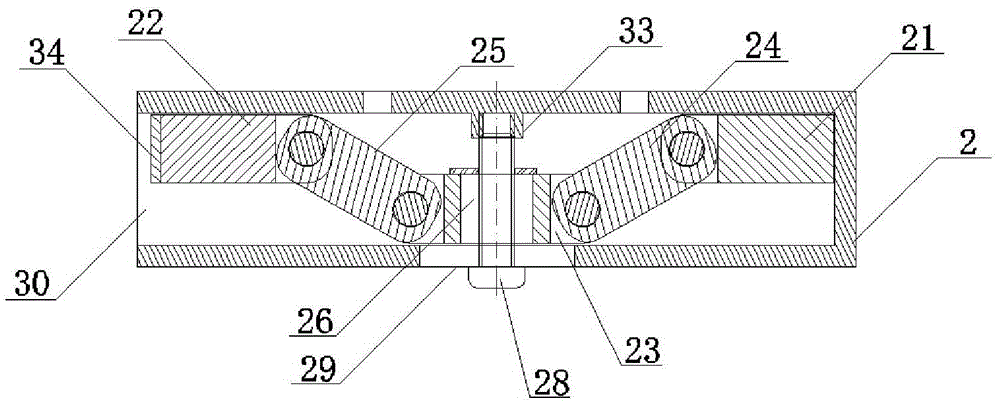

Expansion bolt

The invention discloses an expansion bolt, which comprises a bolt body, an expansion sleeve and a gasket, wherein a nut matched with the bolt body is fixedly connected with the interior of the tail end of the expansion sleeve, four to six groove holes along the axial direction are arranged in the middle of the expansion sleeve, and the middles of the groove holes expand towards two sides to be provided with grooves. The expansion bolt has the advantages of being good in expansion effect, strong in fastening force, good in reliability, fast and convenient to install, convenient to demount, capable of being reused and the like.

Owner:JIANGSU ZHENYA SPECIAL SCREW

Fastening tool and fastening bolt

Owner:ISEL CO LTD

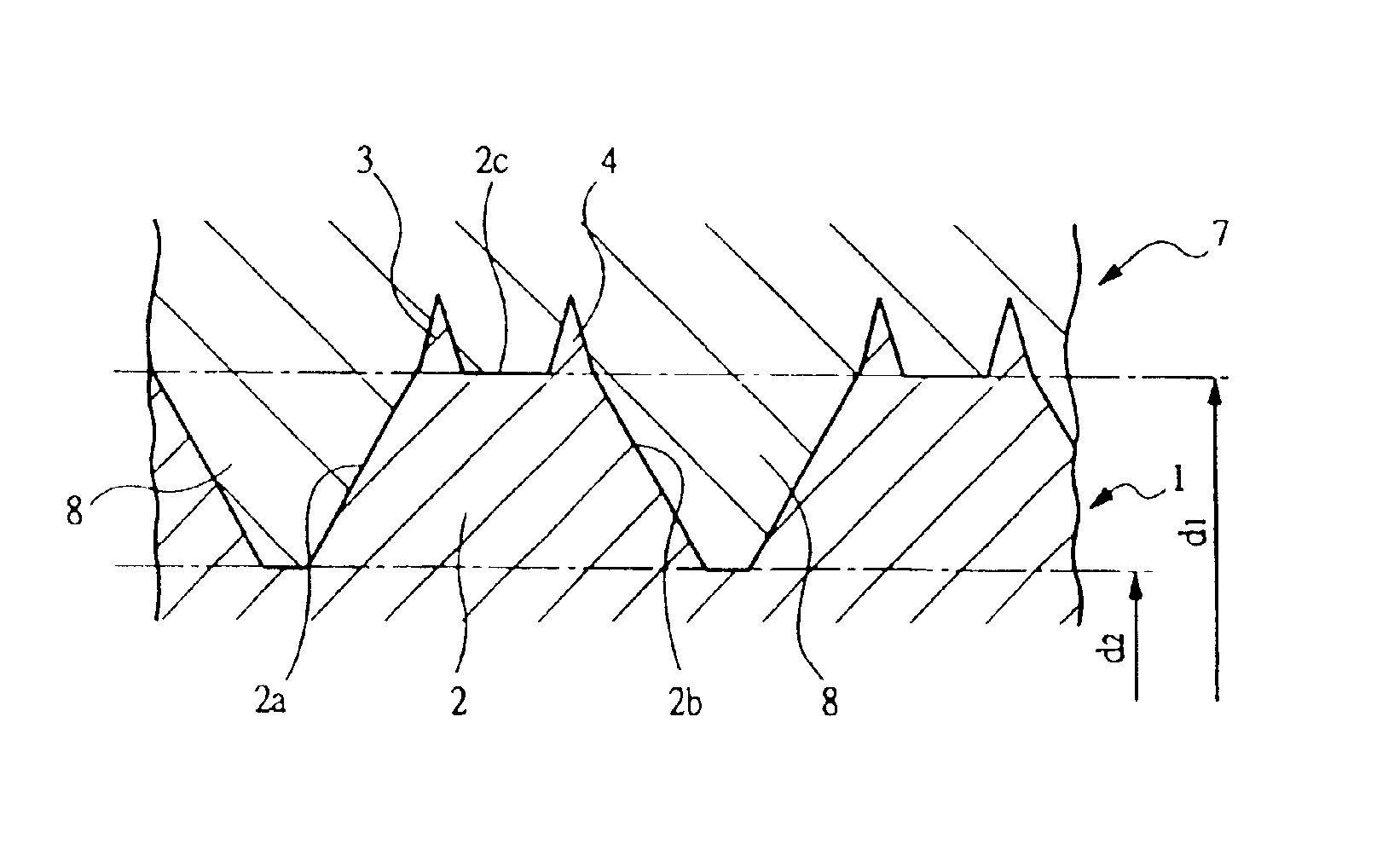

Screws and screw-type mechanical components with shock-resistant, vibration-resistant and tightening force-enhanced structures

InactiveCN102261365AStrong fastening forceSuppresses the drop in torque valueNutsBoltsSingle stageMechanical components

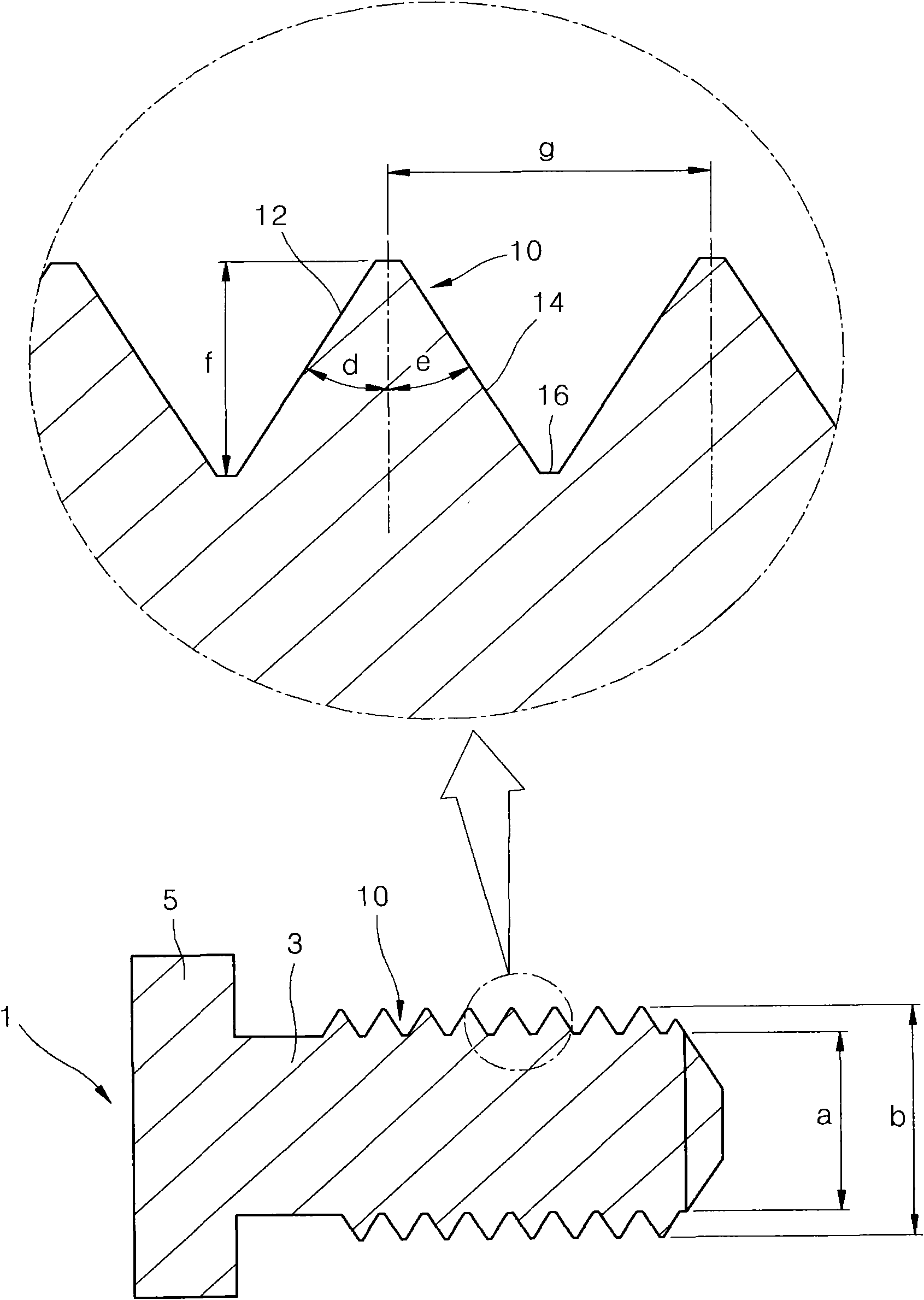

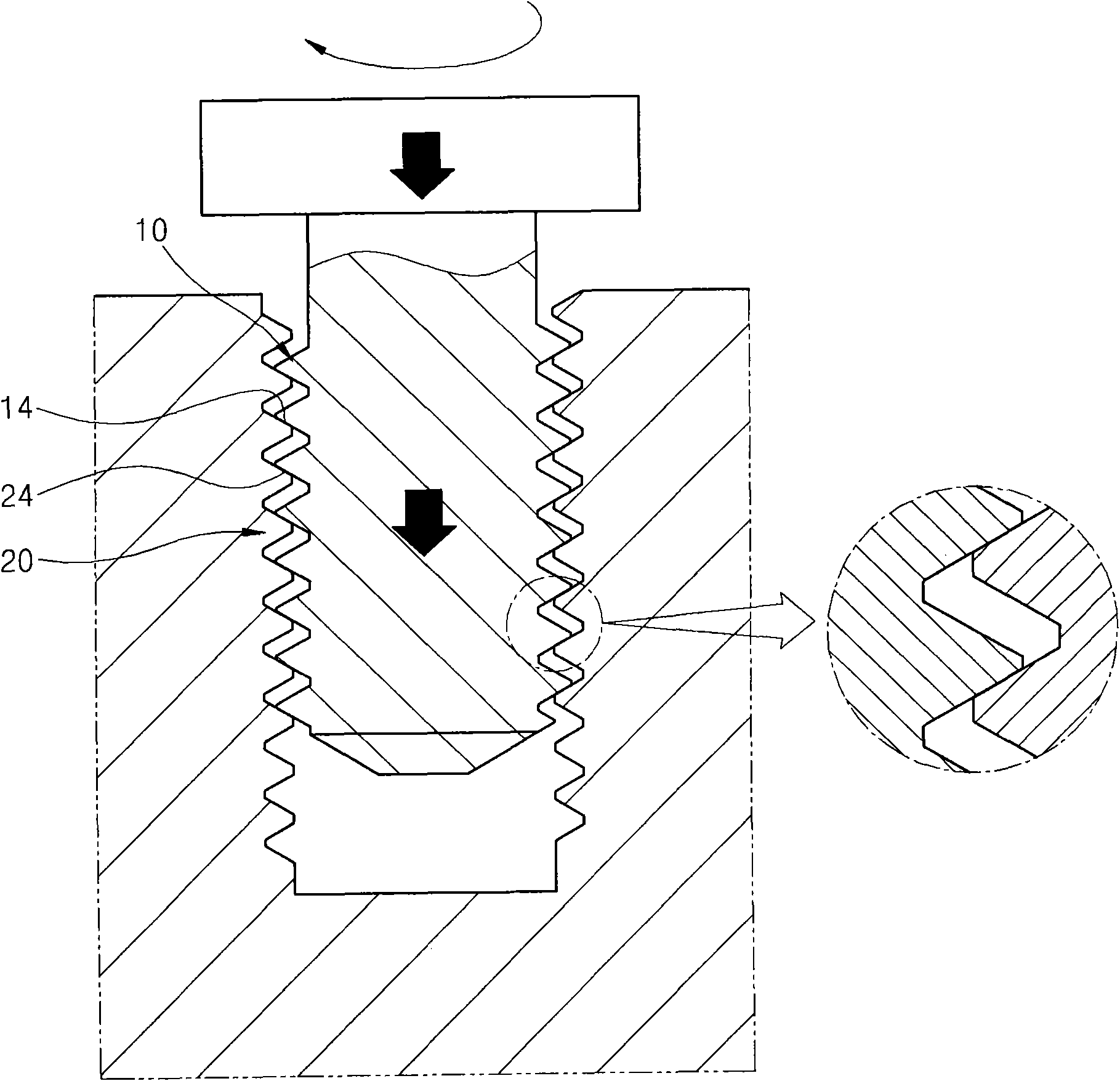

The present invention relates to a screw configured to have improved anti-shock, anti-vibration, and fastening ability, and particularly, to screw technology that: forms an angle of a leading flank surface constituting the inclined plane of a screw thread in an entry direction to be less than an angle of a trailing flank surface constituting the inclined plane of the screw thread in an exit direction, with respect to the center of the screw thread; and has the trailing flank surface provided as a single stage flat portion formed horizontally within a sloped section, to enlarge the contacting surface area between the screw and a female screw correspondingly coupled to the screw. Thus, upward, downward, left and right vibration of a screw caused by external impacts can be prevented so as to avert autonomous disengagement of the screw, and effectively prevent a reduction of disengaging torque arising from repeated use.

Owner:(株)亚细亚BOLT

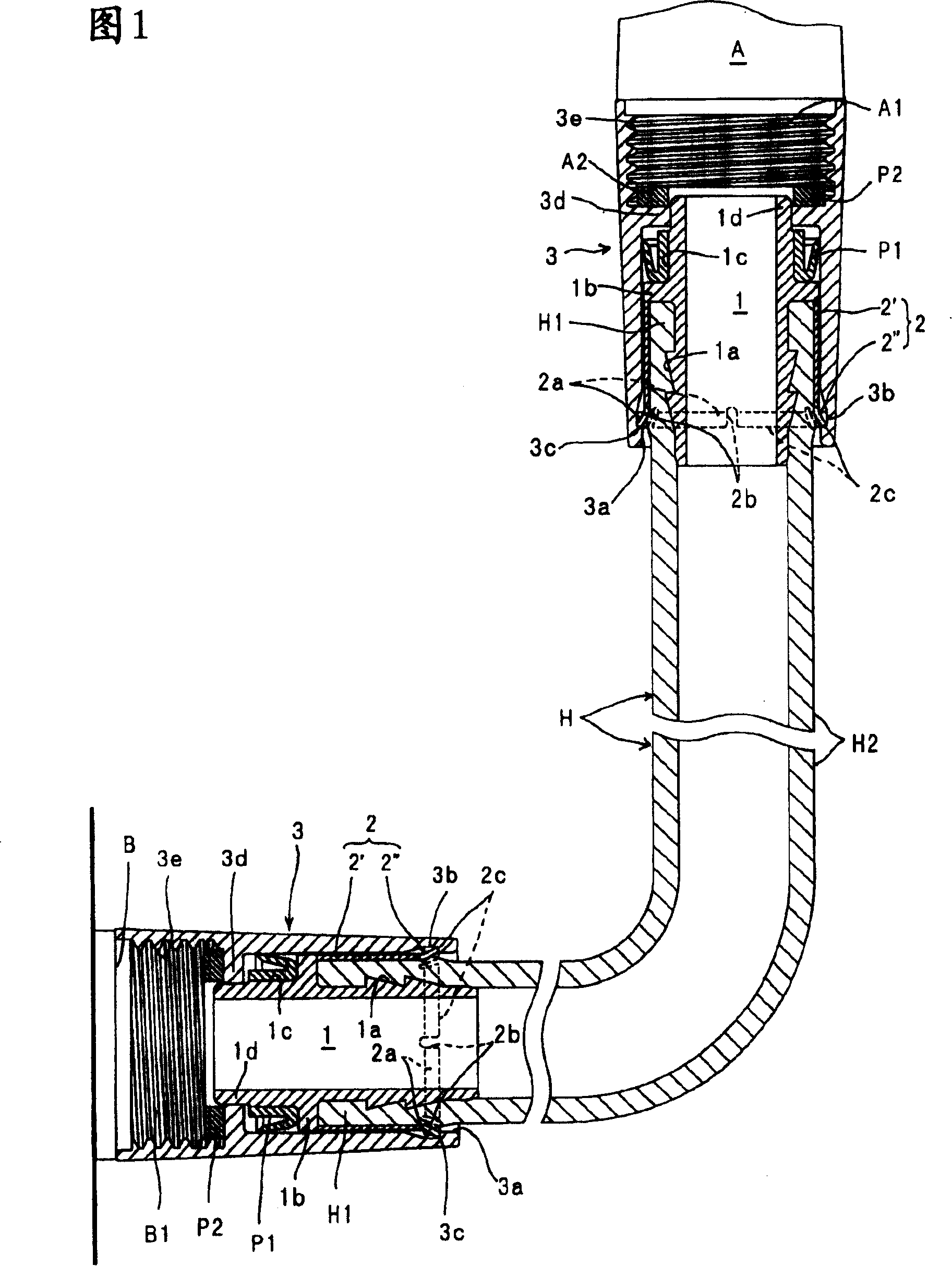

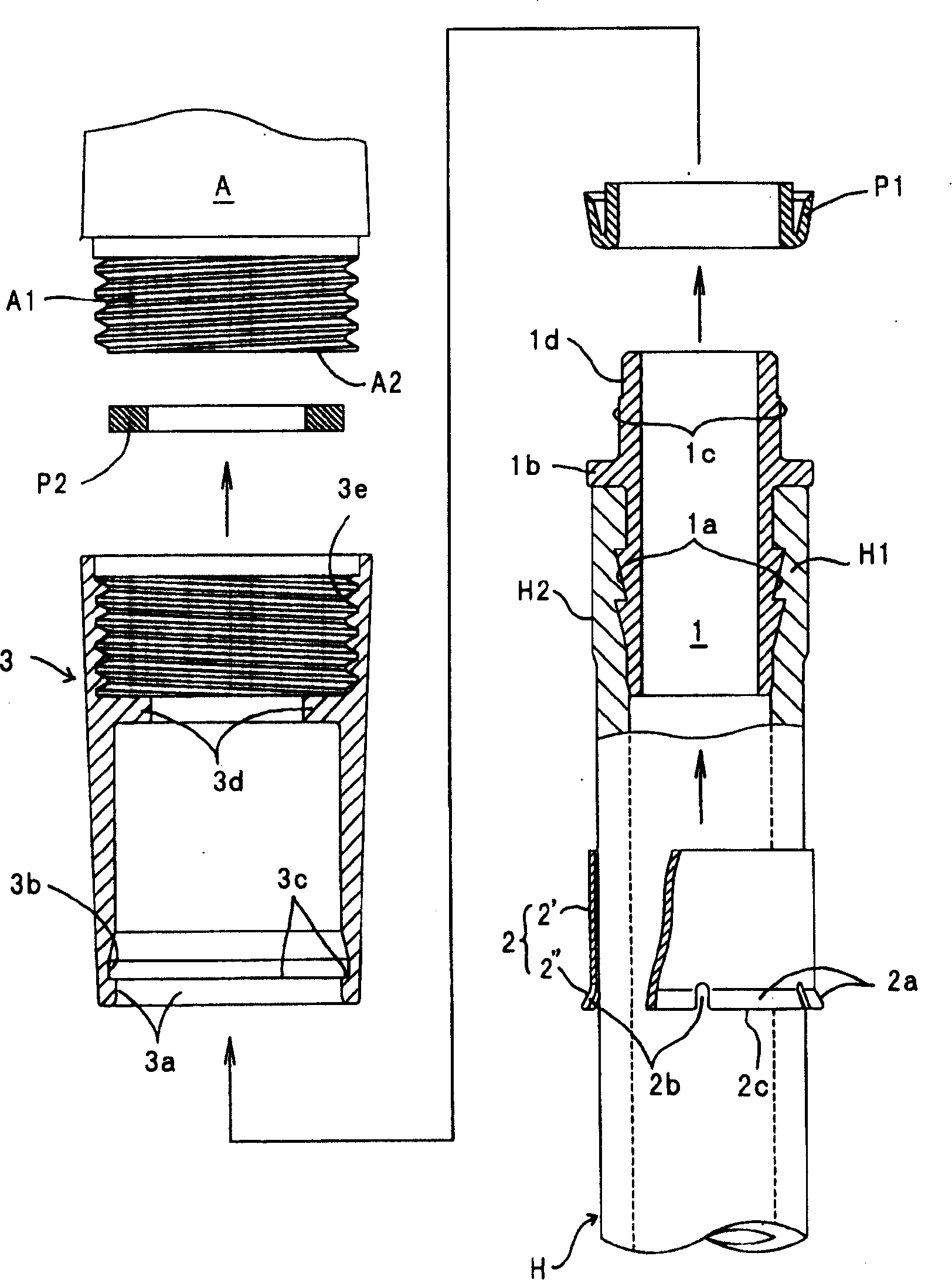

Connection structure of refrigerant tube

InactiveCN105299347APrevent air leakageImprove cooling/heating efficiencyLighting and heating apparatusJoints with sealing surfacesOuter CannulaEngineering

