Double ejection mechanism and injection mold

A secondary ejection and secondary ejection technology, which is applied in the field of molds, can solve the problems of complex mold structure, low quality, and low reliability, and achieve the effects of avoiding stuck failure, improving service life, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

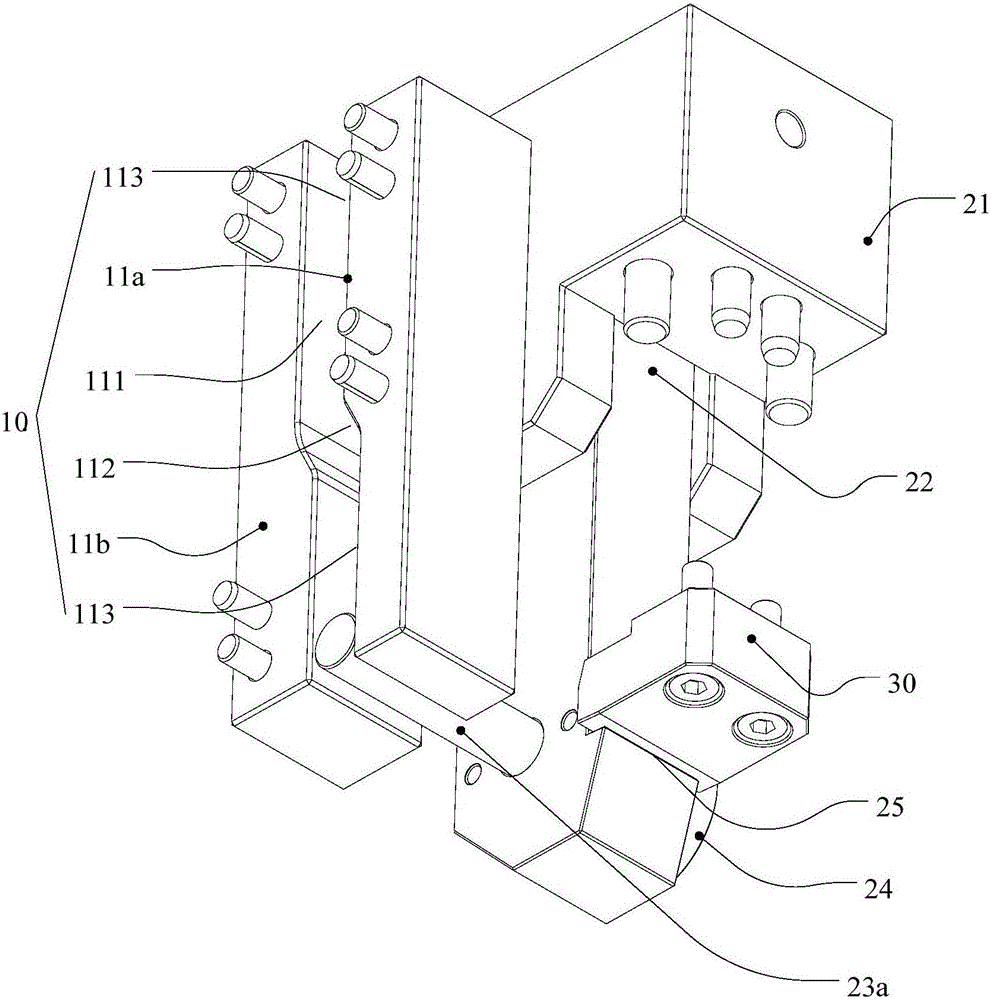

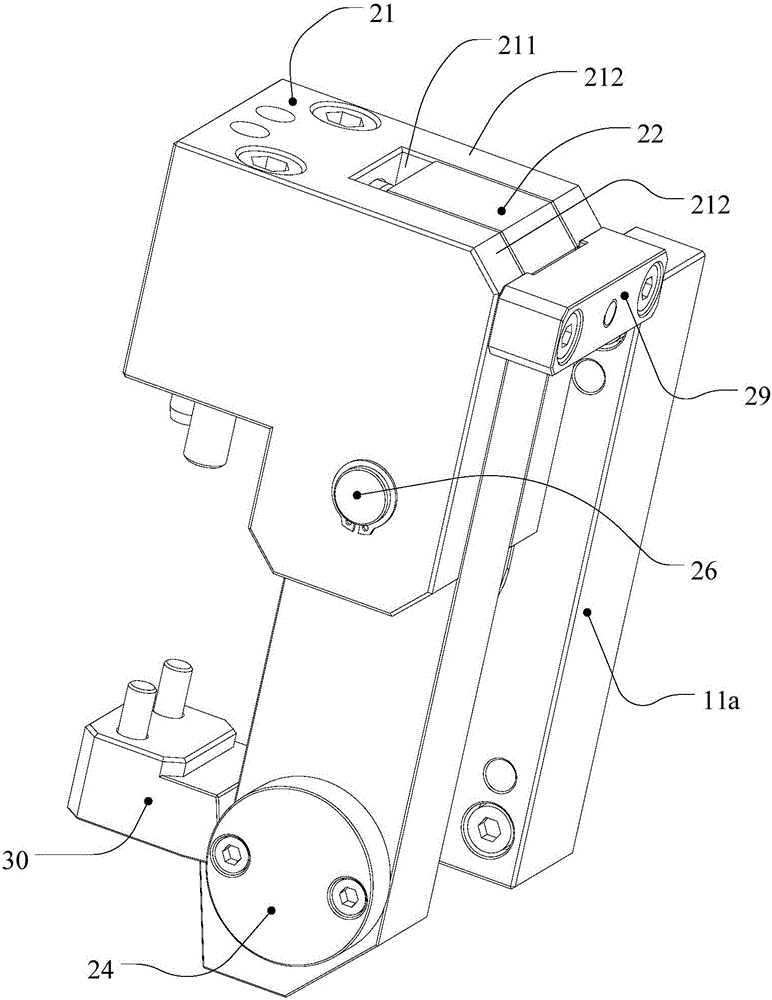

[0030] Embodiment 1 of the present invention: the guide 10 includes two stoppers (11a, 11b) provided with a gap, the gap forms a guide groove 111, the guide groove 111 has an inclined section 112 and a straight section 113, and the first drag hook 22 is away from its hinge. There is a swing arm 23a extending into the guide groove 111 at the axial position. The working process of split type ejection control is as follows: during one ejection process, the swing arm 23a moves along the straight line section 113, the first drag hook 22 is hooked on the second ejector plate 500, and the second ejector plate 500 follows the first ejector plate 400 Move, when the first pull hook 22 moves to the secondary ejection station with the first ejector plate 400 and the second ejector plate 500, the inclined section 112 forces the first pull hook 22 to swing, and releases the second ejector plate 500, the second ejector plate 500 The ejector plate 500 stops moving, and the first ejector plate...