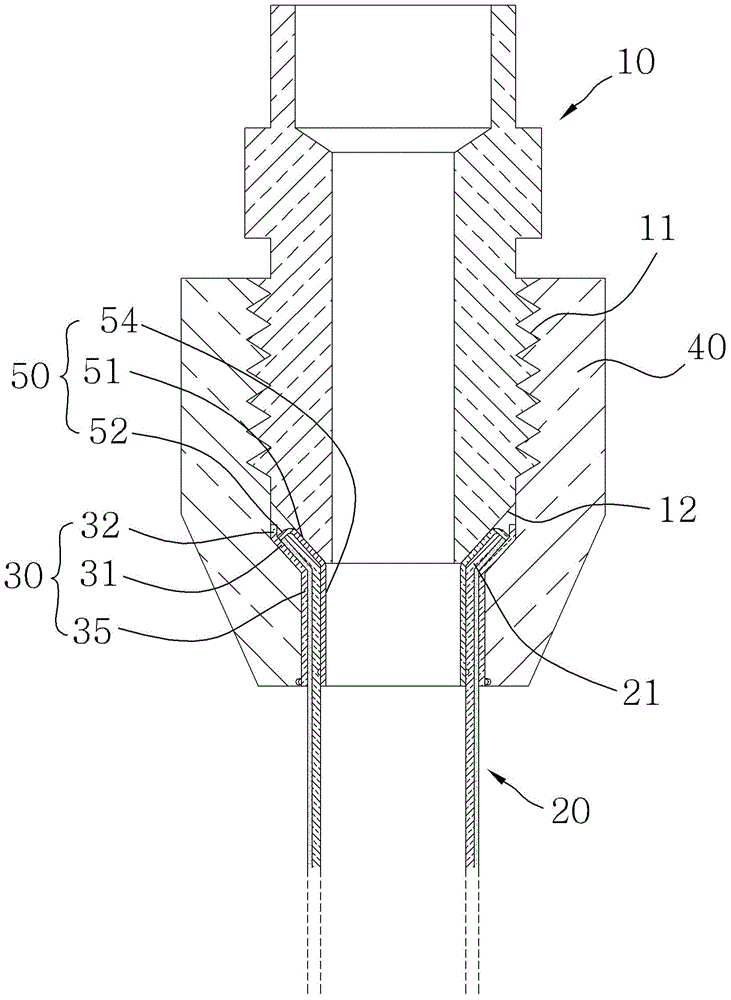

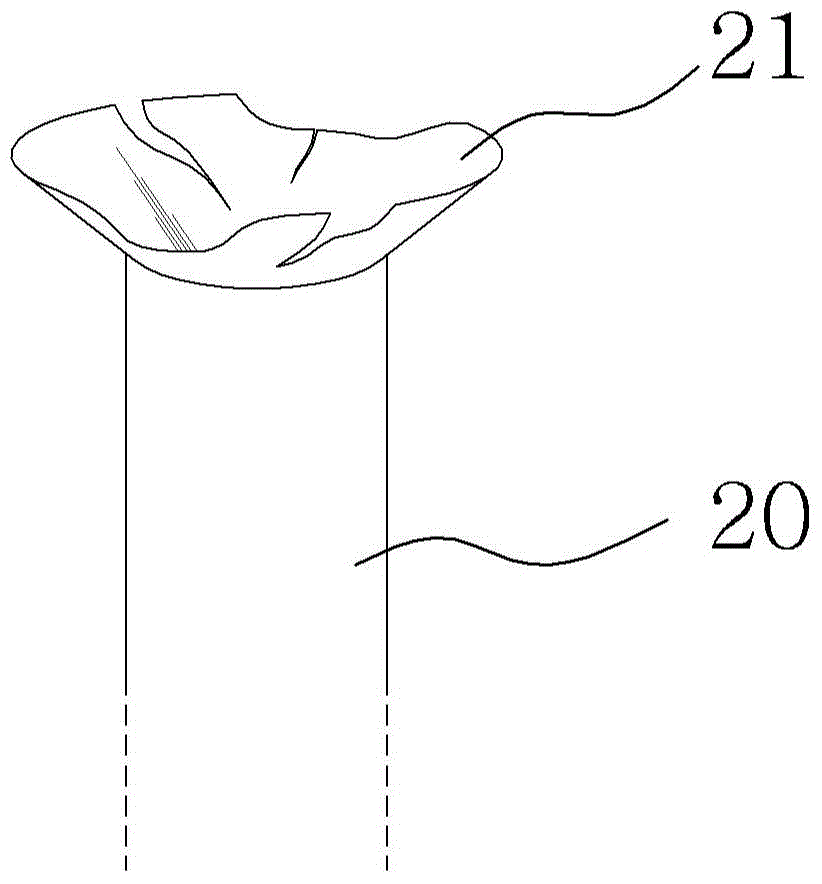

The present invention relates to a connecting structure of a refrigerant pipe, capable of connecting each end part of a refrigerant pipe for inducing a refrigerant gas flow between indoor and outdoor units for making up a cooling device, a heating device, or a cooling / heating device in order to maintain the airtightness. Moreover, the connecting structure of a refrigerant pipe comprises: a valve installed in the corresponding place of indoor and outdoor units of an air conditioner; a refrigerant pipe including a pipe expansion part in the form of a trumpet in the front; an outer sleeve including an outer pipe expansion part inserted into the refrigerant pipe and combined with the outside of the pipe expansion part; an inner sleeve including an inner pipe expansion part inserted into and combined with the pipe expansion part; a nut screwed with the valve by being inserted into the refrigerant pipe to accommodate the outer sleeve inside; a first sealing member in a form to correspond to the form of the inner sleeve having contraction and expansion forces while ensuring airtightness between the inner sleeve and the lower part of the valve; and a second sealing member having contraction and expansion forces while ensuring airtightness between the outer sleeve and the inside of the nut.

Owner:吴炯东

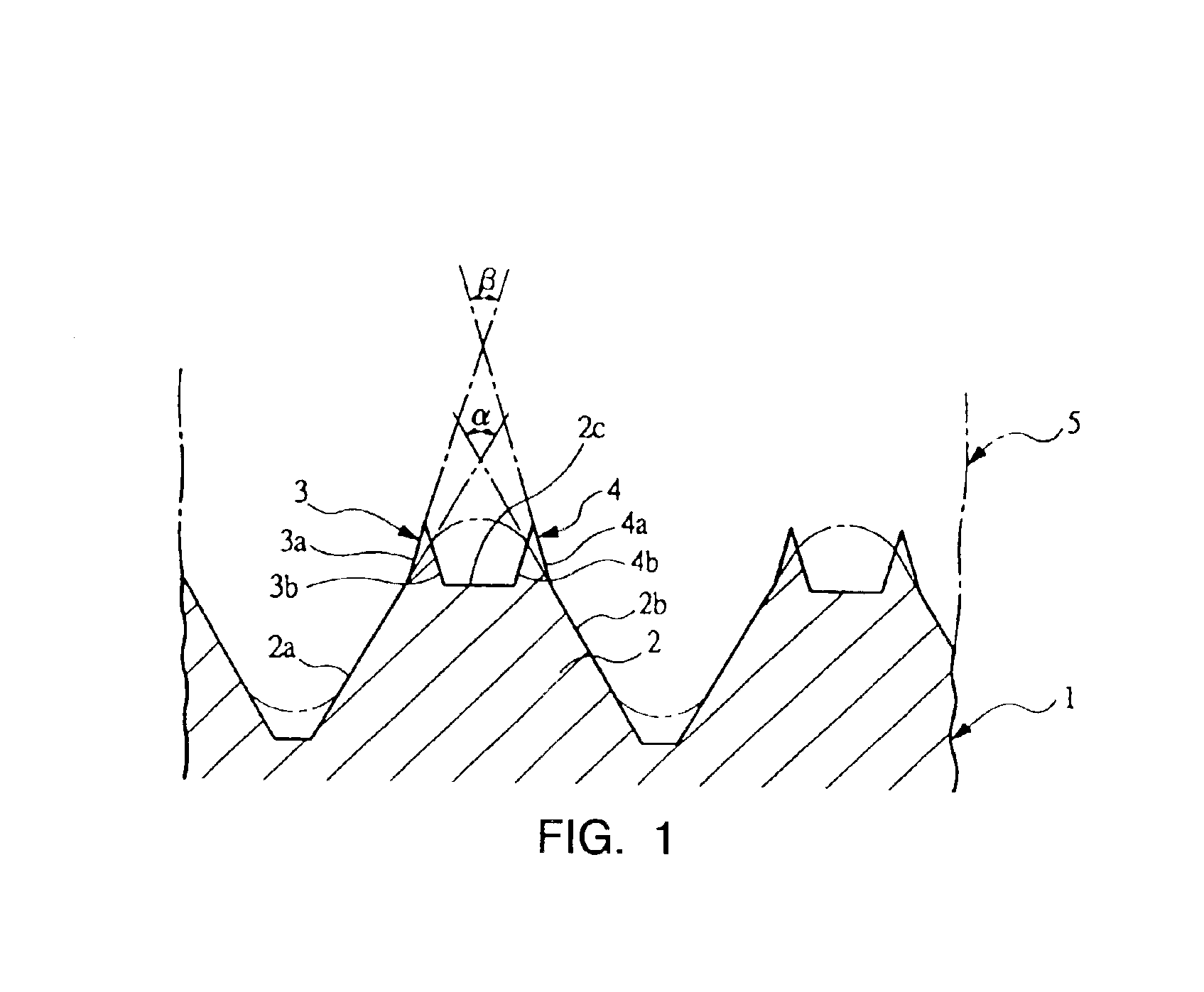

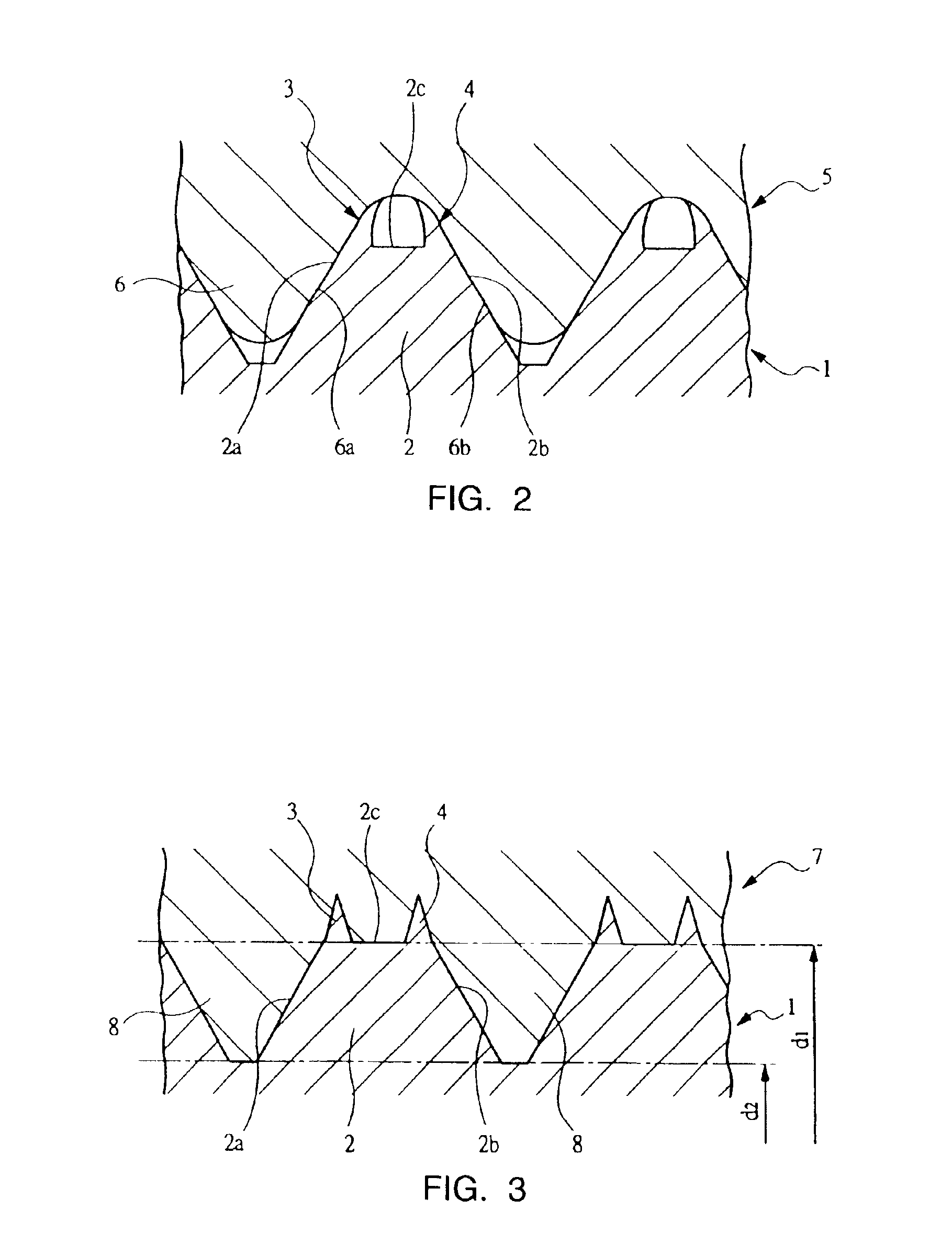

Screw member with biting features

InactiveUS6860690B2Reliable prevention of looseningIncrease contact areaNutsBoltsEngineeringUltimate tensile strength

Owner:ISHIMORI YUSAKU

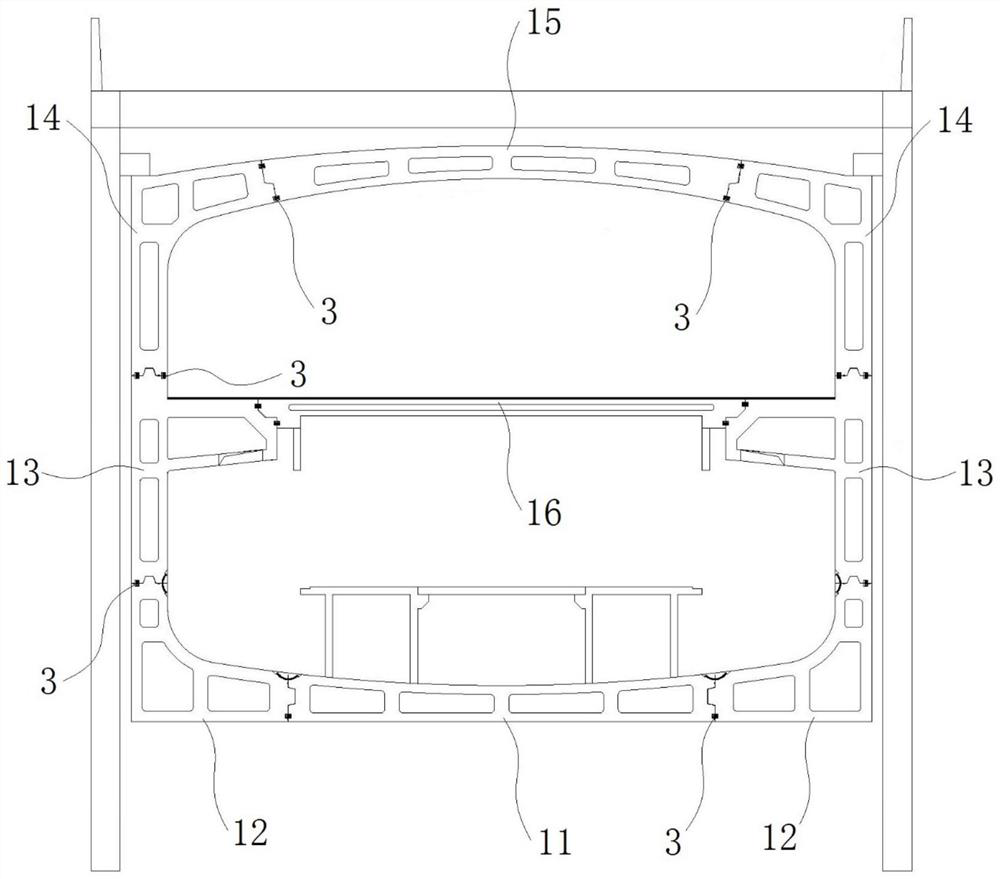

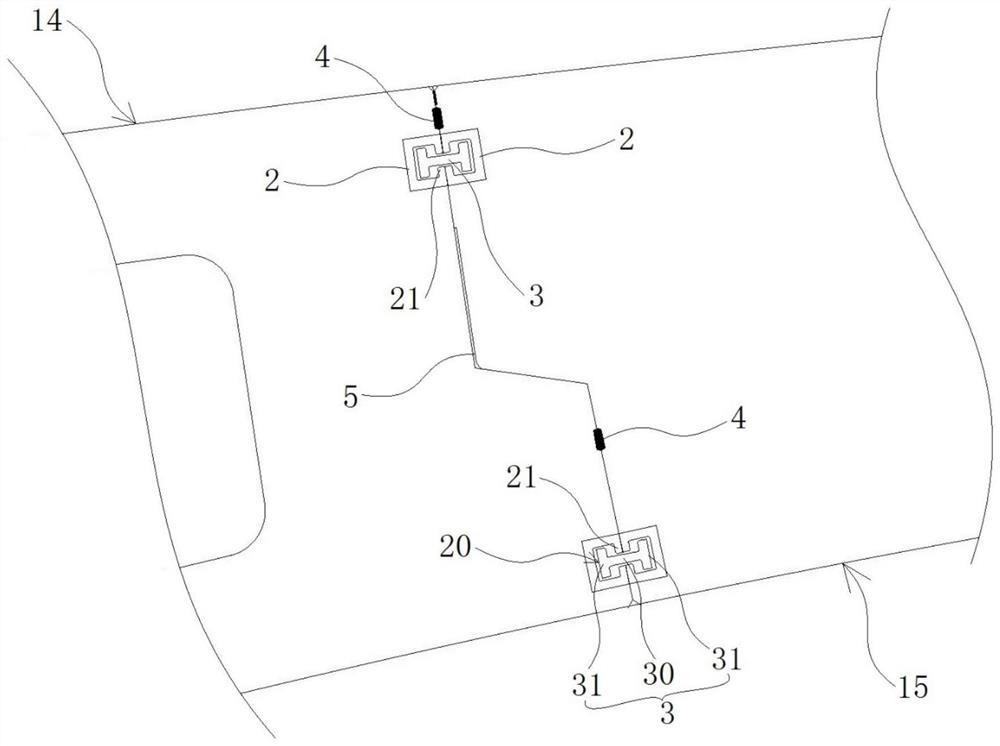

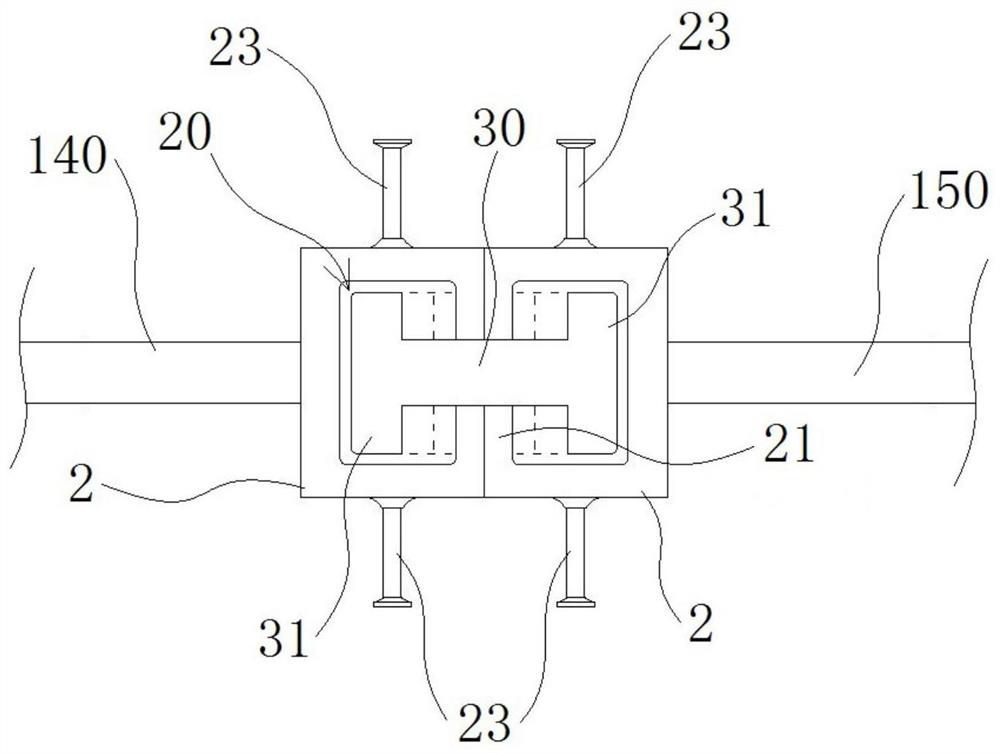

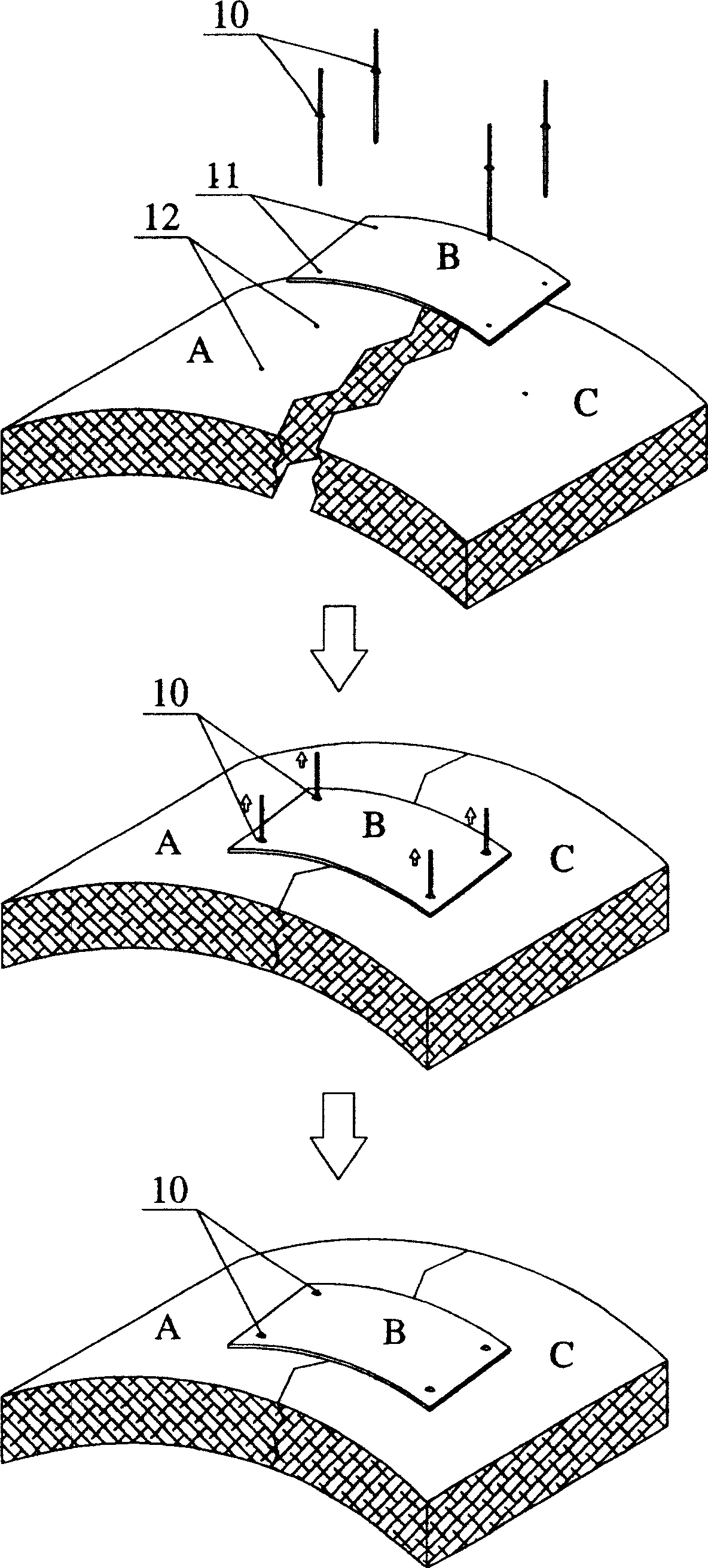

Fabricated subway station and construction method thereof

ActiveCN112281918AGood sealing effectFirm fastening forceArtificial islandsProtective foundationConvex structureButt joint

The invention provides a fabricated subway station and a construction method thereof, and relates to the field of subway stations. The fabricated subway station comprises a plurality of components, wherein the plurality of components are annularly combined, the plurality of components include a bottom plate component, a bottom corner component, a side wall component, a middle plate component, a top corner component and a top plate component, concave-convex structures which are matched with one another are respectively arranged at the edges of the components, and the butt joint positions of every two adjacent components are filled with sealing structures; and embedded grooves which extend in a longitudinal direction are further formed in the edges of the components, the embedded grooves ofevery two adjacent components are oppositely formed, and connecting pieces which are used for forming opposite fastening force on every two adjacent components are installed in the embedded grooves. The opposite fastening force is formed on every two adjacent components through the connecting pieces, so that the sealing structures in the butt joint positions have good sealing effects; and a plurality of bolt structures are replaced by the complete connecting pieces, so that the bending moment is large, the force transmission is uniform, firm fastening force can be formed on every two adjacentcomponents, the high-performance waterproof requirement is met, the operation is simplified, and the construction efficiency is improved.

Owner:GUANGZHOU METRO DESIGN & RES INST

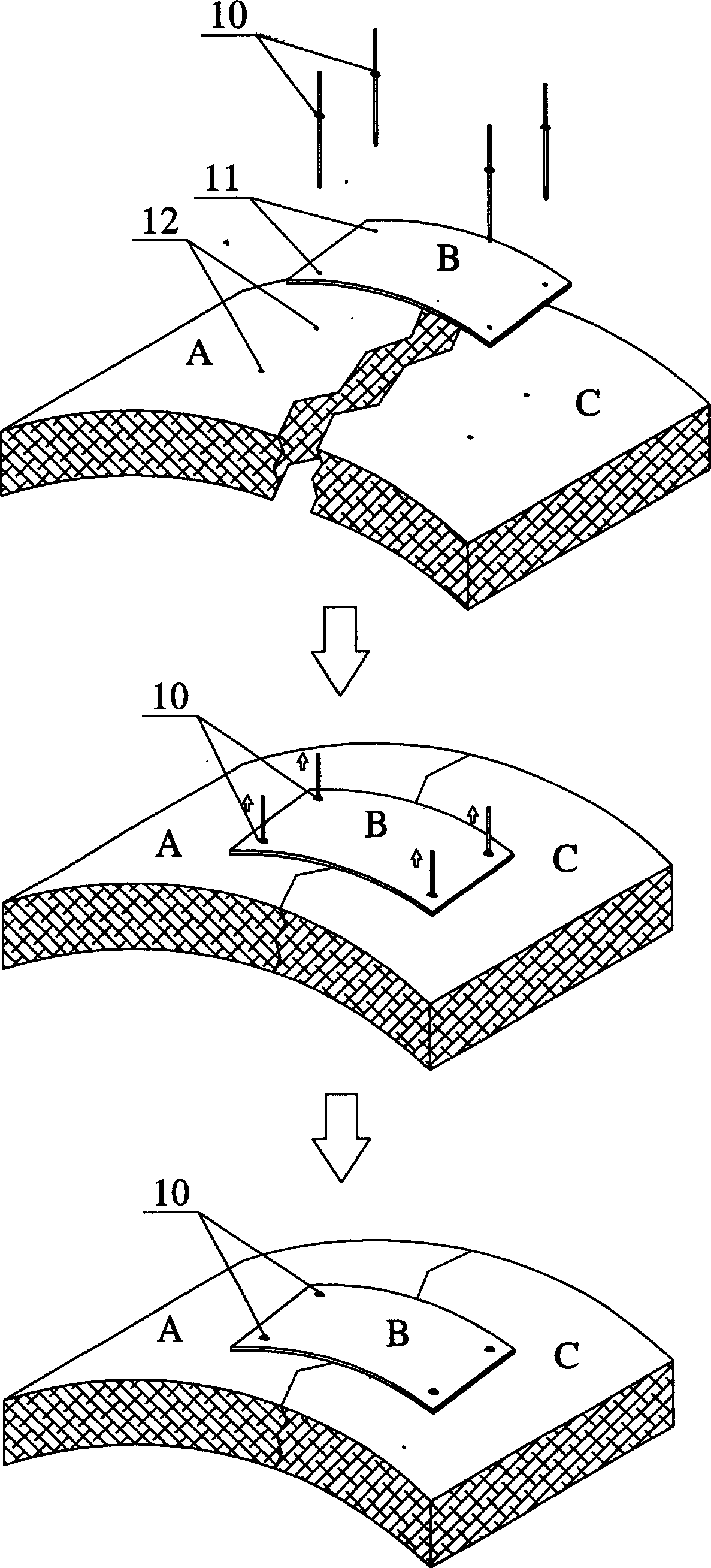

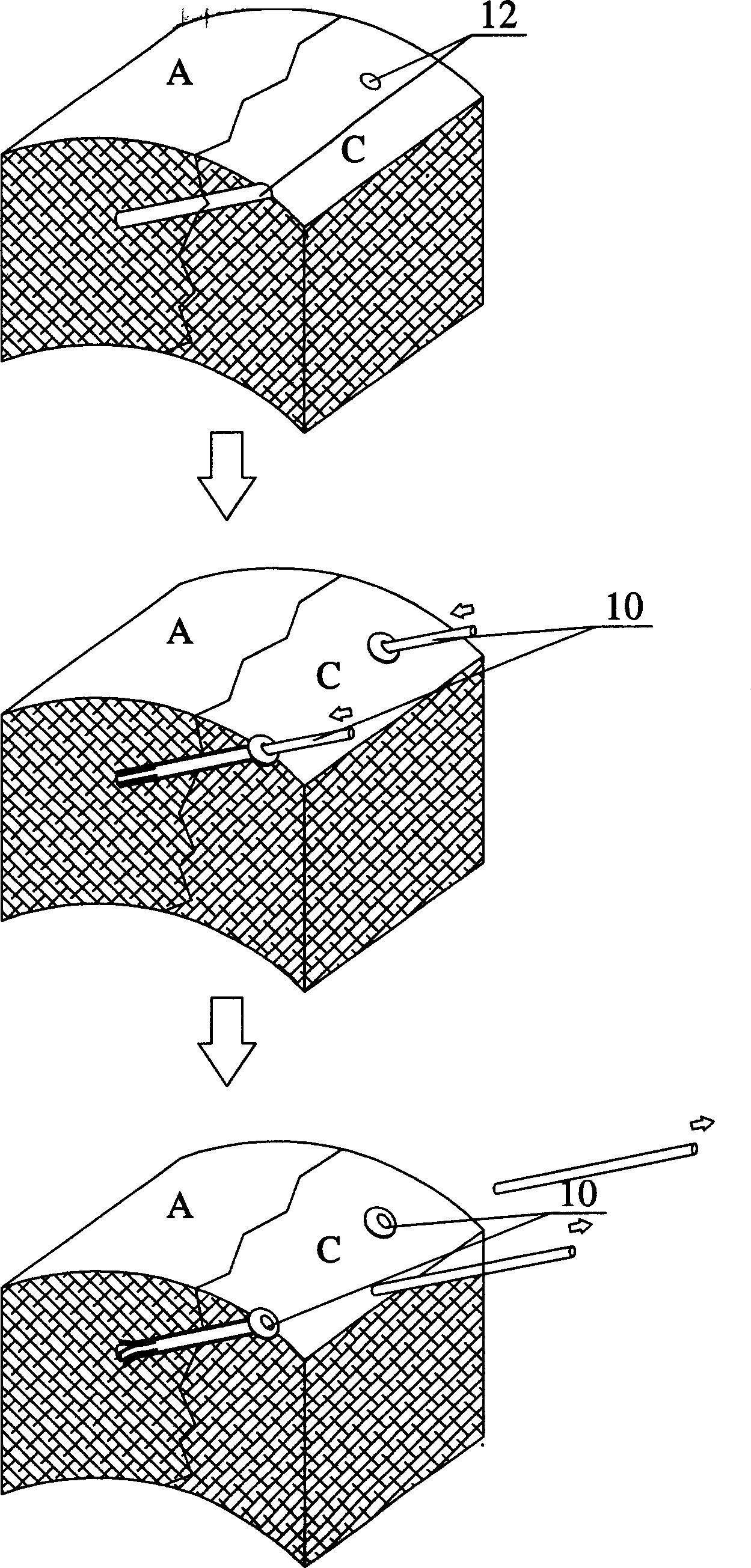

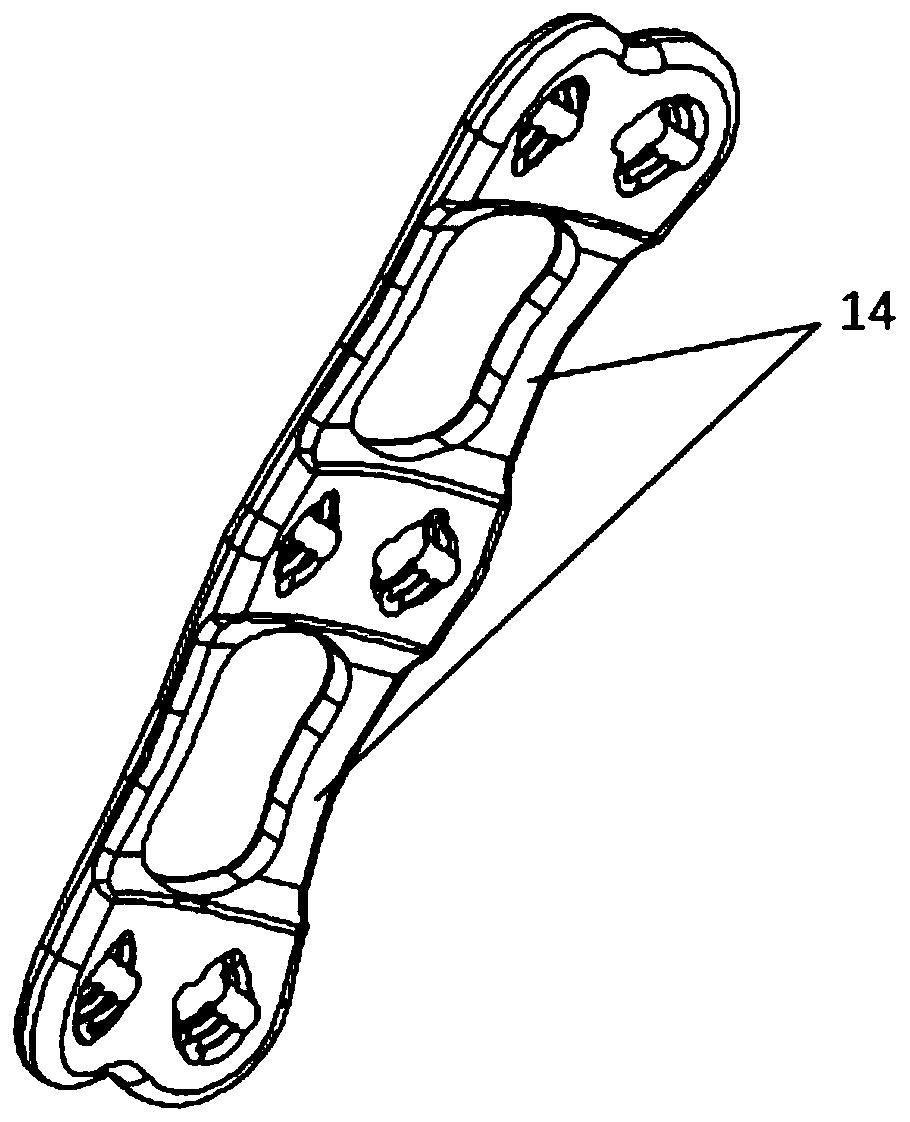

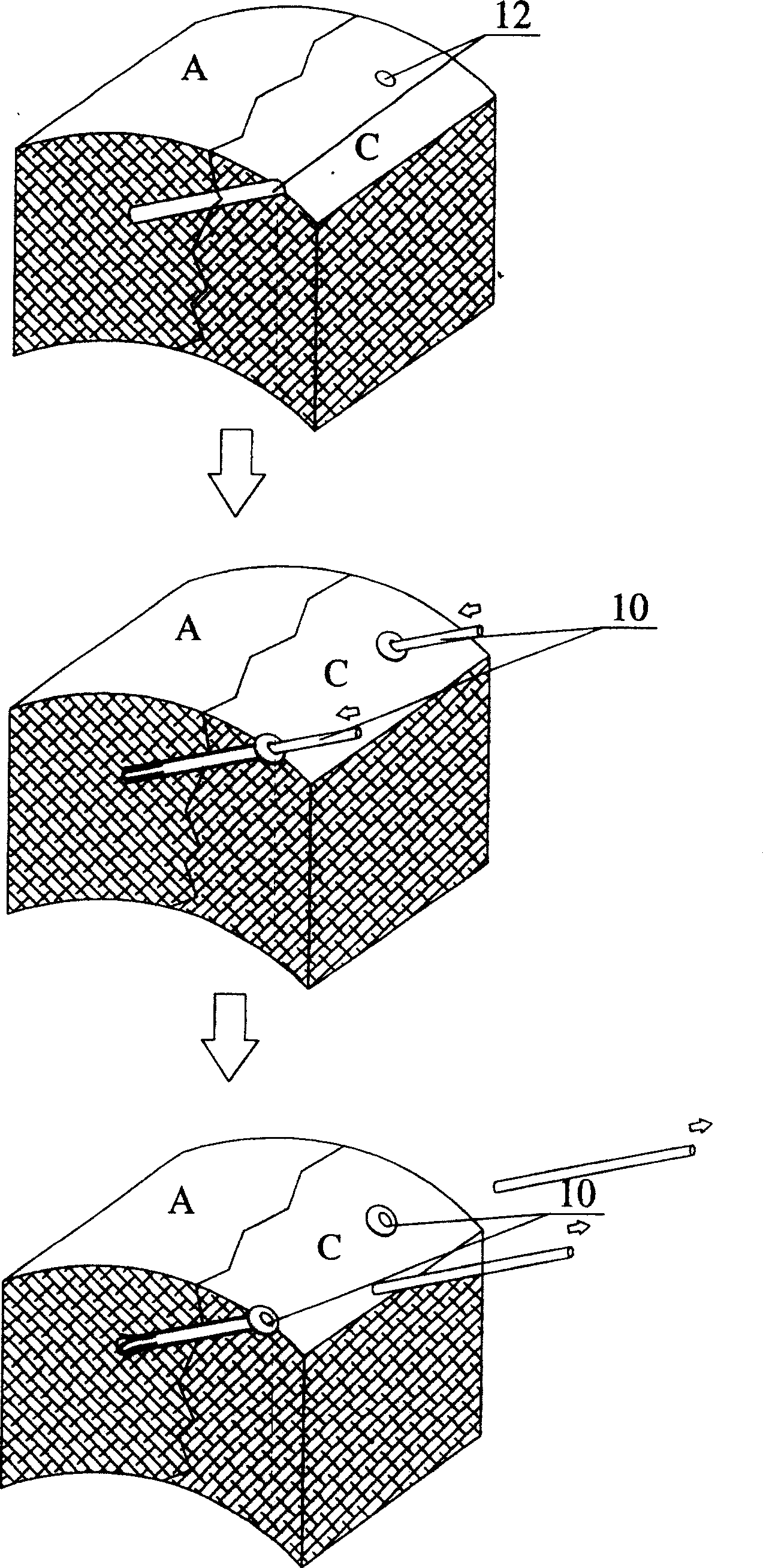

Skeleton fixation method for medical use, and its fixation nails

ActiveCN1785131ASmall lateral pressureAvoid damageInternal osteosythesisFastenersFixation methodUltimate tensile strength

A method for fixing bone in orthopaedic repair operation includes such steps as primary location of fractured bone at the fixing position, installing the fixing nails, deforming the end of said nails for fixing it at the internal side of bone, and using the nail cap to connect the bone to the fixing plate. Said nail features that the deformation at its end is controllable.