Embodiment 2

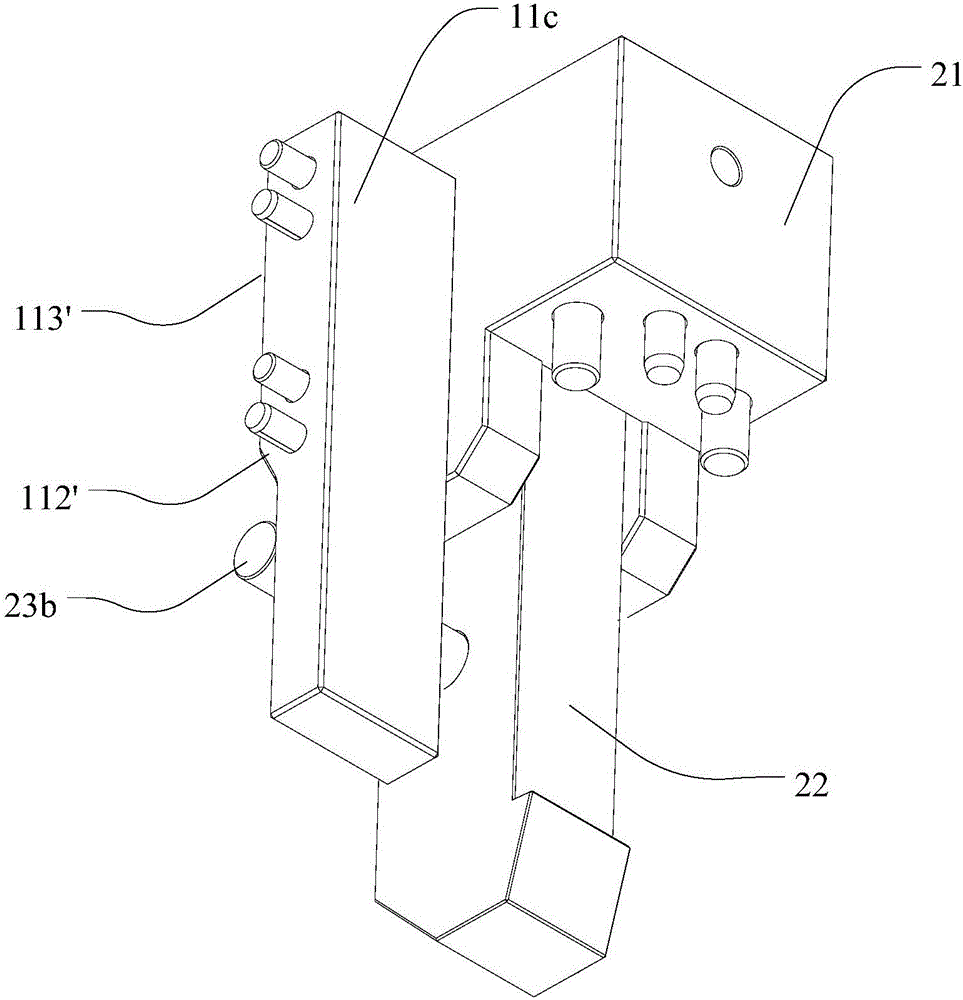

[0031] Embodiment 2 of the present invention: refer to figure 2, the guide 10 is a cam structure, the cam surface of the cam structure has an inclined section (112') and a straight section (113'), the first pull hook 22 has a swing arm 23b extending to contact with the cam surface, and a spring is arranged in the bracket 21 Reset piece (not marked). The working process of splitting ejection control is as follows: in the process of one ejection, the swing arm 23b moves along the straight line (113'), the first pull hook 22 is hooked on the second ejector plate 500, and the second ejector plate 500 follows the first ejector plate. The ejector plate 400 moves, and when the first pull hook 22 moves to the secondary ejection station along with the first ejector plate 400 and the second ejector plate 500, the inclined section (112') drives the swing arm 23a to force the first pull hook 22 to swing, and The second ejector plate 500 is released, the second ejector plate 500 stops mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com