Owner:梁巍

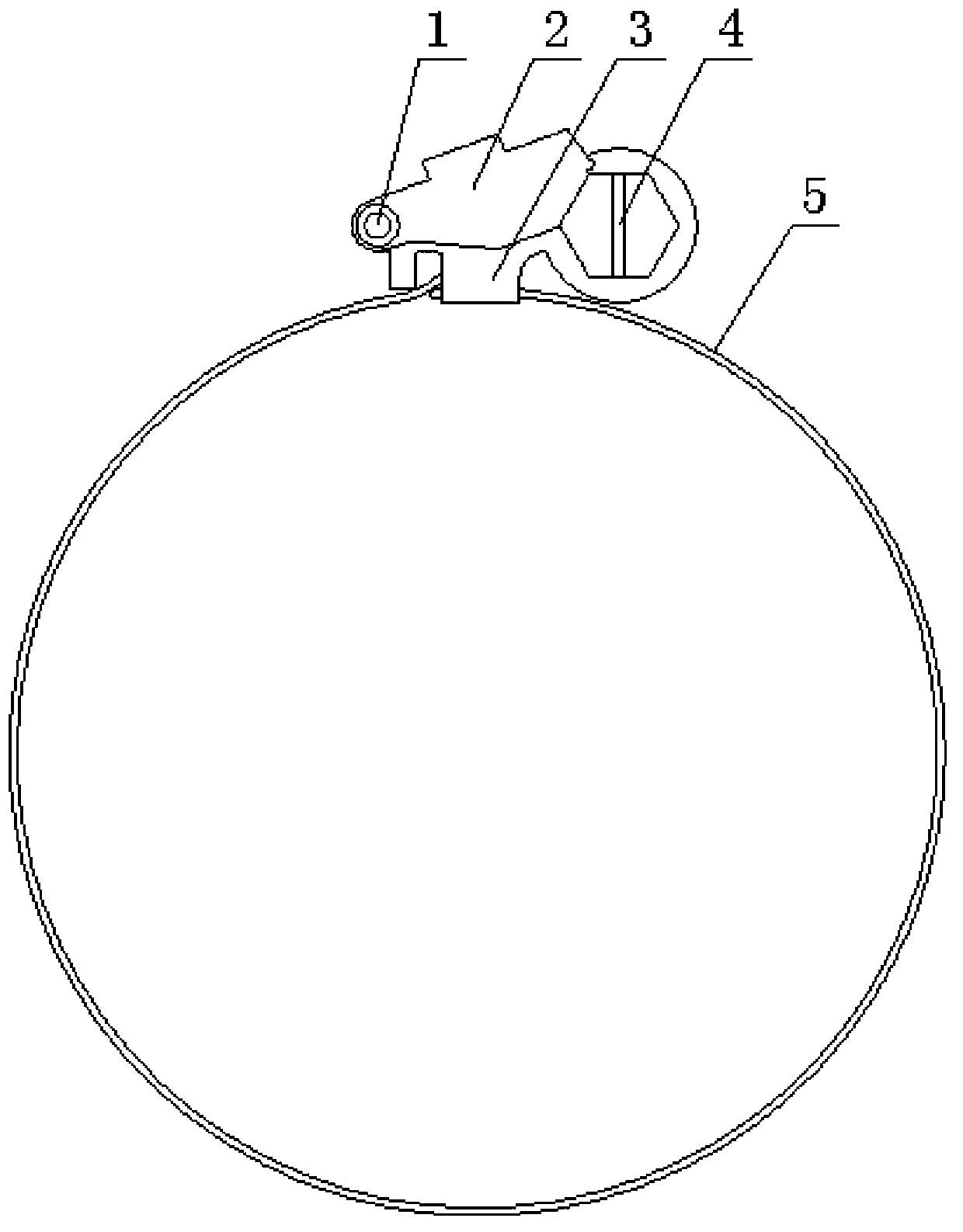

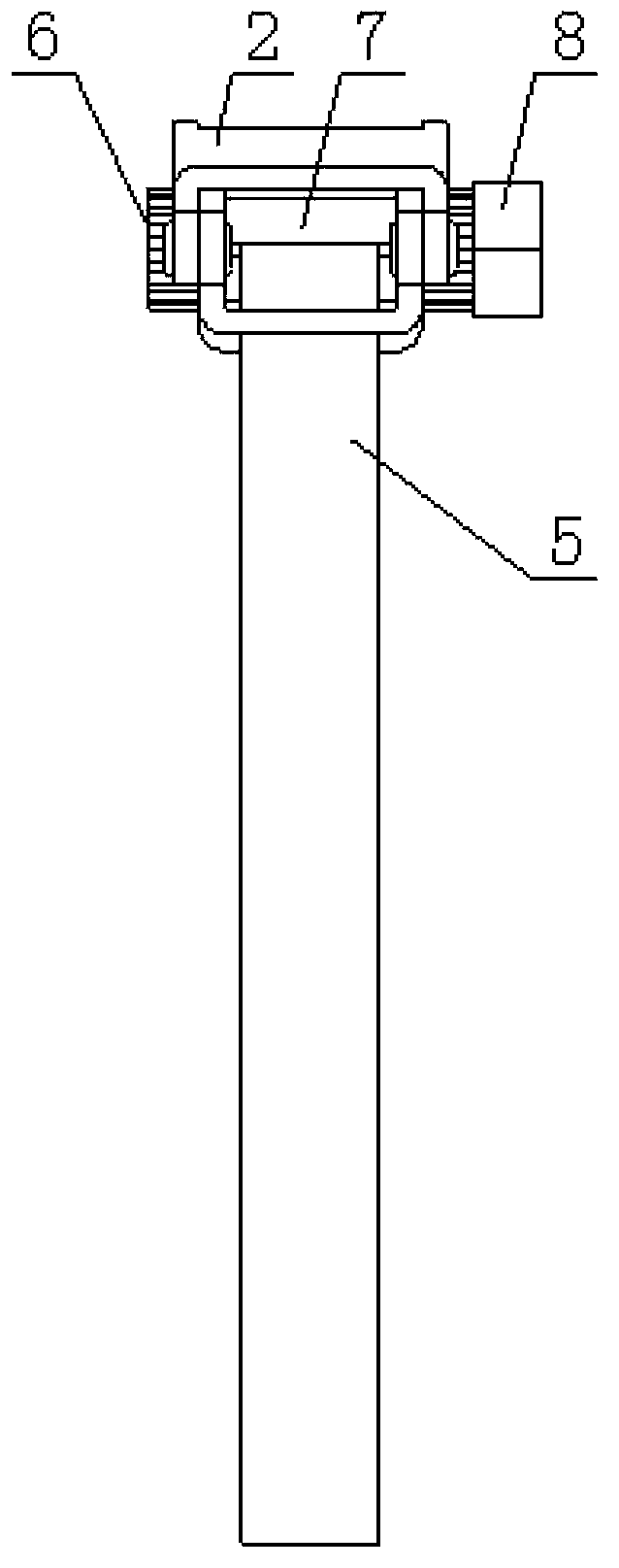

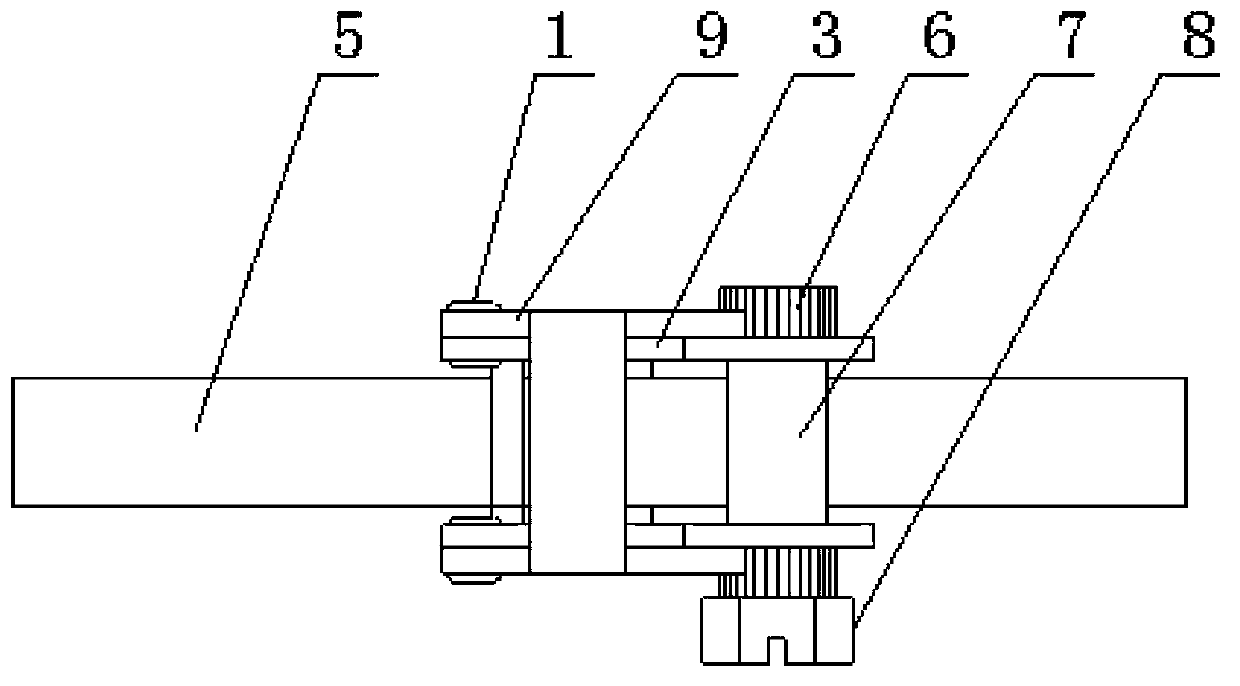

Pipeline anti-damage hose clamp with high fastening forces

The invention relates a pipeline anti-damage hose clamp with high fastening forces, which comprises a strap and is characterized by further comprising a connecting bracket, a retreat preventing baffle group, rivets and a screwing rod, wherein the connecting bracket is fixedly arranged on the fixed end of the strap; a screwing rod installation hole is formed in the head of the connecting bracket; rivet installation holes are formed in the tail of the connecting bracket; the screwing rod is arranged in the screwing rod installation hole in the connecting bracket; a penetrating seam for a free end of the strap is axially formed in the body of the screwing rod; a meshing fluted disc is arranged on the body of the screwing rod; the retreat preventing baffle group is arranged on the rivet installation holes in the connecting bracket through the rivets; and the retreat preventing baffle group is provided with meshing teeth which are engaged with the meshing fluted disc of the screwing rod. The hose clamp has the advantages of being scientific and reasonable in structure design, high in fastening force, quakeproof, capable of preventing pipeline damage, easy in disassembly, difficult in fracture, long in service life and convenient in use, and is a highly innovative hose clamp.

Owner:天津市凯诺实业有限公司

Fixing device

Owner:陈金柱

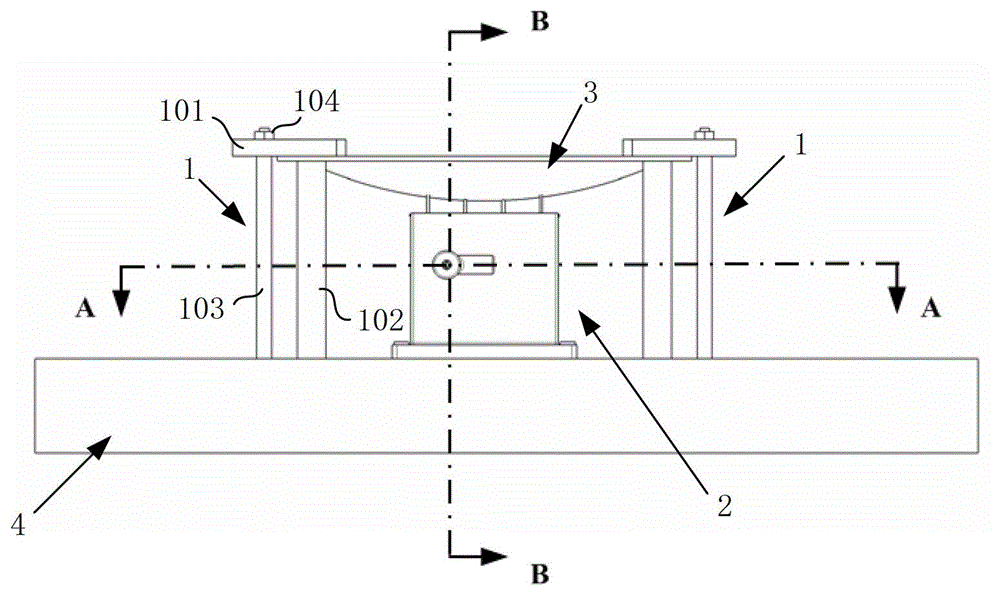

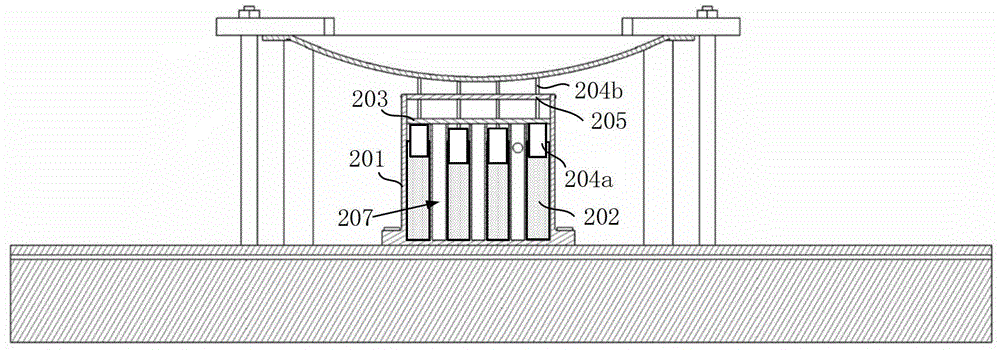

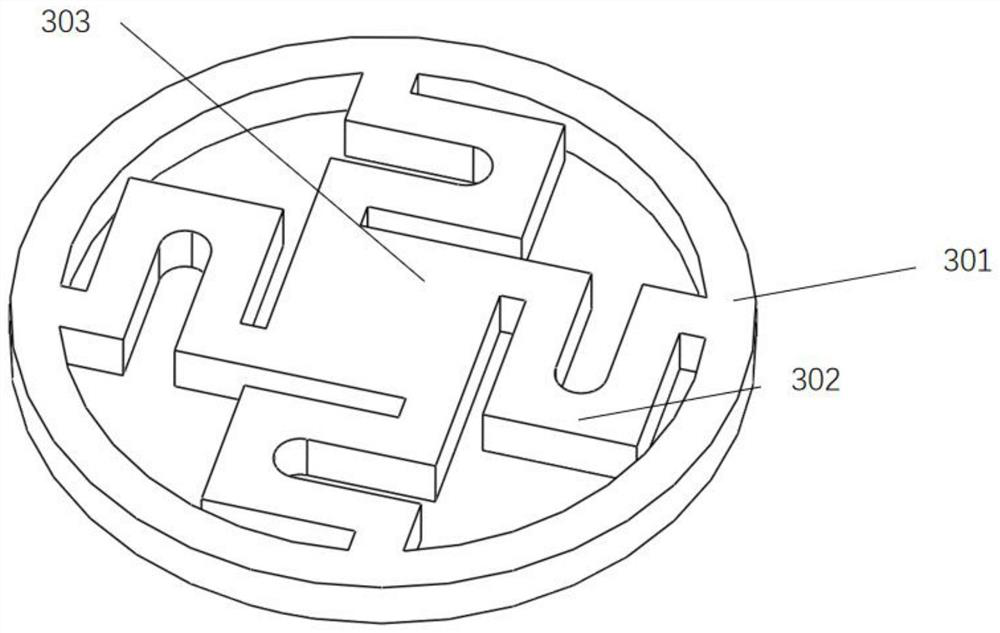

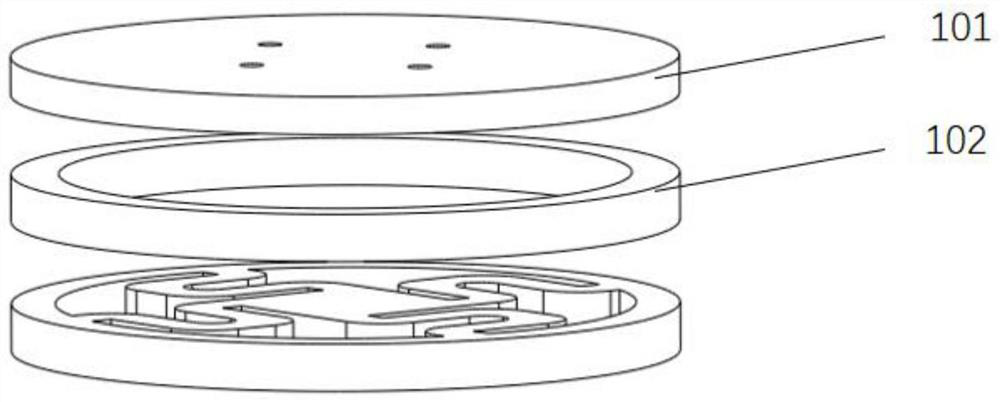

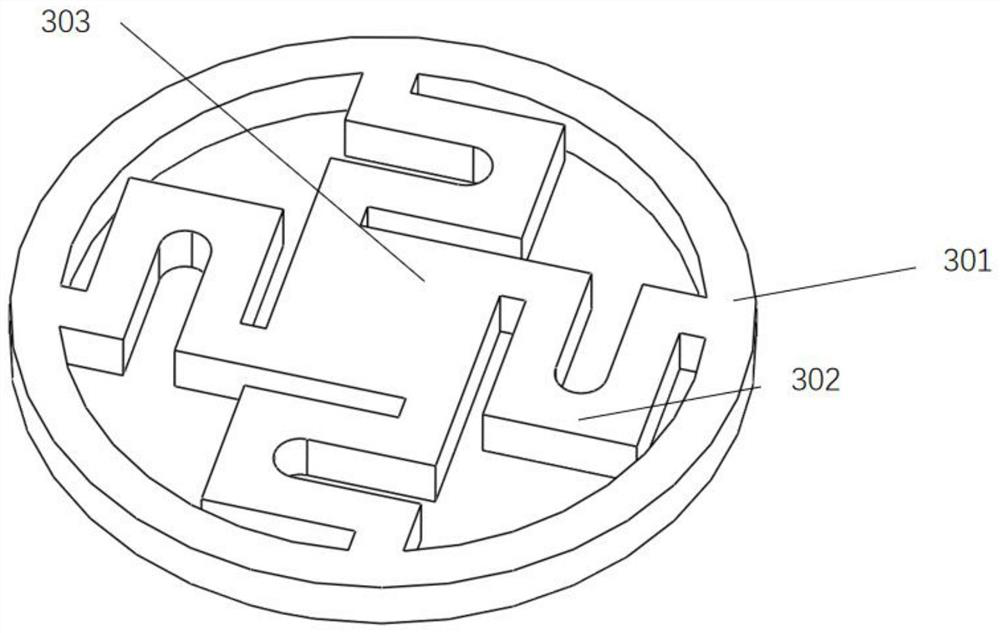

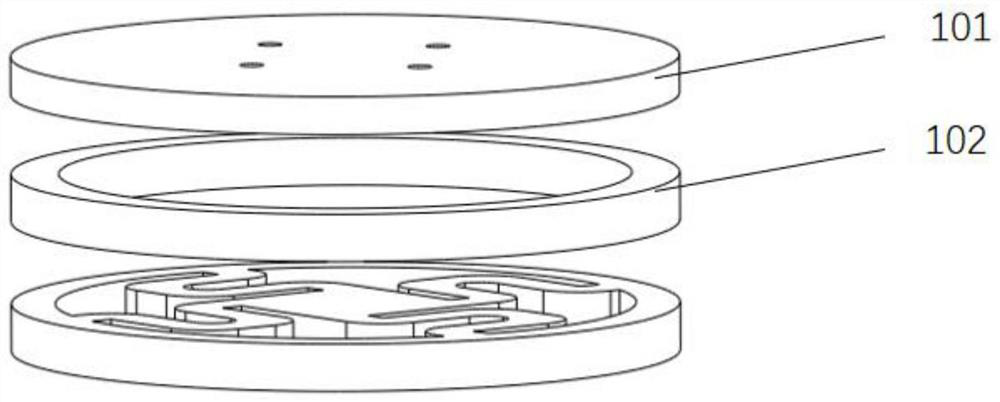

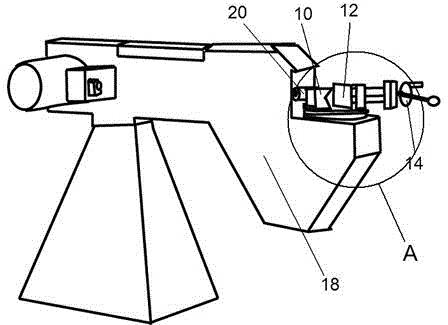

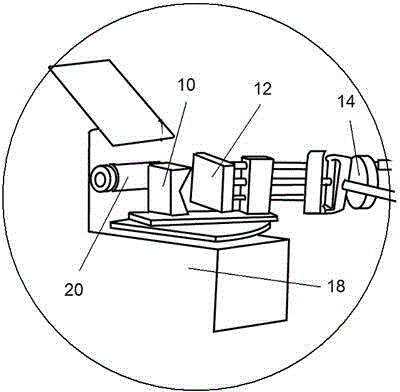

Freezing fixation flexible clamp used for numerical control cutting machining of thin-walled part

InactiveCN103100907BGood effectHigh quality and efficient processingPositioning apparatusMetal-working holdersNumerical controlProcess systems

The invention discloses a freezing fixation flexible clamp used for numerical control cutting machining of a thin-walled part. The freezing fixation flexible clamp used for the numerical control cutting machining of the thin-walled part comprises a clamping mechanism and a longitudinal positioning mechanism, wherein after the clamping mechanism clamps the thin-walled part, the thin-walled part is positioned on a lathe. The longitudinal positioning mechanism is arranged below the thin-walled part on the lathe and is wholly a container containing phase change material, a vertical support is arranged on the upper surface of the phase change material in a floating mode, and a cooling passage is designed between two opposite lateral walls in the container. Therefore, after the clamping mechanism clamps the thin-walled part, the bottom surface of the thin-walled part contacts the support and applies pressure on the support in the process of contacting, and the support is sunk. At present, cooling gas is injected into the cooling passage through a vortex tube to enable the phase change material to be converted into a solid state, the support is frozen and fixed, and longitudinal positioning of the thin-walled part is achieved. The freezing fixation flexible clamp used for the numerical control cutting machining of the thin-walled part has the advantages of being obvious in effect, convenient to achieve, low in cost, and free of pollution to the environment, and effectively improving efficiency and machining quality in the process of numerical control cutting machining of a weak-rigidity process system.

Owner:BEIHANG UNIV

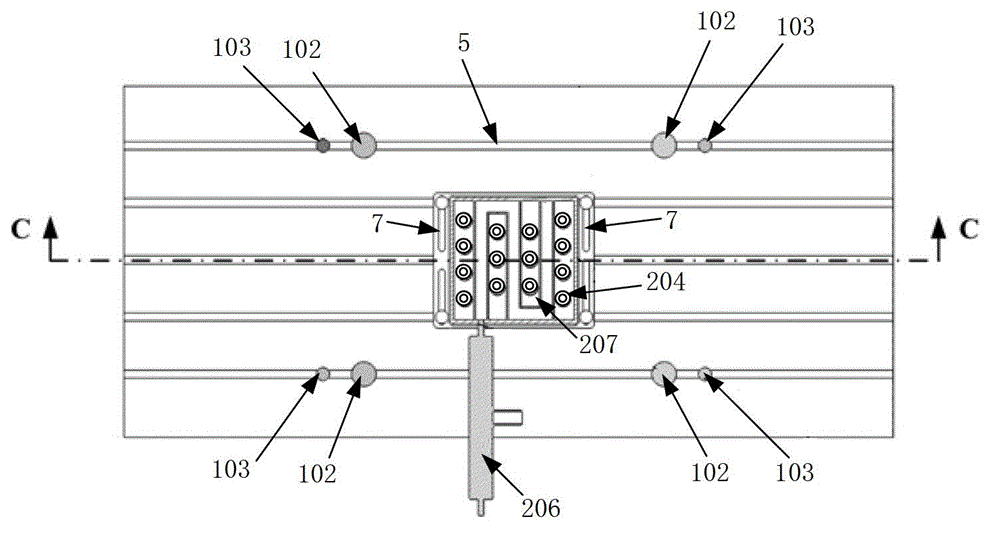

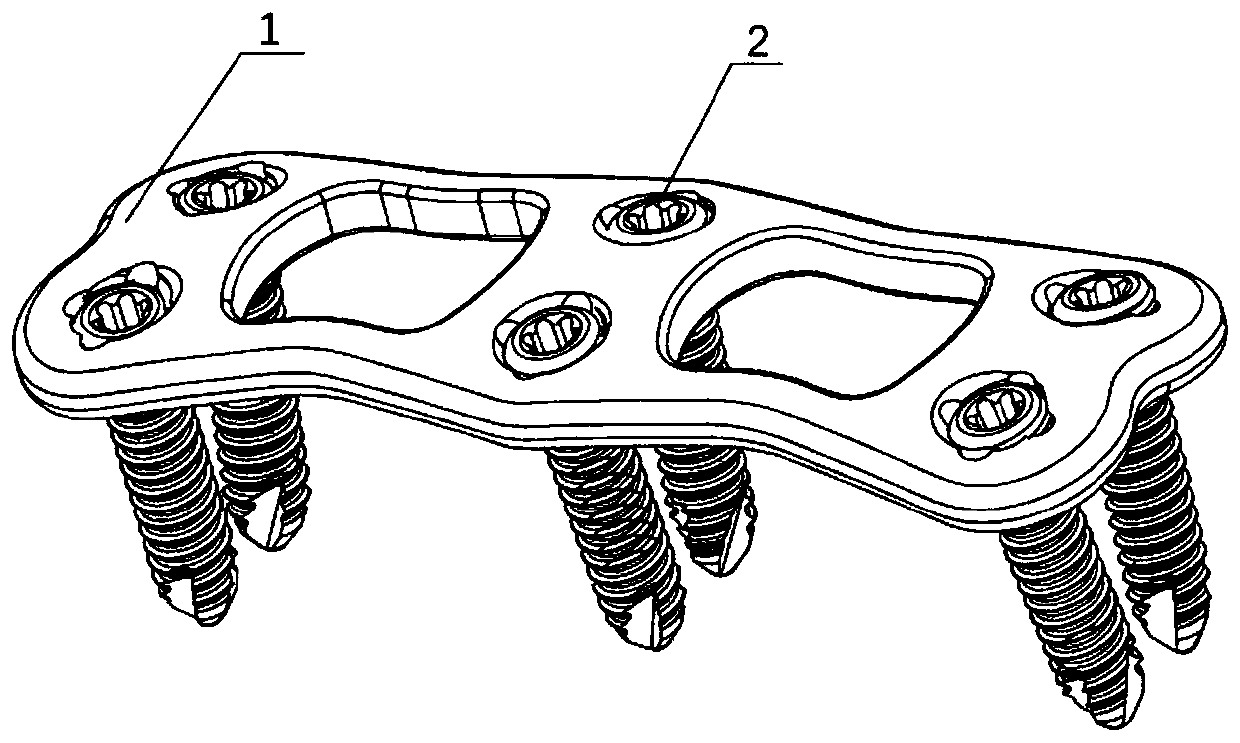

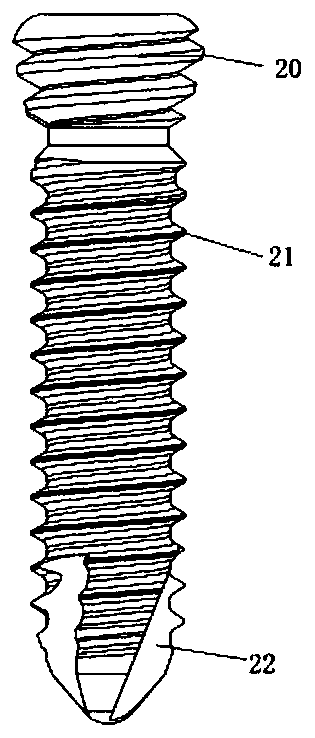

Novel anterior cervical spine fixing plate

PendingCN110731814AStrong fastening forceFixed flexibleInternal osteosythesisFastenersPostoperative complicationBone grafting

The invention relates to a novel anterior cervical spine fixing plate. The novel anterior cervical spine fixing plate comprises a bone setting plate and screws, wherein a plurality of universal locking holes and bone grafting windows are formed in the bone setting plate; arc-shaped decompressing grooves are formed in the bottom of the bone setting plate; each universal locking hole is a threaded hole formed by multi-piece splicing; each screw can be transplanted and locked deviating from an axis center within the range of 0-15 degrees; and a first thread structure, a second thread structure and a tapping auxiliary structure are arranged on each screw. The novel anterior cervical spine fixing plate disclosed by the invention has the advantages that universal transplanting and locking of thescrews can be performed; the structure is simple, additional screw withdrawing preventing device and screw withdrawing preventing operations are not needed, so that surgery time is saved, and the surgery efficiency is improved; and the incisure is low, so that postoperative complications are reduced, and the surgery prognosis life quality of a patient is improved.

Owner:NINGBO HICREN BIOTECH

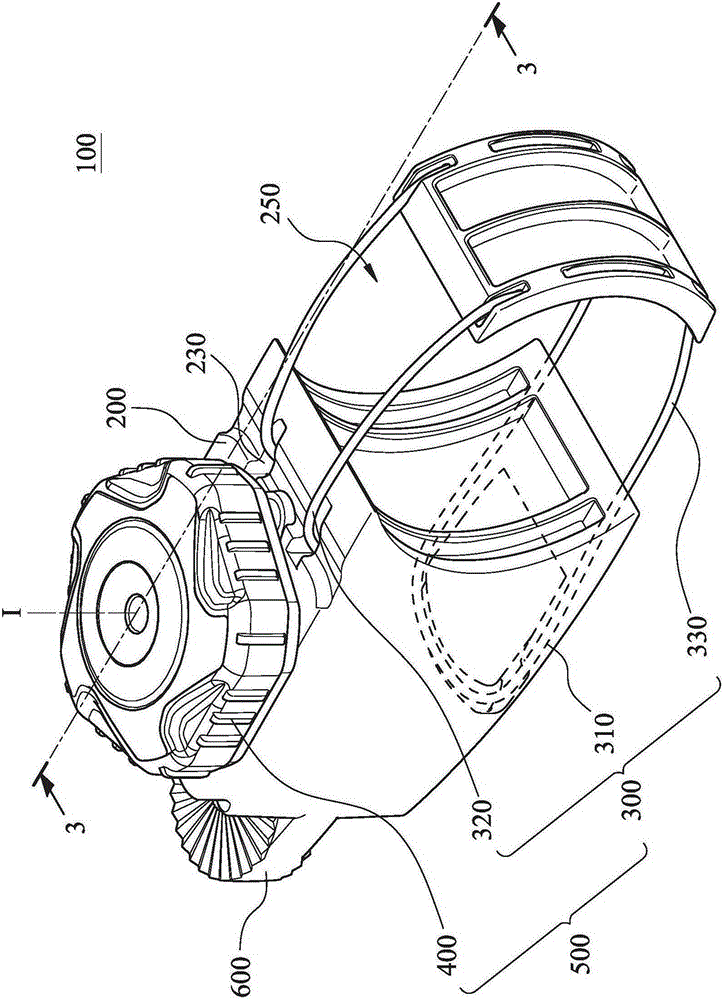

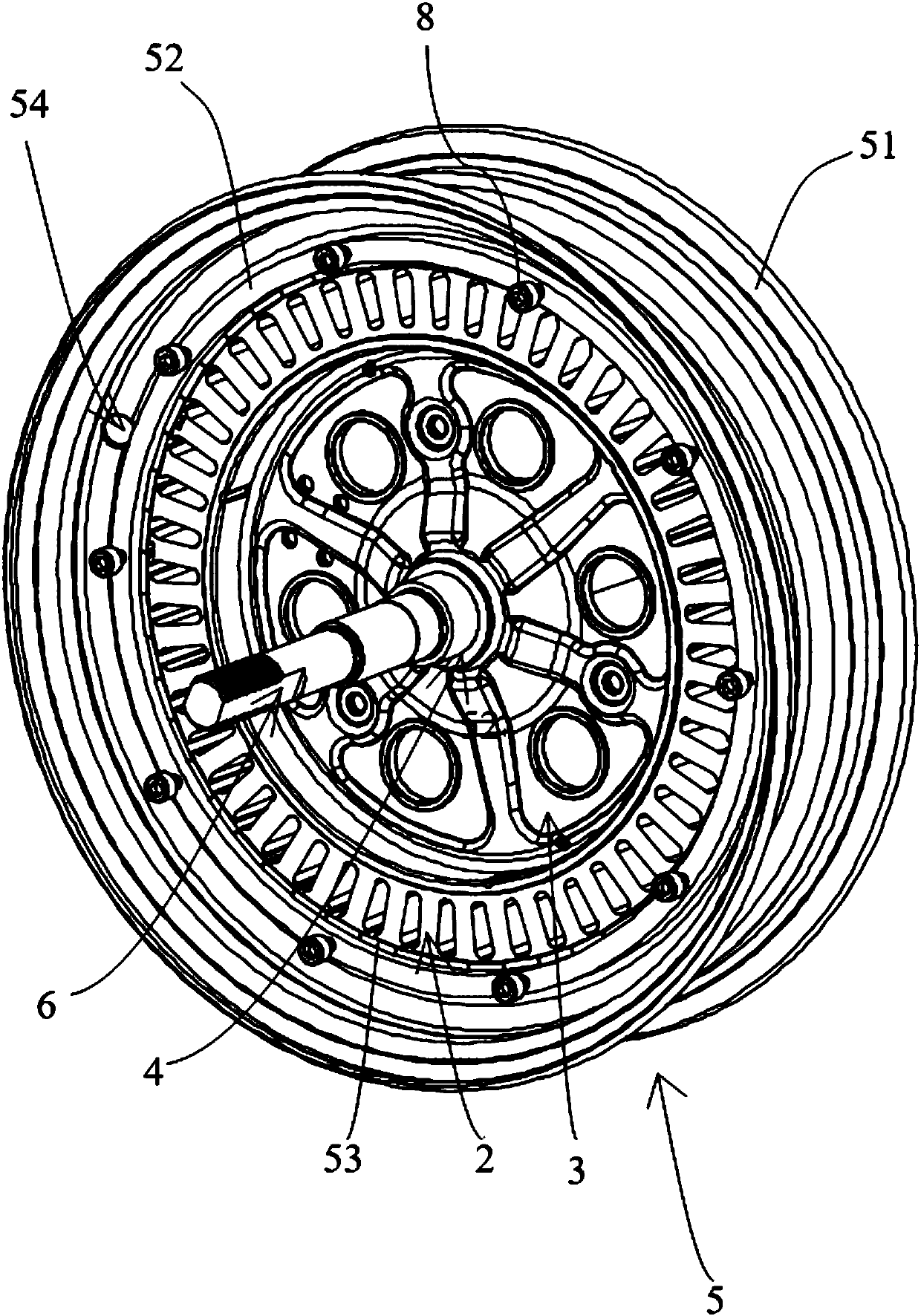

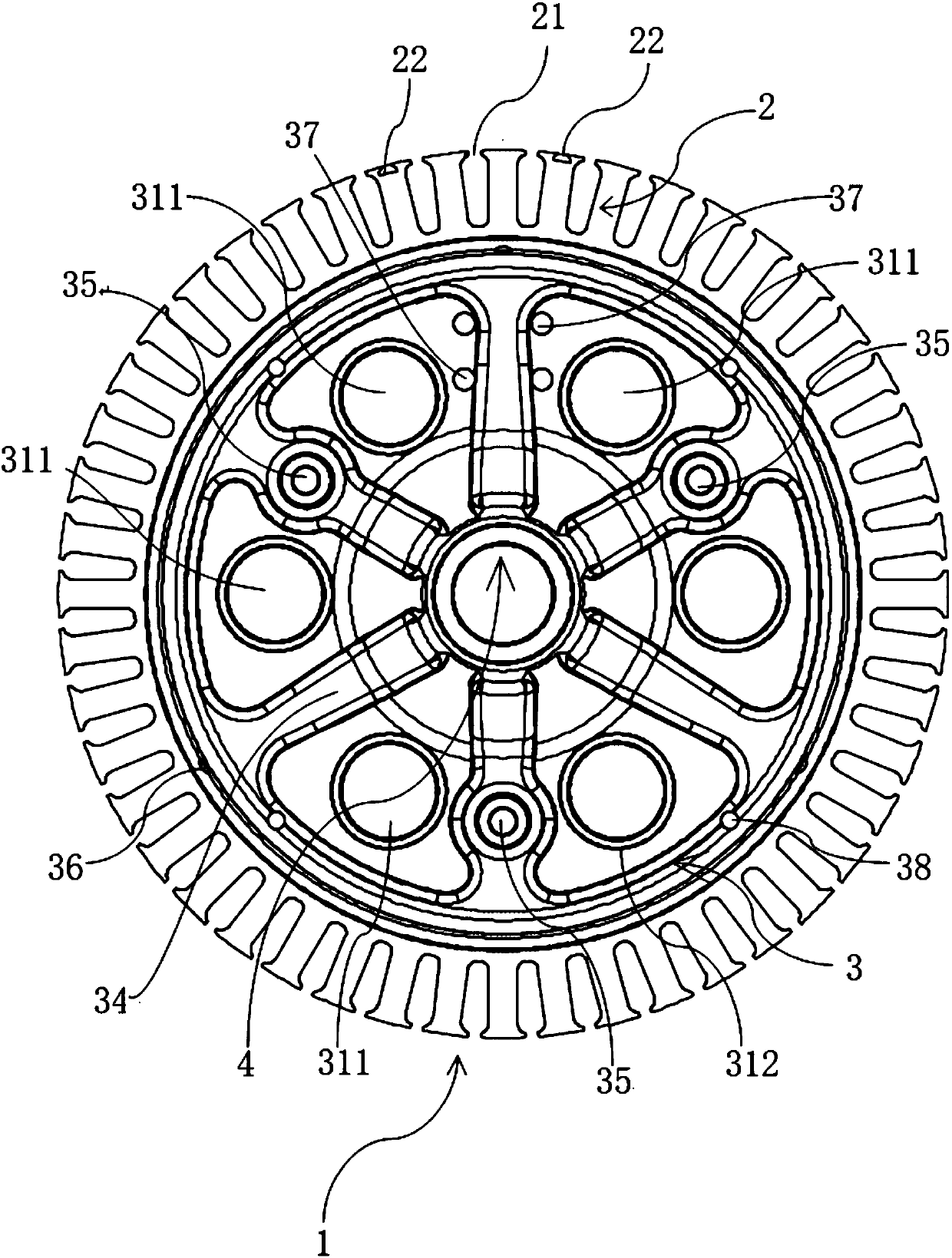

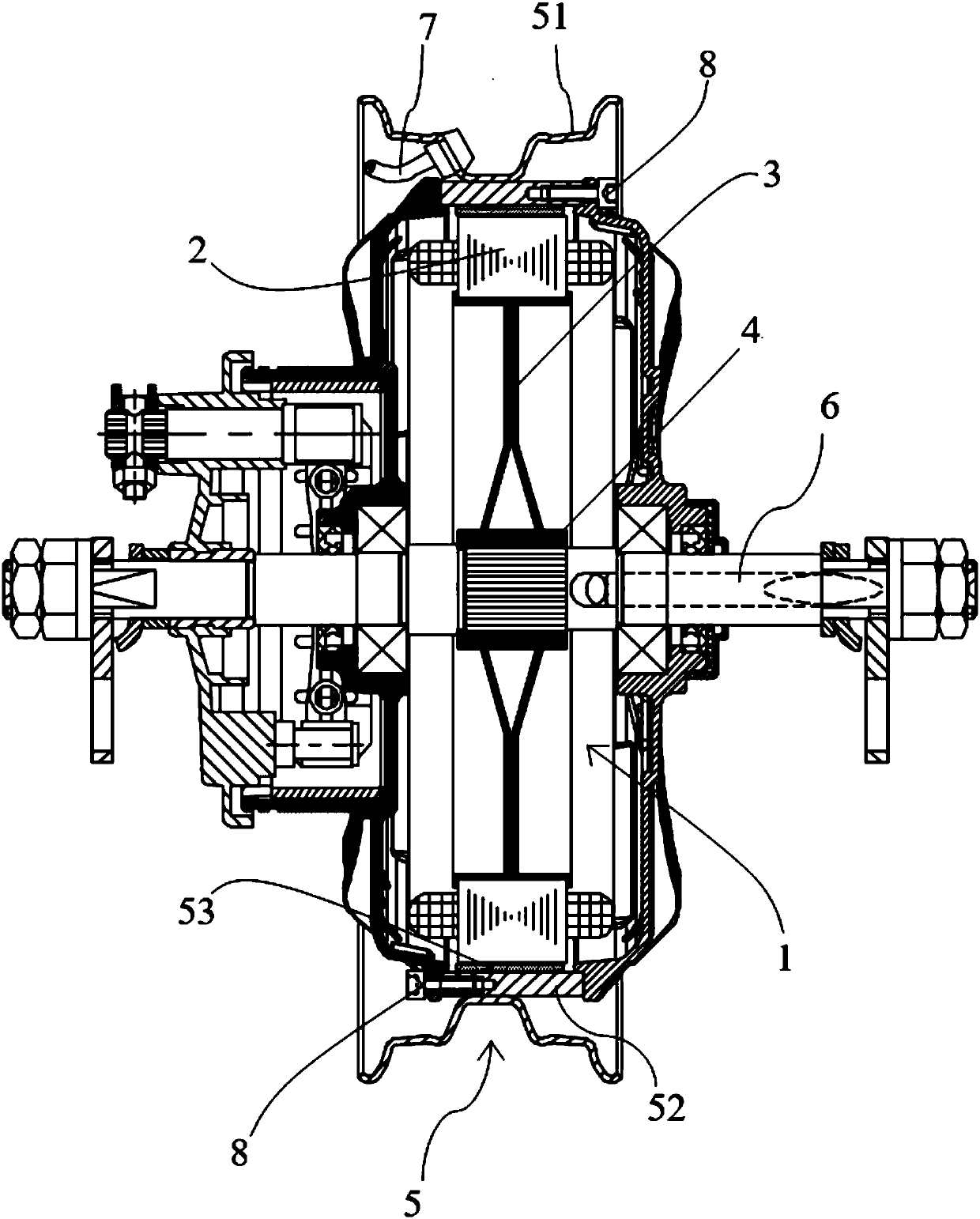

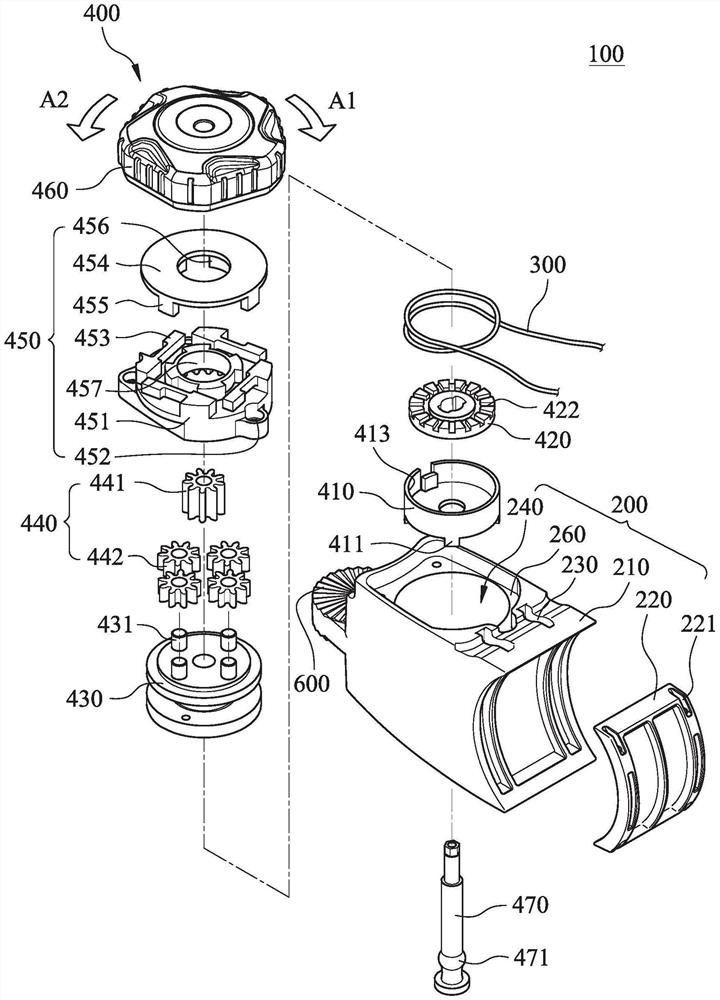

Hub motor for electric vehicle

PendingCN109995179AReduce cogging torqueHigh positioning accuracyElectric machinesMagnetic circuit stationary partsEngineeringElectric vehicle

The invention discloses a hub motor for an electric vehicle, which comprises a stator, a rotor and a connecting shaft, wherein the stator comprises an iron core and a bracket, the iron core is fixed on the bracket and is formed by laminating stator sheets in a spiral winding manner, and the notch width of a tooth socket, the outer diameter of the iron core, the thickness of the tooth lip of the iron core, the inner diameter of the iron core, the thickness of the yoke part of the iron core, the number of the tooth sockets of the iron core and the notch width of the stator sheet meet the following relation: the notch width of the tooth socket = pi x [the outer diameter of the iron core - 2 x the thickness of the tooth lip of the iron core - 2 x alpha x (the inner diameter of the iron core +the thickness of the yoke part of the iron core)] / the number of the tooth sockets of the iron core + the notch width of the stator sheet, wherein the value scope of alpha is 0.45~0.55, and the notch width value scope of the stator piece is 0~2 mm. The hub motor for the electric vehicle has the advantages that: the stator structure optimizes the tooth socket structure of the motor, improves the power density and the working efficiency of the motor, enhances the short-time overload capacity of the motor, reduces the temperature rise and the manufacturing cost of the motor, and prolongs the service life.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

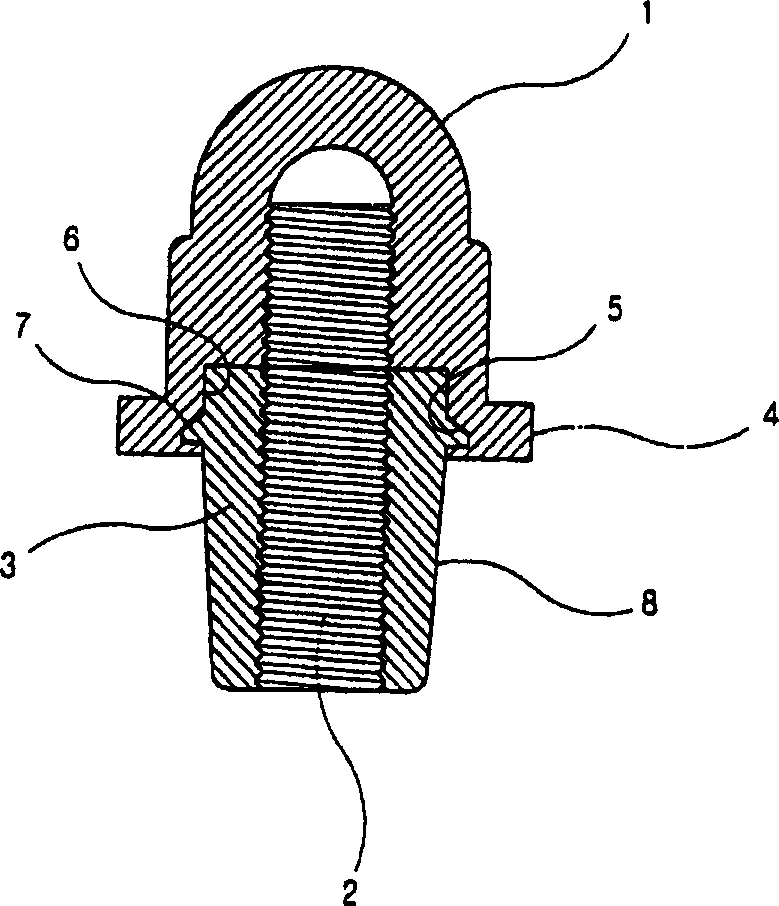

Fastening structure and fastening method

InactiveUS20170218996A1Strong fastening forceStable fastening forceRivetsNutsEngineeringScrew thread

A fastening structure includes a blind rivet and a nut. The blind rivet includes a rivet body having a hollow sleeve, a rivet head at the end of the sleeve and a through-hole; and a mandrel having an elongated stem and a mandrel head. The nut is positioned around the sleeve side end of the rivet body and the mandrel head and abuts one of the workpieces. The end portion of the sleeve is enlarged by the mandrel head and is embedded in the internal screw threads of the nut. The workpieces are thus fastened between the nut and the rivet head.

Owner:NEWFREY

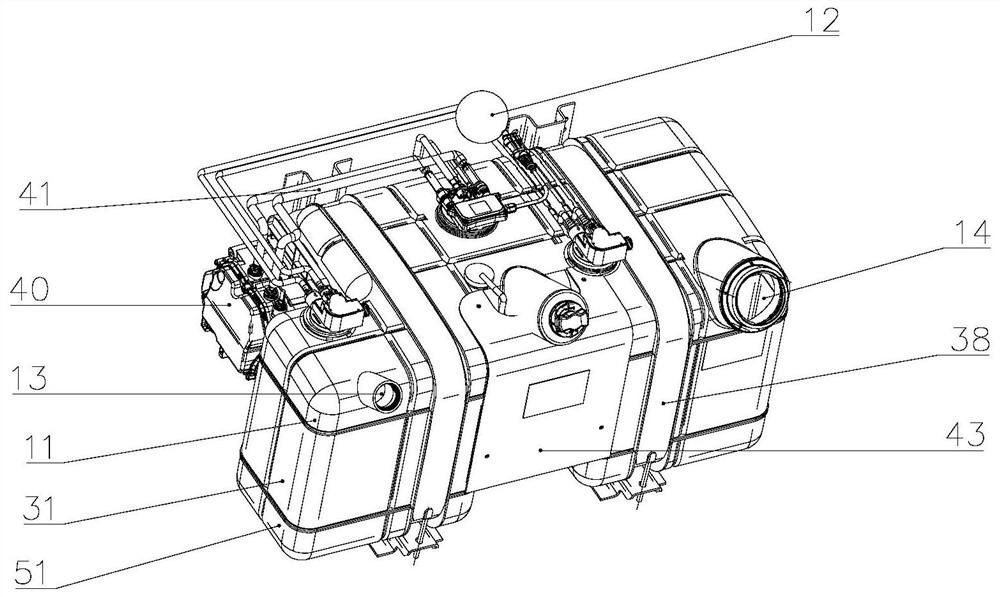

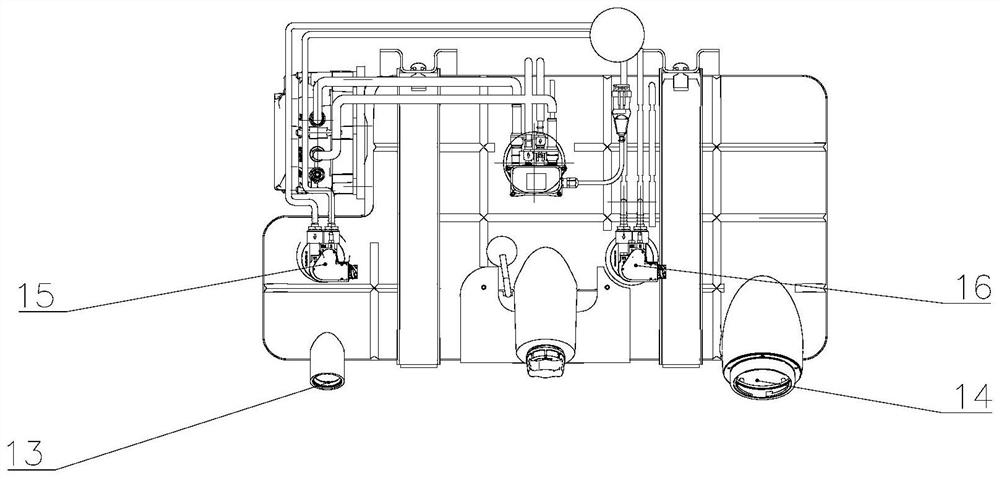

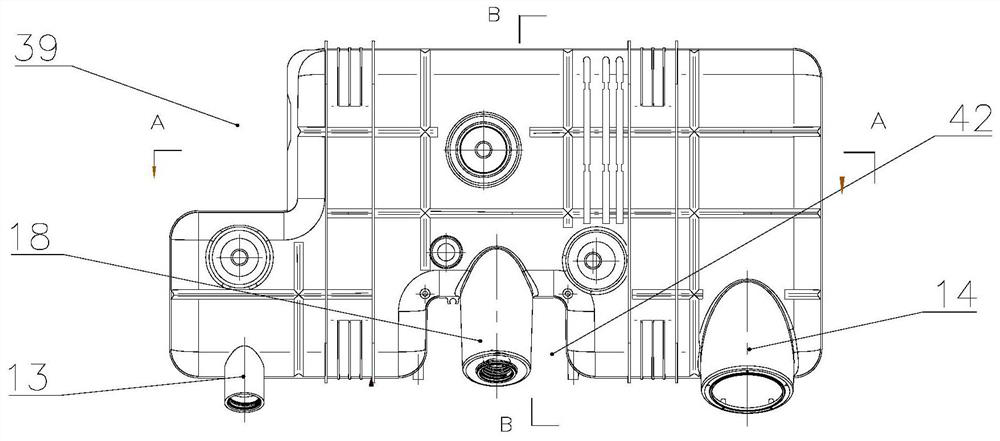

Double oil tanks and integrated double oil tank and urea tank assembly

ActiveCN113427999AImprove rigidityReduce surge phenomenonExhaust apparatusSilencing apparatusFuel tankFuel oil

The invention discloses double oil tanks and an integrated double oil tank and urea tank assembly, and belongs to the field of automobile parts. The double-oil-tank assembly comprises an oil tank shell, the oil tank shell defines a cavity, and the oil tank shell comprises an upper shell area on the upper portion, a middle shell area in the middle and a lower shell area on the lower portion; a middle grid rib structure is arranged in an area, corresponding to the height of the middle shell, in the cavity, the middle part of the cavity is divided into a plurality of middle grid cavities by the middle grid rib structure, the middle grid cavities are not communicated in the radial direction, the middle grid rib structure comprises a first middle grid cavity group and a second middle grid cavity group which are not communicated with each other, the bottom end of the first middle grid cavity group is provided with a first oil passing opening so as to be communicated with each other to form a first fuel oil cavity, the bottom end of the second middle grid cavity group is provided with a second oil passing opening so as to be communicated with each other to form a second fuel oil cavity, and the first fuel oil cavity and the second fuel oil cavity are connected through a conversion valve.

Owner:山东统亚模塑科技实业有限公司

Riveting nail for medical skelecton

ActiveCN100484487CSmall lateral pressureAvoid damageInternal osteosythesisFastenersEngineeringUltimate tensile strength

A method for fixing bone in orthopaedic repair operation includes such steps as primary location of fractured bone at the fixing position, installing the fixing nails, deforming the end of said nails for fixing it at the internal side of bone, and using the nail cap to connect the bone to the fixing plate. Said nail features that the deformation at its end is controllable.

Owner:梁巍

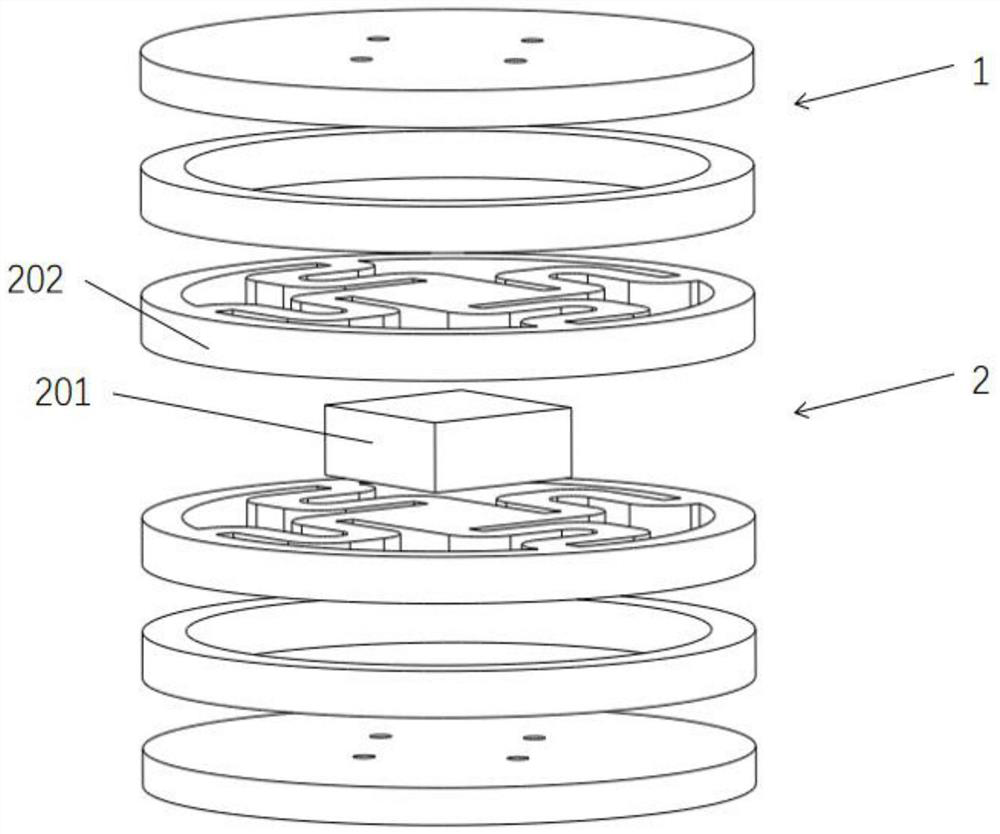

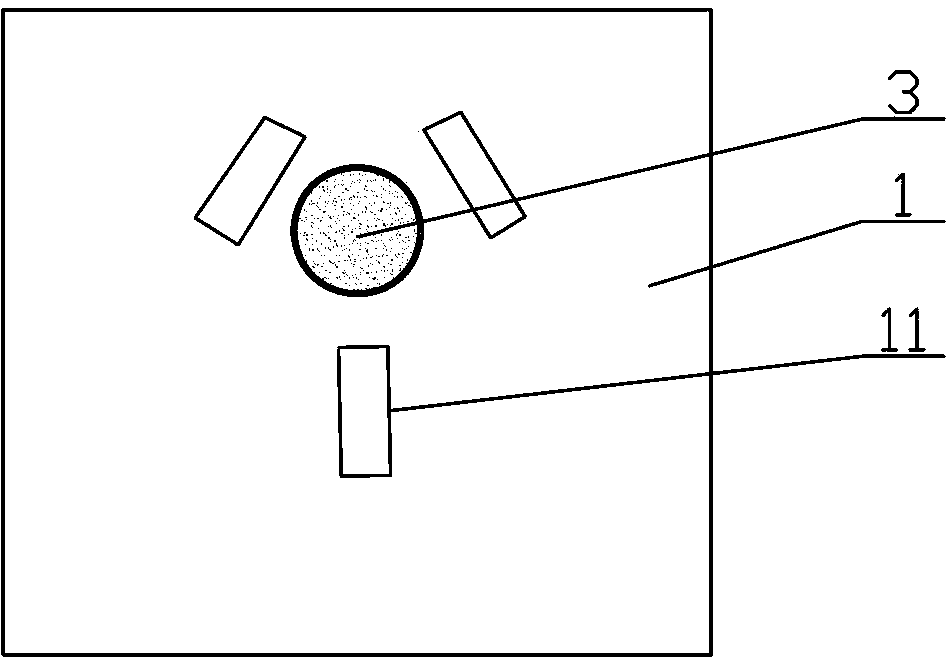

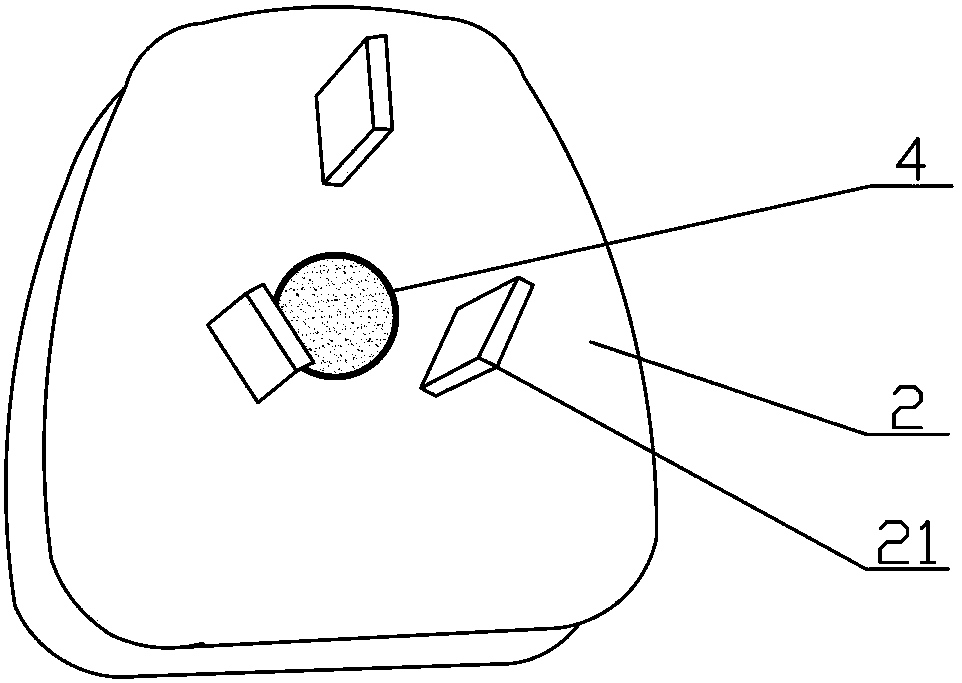

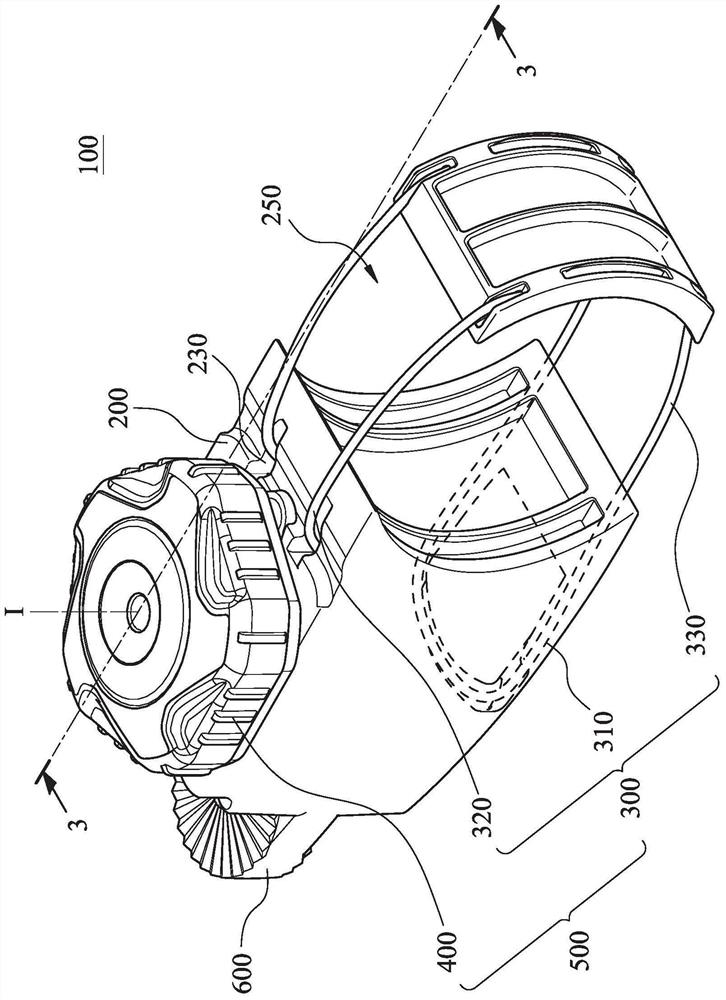

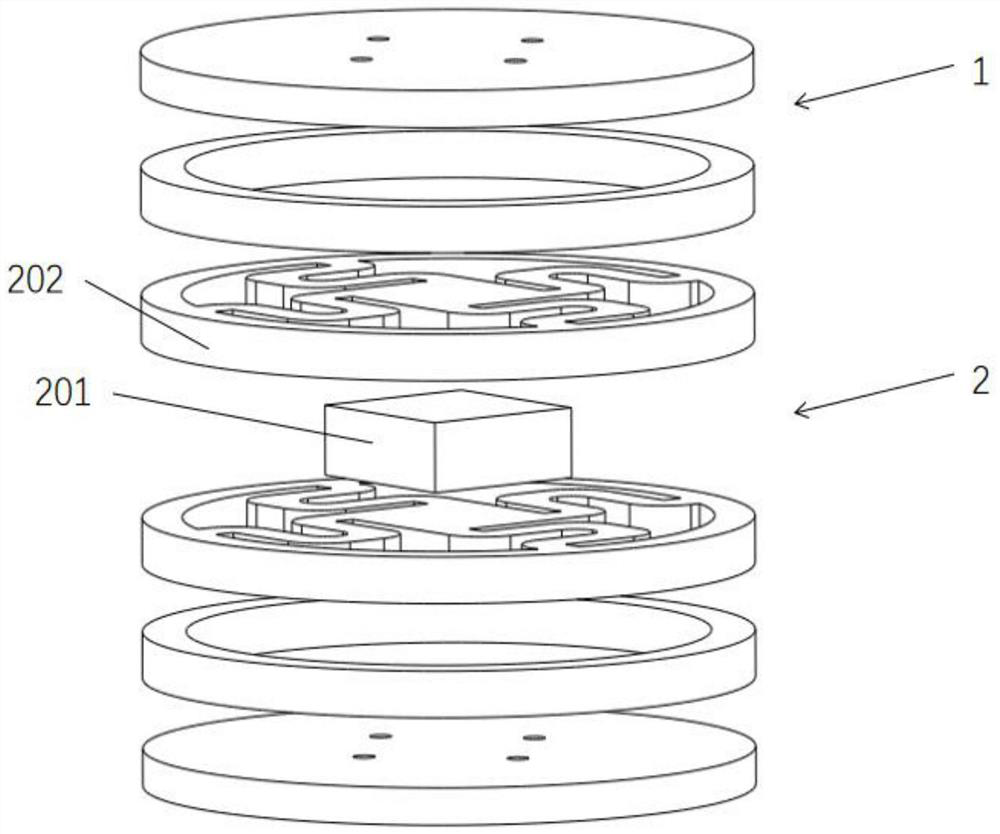

Passive compliance device

ActiveCN111993394AStrong fastening forceAdd passive soft functionProgramme-controlled manipulatorStructural engineeringSelf adaptive

The invention provides a passive compliance device which comprises two connecting parts and a compliance part. The compliance part is arranged between the two connecting parts, the compliance part isa structural part made of a flexible material, the compliance part is used for carrying out adaptive compliance when the passive compliance device is stressed, the connecting parts are used for fixingthe compliance part, the sides, away from the compliance part, of the connecting parts are used for being connected with external devices, and the connecting part is used for transmitting the compliance effect of the compliance part. The passive compliance device can perform passive compliance on the contact of an adjusting tail end of a robot.

Owner:CENT SOUTH UNIV

Magnetic-attraction fall-off-preventing connector

InactiveCN103794942AStrong fastening forceEasy to useEngagement/disengagement of coupling partsEngineeringMagnetic poles

The invention discloses a magnetic-attraction fall-off preventing connector which includes a socket and a plug. A magnet a is installed on the socket. A magnet b is arranged on a position of the plug, corresponding to the magnet a. Magnetic poles of contact ends of the magnet a and the magnet b are opposite poles. The magnet a is arranged on the socket and the magnet b is arranged on the plug and the contact ends of the magnet a and magnet b are opposite in magnetic poles so that the socket and the plug can absorb each other through making use of the magnetic attraction force of the magnet a and the magnet b and thus it is ensured that the plug is stilled fastened on the socket under the action of an external force. When a power line is subjected to impacts of a powerful external force, the plug can fall off before the power line is broken so that use security is ensured. The connector has the advantages of being simple in structure, reliable in plug-in connection, low in cost, safe to use and large in fastening force.

Owner:江苏省天一中学

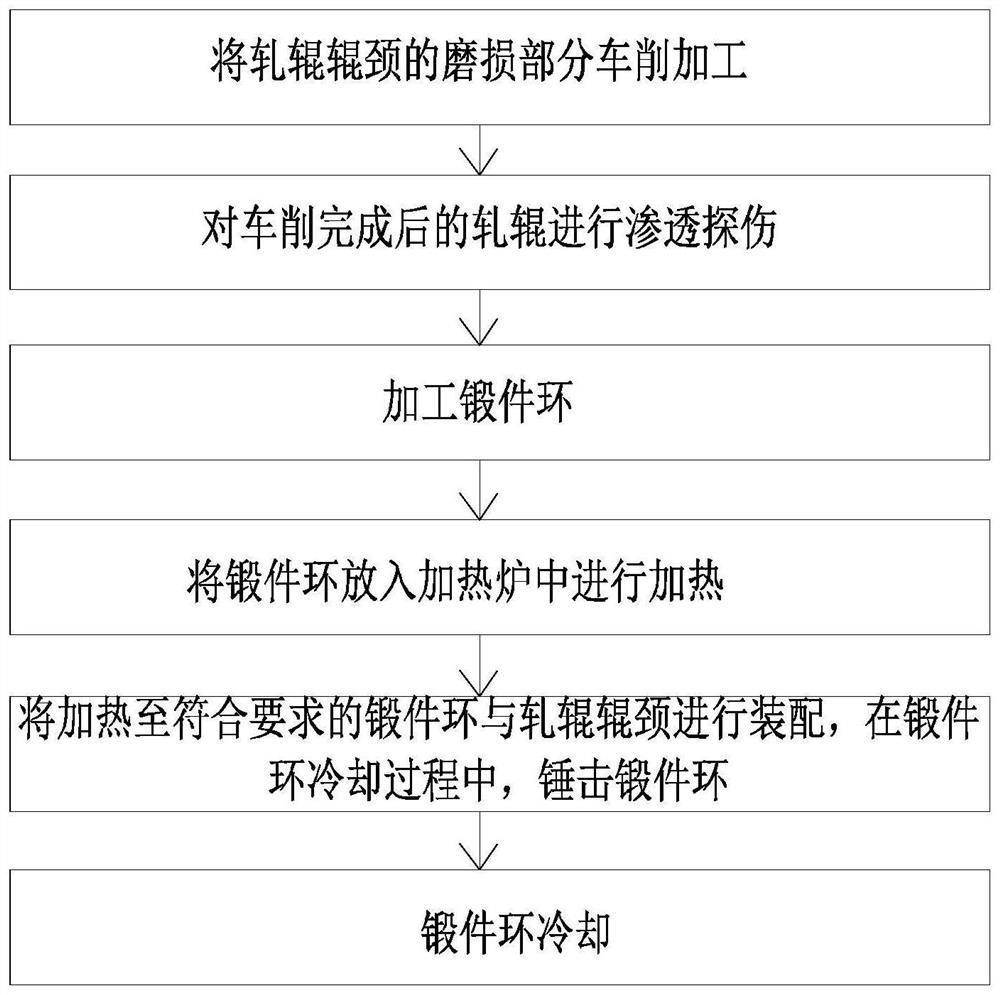

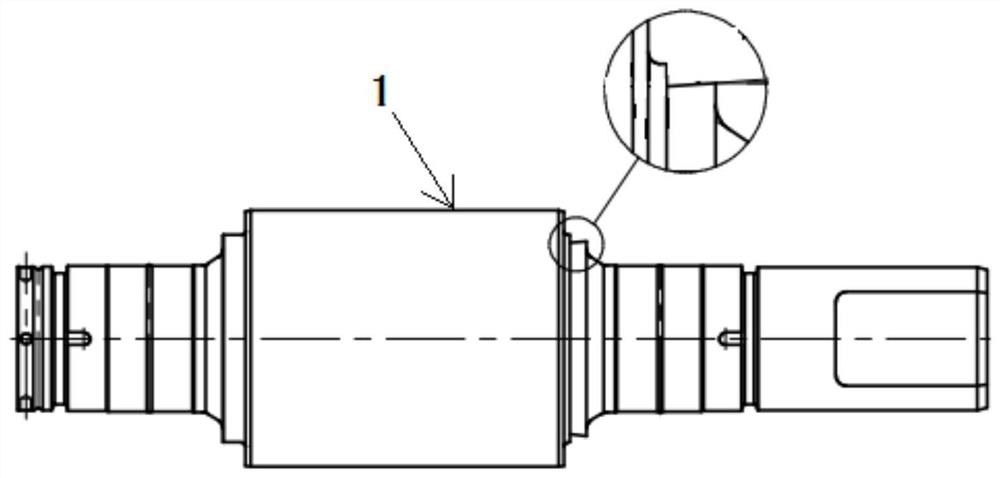

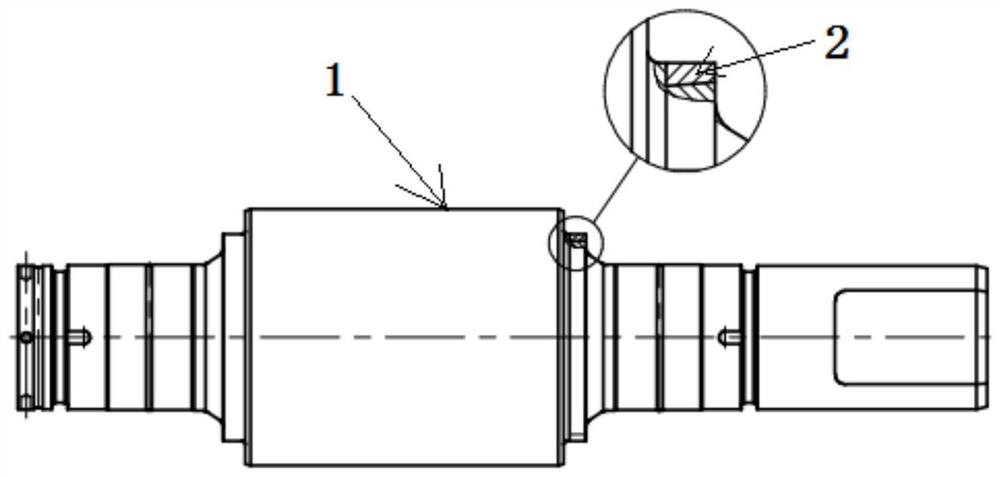

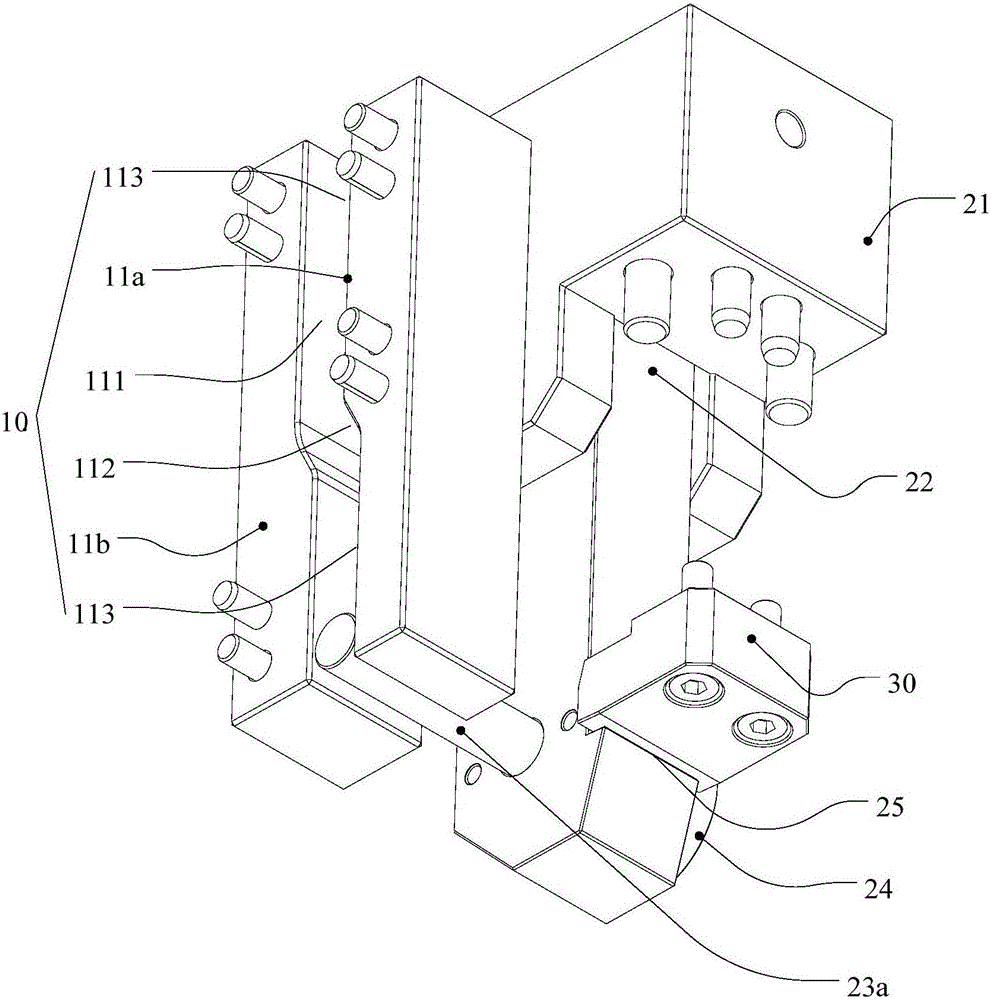

Roller repairing method

PendingCN113441902AShedding doesn't happenIncrease the amount of interferenceStructural engineeringHeating furnace

The invention provides a roller repairing method which comprises the following steps: step 1, carrying out turning processing on the surface of the roller neck part of a roller and removing the abraded part of the surface, so as to obtain the clean roller surface; step 2, carrying out penetrant flaw detection on the turned roller and detecting whether sunken parts exist on the roller surface or not; step 3, processing a forging ring, wherein the interference magnitude of the forging ring ranges from 0.4 / 1000 mm to 0.6 / 1000 mm; step 4, putting the forging ring into a heating furnace for heating and measuring the size of an inner hole in the forging ring in the heating process; step 5, assembling the forging ring which is heated to meet the requirement with the roller neck of the roller and hammering the forging ring in the forging ring cooling process the forge piece ring, so as to ensure that the forging ring can be tightly matched with the end surface of the roller; and step 6, completing the assembling and repairing operation after the forging ring is cooled. Through the roller repairing method, the problem that when a pin shaft is used for fastening in a structure of the prior art, the position of a pin hole in a ring component is fractured and even the ring component falls off can be solved.

Owner:成都三强轧辊股份有限公司

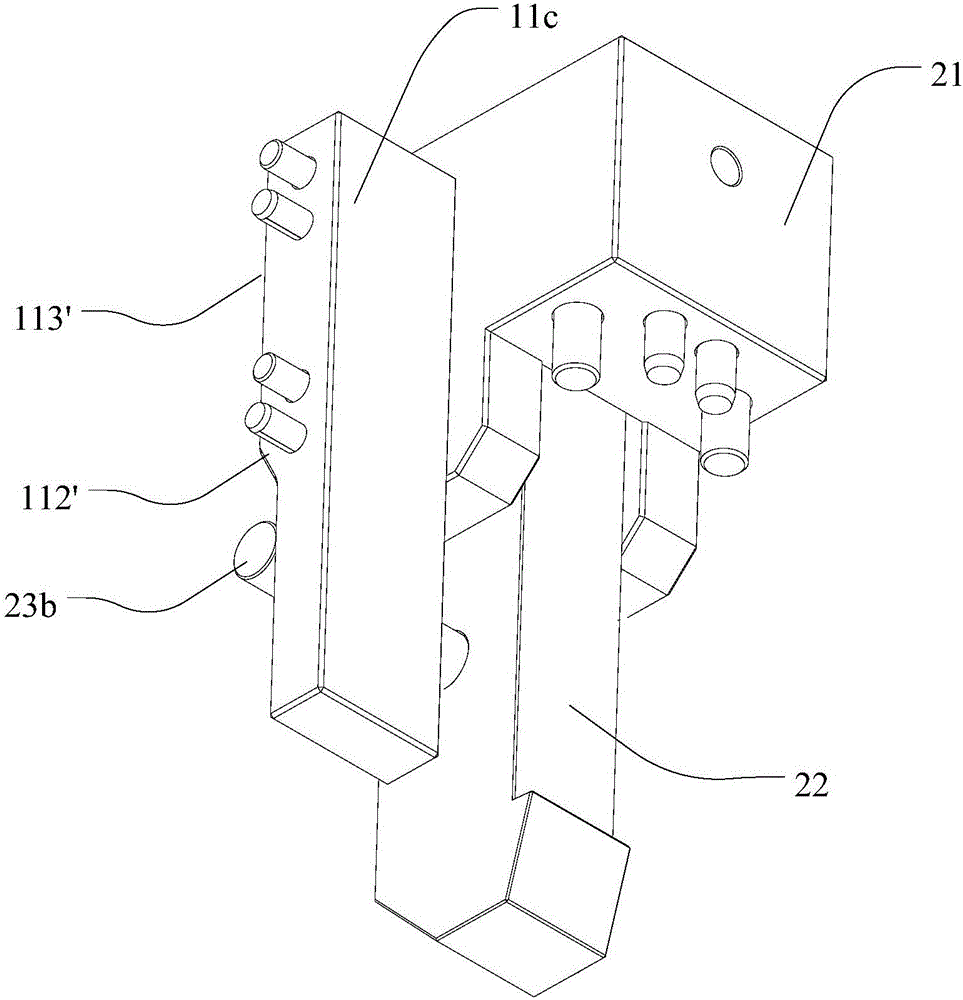

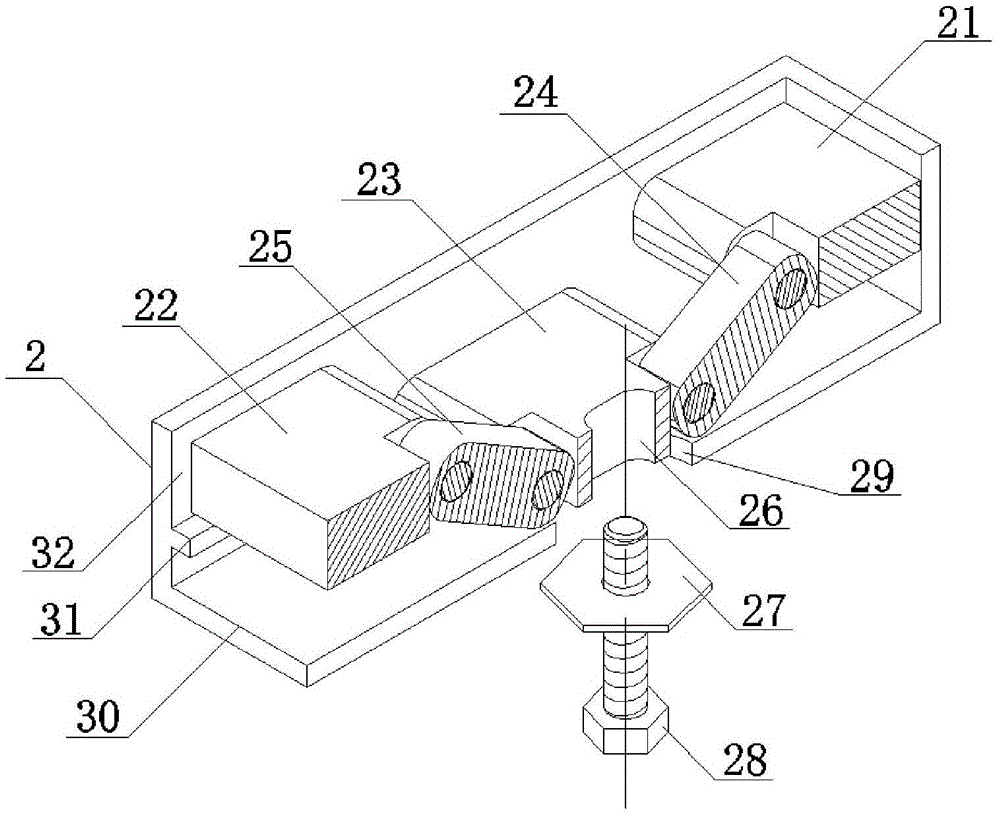

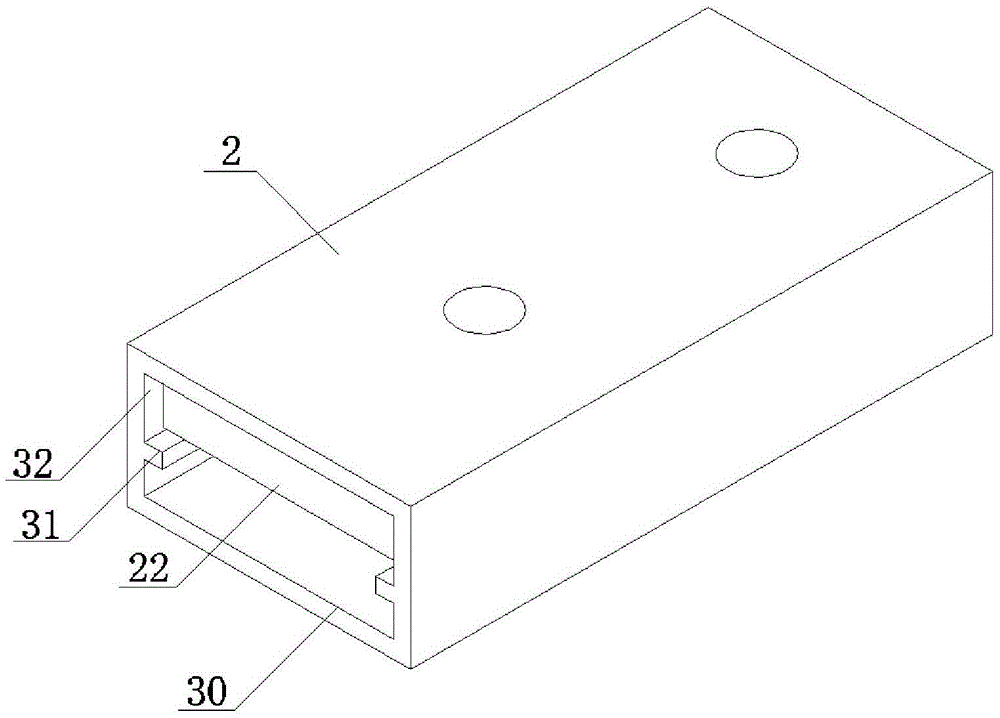

Double ejection mechanism and injection mold

ActiveCN105773934AAvoid the phenomenon of stuck failureStrong fastening forceMechanical engineeringEngineering

The invention discloses a double ejection mechanism and an injection mold, wherein the double ejection mechanism comprises a guide piece detachably connected to a die support, a bracket detachably connected to a first ejector plate of the die, and a first drag hook hinged to the bracket; the first drag hook is matched with the guide piece; during primary ejection, the first drag hook is hooked on a second ejector plate of the die, and the second ejector plate moves along with the first ejector plate; and when the first drag hook moves to a secondary ejection station along with the first ejector plate and the second ejector plate, the guide piece drives the first drag hook to swing, the second ejector plate is released and stops moving, and the first ejector plate continues to move and complete secondary ejection. The technical scheme is simple in structure, strong in practicability, high in reliability, convenient to operate, steady in structure and easy to machine.

Owner:SHENZHEN SILVER BASIS TECH

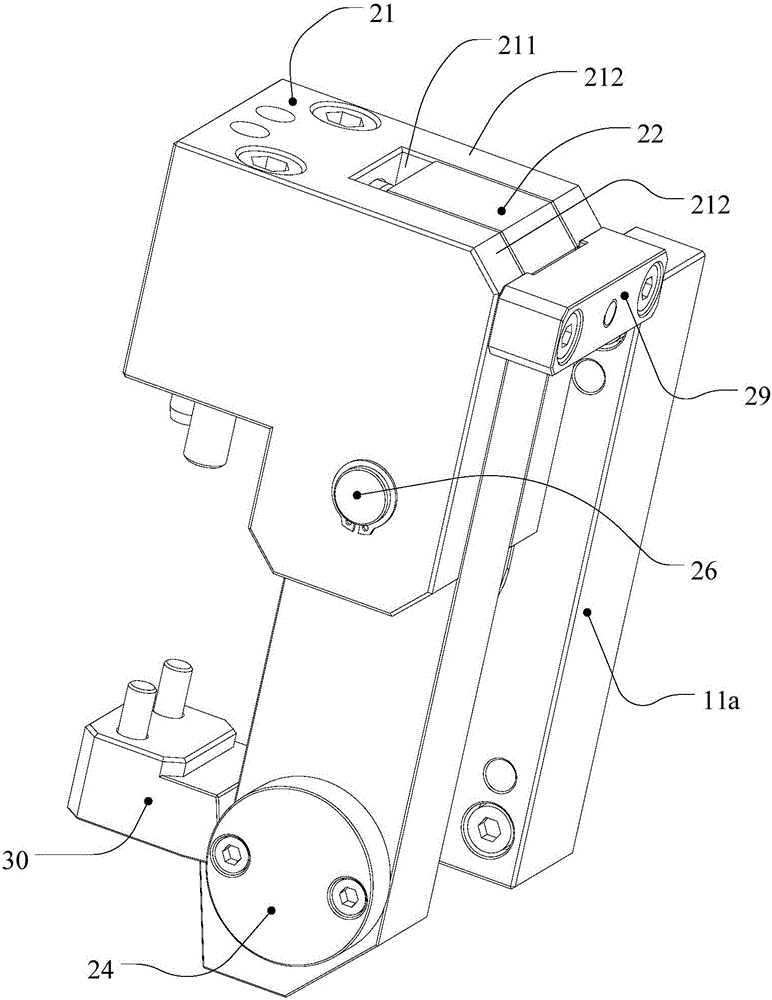

Fixtures

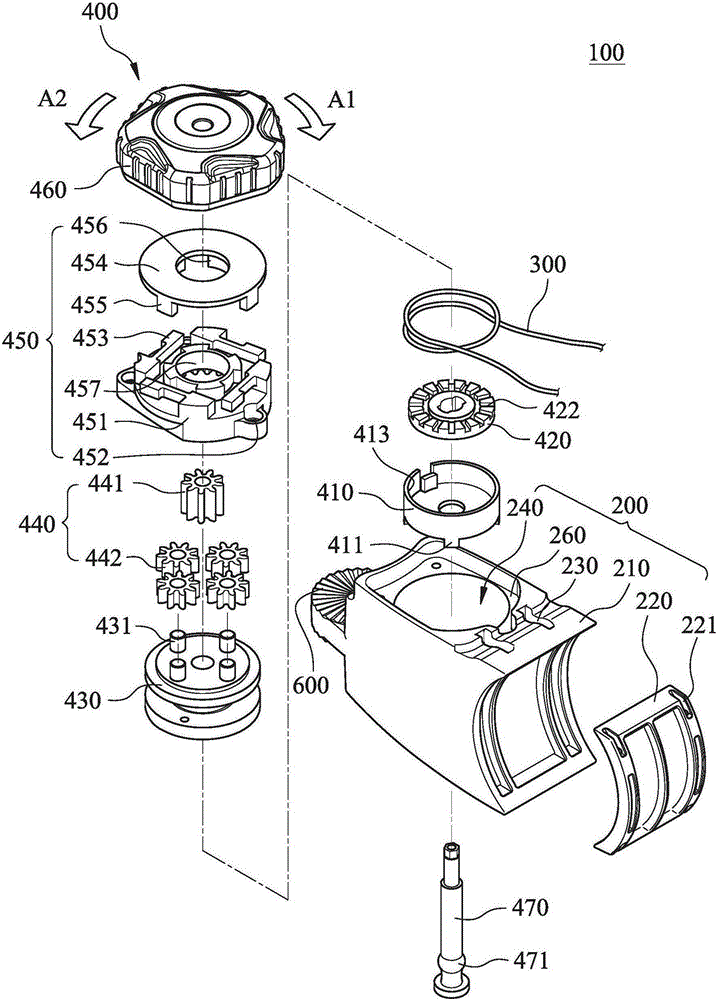

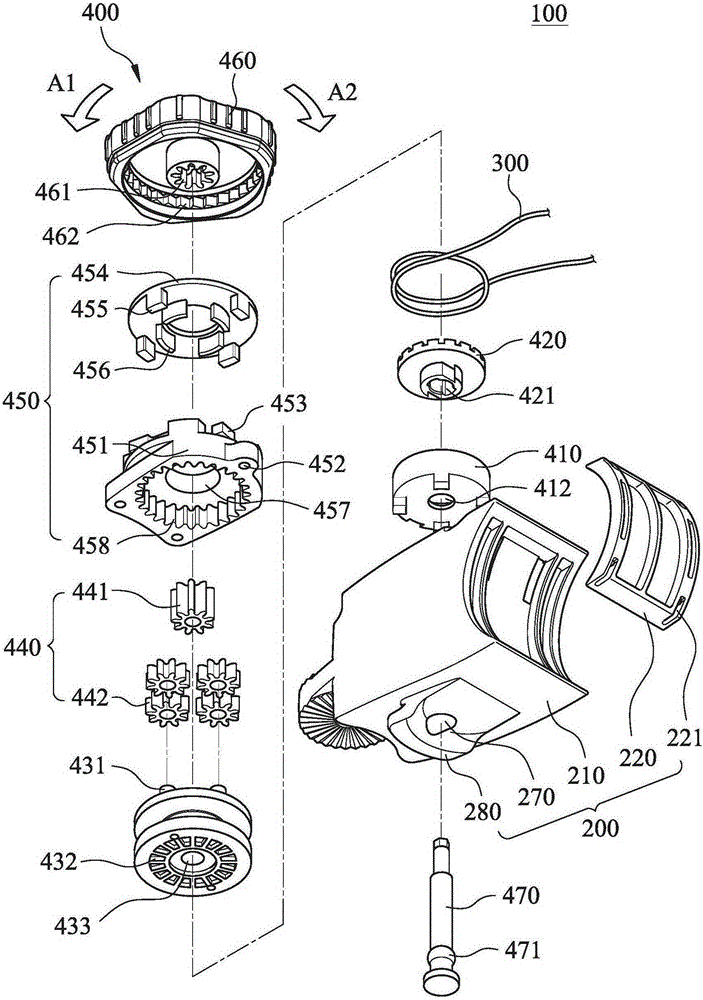

ActiveCN106545552BQuickly adjust the tightnessStrong fastening forceFriction grip releasable fasteningsEngineeringTension member

The invention discloses a fixing device, which comprises a main body and a converging unit. The main body includes a channel, the converging unit is arranged on the main body and includes a tension member and an adjustment member, the tension member includes a first end, a surrounding portion and a second end, the first end is connected to the main body, and one end of the surrounding portion is connected to the first end , the second end is connected to the other end of the surrounding part, and the second end penetrates into the channel and surrounds with the first end, the main body and the surrounding part to form a locking space. The adjusting member is arranged on the main body and coupled with the tension member to adjust the size of the locking space. The adjusting member rotates around an axis relative to the main body, wherein the axis passes through the main body but does not pass through the locking space. Thereby, the fixing device of the present invention can quickly and conveniently adjust the size of the locking space by adjusting the tension member through the adjusting member, so as to achieve the convenience of use.

Owner:陈金柱

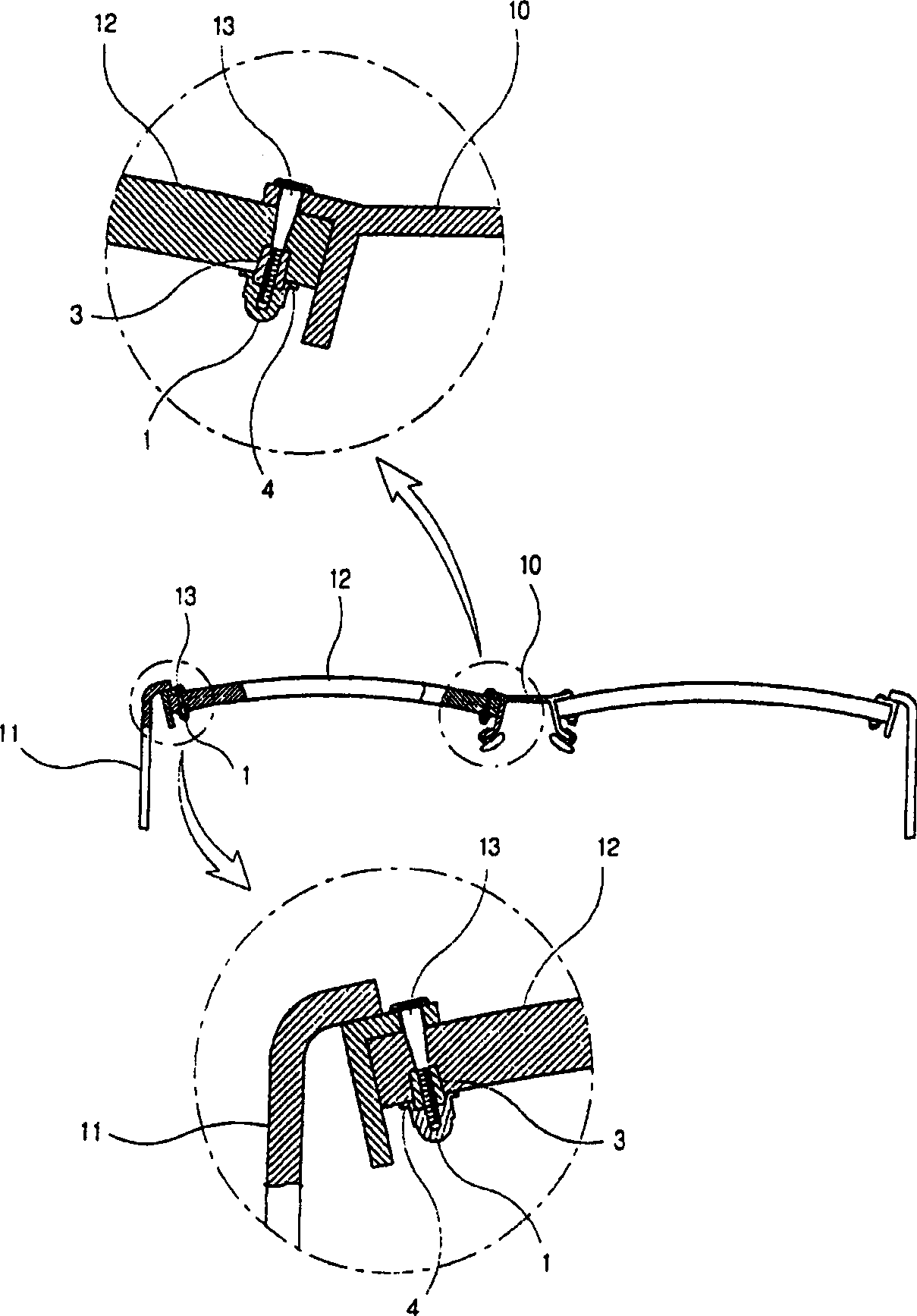

Lens fixing device for glasses without frame

Disclosed is a lens fixing device for rimless glasses. The lens fixing device comprises a first fixing member made of soft synthetic resin, having a guide portion formed at its lower end, constituting a threaded hole, and having a tapered portion whose diameter decreases towards its upper end; and made of metal or hard synthetic resin. The second fixing member made of resin, manufactured separately from the first fixing member and connected to the first fixing member, has a flange portion formed on its outer surface and upper end, and is formed with a screw groove and the first fixing member can The mating groove and the main body part fit into it.

Owner:金泂植

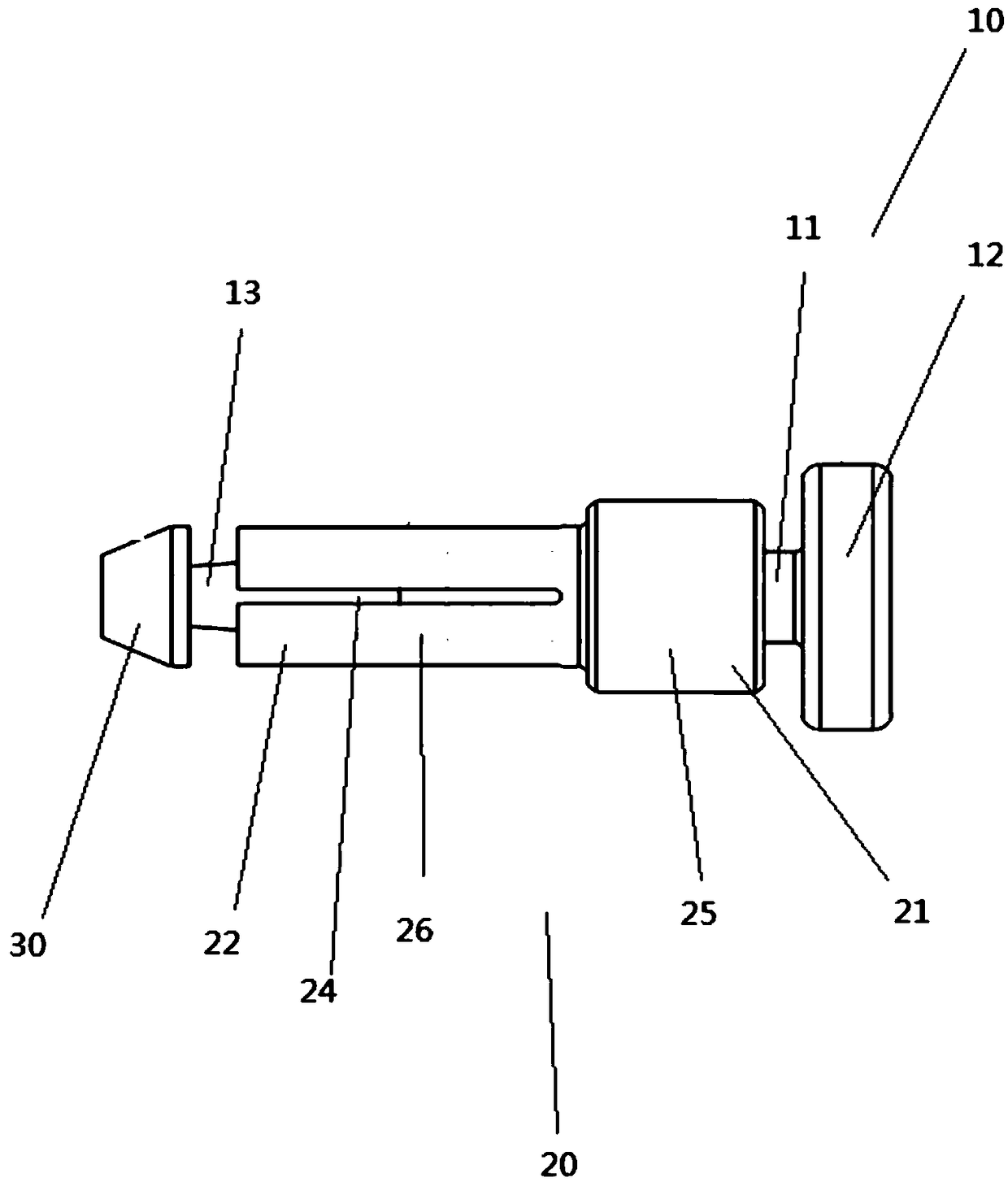

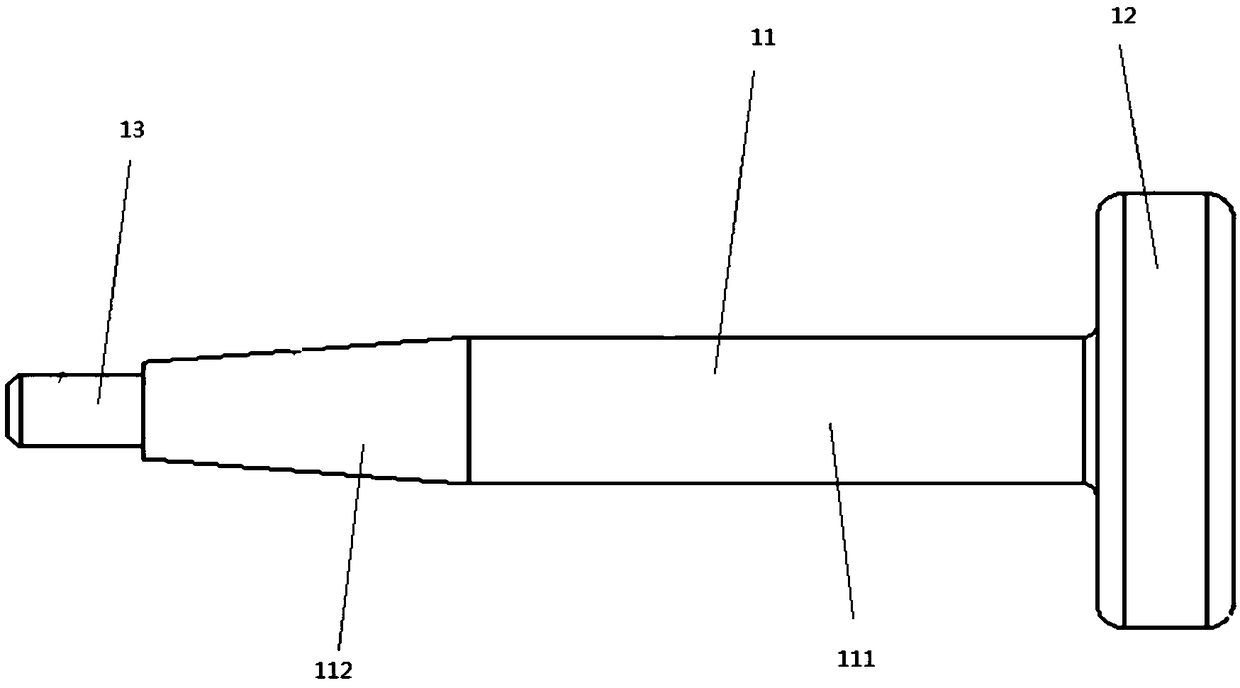

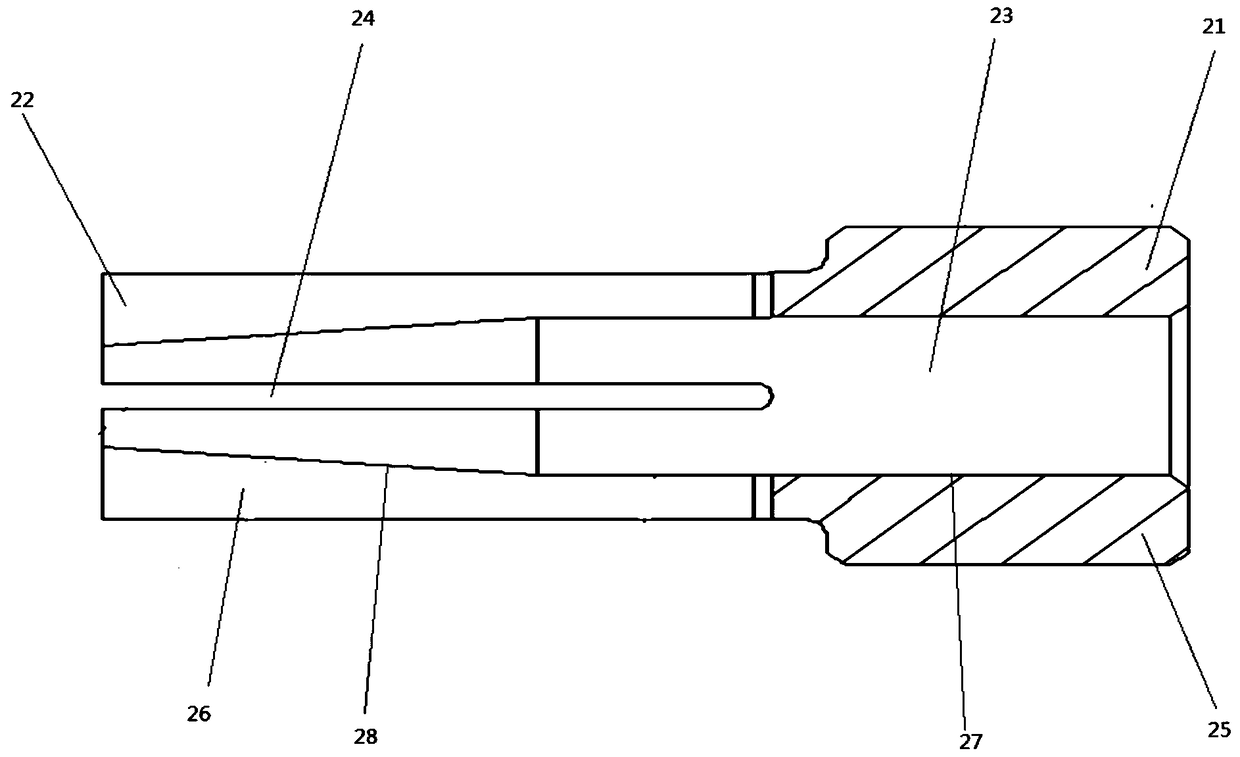

Push-pull elastic fixed connector

A pushing and expanding drawing type elastic fixed connector comprises a screw head, an expanding sleeve and a tight expanding bolt; and the tight expanding bolt is installed behind an installing channel of the expanding sleeve, the screw head is connected with the connecting end of the tight expanding bolt, and therefore the tight expanding bolt can be kept in the installing channel. By means of the simple pushing and pulling action, the pushing and expanding drawing type elastic fixed connector makes a connecting object and a connected object fast and conveniently connected and separated, so that operation is convenient. The pushing and expanding drawing type elastic fixed connector is simple and compact in structure; no gap exists between connecting pieces; the sliding phenomenon is avoided after installation; the fastening force is high; machining is easy; and the pushing and expanding drawing type elastic fixed connector can be repeatedly used, and therefore the pushing and expanding drawing type elastic fixed connector has better economical performance.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS +1

A passive compliance device

ActiveCN111993394BStrong fastening forceAdd passive soft functionProgramme-controlled manipulatorEngineeringSelf adaptive

Owner:CENT SOUTH UNIV

Screw-free installation structure for shower room

ActiveCN105544809AStrong fastening forceImprove installation efficiencyWallsEngineeringMechanical engineering

The invention relates to the technical field of bathrooms, and discloses a screw-free installation structure for a shower room. The screw-free installation structure comprises a regulating box fixed to a shower room body aluminum alloy framework, and a fixed block, a sliding block, a connecting part, a first connecting rod for connecting the fixed block with the connecting part, a second connecting rod for connecting the sliding block with the connecting part, a regulating through hole formed in the perpendicular direction of the connecting part, a pressing sheet and a screw. The screw sequentially penetrates through the pressing sheet and the regulating through hole to be tightly fixed to the top of the regulating box; a regulating hole for conveniently fastening or loosening the screw is formed in the bottom of the regulating box; the fixed block is fixedly connected with the inner wall of the regulating box, an opening allowing the sliding block to conveniently extend out to be fixed with a wall is formed in the portion, located on one side of the sliding block, of the regulating box, reinforcing ribs are arranged on the front side wall and the rear side wall of the regulating box, and a sliding groove used for containing the sliding block is formed by the reinforcing ribs and the space above the reinforcing ribs. The screw-free installation structure for the shower room is simple in structure, convenient to operate, disassemble and assemble and is not limited by a narrow space, and the fastening strength between the sliding block and the wall is higher.

Owner:GUANGDONG SUNCOO TECH

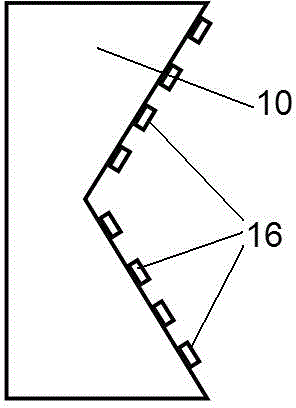

Abrasive belt grinder steel pipe fixing device

InactiveCN103056756ASimple structureStrong fastening forceBelt grinding machinesSteel tubeMachining process

The invention discloses an abrasive belt grinder steel pipe fixing device which comprises a fixing block and a moving block corresponding to the fixing block, and is characterized in that the cross section of the side surface, corresponding to the moving block, of the fixing block is V-shaped. Due to the fact that the cross section of the fixing block is V-shaped, namely, an included angle is formed by the upper side surface and the lower side surface, the abrasive belt grinder steel pipe fixing device is capable of enabling a round pipe to be fixed in the middle, avoiding vertical movement of the round pipe during processing, simple in structure and strong in fastening force.

Owner:汪涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com